Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is a comparison between Version 1 by Julius Cudjoe Ahiekpor and Version 2 by Peter Tang.

Finding sustainable solutions to the increasing waste generation in Ghana has received a lot of attention. Through several waste-to-energy processes, the energy potential of municipal solid waste has recently witnessed significant technological advancements. The Renewable Energy Master Plan has projected the production of about 122 MWp from waste-to-energy installations by 2030 in Ghana.

- bioenergy

- Ghana

- municipal solid waste

- incineration

- anaerobic digestion

- energy

1. Introduction

Municipal solid waste (MSW) is produced more frequently due to increased resource consumption driven by an increase in population, the management of which is causing major environmental challenges globally [1]. Unsanitary landfill activities, open dumping, and open incineration methods were frequently utilized in previous years to eliminate municipal solid waste (MSW) without taking into account the potential of MSW for energy production and environmental impact [2]. In recent years, harnessing the energy potential of MSW has seen major advances and technological pushes through several waste-to-energy processes. Waste-to-energy (WTE) plants produce power while lowering the quantity of MSW dumped in landfills [3]. In Ghana, MSW accounts for nearly 80% of all waste generated [4]. Due to rising economic and population growth, people’s living standards are changing, contributing to an increase in waste generation in Ghana. Environmental policies governing how waste is to be disposed of are in place in Ghana; however, they have not been put into effect. Therefore, waste can be disposed of at any time and anywhere by individuals [4]. The overall amount of MSW produced nationwide in Ghana has also been influenced by the quick rise of numerous manufacturing businesses within the country’s major communities. Although the majority of MSW from the industries is recyclable, the waste is nevertheless disposed of in landfills and incineration sites due to a lack of effective technologies, policies, and funding [4]. The primary cause of climate change effects is the use of non-renewable fuels and the subsequent release of greenhouse gases (GHG), which have an adverse effect on the environment and human health [5].

2. Municipal Solid Waste (MSW)

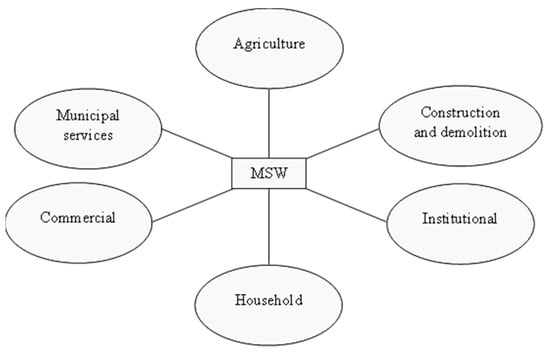

A variety of solid wastes are regularly disposed of by urban and rural residents as trash. Different municipalities and countries generate municipal solid waste with varying compositions. The differences in lifestyle, economic conditions, industrial structure, and waste management laws are the main causes of the compositional variations [6][7]. Approximately 2 billion tonnes of municipal solid waste are produced each year around the world [7][8]. Figure 1 shows the various sources of MSW.

Inappropriate management of MSW has serious environmental and health consequences [9][10]. MSW can clog drains, contribute to floods during rainy seasons, allow stagnant water to build up, and serve as a mosquito breeding ground in cities and towns [6][7]. As a result of this, improving waste management is crucial for optimal safety and health [10][11].

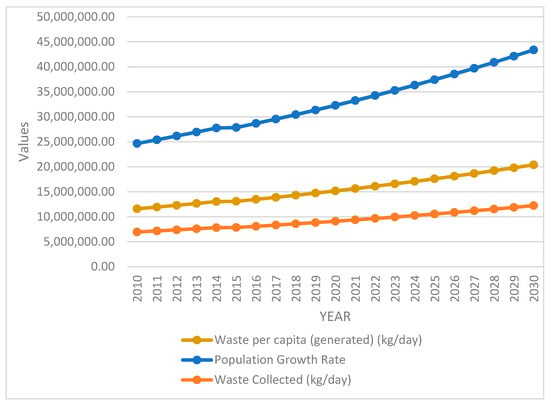

Municipal solid waste management generally involves three stages: (1) waste generation; (2) waste collection, handling, and transfer; and (3) waste disposal, processing, and treatment [7][11][8,12]. Waste-to-energy systems are well established in developed nations for converting municipal solid waste to heat and power [12][13]. In Ghana, in 2022, waste was generated at a rate of 0.47 kg per person per day, or 12,710 tons per day [13][14], by a population of about 31 million. An enormous amount of the solid waste produced by residents—between 30 and 50%—is not collected for disposal and instead ends up scattered on streets, in sewers, and in streams, where it serves as a breeding ground for pests that spread disease [13][14][14,15]. Figure 2 shows that it is estimated that the waste generation in Ghana will continue to increase from approximately 16,581 tons/day to 20,392 tons/day from 2023 to 2030. This translates to a 122.9% generation increment within 5 years [15][16].

Figure 2.

Estimation of MSW generated in Ghana due to population growth.

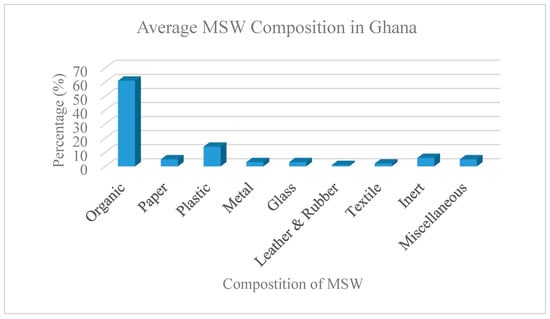

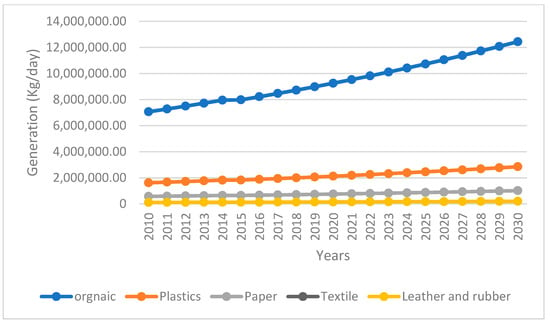

The organic fraction of MSW (OFMSW) is the world’s leading contributor to MSW, accounting for about half of all generated waste [16][17]. Using the waste composition of 61% organics, 14% plastics, 5% paper, 1% leather and rubber, and 1% textiles in 2015 [17][18] as a base (shown in Figure 3), MSW compositional generation from 2010 to 2030 was estimated for Ghana from the data obtained from Akrami (2021) [15][16], as shown in Figure 4. Ghana is known to be a country heavily engaged in agriculture. Most of the produce from agriculture is consumed by the population in Ghana. After consumption, the food waste produced is high, and this is the reason why organic waste has the highest MSW content in Ghana. Unutilized OFMSW produces unutilized methane gas, which contributes to global warming and causes rapid climate change. It is estimated that the organic fraction of MSW in Ghana will reach a generation of approximately 12,439 tons/day by 2030.

Figure 4.

Estimated MSW composition generation in Kg/day. Textile fraction and leather and rubber fraction trends assume the same paths.

3. Current Bioenergy Technologies and Waste Management Practices

Every country in the world engages in waste management practices to deal with the rising generation of MSW brought on by the growing population. Waste management techniques can be utilized to generate valuable products from waste, in addition to their core goal of eliminating waste [18][19][27,28]. Effective waste management methods commonly employed can be classified into thermal and biological conversion technologies. Thermal conversion technologies include incineration, combustion, gasification, and pyrolysis. Biological conversion technologies include anaerobic digestion, landfilling, and composting. These various technologies are discussed below.

3.1. Thermal Conversion Technologies

3.1.1. Incineration/Combustion

Incineration refers to the waste treatment technology that involves the controlled burning of waste at a temperature of 870–1200 °C (1600 to 2200 °F) for long enough to oxidize approximately 99% of the organic materials in the solid waste and produce high-pressure steam for power generation [4]. Hot combusted gas, an end-product of waste combustion, is generally made up of nitrogen (N2), carbon dioxide (CO2), water (H2O, flue gas), oxygen (O2), and noncombustible residues [20][29]. In a heat exchanger, hot flue gases generated from combustion can be used as a hot stream to produce steam from water [20][29]. The volume and weight of the waste decrease by 90% and 70%, respectively, during incineration [21][30]. The four major steps of waste-to-energy (WTE) production via incineration are waste pre-treatment, waste combustion, gas scrubbing (including air pollution management), and electricity/steam generation [21][30]. Incineration works well with non-biodegradable combustible MSW with a low moisture level [22][31]. Auxiliary fuels are sometimes utilized with MSW during incineration, but this is not required when the waste’s lower heating value (LHV) is between 1.000 kcal/kg and 1700 kcal/kg or above [23][32]. The calorific value of waste may decrease due to the presence of inert waste and its moisture content. As a result of this, the combustibility of MSW is affected, which directly affects the performance of an incinerator [24][33]. To solve this problem, waste pre-treatment (thermal, mechanical, chemical, and biological) is occasionally used to remove excess moisture content, inert waste, and dangerous substances such as chlorine and mercury [25][34]. Incinerating a tonne of MSW produces between 36 and 45 kg of oil equivalent (kgoe) [26][35]. In Ghana, it is projected that about 1000 tons of MSW generated each day in the Kumasi metropolis will be consumed by the WTE incineration plant in the metropolis to produce between 30 and 52 MWh of electricity [4]. The generation of fly ash is a major disadvantage of incineration. An estimated 3–10% of incineration waste is made up of fly ash [27][36]. This fly ash contains pollutants, including heavy metals and dioxins, which build up in living organisms and have long-lasting detrimental impacts on both human health and the environment [27][36].

3.1.2. Gasification

Gasification of MSW is a two-stage process that involves the partial combustion of MSW at elevated temperatures in a controlled environment, converting almost all the MSW into gas and char [28][37]. The MSW is partially combusted in the first stage to yield producer gas (CO2 and H2O) and char. The char (or charcoal) chemically reduces CO2 and H2O in the second stage to produce primarily carbon monoxide (CO) and hydrogen gas (H2) [4]. The primary factors influencing the gasification process are temperature, pressure, and oxygen concentrations [29][38]. For gasification, conditions must include temperatures between 750 and 800 °C and an atmospheric pressure of at least 1 atm [4]. CO, H2, H2O, and CH4 are produced by the gasification process [30][39]. Syngas constitutes carbon monoxide (CO), hydrogen (H2), and CO2 [29][38]. Syngas is utilized directly to generate energy in gas turbines [26][35]. Bottom ash is also produced during the gasification process and can be used as road filler material [31][40]. The gasification method reduces waste by 95% while requiring a less intense cleanup of combustion gases than incineration [32][41]. It is estimated that the net energy generated by the gasification of a tonne of MSW is between 36 and 63 kgoe [26][35]. However, MSW has a heterogeneous nature, which makes gasification and syngas purification more difficult [33][42]. Biomass gasification in Ghana is only currently studied at the plant assessment and research and development stages [34][43].

3.1.3. Pyrolysis

Various materials, including organics and plastics, can be thermally degraded in an irreversible process known as pyrolysis [35][44]. Materials subjected to pyrolysis undergo constant changes in their physical phase and chemical composition. Pre-treatment is a crucial step for the removal of glass, inert materials, and metals during pyrolysis. In the initial stage of pyrolysis, the thermal decomposition of pre-treated waste material occurs in an oxygen-free heated chamber at 300 °C [36][45]. The temperature eventually rises to 800 °C in a non-reactive environment [37][46]. The primary products obtained via pyrolysis include condensable (tars) and non-condensable volatiles and char [34][43]. Usually, condensable volatiles (tars) are categorized as liquids (bio-oil). Bio-oil is the most desired intermediate energy carrier due to its purity and stability [38][47]. Bio-oil can be used in diesel engines, turbines, and furnace/boiler systems [39][48]. The non-condensable volatiles are primarily gases, such as CO, CO2, H2, and C1-C2 hydrocarbons [34][43]. Biochar, a carbonaceous material, can be processed into activated carbon due to its large surface area [40][49]. By enhancing nutrient and water retention, biochar boosts the fertility of the soil. Furthermore, using biochar in agriculture reduces the acidity and density of the soil and boosts microbial activity [41][50]. Pyrolysis can be classified into three types based on the parameters involved in the process: slow, fast, and flash pyrolysis [35][44]. Slow pyrolysis is used mainly to produce biochar, while fast pyrolysis primarily produces bio-oil and gas [42][51]. Major factors that influence biochar, bio-oil, and gaseous yields are pyrolysis temperature, MSW size, and heating rate [42][51]. Catalysts such as nickel and ruthenium-built catalysts, zeolites, and dolomite, when used in pyrolysis, improve the product yield and reduce the energy demand for the process [43][44][52,53]. Products from the pyrolysis process most often possess similar properties to fuels. As a result, the pyrolysis of MSW is primarily intended to recover energy. The utilization of the energy products obtained from the pyrolysis process improves the operational efficiency of larger-scale pyrolysis plants [35][44]. Approximately 45–50 kgoe is generated as net energy via the pyrolysis of a tonne of MSW [45][46][54,55]. Additionally, MSW volume can be substantially decreased by pyrolysis by about 84% [23][32]. The primary limitations of pyrolysis include the following: Utilizing wastes with a high moisture content results in lower net energy recovery; also, it is challenging to burn and transport high-viscosity pyrolysis oil [41][50]. In Ghana, a pyrolysis plant with a capacity of 6 tonnes was set up to provide an alternative fuel using sawdust as feedstock [47][56]. This is the only pyrolysis pilot project known to have been established in Ghana, although there have been several laboratory investigations of pyrolysis [48][49][57,58]. The projected yields of char and oil of the pyrolysis plant were 25% and 18%, respectively [34][43]. However, low yields, between 6% and 13%, were attained [34][43]. This challenge, along with the inadequate feedstock supply and drying and the use of manual process controls, led to the shutdown of the plant [47][56].

3.2. Biological Conversion Technology

3.2.1. Anaerobic Digestion (AD)

Anaerobic digestion (or biomethanation) involves the production of biogas and the stabilization of sludge via the microbial decomposition of organic biodegradable matter in the absence of oxygen. Anaerobic digestion degrades and converts the organic components of biodegradable MSW into methane through a series of stages [24][33]. The first stage, hydrolysis, converts complex organic compounds of MSW, such as carbohydrates, proteins, and fats, to soluble organic molecules such as sugars, amino acids, and fatty acids. During fermentation, the next stage of anaerobic digestion, acetic acid, H2, and CO2 are generated through the breakdown of the organic molecules. Methanogenesis is the final stage during which methane forms acetic acid and H2 [24][29][33,38]. Methane is the main component of the biogas produced, coupled with carbon dioxide and traces of contaminants. By removing carbon dioxide, water, and other trace elements, biogas can be converted to pure methane (with a higher calorific value) [33][42]. Different feed formulation and process parameters, including the organic loading rate, C/N ratio, pH, temperature, moisture content, and retention time, affect the anaerobic digestion of organic MSW [26][35]. Various temperature ranges, such as 30–37 °C for mesophilic and 50–60 °C for thermophilic anaerobic digesters, are used in AD [33][42]. Anaerobic digestion processes are classified as “wet” (10–15% dry matter content) or “dry” (24–40% dry matter content) processes [50][61]. In the wet process, more liquid waste and less solid product are generated. The volume of reactor required for the wet process is less than that required for the dry process [24][33]. Anaerobic digestion is projected to produce 2–4 times more methane per tonne of MSW in 3 weeks than a landfill does in 6–7 years [51][62].

3.2.2. Landfill Gas Recovery

Landfilling is the most commonly used waste treatment and disposal method in most nations, particularly in low- and upper-middle-income countries [52][64]. It is estimated that 70% of all MSW generated worldwide is disposed of in some sort of landfill (sanitary and unsanitary landfills, open dumps) [52][64]. After the conversion process, all residues from all other available MSW management methods end up in landfills, making landfills a better alternative for MSW management [4]. Sanitary landfilling deals with the regulated disposal of waste on land. Sanitary landfilling minimizes the environmental impact of waste through biogas recovery and leachate treatment [24][33]. Unsanitary landfilling is frequently employed in developing countries since it provides a simpler and more affordable alternative for disposing of the increasing waste quantity. However, unsanitary landfilling poses a major environmental concern [53][65]. The organic components of MSW begin to undergo biochemical reactions immediately after MSW is landfilled. Since the surface of the landfill is exposed to atmospheric air, natural organic compounds are oxidized aerobically. This reaction is similar to combustion in that it produces carbon dioxide and water vapor as a result of the process [54][66].

3.2.3. Composting

Composting is the controlled microbial breakdown of organic matter in wet, warm, oxidative, and nonoxidative environments [55][69]. Compost, an output of composting, has a huge impact on agriculture [56][70]. This compost is usually pathogen-free and can be used as a fertilizer on farms [57][71]. Composting also generates heat, water, carbon dioxide, nitrate, sulfate, ammonia, and organic acids [26][35]. The composting method is the most widely used and cost-effective method for treating the organic component of municipal solid waste [16][17]. Composting processes are classified into two types: aerobic composting and anaerobic composting [6][7]. Microbes decompose organic waste in the presence of oxygen during aerobic composting. Oxygen is absent during anaerobic composting [11][12]. Composting methods can reduce waste by 50 to 85% [58][72]. Composting has the ability to operate as a soil conditioner, improve the quality of solids, and act as an organic input into agriculture, all while lowering the load on landfills [6][7]. Composting has some drawbacks, such as the need for an enormous amount of time and a large area of land. Furthermore, when compost generated from unsorted MSW is applied to the soil to increase soil fertility, the soil is more likely to become contaminated with harmful pollutants [59][73]. Numerous individuals and organizations in Ghana are engaged in the formal or informal production of compost [60][74].

3.3. Ways of Implementing Bioenergy in Ghana

From the above literature, it can be concluded that among thermal conversion technologies, gasification generates the highest amount of energy from MSW, followed by pyrolysis and then incineration. Furthermore, the volume of MSW is reduced by the maximum proportion (95%) during gasification, followed by incineration, and finally pyrolysis. Biochar, a product of pyrolysis, boosts soil fertility and microbial activity. As a result, the pyrolysis process is advantageous for agriculture. Biological conversion technologies are preferable to thermal conversion technologies when the organic and moisture content of MSW is high. The majority of MSW is frequently dumped in landfills. However, with an appropriate leachate treatment system and an effective system for collecting and managing landfill gas, landfilling could be the most common and effective treatment method for MSW. Biogas, primarily produced by anaerobic digestion, is used for energy generation. However, anaerobic digestion would benefit agriculture since the digestate it produces is utilized as fertilizer. Yet it could be deduced that there are no or few implementations of these bioenergy technologies in Ghana, with very small outputs. This is due to social, economic, and security-related obstacles impeding the growth of bioenergy in Africa, including Ghana [61][88]. Industry Revolution 4.0 technologies hold the opportunity to nullify these bioenergy implementation obstacles or improve the economic feasibility of bioenergy technologies in Ghana. Solid waste management and efficiency could be greatly improved by implementing Industry 4.0 technologies, such as cloud computing, IoT, system integration, smart automation, and cyber-physical systems. With the help of these technologies, real-time data can be generated in both quantity and quality, providing better management and decision-making insights [61][62][88,89]. These developments open up the possibility of automating smart systems. Material traceability is improved by RFID and wireless communications, which also help to identify opportunities in the circular economy, including bioenergy technologies [61][88]. The development of more complex systems, like centralized cloud computing, is made possible by system interconnectivity and automated data transfer, which lower costs by doing away with the requirement for separate computer systems. All things considered, the application of IR 4.0 technologies to waste management holds great potential for streamlining procedures and producing more environmentally friendly outcomes [61][62][88,89]. A machine learning (ML)-based optimization system for hydrothermal gasification (HTG) recently developed and purposed to optimize process conditions by taking biomass properties into account [63][90] could be applied in the implementation of gasification systems in Ghana. This approach is used to automate the optimization of temperature and pressure, two of the many parameters that affect the quality of gasification [64][91], and to predict gas yield to save time and shorten cycle times [61][88]. Supervisory Control and Data Acquisition (SCADA) in cyber-physical systems and the internet to automate control processes in municipal plastic waste pyrolysis complexes could be used to optimize and automate pyrolysis plants [65][66][67][92,93,94] in Ghana and can advance the implementation of pyrolysis plants. Adopting smart technologies to manage composting processes should not be put off any longer, and laws should take into account the possibility of easing the timing restrictions on these processes if they take place under supervision. Additionally, an economic analysis demonstrated that the environment and the community can benefit from investments made towards automating bio-containers in a number of ways [62][89].