Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is a comparison between Version 1 by Nelson Herrera Nuñez and Version 2 by Jason Zhu.

The mining sector has increasingly embraced simulation and modelling techniques for decision-making processes. This adoption has facilitated enhanced process control and optimisation, enabling access to valuable data such as precise granulometry measurements, improved recovery rates, and the ability to forecast outcomes. Soft computing techniques, such as artificial neural networks and fuzzy algorithms, have emerged as viable alternatives to traditional statistical approaches, where the complex and non-linear nature of the mineral processing stages requires careful selection.

- mineral extraction

- soft computing

- process control

- prediction accuracy

1. Introduction

The mining industry contributes to approximately 10% of global economic activities, of which industry payments for services and direct support comprise another 10%, making it a critical part of multiple production chains [1]. Over time, this industry has been a precursor for technological developments. According to the European Parliament [2], during the past 12 years, a quarter of the mining industry has doubled its investments in technology, reaching 93% implementation with successful results. Over 90% of mining companies believe that complementing their operations with technology translates into added value and helps to revolutionise their business. The advancement of technology has led to the emergence of untapped prospects in the field of big data capture systems, which have not yet been fully explored or utilised in industrial settings. For instance, these systems can be employed for routine inspections of operational equipment or for the creation of daily production records [3]. This volume of data is expected to grow exponentially over time, reaching an amount of one hundred and twenty zettabytes in 2023, corresponding to a 675-fold increase since 2005 [4][5][6][4,5,6].

The mining industry and metallurgical processes are familiar with the concept of capturing large amounts of data. However, the analysis and interpretation of this data present novel problems for operators and decision-makers who aim to enhance productivity and sustainability in their operations. The European Union has set four key goals for the year 2030, as outlined by Usman et al. [7], which include prioritising energy efficiency, reducing CO2 emissions, and promoting the adoption of clean energy sources. To achieve these objectives, the EU emphasises the importance of sustainable raw material production through the utilisation of digital tools, as well as advancements in safety, productivity, and profit margins [8]. While the World Economic Forum has predicted that from 2017 to 2025, $425 trillion will be invested globally in the application of artificial intelligence (AI) for the productive sector [9], in Chile, the creation of national policies and initiatives such as the Roadmap Mining 4.0 [10] policy seeks to implement digital technologies in the mining industry. There is a correlation between artificial intelligence (AI), Mining 4.0, and machine learning technologies that can potentially drive transformative advancements in mining processes, enhance productivity, and enable data-driven decision-making in an increasingly interconnected and digital world.

2. Performance of Soft Computing Applied in Mineral Extraction and Processing

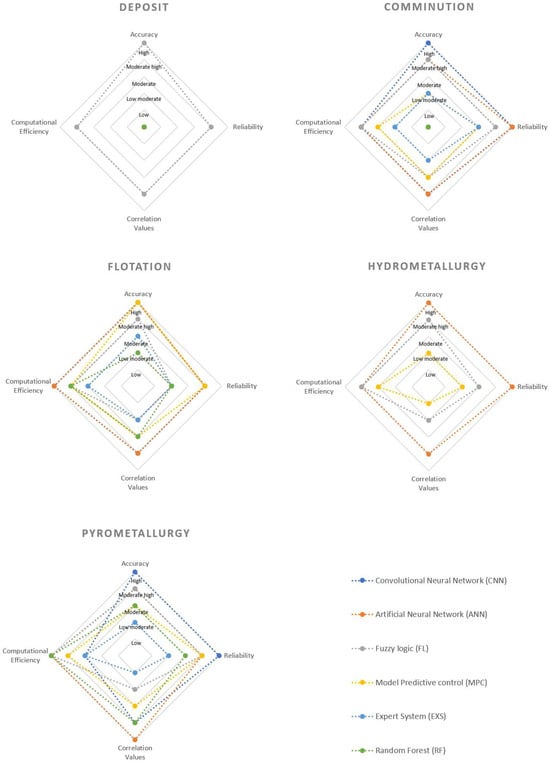

Figure 1 5 illustrates a comparison of the soft computing techniques employed in the stages analysed early and based on the total number of publications. The performance of each method is evaluated based on four criteria: accuracy, reliability, correlation values, and computational efficiency. The scores are based on accuracy values, with higher scores indicating better accuracy; reliability scores are based on mean residuals and standard deviations in the papers; correlation scores are based on correlation coefficients; and computational efficiency scores are based on the characteristics and advantages of the methods in the papers.

Figure 15.

Qualitative comparison of soft computing methods applied in mineral processing.

3. Proposed Approach for the Application of Soft Computing in Waste Disposal in Mineral Extraction and Processing

One critical challenge to ensuring medium- and long-term operation is to achieve the adequate disposal and management of mining tailings (Residues from sulphide mineral flotation composed of material without the mineral of interest and water that are disposed in specific deposits known as TSF) and spent heap leaching spoils (Material that remains as a residue from the heap leaching process once all of the mineral of interest has been recovered). This has been declared as critical within the sustainability and responsible operation programs by the European Union to ensure proper management to avoid damaging the environment [11][12][74,91]. The incorporation of better technology for tailing storage facilities (TSFs) and spent heap leaching spoils dumps (leaching waste deposit, LWD) and the development of mechanisms for the measurement of parameters and variables are the final objective in controlling physical and chemical stability monitoring systems and establishing a robust understanding of the makeup and water balance of the process. In Chile, copper production as a concentrate will reach 89.9% in the year 2027 due to the depletion of oxidised copper minerals [11][74], while the use of continental water consumption exceeds 0.36 m3/ton of ore, with the consumption expected to rise further [13][92]. The application of soft computing to waste disposal may provide quality, reliable, and real-time information on the waste ore and tailings according to the operational needs. In addition, authorities and communities may benefit from the accessibility of this information, to improve, make transparent, and strengthen the ties between the industry and the communities, taking an important step to comply with national legislation and to improve the sustainability culture. The proper management and ultimate disposal of these wastes is critical to the continuity of the profit chain and are linked to a successful storage operation, adequate use of land, security, and, in a relevant way, to the environmental commitment of the mining operation. In countries with a mining tradition, such as Chile [14][93], Finland [15][94], and Canada [16][95], regulations and guides provide information to design, install, and manage waste rock dumps and TSFs focused on the beginning of the deposit creation, leaving the subsequent monitoring and control of these deposits to their own criteria against structural behaviour, physicochemical stabilization, and mitigation of possible failures. Industrial practices and the changes that take place in a dynamic operational environment mean that on many occasions the original design is strongly modified for safety or even does not reach the useful life that was originally planned. The stability of a tailings storage facility (TSF) can be influenced by [17][18][96,97]:-

Operating factors (input material, deposition rate, geometrical and geotechnical controls such as humidity and compaction).

-

Deposit location (climate and geological factors that include the seismicity, ground foundation slope, and confinement of the land degree)

-

Deposit type selected (type of the TSF, geometric configuration including height, volume, and slope angle)

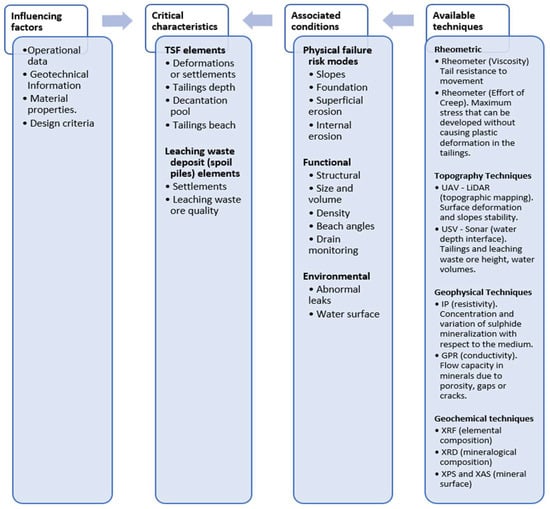

Figure 26.

Parameters for a database generation for TSF and LWD.

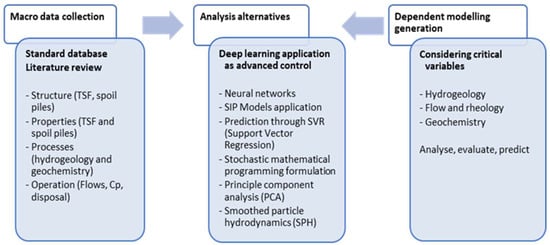

Figure 37.

Example of possible correlations between parameters with different soft computing techniques.