Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is a comparison between Version 1 by Abrahem Ali Blash and Version 3 by Sirius Huang.

Unreinforced masonry (URM) is a construction of brick or concrete block unit that is joined together using mortar, without steel reinforcement. Because of the heterogeneous nature and difference in mechanical properties of the masonry elements, analyzing and capturing the structural behaviour of URM walls under various loading conditions is therefore complex.

- compressive strength

- elastic modulus

- masonry wall

- masonry design standards

- stress–strain relation

- unreinforced masonry

1. Introduction

A masonry wall is the structural assemblage of masonry elements, i.e., bricks or blocks with mortar as the binding material. Masonry walls and the building as a whole are designed to be durable, stable, and resilient under sustained loading. In masonry construction, the imposed loads are supported and transmitted to the foundations by the bricks or blocks joined together by mortar and, in some cases, are filled with grouts and reinforcements. One significant benefit of masonry building—aside from the ease of construction with readily available basic materials—is the durability of masonry materials such as the unit, which, with proper selection, could be expected to last for several decades, if not centuries, with very little maintenance [1]. Despite the ease with which masonry buildings are constructed, the analysis of its structural behaviour still remains a difficult challenge.

Unreinforced Masonry (URM) walls are largely non-homogeneous, non-elastic, and anisotropic elements made up of two materials with very different characteristics—one element of either mortar or unit considerably stiffer than the other—and a relatively weak bond between them [2][3][4][2,3,4]. Thus, masonry walls are relatively weak in tension. As a result, the walls are usually designed and expected to resist only compression loads [5][6][7][8][5,6,7,8]. Over the last several decades, research studies have been dedicated to investigating the structural behaviour of masonry walls and improving design standards [9][10][11][9,10,11]. In particular, significant attention has been focused on masonry components and the interaction between them. The walls of a structural masonry building serve as the primary resisting component against dynamic or static loads exerted on the structure, and as such, its compressive strength is of utmost importance when designing masonry walls in different loading conditions. In addition, the compression behaviour of masonry walls is a key factor in the design of masonry structures for other actions, such as in-plane shear and out-of-plane flexural behaviour [12]. However, the analysis of masonry walls under axial compressive load has been largely overlooked in the past.

In recent years, several research studies have been dedicated to investigating the axial compressive behaviour of URM walls [13][14][15][16][17][18][19][20][21][22][23][13,14,15,16,17,18,19,20,21,22,23]. In general, the mechanical properties of each masonry element and bonding properties between mortar and units are of major significance in the compressive behaviour of URM walls as a composite material. As a result, the behaviour of axially loaded URM walls becomes very complicated because it is dependent on several factors relating to the slenderness ratio and eccentric loading conditions of the walls. Moreover, multiple provisions in the masonry design standards are stipulated in predicting the strength of URM walls under axial compressive loading [24][25][26][24,25,26]. Nonetheless, there are discrepancies observed in existing design standards to predict the compressive strength of URM wall structures, particularly in the guidelines in choosing and testing of wall configurations.

2. Masonry Units in Construction

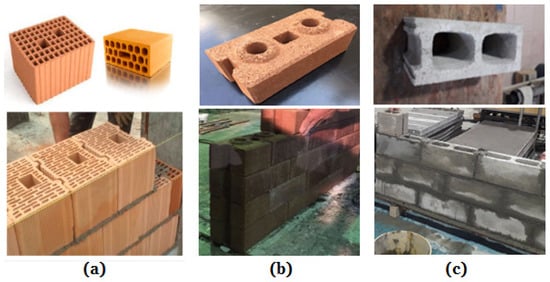

Masonry wall units such as blocks or bricks are primarily made of concrete, calcium silicate, and clay. Blocks and bricks come in a variety of forms, shapes and sizes, including solid, hollow, and interlocking (e.g., see a selection in Figure 13). All these units have roughly comparable functionalities, but their properties vary markedly and are dependent on their constituent raw materials employed and their mode of production. Besides solid block and brick units, hollow concrete blocks (HCB) are widely attractive nowadays in low- and medium-rise constructions due to their advantages like light weight, ease of construction, and higher load-bearing capacity, as well as their ability to facilitate conduits for concealing electrical units, sewer, and water pipes [9][27][28][9,41,42]. Under similar conditions, the quantity of masonry mortar used to lay HCB can be lowered by more than 50% when compared to solid concrete blocks, thereby significantly lowering construction costs.

Figure 13. Construction method of unreinforced masonry: (a) hollow clay bricks, (b) interlocking clay brick, and (c) hollow concrete block masonry.

3. Overview of Experimental Research in the Literature

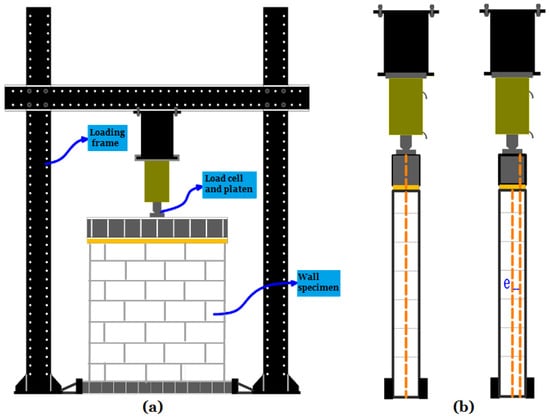

As previously stated, various construction and testing parameters can influence the compressive performance of URM walls. The primary factors are the strength of masonry units (brick/block) and mortar strength, as well as the slenderness ratio and eccentric load conditions of the walls [17]. Apart from these parameters, the presence of openings is another significant parameter which could affect the performance of the masonry structure and should be properly taken into account. All the above-mentioned parameters can be varied during the construction and testing of masonry walls, leading to a more accurate assessment of the design of load-carrying URM elements. When evaluating the structural response of URM walls, both shear capacity and bending moment should be considered by taking into account its interaction with compression forces due to lateral load and gravity [45][46][47][58,59,60]. In the context of masonry structures in general, substantial eccentricity loadings could be precipitated either by in-plane or out-of-plane lateral forces or a combination of both [48][61]. The latter are typically induced by thrusting components (e.g., vaults and arches), wind and soil pressures and seismic actions transmitted from the masonry floor. In contrast, the former can be seismic-induced shear force ensuing from box-type global seismicity of the building structures. As observed from the literature (e.g., see ref. [49][62]), axial loading differs from eccentrically loaded walls since the former is a statically determinate problem in which the strength of a given wall panel may be presumed to be maximum compression forces divided by the total cross section (Figure 24). On the contrary, eccentrically loaded wall panels are statically indeterminate problems in which the bending moment could be defined by integrating the normal stress and the corresponding axial strain over the given gross sectional area [50][51][52][63,64,65]. As a general recommendation in the design of URM structures, the capacity reduction factor (Φ)—expressed as a ratio of prism strength to the strength of the wall—can be introduced to accommodate and account for different characteristics and to obtain the permissible compressive strength of the masonry [24][53][54][24,40,66].

Figure 24.

Axial compressive test of URM wall: (

a

) wall with test frame and (

b

) concentric and eccentric loading.

Table 1.

Overview of experimental studies on compressive tests of unreinforced masonry.

| Reference | Year of Publication | Unit Type | Material | Wall Dimensions | No. of Samples | Properties of Masonry Elements (MPa) | Test Parameter | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Reference | Masonry Type | Model | H × L × T (mm) | fb | fm | fg | ||||||

| Camacho et al. [13] | 2015 | HCB | Conv. concrete | 1000 × 900 × 140 | 9 | 8.64; 15.76 | 7 | |||||

| Eurocode 6 [24 | 17 | ] | Clay and calcium silicate units | f’k = 0.55 f | Axial load; stress–strain. | |||||||

| b | 0.70 fm 0.3 | Fortes et al. [14] | 2017 | HCB | ||||||||

| Gumaste et al. | High-strength concrete | [15] | 2200 × 1200 × 140, | 2200 × 800 × 140 |

30 | Calibrated for table moulded brick masonry | f’m = 0.317 fb 0.866 fm 18.7–34.5 | 0.13413.4–26.9 | 31.3–42.4 | Axial load; stress–strain. | ||

| Keshava and Raghunath [16] | 2017 | Brick | ||||||||||

| Khan et al. [57][69] | SCB HCB |

Calibrated for clay brick wallette | f’m=𝑓b (Table moulded; Conv. Concrete; Conv. Concrete. |

4+/𝑡+2500 × 950 × 220; 2560 × 1030 × 150; 2600 × 830 × 150 |

14 | 5.8 4.5 6.0 |

9.4 | 5– | Axial load; slenderness ratio and eccentricity. | |||

| 0.1 | 𝑓 | 𝑚1.5𝑙ℎ/𝑡) | Amalkar et al. [17] | 2020 | ||||||||

| Hendry and Malek [58][ | CCB | HCB |

Conv. Concrete; Conv. Concrete. |

2667 × 802 × 200; 2680 × 800 × 200, 2680 × 830 × 150 |

9 | 7.1 13.7; 6.6 |

5.3 | – | Axial load; slenderness ratio and eccentricity. | |||

| 70] | Calibrated for clay brick masonry | f’m = 0.317 fb 0.531 fm 0.208 | Dharek et al. [18] | 2021 | HCB | Conv. Concrete. | 2600 × 845 × 152. | 2 | 8.86 | 5.3 | 23.5 | Axial load. |

| Costigan et al. [64][76] | Calibrated for fired clay brick wallette | f’m = 0.56 fb 0.53 fm 0.5 | Hasan et al. [19] | 2021 | ||||||||

| Zhou et al. [68][80] | HCB | Brick |

Calibrated for HCB wallette | f’m = 0.886 fb 0.75 fm Conv. Concrete; Clay. |

300 × 200 × 150–1200 × 750 × 150 | 0.1824 | 7.5–19.2 5.8 |

7.5 | Axial load. | |||

| Gumaste et al. [15] | 2007 | Brick | Table moulded; Wire-cut |

520 × 600 × 105; 520 × 665 × 230 |

9 | 5.7 23.0 |

0.8–6.6 0.6–12.2 |

– | Axial load, elastic modulus. | |||

| Watstein and Allen [21] | 1970 | Brick | Extruded wire-cut | 940 × 685 × 94–3716 × 3200 × 97. | 36 | 54.2–174.3 | 10.0–48.6 | – | Axial load; slenderness ratio and eccentricity. | |||

| Kirtschig and Anstotz [22] | 1991 | SCB | Calcium silicate; Lightweight aggregate. |

635 × 1000 × 115–3120 × 1000 × 115 | 64 | 20.9 4.1 |

5 | – | Axial load; slenderness ratio and eccentricity. | |||

| Hendry and Malek [58][70] | 1987 | Brick | Clay; Lightweight AAC |

590 × 665 × 102 590 × 665 × 215 |

48 | 28.8–92.4 4.4 |

17.6; 27.4 | – | Axial load; stress–strain | |||

| Fattal and Cattaneo [59][71] | 1976 | Brick HCB |

Wire-cut Conv. Concrete |

2438 × 812 × 90 2438 × 812 × 140 |

56 | 90.2 8.5 |

10.4 | – | Axial load; stress–strain. | |||

| Khan et al. [57][69] | 2023 | Brick | Fired-clay | 530 × 410 × 75; 445 × 445 × 75 |

18 | 16.1–20.2 | 5.0; 6.7 | – | Axial load. | |||

| Milani et al. [60][72] | 2021 | Brick | Clay | 965 × 580 × 140 | 8 | 14.6–19.6 | 5.8 | – | Axial load; stress–strain. | |||

| Calderón et al. [61][73] | 2023 | Brick | Multi-perforated clay | 745 × 745 × 140 | 9 | 19.5–22.3 | 7.6–28.0 | – | Axial load; stress–strain. | |||

| Bergami and Nuti [62][74] | 2015 | Brick | Clay | 1010 × 1010 × 260; 770 × 770 × 120 | 48 | 10.4–23.3 | 23.4; 11.7 | – | Axial load. | |||

| Jafari et al. [63][75] | 2022 | Brick | Clay; CS | 430 × 475 × 100; 880 × 300 × 100 210 × 180 × 100 |

54 | 13.1–36.4 | – | Axial load; stress–strain; shear compression. | ||||

| Costigan et al. [64][76] | 2015 | Brick | Fired-clay | 5 | 12.7 | 1.4–22.2 | – | Axial load; stress–strain. | ||||

| Zhu et al. [65][77] | 2017 | HCB | Conv. concrete | 990 × 590 × 190 | 6 | 25.75 | 15.55 | - | Axial load. | |||

| Sandoval et al. [66][78] | 2011 | Brick | Clay | 238 × 300 × 35; 896 × 300 × 35. | 36 | 32.5 | 7.3 | – | Axial load; slenderness ratio and eccentricity. | |||

| Mohammed et al. [67][79] | 2009 | Brick | Fired-clay | 1700 × 1700 × 102 | 12 | 80 | 5.3–11.6 | Axial load; stress–strain; opening. | ||||

| Zhou et al. [68][80] | 2017 | HCB | Conv. concrete | 990 × 590 × 190 | 24 | 14.1–31.1 | 6.3; 15.5 | – | Axial load; stress–strain. | |||

| Thamboo and Dhanasekar [69][81], | 2019 | Brick | Clay; Compressed-earth |

410 × 430 × 100; 590 × 570 × 140 | 40 | 3.8–15.8 6.5; 7.9 |

6.4; 3.9 | – | Axial load; stress–strain. | |||

Note: HCB = hollow concrete block, SCB = solid concrete block, CCB = cellular concrete block, CS = calcium silicate, AAC = autoclaved aerated concrete, Conv. = conventional, fb = compressive strength of unit, fm = compressive strength of mortar, fg = compressive strength of grout.

Table 2. A summary of selected equations proposed in the literature for predicting either the characteristic compressive strength of the masonry, fk, or the mean value, f’m, using the normalized compressive strength of the unit, fb, and the compressive strength of the mortar, fm.