You're using an outdated browser. Please upgrade to a modern browser for the best experience.

Please note this is a comparison between Version 1 by Claudia Garrido Martins and Version 2 by Rita Xu.

Concurrent engineering through overlapping of activities (i.e., fast-tracking) has been used as a schedule acceleration technique. Fast-track construction projects are generally recognized as riskier and subject to risks arising due to the concurrency of work.

- construction risk

- construction risk management

- risk perception

1. Introduction

The construction industry has responded to reduced project delivery times by introducing acceleration techniques into the project schedule. The conventional schedule acceleration technique is concurrent engineering, which overlaps activities that are traditionally performed sequentially. Acceleration through overlapping (also called fast-tracking) benefits the project but is generally considered riskier [1].

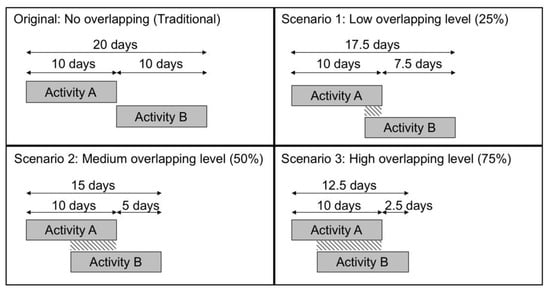

The basic idea is to reduce the total execution time by executing activities in parallel instead of performing these activities sequentially. The first activity in an overlapping pair is called the predecessor or upstream activity, and the second is called the successor or downstream activity. The degree of overlapping (i.e., amount of concurrency) is defined as a length of time or percent of the duration of the predecessor activity. However, the degree of overlapping can vary depending on conditions, such as the relationship type and the characteristics of the overlapped activities [1][2][3][4][1,2,3,4]. Factors involved in this relationship can influence and be the source of risks, such as the production rate of the predecessor activity, information uncertainty, resource availability, physical space, and safety conditions. Figure 1 illustrates a traditional schedule without overlapping and three overlapping scenarios with 25%, 50%, and 75% overlap. For example, if each activity has a duration of ten days, overlapping 25% in a finish-to-start relationship means the two activities will be concurrently performed during the last 2.5 days of the predecessor activity (which would also be the first 2.5 days of the successor activity).

Figure 1. Example of a traditional schedule and three different scenarios of overlapping.

Regardless of the intrinsic risks associated with a traditional construction project, there is a general consensus within the industry that fast-track projects have additional risks. Earlier studies about overlapping, either in product development or construction, mention that adopting a fast-track approach will result in more risks [1][2][5][6][7][1,2,5,6,7]. Applying overlapping in construction projects has become a routine but challenging procedure. To successfully deliver fast-track projects, it is necessary to understand the risk dynamics involved, adopt practices to manage the risks and provide attention to aspects such as the design phase, coordination, information, and project team involvement [8][9][10][8,9,10].

Since fast-track projects may be riskier, adopting a systematic and iterative process to manage these risks and identify and respond to schedule threats is essential. A risk management process includes the steps of process planning, risk identification, risk analysis, risk response strategy and implementation, and risk control [11][12][11,12]. The importance of risk management in construction and how construction risk is perceived were already the focus of earlier studies [13]. A critical step in risk management is risk identification, which primarily consists of deciding and documenting which threats the project may be exposed to. Risk identification is the process of applying various techniques to determine what, why, and how risks may happen [14]. The risk identification phase is considered essential and challenging because risks cannot be managed unless they are identified, impacting the risk management process efficiency and influencing the risk assessment accuracy [12][15][12,15]. According to Salas et al. [16], risk perception is how risks are processed, and it is the subjective judgment of professionals about risk characteristics. An improved risk identification process may also include the analysis of historical data, such as risks identified in previous, similar projects.

Traditional construction projects have always been characterized as risky, and it is natural that when new elements, such as schedule acceleration through overlapping, are introduced, additional risks might arise. In the case of overlapping, additional risks may be more changes, rework, delay, duration and effort increase in the successor activity, quality loss on the predecessor activity, poor prototyping criteria, overdesign strategy assumptions not being conservative enough, lack of design optimization and coordination, increased materials wastage, inadequate coordination between design and construction, and inadequate scheduling of the work package interfaces, to name a few [1][2][5][7][9][1,2,5,7,9]. Therefore, it is necessary to understand how the construction industry perceives these risks. Emerging studies about risk assessment or project acceleration in construction do not specifically address the risk perception of construction professionals when different degrees of overlapping are applied in construction projects.