Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is a comparison between Version 1 by Irshad Ahamad Khilji and Version 2 by Fanny Huang.

Researchers are exploring the use of natural fiber-reinforced polymer Composites (NFRPC) to bridge the gap between sustainability and material performance. Natural fiber composites are a viable option for several applications due to their low production cost. Possible applications include car bodies and interiors, storage devices, walls and ceilings in commercial and industrial spaces, and even false ceilings.

- natural fiber composite

- sustainability

- hybrid composites

- fiber-reinforced polymer Composites (NFRPC)

1. Introduction

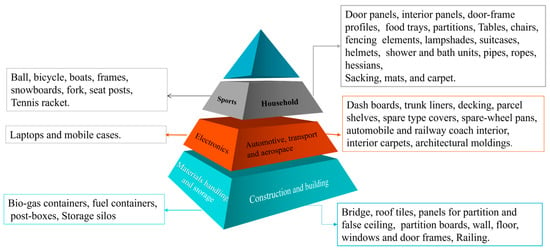

Natural fiber composites are a viable option for several applications due to their low production cost [1][94]. Possible applications include car bodies and interiors, storage devices, walls and ceilings in commercial and industrial spaces, and even false ceilings. Figure 1 depicts many applications in the automobile, transportation and aerospace, construction and building, electronics, sports, residence construction, and material handling and storage industries. The ever-increasing size of aircraft wings and wind-turbine blades is continuously testing advanced materials, designs, and fabrication techniques. Composites will be made with processed fiber and resin as fillers [2][95]. Research efforts focus on using high-quality components and streamlined production procedures. When weight-bearing ability is a primary concern, NFPCs can be used instead of glass in several contexts. The superior mechanical characteristics and lower cost of fiber-reinforced composites make them superior to polymer resins for structural applications.

Figure 1. Applications of Reinforced Natural Fiber Composites in Industrial sectors.

Commercial aircraft use composites in construction: 50% in the Boeing 787 Dreamliner, 53% in the Airbus A350 53%, and 25% in the Airbus 380. Fuel efficiency can be significantly enhanced by using lighter materials. Using composites reinforced with natural fibers allows for a 35% reduction in aircraft weight. The Mercedes Benz E-class was the first to employ NFRCs for the inner door panel, combining flax and sisal with epoxy polymer, achieving weight savings of 20% [3][96].

Numerous new applications for biofiber materials have emerged, including window frames and decking, dashboards and parcel shelves, door panels, seat cushions, and backrests, and cabin linings. More industries, such as the automotive, aerospace, marine, electrical and electronics, sports, recreation equipment, and machinery office-equipment sectors, are switching to NFCs from petroleum-based fibers, as are the automobile and construction industries, because of its low-cost processing, excellent comparative mechanical properties, ability to withstand corrosion and fatigue, and recyclability. Many companies use natural fibers. For instance Daimler Benz constructed dashboards, center-armrest consoles, and seat shells out of natural fibers. Volkswagen utilized natural fibers to create the boot-lid finish panel, seatback, boot lining, and door panel for the Passat, A4, Golf, and Bora. The use of cellulose fibers like flax and abaca increased NFC use in several vehicles by about 98% over older models [4][97].

The European Commission issued directives in 2000/53/EC mandating that 85% of the weight of products, particularly vehicles, be recyclable by 2005. By 2015, manufacturers were to achieve a recycling rate of 95%. Automakers must incorporate biofibers in composites to balance sustainability and cost [5][98].

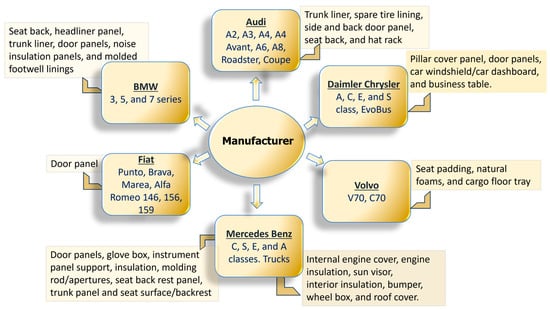

Biofibers are used extensively in the production of door panels, dashboards, parcel shelves, seat cushions, backrests, and cabin linings. More industries, such as the automotive, aerospace, marine, electrical and electronics, sports, recreation equipment, and machinery office-equipment sectors, are switching to natural fibers from petroleum-based fibers [6][99]. The automotive manufacturing applications of natural fiber-reinforced polymer composites are depicted in Figure 2. Natural fibers were used by Opel’s other producers on the instrument panel, headliner panel, door panels, and pillar-cover panel of models such the Astra, Vectra, and Zafira. The Citroën C5 model included interior door-paneling components made from natural fibers. The Raum, Brevis, Harrier, and Celsius Toyota models included door panels, seat backs, floor mats, and spare tire covers made from natural fiber. Mitsubishi (Space Star, Colt Cargo) used natural fibers for flooring, instrument panels and door panels. Rear parcel shelves made from natural fibers used by Renault (Clio, Twingo), and Volkswagen (Golf A4, Passat, Variant, Bora) includes natural fiber in the door panel, seat back, boot-lid finish panel, and boot liner. The Lotus Eco Elise model includes body panels, spoilers, seats, and interior carpets made from natural fibers [7][100].

Figure 2. Natural Fiber-Reinforced Polymer Composites Used in Various Automobiles.

Hybrid polymer-based composites increasingly use synthetic fibers, including glass, carbon, and aramid, for their superior stiffness and strength. Biodegradability, high initial processing costs, non-recyclability, high energy consumption, machine abrasion, and potential health risks are some of the main disadvantages of using these fibers [8][101].

Some challenges of using natural fibers in composites are their relatively low degradation temperature and high flammability. Additionally, variability in fiber characteristics and properties contributes to large scatter in the properties of NFRCs. Certain fibers are not compatible with certain polymer matrices and may be susceptible to damage from insects and fungi. Product performance and reliability depend on whether the natural fiber causes higher moisture absorption (swelling), and variation in natural fiber characteristic features/quality depends on the conditions of cultivation and weather, a complex supply chain, and geographical availability. NFRCs exhibit low thermal conductivity compared to glass fiber-reinforced composites, but natural fibers exhibit poor wettability, resulting in weak fiber-matrix interfacial bonding and worse mechanical properties. They are also subject to fluctuations in price and supply due to weather and crop production, as weather and crop yield can significantly affect both prices and supplies. NFRCs have a service temperatures lower than 200 °C, so they can be used only for non-structural components [9][11].

The fundamental drawback of incorporating NFRCs into a polymer matrix is the absence of interfacial interaction between the two components, which results in a less ideal end product. Chemical modifications such as alkaline treatment can strengthen the bond between the NFRC and the matrix. Morphological examination demonstrates that when non-cellulose materials are removed from the surface of alkali-treated particles, the interfacial adhesion between the particles and matrix is improved [10][12].

The mechanical characteristics and dimensional stability of composites are reduced by humidity and aging. Matrix materials like polyester are quickly hydrolyzed by moisture, lowering the molecular weight of the polymer. Temperature and humidity affect how quickly materials decompose through hydrolysis [11][102]. Salem et al. examined the effects of fiber loading (10 to 40) wt percent) on the ability of a kenaf/polyester composite’s to absorb water at room temperature. Because of the high hydrophilicity of NFRCs, natural fiber composites typically absorb 2% of their weight in moisture within 24 h, 5% within a week, and up to 22% after many months [12][103]. Moisture-exposed composites have different surface morphologies than their dry counterparts, with increased permeability, swelling, gaps, adsorption in cracks, and fissuring around the NFRCs. Between 215 and 310 degrees Celsius, most natural fibers undergo around 60 percent thermal degradation has been found [13][104]. Solar ultraviolet (UV) radiation causes the breakdown of covalent bonds in organic polymers, leading to consequences such as yellowing, discoloration, weight loss, surface roughening, deterioration in mechanical properties, embrittlement, and a pronounced decline in the thermal stability of natural fiber composites [14][105].

Natural fibers often have their surfaces treated to improve their properties before they are used to make composite materials. Surface modification improves fiber-matrix interfacial bonding, roughness, and wettability, hence decreasing the fibers’ moisture absorption. The resulting composites have enhanced mechanical properties. Hybrid composites benefit from fiber treatment because of this enhanced performance [15][18].

Physical treatment: Adhesion among the fiber surface and the polymer matrix can be enhanced by applying physical treatments that affect the fiber surface and increase fiber strength. The interfacial bonding between the NFRC and the matrix is improved through physical treatment, which reinforces the interface without affecting the chemical properties of the fiber [16][106]. Plasma, corona, electron radiation, ultraviolet, heat treatments, and fiber beating are used to modify the surface of natural fibers. Gassan and Gutowski showed that Corona treatment modifies cellulose fibers’ surface energy, making them more amenable to incorporation into the NFRC. This technique employs high voltage at low temperatures to generate plasma at atmospheric pressure. In plasma therapy, the gas type, rate of gas flow, gas pressure, and gas concentration are controlled [17][107]. The NFRCs are heated to a temperature close to their degradation point during heat treatment. However, this treatment affects the NFRC’s physical, mechanical, and chemical characteristics, including their chemical composition, fiber strength, and cellulose crystallinity. These processes affect the fibers’ surface characteristics without changing their structural makeup, enhancing the bond between the fiber and the matrix. When comparing chemical and physical treatments, the primary difference is the cost of the equipment for physical treatments [18][108].

Chemical treatment: Enhancing adhesion to the fiber matrix through chemical bonding or mechanical interlocking at the interface, as is done in many chemical treatments, is a common way to reduce the fibers’ water absorption [19][109]. Compounds used for this purpose include acetic acid, benzoyl chloride, sodium hydroxide, silane, malleated coupling agents, peroxides, isocyanates, and stearic acid. Sumrith et al. used water-hyacinth fibers treated with NaOH and silane to form reinforced bio-epoxy-based composites by casting. The results show that hyacinth fibers can be used with bio-epoxy polymer as a reinforcement material to produce biobased, eco-friendly composites with lightweight structures [20][110].

Chemical methods result in better enhancement of properties than physical methods. Mechanical and thermal properties are enhanced by chemical concentration and are dependent on exposure time. Sometimes, the mechanical and thermal properties resulting from combined treatment with two chemicals were superior to those resulting from either treatment used alone [21][111].

Improvements in fiber-matrix interfacial adhesion, roughness, and wettability were observed in chemically and physically modified natural fibers. Most treatments also lessen natural fibers’ hydrophilicity and their propensity to absorb moisture. Depending on fiber, matrix, filler, and other factors, fabric polymer composites can exhibit improved mechanical and thermal properties. Fiber content, aspect ratio, and fiber orientation are important characteristics of composites. The manufacturing process and the techniques used to create the fiber (cylindrical, spherical, or rectangular cross-sectioned prisms or platelets) are significant as well [22][112].

The matrix contributes significantly to the composite’s shear properties, compression, and transverse modules (mechanical properties). Matrix properties like curing temperature, duration, viscosity, and fiber-bonding behavior influence the manufacturing strategy [23][113]. The matrix in composites binds the fibers and distributes loads between them. Aims include the optimum orientation and location of the fibers, shielding them from damaging environmental factors such as temperature, humidity, chemicals, and abrasion, and supporting interlaminar shear. The matrix enhances the composite’s transverse properties [24][114]. Limited shrinkage, dimensional consistency, chemical resistance, reduced coefficient of thermal expansion, decreased water absorption, resistance to damage from significant temperature increases, elasticity for load transfer to the fiber, excellent flow characteristics that allow the matrix to penetrate fiber bundles and remove voids during compacting, and the ability to be easily shaped into the final composite form are highly desirable properties of a composite matrix [25][115]. The fiber/matrix employed and the composite’s intended use will determine the best technique for fiber modification. To use NFRCs and hybrid composites, it is crucial to understand the interfacial properties and bonding mechanisms of the fiber-matrix interaction, which necessitates extensive research [26][116]. Inadequate adhesion between the fibers and the matrix will lead to inefficient load distribution, reducing the composite materials’ mechanical properties (such as tensile, flexural, and impact strength). Obtaining the correct mechanical and thermal properties in composites involves finding the right fiber/matrix combination [27][117].

The matrix protects the reinforcement fibers from wear and tear caused by mechanical and chemical abrasion, keeps the fibers in their proper positions, and transfers stress adequately between them.

Matrix types include ceramic, metallic, and polymeric matrices. There are two broad categories of polymer matrix: thermosets and thermoplastics. Polymeric (thermoset or thermoplastic) matrices are most typically utilized to make hybrid natural fiber composites because they can be produced at low temperatures and are lightweight. Thermoplastic polymeric matrices include nylon, cellulose acetate, polylactic acid, polycarbonate, polyethylene, polypropylene, polystyrene, polyvinyl chloride, polylactic acid, and polyether-ether ketone, while thermoset polymeric matrices include epoxy, phenolic, polyester, polyamide, polyurethane, and ester vinyl chloride. Epoxy and unsaturated polyesters are the primary thermoset resins used in hybrid natural composites [28][118]. Epoxy resins are resistant to environmental deterioration and have high mechanical strength. Epoxy resins are known for their strong adhesive properties and are simple to use and cure. A crucial advantage of epoxy resins over phenolic, polyester, and vinyl ester resins is that no volatile substances are created during curing. Additionally, compared to polyesters, epoxy resins experience less shrinkage [29][119]. The relative brittleness of epoxy resins, which has serious negative effects on the interlaminar characteristics of the matrix and the fiber reinforcement, is a disadvantage. Epoxy resin undergoes a catalytic chemical reaction when it cures from a liquid to a solid, forming strong bonds that are difficult to undo or reform. This reaction results in this matrix material having superior performance compared other matrices, but recycling this material is still difficult. Most natural fibers become unstable at temperatures above 200 °C, and matrices that call for high processing temperatures are ineffective for producing NFRCs or hybrid natural fiber composites [30][120].

2. Automotive Industry

Natural fiber composites have made a positive impact in the automotive industry due to their light weight and desirable mechanical properties. Their light weight decreases the overall weight of the vehicle, hence decreasing fuel consumption, which makes the vehicles more sustainable. Natural fibers have been investigated for potential automotive applications by several authors in the literature. The structural design of a bonnet containing flax-fiber composite was investigated through impact-damage analysis. The structure was first manufactured using resin-transfer molding. Steel panel and flax-vinyl ester panels were compared in compression and impact tests, and it was concluded that the composite resulted in a 31.7% weight reduction with similar mechanical properties compared with the steel panels [31][121]. Another composite investigated for automotive applications, especially for the front cabinet, body sheet and lighting frames, is caryota fiber and polyester with 40% weight fiber loading. A 50 mm fiber length and 40% weight of fiber loading had the best mechanical properties [32][122]. Nachippan investigated the impact strength of automotive bumpers and bodies using glass fiber, natural fiber (hemp), and hybrid composites mixed with epoxy. They concluded that hybrid composites possess better impact strength and can protect the vehicle body and passengers better than glass-fiber composites [33][123]. Another study investigated the applications of composites of alkali-treated sugarcane bagasse and palm-sheath fibers in an epoxy matrix in automobile dashboards. A matrix: fiber ratio of 60:40 with a hybrid combination of treated 40% palm and 60% bagasse showed the highest tensile strength, Young’s modulus, elongation, flexural strength, impact strength and hardness, making it a superior composite for dashboard applications [34][124]. Another investigation subjected Desmostachya bipinnata fibers to silane treatment to fabricate brake-pad composites. The pretreatment increased hydrophobicity, hardness and shear strength, and the wear rate of treated fiber-composite brake pads was lower. This result shows that pretreated Desmostachya bipinnata fibers are suitable for use in brake pads because of their wear resistivity and high coefficient of friction [35][125].

Vehicle manufacturers have started using natural fibers, especially lignocellulosic biomass waste, in their vehicles. Mercedes Benz, one of the leading automobile manufacturers from Germany, included jute and flax fibers in an epoxy matrix in their A- and E-class models, mainly in their sunroof, gearbox and door panels. The sunroof frame was developed using 70% renewable materials, mostly sourced from natural fibers such as jute ad sisal. and offers up to 50% reduction in weight compared to a traditional metal sun roof frame [36][37][126,127]. Before Mercedes Benz, BMW had been one of the first car companies to use natural fibers in their cars, where flax and sisal were used in the car door lining and some of the vehicle panels, which increased the vehicles’ impact resistance. BMW also incorporated wood fiber and cotton for a high-quality sound system and as filler for car seats, and this method has been used in many car manufacturers after them [38][128]. Additionally, Audi used flax and sisal fibers in their door panels, with the polymer matrix being polyurethane (PU) [39][129]. In the 2003 Toyota RAUM, the spare-tire cover was made out of sustainable composites based on kenaf fibers reinforced with sugarcane- and sweet potato-based PLA [40][130].

3. Aerospace Industry

Even though research is being done into developing sustainable composite materials for the aerospace sector, the composites currently used in aircrafts are mainly made from carbon fiber, aluminum, and titanium due to their high strength-to-weight ratio. The widely available Boeing 787 Dreamline and Airbus 350 XWB include some composite parts, including but not limited to turbine housing, wing panels and stabilizers. This choice has shown to increase passenger comfort and noise cancellation, while reducing weight and fuel consumption [41][131]. Other common applications include interior parts such as seating, cabin dividers, restrooms panels, overhead bins, flooring, and wall coverings [42][132]. Within the aviation sector, critical objectives include reducing aircraft weight, enhancing fuel efficiency, increasing payload capacity, and improving aircraft maneuverability [43][133]. These objectives can be effectively achieved by employing NFRP composites, which not only contribute to heightened aircraft efficiency through reduced fuel consumption and emissions but also offer remarkable strength and stiffness, facilitating the fabrication of intricate aerodynamic shapes. NFRP composites exhibit excellent fatigue resistance and corrosion resilience [42][44][132,134].

More than 200 aircraft components are crafted from NFRP composites, encompassing elements such as cabin furnishings, sidewalls, and propulsion systems [43][44][133,134]. This significant shift towards NFRP composites in aviation has been supported by the European Union through initiatives like the Cayley project, a collaborative effort involving Boeing Research and Technology, Invent GmbH, Aimplas, and Lineo. The aim of this project is to develop environmentally friendly interior panels for aircraft by utilizing flax fiber and recycled thermoplastic sheets [45][135]. Another EU-funded project, known as Eco-Compass, is dedicated to the development of eco-friendly composites derived from bioresources and recycled materials for aviation applications. The primary focus of this project is to explore alternative ways to reduce the use of carbon- and glass-reinforced polymer composites in aircraft by incorporating bioresins, natural fibers, or recycled carbon fibers in secondary structural and interior applications. Flax and ramie fibers have demonstrated potential for incorporation into NFRP composites for aircraft, offering improvements in tensile strength and flame-retardant properties [46][47][136,137].

Similar to the Boeing 787 and the Airbus 350 XWB mentioned earlier, the Boeing 737 aircraft also used natural fiber composites, namely flax/epoxy sandwich composites in the sidewall panels, with the flax fabrics treated to be halogen-free and fire-retardant. These flax/epoxy panels are not only 35% lighter than carbon/epoxy composites, but also have a structure similar to that of glass/epoxy unidirectional composites [42][132]. Beyond epoxy, phenolics and engineering thermoplastics such as polyphenylene sulfide, polyether ether ketone, polyamide (PA), and polycarbonate (PC) have garnered significant attention in the aviation industry. This attention is primarily due to their excellent fire resistance, aligning with the stringent flame, smoke, and toxicity regulations applicable to aviation materials [48][138]. For instance, polyether ether ketone (PEEK) was reinforced with chopped glass and carbon fiber by Victrex Europa GmbH, who developed VICTREX® PEEK for aircraft applications. This composite exhibits mechanical strength and dimensional stability comparable to those of metal alloys, withstanding high temperatures and displaying resistance to corrosion, chemicals, wear, and abrasion [41][131].

4. Medical Industry

In the biomedical industry, lignocellulosic fibers rarely are used, except for in recent novel regenerative studies, but the wearable technology sector has taken this opportunity to utilize biomass waste to develop a strain sensor for biomedical applications. The sensor was constructed from a conductive and flexible composite in which carbonized walnut shell powder was blended with polydimethylsiloxane (PDMS). The composite demonstrated exceptional sensitivity in detecting human body movements. The potential applications for this innovative sensor are boundless, with the tantalizing prospect of it evolving into a versatile and adaptable technology for wearable, flexible sensors that enhance our daily lives [49][50][139,140].

Animal-based fibers such as silk and chitosan and cellulose-based nanoparticles have been studied. with promising results. Silkworm- and spider-produced silk have been applied in medical components such as sutures, sponges, and films [51][52][53][54][141,142,143,144]. The allure of silk lies in its distinctive usefulness as a scaffold biomaterial, in particular because of its ability to degrade gradually. This unique feature aligns perfectly with the demands of biomedical applications, offering a material that seamlessly integrates with the body’s natural processes. One particularly striking advantage of employing animal-based fibers like silkworm silk and spider silk in medical implants and bone repairs is the elimination of the need for a secondary surgical procedure to remove metallic implants. This groundbreaking advancement not only enhances patient comfort, but also reduces the associated risks and costs, revolutionizing the field of medical interventions [53][55][143,145].

Steering researchers' focus towards the world of advanced technology and biosensors, researchers encounter an exciting development in the form of nanocomposites. These nanocomposites, designed to encapsulate gold nanoparticles with the aid of camphorsulfonic acid (CSA) surfaces, have applications in electrical devices and biosensors. The nanocomposites showed high solubility in water and select organic solvents, rendering them exceptionally versatile for an array of applications [56][146]. Another noteworthy innovation is a self-cleaning and antimicrobial hybrid system. This ingenious system is based on a foundation of polybutylene succinate (PBS) and polybutylene adipate-co-terephthalate (PBAT), fortified with the inclusion of lignin and zinc nanoparticles. The result is a material with the remarkable capability to repel dirt and hinder the growth of harmful microbes. This development not only had immediate implications for maintaining cleanliness and hygiene, but also holds significant promise for various sectors that demand durable and hygienic surfaces [57][147].

5. Construction Industry

Geopolymer materials have attracted significant interest for their remarkable technical characteristics, which closely resemble those of conventional Portland cement-based materials, all while significantly mitigating carbon dioxide (CO2) emissions and minimizing their overall environmental footprint. Furthermore, integrating natural fibers, including but not limited to bamboo, flax, hemp, and jute, within the geopolymer matrix is a compelling avenue of exploration. These natural fibers serve as a reinforcing component, enhancing the tensile and flexural strength while reducing material density, creating lightweight construction materials. Another advantage of using these natural fiber composites on the interior of buildings include improved thermal insulation, which leads to energy efficiency and better soundproofing.

Different aspects of natural fiber-reinforced geopolymers have been studied in the literature. One of the important factors in choosing materials for construction is flame-retardation properties, which allow the building material to act as a flame retardant in case of a fire. Silva studied the fire-resistance and head-absorption capabilities of a jute fiber-reinforced pozzolan-based geopolymer. The samples demonstrated an impressive ability to absorb nearly 65% of the heat generated by the flames, with minimal degradation [58][148]. Other common properties sought after by the construction industry are high mechanical strength and hydric properties. Bast-hemp fibers were investigated with and without sodium hydroxide pretreatment at 3% weight loading in diatomite geopolymer, and the composite showed an almost 100% increase in compressive strength and a 35% increase in flexural strength while maintaining thermal conductivity [59][149]. Flax linen, cotton and abaca fibers also showed an increase in compressive strength after being mixed with geopolymer. Alkali treatment of the abaca fiber facilitated fiber bonding with fly ash and increased the flexural strength of the composite [60][150]. When untreated cotton- and flax-based linens were investigated for use in fly-ash composite, the compressive and flexural strength of the composites increased, but the flexural strength of the linen-fly ash composite increased significantly, by 60% [61][62][45,151].

With a rising global emphasis on sustainable materials, recent breakthroughs in FFFs have broadened their usefulness across numerous domains. Material innovation has witnessed the development of novel hybrid resins for DLP 3D printing of biocompatible scaffolds using renewable resources [63][152], extrusion methods for high-performance thermoplastics derived from recycled materials [64][153], and laser-sintering techniques for silicon carbide-based ceramics utilizing post-industrial waste [65][154]. Process improvements include adaptive process control for laser powder bed fusion [66][155] AM to optimize material usage, in situ monitoring using computer vision to minimize material consumption, and multi-material AM systems with extrusion-based approaches that facilitate the effective integration of sustainable materials [67][156]. Personalized orthotics and prosthetics made of recyclable and biocompatible materials, aerospace parts like rocket engines and aircraft parts made of lightweight, sustainable materials, and medical devices like implants and surgical guides that are made with biocompatibility and sustainability in mind are just a few of the numerous applications of additive manufacturing (AM) [68][69][157,158]. These developments highlight AM’s revolutionary potential to promote a circular economy and advance environmentally friendly manufacturing techniques, opening the door for more ground-breaking discoveries in the years to come.