Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is a comparison between Version 1 by Shuai Chang and Version 2 by Jessie Wu.

Organic light-emitting diodes (OLEDs) have emerged as a promising technology for various applications owing to their advantages, including low-cost fabrication, flexibility, and compatibility. However, a limited lifetime hinders the practical application of OLEDs in electronic devices. OLEDs are prone to degradation effects during operation, resulting in a decrease in device lifetime and performance.

- analytical techniques

- degradation

- failure modes

- organic light-emitting diodes

1. Introduction

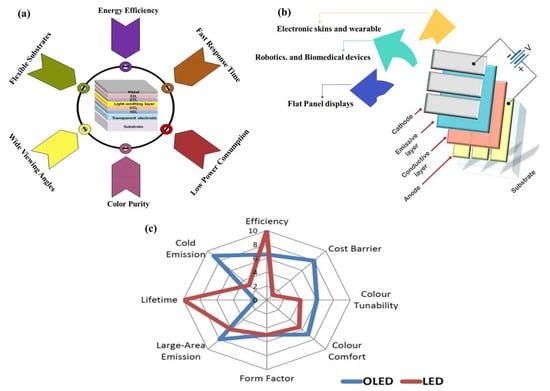

Organic light-emitting diodes (OLEDs) are poised to become the leading technology in high-quality flat-panel display [1] and solid-state lighting. Their disruptive features, including energy efficiency [2], wide viewing angles, fast response times, high contrast, and exceptional color purity (Figure 1a), make them ideal candidates for various applications (a few of them are shown in Figure 1b). In contrast, traditional light-emitting diodes (LEDs) require complex processing to achieve comparable light quality, and achieving uniform dispersion into a near-plane light source remains a challenge for them. A clear comparison of LEDs and OLEDs is shown in Figure 1c.

Figure 1. (a) Advantages of OLED. (b) Applications of OLED. (c) Comparison of OLED and LED. Reprinted from “The Global Information Hub for Lighting Technologies and Design”.

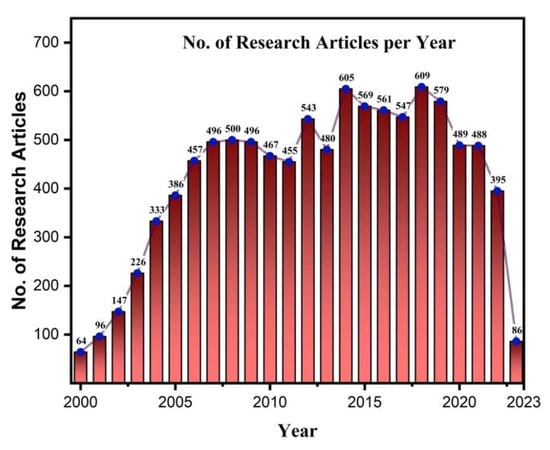

Moreover, OLED technology offers unique advantages in flexible and stretchable substrates [3], enabling applications in wearable electronics [4], biomedical devices [5], electronic skins [6], and robotics [7]. OLEDs’ thinness, flexibility, and durability allow them to withstand harsh mechanical conditions, such as bending and twisting. Additionally, OLEDs offer the ability to adjust color and color temperature over a wide range, allowing for the replication of natural light styles. While OLEDs excel in various applications, their use in general lighting presents cost challenges. The manufacturing costs of components increase proportionately when larger OLED lighting panels are required for uniform illumination in spaces like offices or reading areas. Due to their importance in industry and academia, OLEDs are receiving much focus in research with a large number of research articles published every year on the topic, shown in Figure 2 and Figure 3.

While OLED researchers and market analysts are optimistic about OLED technology disrupting conventional lighting and capturing a significant market share, it is crucial to streamline market-related content. The Global OLED Display Market, valued at 43,066 million USD in 2022, is projected to reach 11,709,730 million USD by 2028, with a CAGR of 18.14%. This growth is driven by the rising adoption of OLED technology, advancements in display technology, and increasing consumer demand for high-quality displays.

Figure 2.

No. of research articles published per year till now on OLED (Web of Science).

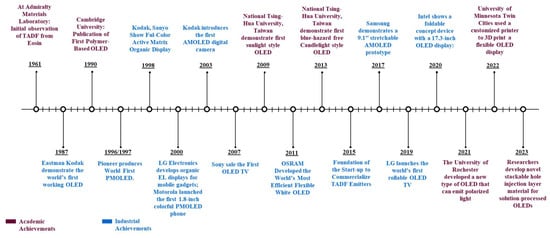

Figure 3.

Academic and industrial achievements of OLED.

Researchers are exploring innovative strategies to enhance efficiency and mitigate degradation in organic light-emitting diodes (OLEDs) [8]. A notable approach involves the utilization of thermally activated delayed fluorescence (TADF) materials, capable of converting less efficient triplet excitons into more efficient singlet excitons. This holds the potential for significant improvements in OLED efficiency [9]. Another avenue is the adoption of triplet–triplet annihilation (TTA), a process wherein two triplet excitons combine to form a singlet exciton, contributing further to enhanced OLED efficiency. Despite some limitations of TADF OLEDs, such as broad emission spectra and longer lifetimes, the technique of hyperfluorescence proves effective in overcoming these constraints [10]. Hyperfluorescence entails employing TADF emitters as assistant hosts for fluorescent end-emitters, resulting in OLEDs with up to 100% internal quantum efficiency (IQE) [11]. The introduction of TED-TADF, a novel OLED technology amalgamating the advantages of TADF and TTA, demonstrates the efficient harnessing of triplet excitons and their conversion into singlet excitons, leading to heightened device efficiency and prolonged operational life, particularly in deep-blue OLEDs [12][13][12,13]. Overall, numerous promising approaches to enhancing OLED efficiency, including TADF, TTA, and TED-TADF, are showing significant potential, with ongoing research aimed at refining techniques for further improvements.

Despite the numerous advantages, one significant challenge that OLEDs face is degradation during operation, which can lead to a decrease in device lifetime and performance. OLED degradation mechanisms can occur internally or be influenced by external factors. Internal degradation processes involve reactions within the OLED materials, such as the degradation of organic layers or the formation of non-radiative recombination sites. One of the most common intrinsic degradation mechanisms in OLEDs is the formation of excitons (electron–hole pairs) in the organic layers. These excitons can generate reactive species, such as free radicals and triplet excitons, which react with organic materials, forming non-emissive species and reducing device efficiency [14][15][14,15]. Additionally, the diffusion of organic molecules from the emissive layer into adjacent layers or the substrate can result in the formation of non-emissive species or chemical reactions with other materials in the device. Metal ions diffusing from the cathode into the organic layers can also contribute to reduced efficiency [16]. External factors, such as moisture, oxygen, and UV radiation exposure, can also contribute to OLED degradation. Moisture and oxygen can react with organic materials and affect their properties, impacting efficiency and lifetime. Light exposure can generate reactive species like singlet oxygen, which can also lead to the formation of non-emissive species [17]. OLED degradation can also occur through various factors, including chemical, electrical, thermal, and optical degradation. Chemical degradation is caused by exposure to environmental factors like oxygen and moisture, leading to reduced efficiency [18]. Electrical degradation occurs due to charge buildup in the organic layers, resulting in chemical reactions and device degradation [19]. Thermal degradation occurs when OLEDs are exposed to high temperatures, degrading organic materials and decreasing efficiency [20][21][22][20,21,22]. Optical degradation occurs when OLEDs are exposed to light, causing degradation of the organic materials [23].