You're using an outdated browser. Please upgrade to a modern browser for the best experience.

Please note this is a comparison between Version 2 by Jessie Wu and Version 4 by Jessie Wu.

Remining can be defined as the use of mine waste, including solid and liquid waste, as the source material from which to extract metals or create other materials of economic value. The socioeconomic appeal of remining derives from its ability to increase domestic supply, create jobs, and improve environmental conditions in areas affected by existing and historic mining activity. Renewable energy metals from remined materials can be sourced from legacy and modern mine wastes for original target metals/minerals and for metals/minerals that were not originally targeted.

- reprocessing of mine waste

- renewable energy

- characterization

- circularity

1. Introduction

The potential for recovery of critical minerals and metals from sources such as tailings, waste rock, coal ash, acid mine drainage (AMD), and ore-processing facilities (e.g., electrowinning anodes) is currently difficult to estimate because characterization and processing of the sources are generally in the early stages of development. Examples of recovery potential have been provided for specific sites, but they rarely take the costs of characterization, processing, transportation, and construction of needed facilities into account. In general, the reprocessing of tailings or waste rock is more likely to be able to use existing infrastructure, especially at operating mine sites. Importantly, the potential for recovery of critical minerals for renewable energy must also consider community acceptance, worker safety, and environmental effects.

For virgin extraction, different levels of resource estimates are made based on multiple factors and are divided in the broader and less reliably estimated mineral resources compared to the economically mineable part of the resources, mineral or ore reserves; both are usually reported in terms of grade and tonnage [1]. For remined sources, as for virgin mining sources, it is not possible to economically or technically extract and process all the metal in the wastes.

Despite these limitations, estimates of the mass of mine waste and the total amount of renewable energy metals in the wastes can provide a rough idea of the potential for mine wastes to serve as important sources of metals for the new energy economy. The findings show that the estimates are very rough, and, in some cases, outdated, and further characterization of mine wastes is needed.

2. World-Wide Estimates

The amount of mine waste produced per unit of mined commodity has increased over time due to declining ore grades. An estimated 8500 active, inactive, and closed tailings storage facilities exist worldwide [2]. Using their estimate for the volume of tailings in facilities listed in public disclosures and extrapolating to 8500 total facilities, roughly 217 billion m3 of tailings are in storage globally. Franks et al. [2] estimate the annual growth in tailings from 2020 to 2025 at 11.1 billion m3. A separate and similar 2015 estimate suggests that the mining industry produces ~14 billion tonnes of tailings annually [3], Marín et al. [4] estimate global annual tailings production at between 5 and 7 billion tonnes, and Mudd and Boger [5] estimated global tailings and waste rock production in 2011 at more than 7 billion and 55 billion tonnes, respectively. All these values are estimates based on global mineral production from the USGS and other sources and show uncertainty in the overall amount of tailings in storage and produced annually worldwide. While there is clearly no shortage of tailings as a potential source material for recovery of renewable energy metals, the “resource” and “reserve” of the deposits have not been estimated.

Some mined commodities produce a higher percentage of the world’s tailings than others: Cu accounts for 46%, Au for 21%, followed by Fe (9%), coal (8%), phosphate (4%), Pb/Zn (3%), Ni (2%), and other commodities (7%) [6]. Zhang et al. [7] estimate that sulfide tailings generated from Cu mines account for more than ~27 million tonnes of tailings worldwide, of which almost 90–95% are produced from the flotation process.

Patel et al. [8] estimate total REE concentrations, and the concentrations of some individual REEs, in fly ash, coal ash, red mud, mine tailings, and other industrial wastes in 11 countries around the world. The highest REE concentrations are found in REE magnet scraps (up to 36.7%, or 36,700 mg/kg, for multiple REEs), but concentrations are also high in red muds (up to 1777 mg/kg in Greece and Turkey). While the concentrations suggest potential for secondary recovery, the total REE amounts were not provided.

3. Regional Estimates for the Europe

A survey of mines across Europe conducted by the BRGM [9] gathered data on the waste quantities produced for the whole period of mining activity (from the middle of the 19th century, although for some sites’ data went back to Roman times) in four categories: ferrous metals, non-ferrous metals, industrial metals, and coal—including known closed and abandoned mine sites. The total amount of waste rock and tailings, and the amounts stored for each of the four categories, were reported. The countries queried included Denmark, Finland, France, Germany, Greece, Ireland, Portugal, Spain, Sweden, and the United Kingdom. Coal waste volumes were the largest. The results, although inconsistent across countries, showed that more than 4.7 billion tonnes of mining waste and more than 1.2 billion tonnes of tailings waste were stored at that time in the Europe (EU) [9].

According to Blengini et al. [10], no EU or Member State database reports the volumes of extractive waste for closed or active mines disaggregated by targeted mineral or waste type—or the volumes of the different extractive waste streams. However, the material system analysis (MSA) study investigated the flows and stocks of 28 raw materials from “cradle-to-grave” and produced a comprehensive inventory of extractive waste disposed as tailings annually, and the “stock in tailings,” which is the accumulated amount of tailings in the EU over time. The estimates for certain metals of importance to renewable energy include totals of approximately 1000 tonnes of Co, 2000 tonnes of Ga, 200 tonnes of In, and 100 tonnes of natural graphite in EU tailings. These are the most recently available estimates on remining source materials in the EU, and they date back to 2012. An update on tailings and mine waste mass and volume and chemical compositions should be conducted as soon as possible. The same edited volume [10] estimated the amount of bauxite residue (red mud) from alumina industry across Europe as 7 million tonnes per year (dry basis) and noted its importance for REE/Sc recovery. The extraction of REEs from Mytilineos’s (Greece) annual red mud production was estimated to meet ~10% of European demand for REEs [11]. The same paper estimated that extracting Ga from the red mud and the Bayer liquor from just one European alumina refinery would be equivalent to global levels of gallium production (annual world production in 2012 was 284 tonnes).

The potential for recovery of Mo, Nb, Re, Ta, and W from secondary resources, especially mine wastes, across Europe was evaluated in 2016 as part of the MSP-REFRAM project, funded by the EU [12]. The project reported concentrations and tonnages, when available, using the dataset from PROMINE and other sources. The number of sites in Europe with recovery potential calculated using data from PROMINE was the highest for Mo and W (28 and 24 sites, respectively) and lowest for Nb, Re, and Ta (with 8, 1, and 0 sites, respectively).

The information required in the Critical Raw Materials Act Article on remining, assuming it remains in the final version, will provide much-needed updated information on remining potential across Europe.

4. Estimates for the United States

The United States requires active metal mines and many other industries to report their emissions to land, air, and water annually as part of the US EPA’s Toxics Release Inventory (TRI; [13]), and many of the metals that are required to be reported are considered critical metals for renewable energy. Publicly available data from the TRI were used to calculate the amount of cobalt compounds for the top 10 releasers in 2021 (Table 1). The amount of metal compounds reported is much higher than the amount of metal reported. The total amount of cobalt compounds released in 2021 totaled 703 tonnes. None of the mines are primary Co mines; and Co is primarily produced as a byproduct of Cu production. However, the Co content in wastes from the mines listed in Table 1 are from tailings or other mine wastes, not from byproduct production.

Table 1. Top 10 U.S. mines with releases of cobalt compounds, TRI data, 2021.

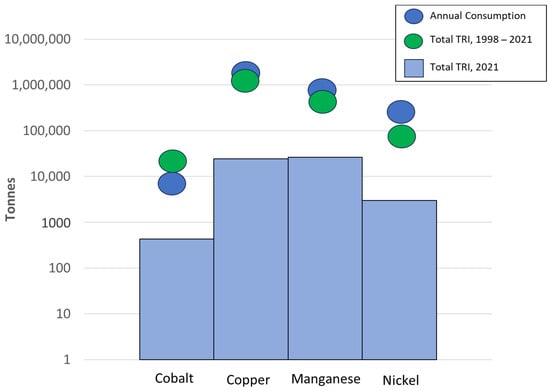

The total TRI releases to land, water, and air from all metal mines for metals of interest for renewable energy are listed in Table 3. As noted previously, metal and metal compounds cannot be added together because the composition of the metal compounds is not listed in the TRI data. Assuming that the amount of Cu in “Cu compounds” is 50% of the amount listed in Table 3, and, adding to that the amount reported for “Cu,” the total amount of Cu released to the environment from metal mines as waste in 2021 was 24,395 tonnes.

Table 3. Total TRI releases from metal mines for metals of interest for renewable energy for 2021 and 1998–2021 compared to U.S. annual consumption.

| Chemical | Total TRI, 2021 (tonnes) | U.S. Annual Apparent Consumption (tonnes) a | Total TRI, 1998–2021 (tonnes) |

|---|---|---|---|

| Sb | 0 | 27,000 | 786 b |

| Sb compounds | 2163 | 112,147 | |

| Cr | 1025 | 590,000 | 35,423 |

| Cr compounds | 3746 | 159,695 | |

| Co | 100 | 7800 | 255 c |

| Co compounds | 665 | 29,713 | |

| Cu | 78 | 1,900,000 | 132,732 |

| Cu compounds | 48,635 | 2,838,186 | |

| Mn | 304 | 890,000 | 34,831 |

| Mn compounds | 52,033 | 983,519 | |

| Ni | 310 | 220,000 | 10,348 |

| Ni compounds | 5355 | 132,370 | |

| Ag | 0 | 6400 | 159 d |

| Ag compounds | 79 | 5773 | |

| Zn compounds e | 180,321 | 910,000 | 5,631,180 |

| Facility, State | Primary Commodity | Total TRI Releases (tonnes) | |||

|---|---|---|---|---|---|

| Eagle Mine, Michigan | Cu, Ni, Pb, Zn | 172 | |||

| Cu, Ni, Pb, Zn | 2949 | Montana Resources, Montana | Cu, Ni, Pb, Zn | 147 | |

| Freeport-McMoran Miami, Arizona | Smelt./refining | 101 | |||

| Freeport-McMoran Morenci, Arizona | Cu, Ni, Pb, Zn | 50 | |||

| Carlin South, Nevada | Au | 47 | |||

| 45 | |||||

| Red Dog Mine, Alaska | All other metal ore | 1034 | Goldstrike, Nevada | ||

| Goldstrike Mines, Nevada | Au | 429 | Au | ||

| Stillwater—Nye Mine, Montana | All other metal ore | 201 | Phoenix, Nevada | 43 | |

| Carlin South, Nevada | Au | 183 | Au | ||

| Stillwater—East Boulder Mine, Montana | All other metal ore | 118 | Oceanagold Haile, S. Carolina | ||

| Montana Resources, Montana | Cu, Ni, Pb, Zn | 115 | Au | 34 | |

| Eagle Mine, Michigan | Cu, Ni, Pb, Zn | 64 | Turquoise Ridge, Nevada | Au | 33 |

| Cortez District, Nevada | Au | 32 | |||

| Total, 2021 (Top 10 only) | 703 |

Source: [13].

Similarly, the TRI data from 2021 were used to calculate the total amount of Ni compounds for the top 10 releasers in 2021, which totaled 5210 tonnes (Table 2). Three of the mines list Ni in their primary commodity type, and many of the same mines with the highest reported releases of Co compounds also have the highest reported amounts of Ni compounds, as expected because these base metals can occur together in certain ores.

Table 2. Top 10 U.S. mines with releases of nickel compounds, TRI data, 2021.

| Facility, State | Primary Commodity | Total TRI Releases (tonnes) |

|---|---|---|

| Eagle Mine—Humboldt Mill, Michigan | ||

| Oceanagold Haile, S. Carolina | ||

| Au | ||

| 59 | ||

| Turquoise Ridge, Nevada | Au | 58 |

| Total, 2021 (top 10 only) |

a For metal/metalloid using the most recent data (2022); b Only reported in 1998 and 1999; c Not reported in meaningful amounts (either not reported or ≤160 lbs total annually) until 2017; d Only reported in 1998, 1999, 2000, 2014; e TRI Zn is reported as fume/dust (to air) or compounds, annual consumption is for refined Zn. Sources: [13] (using TRI Explorer and selecting for each Year of Data from 1998–2021) [14].

Table 3 includes all TRI releases from 2021 and from 1998 (first year of reporting for metal mines) through 2021. Note that the totals for RCRA Subtitle C surface impoundments, other surface impoundments, and other land disposal combined (in other words, land disposal) are nearly 100% of all on-site releases for the metals of interest. Off-site releases are minimal compared to on-site releases. Therefore, metal releases from metal mines are almost exclusively to land impoundments such as waste rock or tailings facilities. Inconsistencies in the years of reporting, especially for certain metals, and large differences between totals reported in earlier and later years, are an indication of the uncertainties in the TRI numbers. The mass of metals reported dropped considerably after Barrick Gold won a ruling against EPA/Whitman in 2003 regarding the reporting of amounts in waste rock. After April 2003, if concentrations were <1% in waste rock, reporting was not required. The totals in Table 3 include all years between 1998 and 2021.

Using the values in Table 3 for Mn, Ni, and Co, and assuming that 50% of the reported metal compound is the metal of interest, the totals for these metals would be 26,320 tonnes of Mn, 2987 tonnes of Ni, and 432 tonnes of Co in a single year (Figure 12). Using USGS values for metal consumption in the United States in 2022 (the most recent available year [14]), between 1.4% (for Ni) and 5.5% (for Co) of the U.S. annual consumption is thrown out in mine waste each year. Note that the annual consumption is for all uses of the metal; use for renewable energy is not tallied separately, although the Ni price increased by 35% from 2021 to 2022 due to increases in the use of Ni in electric vehicle batteries and the continued strong demand for stainless steel [14]. Table 3 also provides the total TRI releases from 1998–2021 and indicates the much higher potential stock of metals released from active U.S. metal mines since metal mines have been required to report to the TRI (Figure 1). Given the total stock of mine waste in the U.S., including at historic and active mines, mine waste could be a substantial resource for renewable energy metals. Of course, the estimated total amounts would not be completely recoverable, and more work is needed to estimate the metal reserve in mine wastes.

5. Estimates for Other Countries

Finland: In Finland, Kinnunen et al. [15] showed basic characterization data for 19 mines in Finland regarding the size of the deposit, the grams/tonne content, and the presence of infrastructure. The results show that mine tailings across Finland contain Ni, Co, and Zn worth 100 s of millions of Euros, but this value is based solely on total concentration and does not consider processing costs and other factors, such as accessibility.

Chile: Cacciuttolo and Atencio [16] assessed tailings masses, management strategies, and relevant regulations in Chile, which is by far the largest Cu producing country in the world. Chile produces 800 million tonnes of mining tailings per year, or approximately 2,192,000 tonnes per day. Between 1905 and 2022, Chile’s Cu mining operations have generated 13 billion tonnes of tailings, covering a surface area of 26,876 hectares [16]. Tailings in Chile also contain Co, V, Ga, Ge, and REEs. Given the enormous amount of Cu tailings in Chile, the initial discovery of metals needed for renewable energy sources in the tailings, and recent advances in the use of best management practices, including filtered tailings, the potential for remining tailings for renewable energy metals is promising and should be further evaluated.

Spain: The Iberian Pyrite Belt (IPB) in Spain and Portugal is considered the most important mining district in Spain and Europe [17], and several efforts have been directed toward metal recovery from mine wastes and acid mine drainage waters. Bulk metal concentrations and mineralogy were evaluated in legacy (19th–20th century) roasted pyrite wastes in the IPB by Yesares et al., 2023 [18] and found to contain potentially economic concentrations of Pb, Cu, Zn, Ag, and Au. Rosario-Beltré et al. [17] summarized information from mine wastes across all of Spain and conducted grain size, mineralogic, and chemical analyses of the most promising 20 mine waste facilities in terms of the recovery of elements with economic potential, many of which are included in the EU’s list of critical raw materials. Two of the facilities with the most promising economic potential are found in the IPB, and the highest economic potential is estimated to derive from Tl, Ag, and Sc. Their combined economic potential, based solely on total concentrations and estimated tonnage, is estimated at USD 2.6 million. Acidic drainage, primarily from waste rock piles in the IPB, also holds economic potential for the recovery of Co, Cu, Zn, Mn, and other elements. Cánovas et al. [19] focus on the environmental effects of releases from sulfide wastes in the IPB and mention that metal recovery could improve environmental conditions; however, they note that more work is needed to determine grade, mineralogy, and recovery methods. Fortes et al. [20] evaluated 33 mine drainages in the IPB and estimated that, considering the total area of abandoned mine waste dumps in the IPB and measured concentrations in the acidic discharge, more than 400 million USD/yr could be realized from metal recovery of these polluted waters. Bonnail et al. [21] also investigated the recovery of clean water and metal compounds from AMD in the IPB using a passive dispersed alkaline substrate technology and adiabatic sonic evaporation and crystallization, which could be fueled by renewable energy and requires no pretreatment. The methods could be applied to improve ecosystem services in the Tinto and Tinto-Odiel rivers, which currently transport large amounts of metals annually, including 1.3 tonnes Y, 248 kg Sc, 139 kg Ga, 3500 tonnes Zn, 1700 tonnes Cu and 1600 tonnes Mn.

China: China initiated the Nationwide Geochemical Survey and Evaluation of Mine Tailings Project in 2010, and, as of 2014, 291 drill holes and 9747 core samples were collected from 26 tailings impoundments in 23 metal mining areas in the country [22]. The 3D distribution of elements was determined, a 3D tailings model was created, and beneficiation tests were conducted on one of the tailings impoundments (Hongqilin nickel mine in Jilin). Higher concentrations of a variety of metals and elements were found at depth in the tailings, due to the use of less efficient beneficiation methods in the past [22]. Based on the average measured metal concentrations and tailings amounts, up to an estimated 57,860 tonnes of Cu, 62,000 tonnes of Ni, and 112,000 tonnes of Zn are available in single tailings impoundments in China [22]. In addition, a tailings impoundment at an iron mine in Mongolia reportedly contains up to USD 12.8 trillion in REEs [23]. More updated information is needed to assess current estimates of remining metal recovery potential for China.

Although the total amount of renewable energy metals in mine wastes, especially in tailings, has been estimated in many countries and regions around the world, a more detailed characterization of the recovery potential from remined sources is generally lacking. Such an assessment will need to comprehensively evaluate: viable sampling and characterization methods; metallurgical properties that can affect processing choices; the total amount of recoverable metal in the resource and reserve considering economic and other factors; the accessibility of the remined resource; whether reprocessing can occur on-site, nearby, or at a distance that will require waste hauling; and the potential positive and adverse effects on the environment, human health, and the local and regional economy. The findings of these assessments can be used to prioritize sites for remining. The very large amount of mine waste worldwide points to the promising potential for recovery of renewable energy metals from these sources, and further characterization of the economic potential and environmental advantages and challenges is needed to better understand that potential.

References

- Jowitt, S.M.; Mudd, G.M.; Thompson, J.F.H. Future availability of non-renewable metal resources and the influence of environmental, social, and governance conflicts on metal production. Commun. Earth Environ. 2020, 1, 13.

- Franks, D.M.; Stringer, M.; Baker, E.; Valenta, R.; Torres-Cruz, L.A.; Thygesen, K.; Matthews, A.; Howchin, J.; Barrie, S. Lessons from tailings facility data disclosures. In Toward Zero Harm. A Compendium of Papers Prepared for the Global Tailings Review; Global Tailings Review: St Gallen, Switzerland, 2020; Chapter VII; 135p, Available online: https://globaltailingsreview.org/wp-content/uploads/2020/09/GTR-TZH-compendium.pdf (accessed on 23 March 2023).

- Adinansyah, J.S.; Rosano, M.; Vink, S.; Keir, G. A framework for a sustainable approach to mine tailings management: Disposal strategies. J. Clean. Prod. 2015, 108, 1050–1062.

- Marín, O.A.; Kraslawski, A.; Cisternas, L.A. Estimating processing cost for the recovery of valuable elements from mine tailings using dimensional analysis. Miner. Eng. 2022, 184, 107629.

- Mudd, G.; Boger, D.V. The ever growing case for paste and thickened tailings—Towards more sustainable mine waste management. J. Aust. Inst. Min. Metall 2013, 2, 56–59. Available online: https://www.researchgate.net/publication/288595659 (accessed on 25 September 2023).

- Baker, E.; Davies, M.; Fourie, A.; Mudd, G.; Thygesen, K. Mine tailings facilities: Overview and industry trends. In Toward Zero Harm. A Compendium of Papers Prepared for the Global Tailings Review; Global Tailings Review: St Gallen, Switzerland, 2020; Chapter II; 135p.

- Zhang, X.; Kou, J.; Sun, C.; Zhang, R.; Su, M.; Li, S. Mineralogical characterization of copper sulfide tailings using automated mineral liberation analysis: A case study of the Chambishi Copper Mine tailings. Int. J. Miner. Metall. Mater. 2021, 28, 944.

- Patel, K.S.; Sharma, S.; Maity, J.P.; Martín-Ramos, P.; Fiket, Ž.; Bhattacharya, P.; Zhu, Y. Occurrence of uranium, thorium and rare earth elements in the environment: A review. Front. Environ. Sci. 2023, 10, 1058053.

- BRGM. Management of Mining, Quarrying and Ore-Processing Waste in the European Union. Study for DG Environment, European Commission. December 2001; 79p. Available online: https://ec.europa.eu/environment/pdf/waste/studies/mining/0204finalreportbrgm.pdf (accessed on 23 March 2023).

- Salminen, J.; Garbarino, E.; Orveillon, G.; Saveyn, H.; Mateos Aquilino, V.; Llorens González, T.; García Polonio, F.; Horckmans, L.; D’Hugues, P.; Balomenos, E.; et al. Recovery of Critical and Other Raw Materials from Mining Waste and Landfills: State of Play on Existing Practices; EUR 29744, EN; Blengini, G.A., Mathieux, F., Mancini, L., Nyberg, M., Viegas, H.M., Eds.; Publications Office of the European Union: Luxembourg, 2019; ISBN 978-92-76-08568-3.

- Balomenos, E.; Mytilineos, S.A. Bauxite residue as a resource in Europe. In Recovery of Critical and Other Raw Materials from Mining Waste and Landfills: State of Play on Existing Practices; Blengini, G.A., Mathieux, F., Mancini, L., Nyberg, M., Viegas, H.M., Eds.; Publications Office of the European Union: Luxembourg, 2019; pp. 85–90.

- Cuesta-Lopez, S.; Barros, R.; Ulla-Maija, M.; Willersinn, S.; Sheng, Y.X. Mapping the Secondary Resources in the EU (Mine Tailings, Industrial Waste). MSP-REFRAM–D3.1—Issued on 2016-05-16 12:03:16 by ICCRAM. Available online: https://ec.europa.eu/research/participants/documents/downloadPublic?documentIds=080166e5a8ca531b&appId=PPGMS (accessed on 8 November 2023).

- U.S. Environmental Protection Agency (U.S. EPA). TRI Explorer (2021 National Analysis Dataset (Released October 2022)) . 2023. Available online: https://enviro.epa.gov/triexplorer/ (accessed on 26 February 2023).

- U.S. Geological Survey, Department of the Interior. Mineral Commodity Summaries; U.S. Geological Survey: Reston, VA, USA, 2023; 210p.

- Kinnunen, P.; Karhu, M.; Yli-Rantala, E.; Kivikyto-Reponen, P.; Makinen, J. A review of circular economy strategies for mine tailings. Clean. Eng. Technol. 2022, 8, 100499.

- Cacciuttolo, C.; Atencio, E. Past, present, and future of copper mine tailings governance in Chile (1905–2022): A review in one of the leading mining countries in the world. Intl. J. Environ. Res. Public Health 2022, 19, 13060.

- Rosario-Beltré, A.J.; Sánchez-España, J.; Rodríguez-Gómez, V.; Fernández-Naranjo, F.J.; Bellido-Martín, E.; Adánez-Sanjuán, P.; Arranz-González, J.C. Critical Raw Materials recovery potential from Spanish mine wastes: A national-scale preliminary assessment. J. Clean. Prod. 2023, 407, 137163.

- Yesares, L.; González-Jiménez, J.M.; Jiménez-Cantizano, F.A.; González-Pérez, I.; Caro-Moreno, D.; Sánchez, I.M. Unveiling High-Tech Metals in Roasted Pyrite Wastes from the Iberian Pyrite Belt, SW Spain. Sustainability 2023, 15, 12081.

- Cánovas, C.R.; Macías, F.; Basallote, M.D.; Olías, M.; Nieto, J.M.; Pérez-López, R. Metal(loid) release from sulfide-rich wastes to the environment: The case of the Iberian Pyrite Belt (SW Spain). Curr. Opin. Environ. Sci. Health 2021, 20, 100240.

- Fortes, J.C.; Sarmiento, A.M.; Luis, A.T.; Santisteban, M.; Davila, J.M. Wasted Critical Raw Materials: A Polluted Environmental Scenario as Potential Source of Economic Interest Elements in the Spanish Part of the Iberian Pyrite Belt. Water Air Soil Pollut. 2021, 232, 88.

- Bonnail, E.; Vera, S.; Blasco, J.; Conradi, M.; DelValls, T.Á. Metal Pollution and Mining in the Iberian Pyrite Belt: New Remediation Technologies to Improve the Ecosystem Services of the River Basins. Water 2023, 15, 1302.

- Pan, H.; Zhou, G.; Cheng, Z.; Yang, R.; He, L.; Zeng, D.; Sun, B. Advances in geochemical survey of mine tailings project in China. J. Geochem. Explor. 2014, 139, 193–200.

- China Dialogue. Chinese Mining Dump Could Hold Trillion-Dollar Rare Earth Deposit. 14 December 2012. Available online: https://chinadialogue.net/en/pollution/5495-chinese-mining-dump-could-hold-trillion-dollar-rare-earth-deposit/ (accessed on 31 October 2023).

More