Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is a comparison between Version 2 by Rita Xu and Version 1 by Corrado SCIANCALEPORE.

Biopolymers obtained from renewable resources are an interesting alternative to conventional polymers obtained from fossil resources, as they are sustainable and environmentally friendly. Poly(lactic acid) (PLA) is a biodegradable aliphatic polyester produced from 100% renewable plant resources and plays a key role in the biopolymer market, and is experiencing ever-increasing use worldwide.

- biopolymers

- poly(lactic acid)

- polymer blends

1. Introduction

The exponential growth in global plastic manufacturing in recent years is a result of the rising world population, and is having a detrimental effect on the natural world and biodiversity [1]. As of 2020, there were 370 million tons of plastic items produced, up from a total of 1.5 million tons in 1950, and predictions show that by 2050, this percentage will have quadrupled [2,3][2][3].

Moreover, during the last 150 years, the industrial system has been based on a linear economic model involving the production of manufactured goods from fossil-based raw materials, their commercialization, utilization, and finally disposal as waste through incineration or landfill. As a result of the reduction in natural resources and the arising negative environmental impacts, this model is considered no longer sustainable for the future.

Nowadays, the production of most consumable items occurs using non-biodegradable traditional oil-based polymers, mainly polyolefins (polyethylene (PE), polypropylene (PP), polystyrene (PS)) and terephthalic-based polyesters (polyethylene terephthalate (PET)), leading to their accumulation in landfills or the Earth’s environment [4].

Back in 1970, the concept of the circular economy (CE) was introduced for the first time, as a useful industrial and political tool, for the reevaluation of global growth sustainability, changing the paradigm from a linear model, in which thinking is “produce-use-dispose”, to a new circular logic of “produce-use-reuse-recycle-value-reintegrate” [5].

This CE model involved two different types of recycling: biological and technical. Regarding biological recycling, a material of biological origin is used for anaerobic digestion, leading to benefits for the natural ecosystem. Hence, this organic material is considered a renewable resource to support the economy because this type of recycling leads to the regeneration of natural habitat characteristics of, for example, soil or marine environments. Instead, technical recycling allows the recovery of the material or product by exploiting strategies of reuse or repair until recycling is achieved [6]. The goal of this recycling type is to decrease the amount of plastic waste using destructive thermal treatment, such as combustion or pyrolysis [7].

The increasing use of polymeric materials in a wide range of industries makes it reasonable to develop an assessment to the life cycle of plastic products. Life cycle assessment (LCA) is one of the widely recognized and currently commercially available tools for assessing environmental impacts associated with all the stages of the life cycle of a commercial product [8,9][8][9]. It is based on a methodology governed by international standard 14040 and 14044 [10,11][10][11] and allows for quantifying and qualifying the relevant environmental impacts associated with the life cycle of a manufactured product, starting from preparing resources to obtain raw materials to the disposal of the manufactured product itself, through its processing, transportation, manufacturing, and end use. This review [12] reports on the large body of work analyzed to demonstrate that LCA is an important tool for evaluating how a preventive activity can reduce the environmental impact of such materials, and looks at the multiple perspectives that LCA can offer to different sectors (food packaging, agriculture, construction sector, and the automotive sector).

Also, from the perspective of sustainability, it is essential to conduct a life cycle cost analysis (LCC) with a life cycle impact assessment (LCIA). This is essential for building a techno-eco-efficient framework for comparing technical properties, environmental impacts and costs and making sure to maximize the utility and value of waste plastics in industrial applications. In the work of Jayawardane et al. [13], an LCIA and LCC evaluation was performed by comparing an artifact made by 3D printing from a PLA filament from virgin raw material and a filament derived from 100% recycled PLA. It was seen that the mechanical properties, density and hardness decreased dramatically with the content of fully recycled material compared to the virgin material. However, the manufactured product obtained from the fully recycled PLA was more eco-efficient. In tThis study, the evaluation of techno-eco-efficiency was limited to the PLA biopolymer, but this evaluation can be performed on all polymers and blend in future research and applications.

In this context, bioplastic materials have gained great interest in the plastic industry, with the resulting increment in the use of bioplastics derived from renewable sources leading to the reduction in plastic wasted in landfills, and promoting the use of renewable resources derived from agri-food scraps, which contributes to reducing the depletion of fossil resources to obtain plastic materials [14,15,16,17][14][15][16][17].

To clarify the meaning of biopolymer, the European Bioplastic Associations definition considers [18] as biopolymers both macromolecules synthesized starting from at least one monomer originating from sustainable resources and polymers that are biodegradable regardless of the origin of its raw materials [19].

In recent decades, biodegradable polymers, which can be based on either petroleum or renewable resources, are gaining attention as interesting alternatives, since through microbial degradation it is possible to reduce them into simple molecules, such as carbon dioxide (CO2), methane (CH4), water (H2O), biomass, and minerals [20]. The implementation of these new materials means that the CE model, if carefully applied, can be efficient at increasing resource efficiency, decreasing depletable or fossil raw materials, and minimizing the release of harmful substances into the environment [21].

Based on socio-economic pathways, it is necessary to formulate reduction strategies and implement policies to raise global awareness of greenhouse gas (GHG) emissions, as they are detrimental to air quality and ozone layer depletion. The Intergovernmental Panel on Climate Change in 2018 published a report proposing to limit global warming to 1.5 °C in order to avoid a range of global climate change impacts [22]. Unfortunately, GHG emissions occur at every stage of the life of plastics, including the extraction and transport of raw materials, plastic production, waste treatment and release into the environment [23]. Currently, recycling, incineration and landfill are used to manage most fossil-derived plastic waste. Data shown by Plastic Europe [24] state that the largest emissions from the incineration of plastic packaging waste were estimated at 16 million tons in 2015 and that this continued production of plastics will lead to an increase of 84 and 309 million tons by 2030 and 2050, respectively. According to the Intergovernmental Panel on Climate Change (IPCC) Working Group I [25], concentrations of CO2, CH4 and N2O have increased by 41%, 160% and 20%, respectively, since the Great Industrial Revolution, causing serious environmental imbalance problems. The GHGs released can have a negative impact on “carbon fixation” as they adversely affect the photosynthesis process carried out by “phytoplankton”, adversely affecting the natural habitat [26]. For this reason, the introduction of biobased and bio-degradable polymers, mostly of natural origin (deriving from agri-food or bacterial production waste) is essential, as they can reduce the impact of the global carbon footprint, reduce the transport of raw materials, and cancel the extraction process, as well as having a much shorter biodegradation time than conventional polymers and therefore lower GHG emissions. Indeed, if we think of the agricultural field, mulch films are frequently used for cultivation in the soil. According to a review by Somanathan et al. [27], several studies have shown that use of biodegradable polymers to make mulch films lead to rapid decomposition of the film, protection of the agricultural soil from both biotic and abiotic factors, increased yields, increased nutritional values to the soil, and maintenance of the bacterial population in the soil without polluting it.

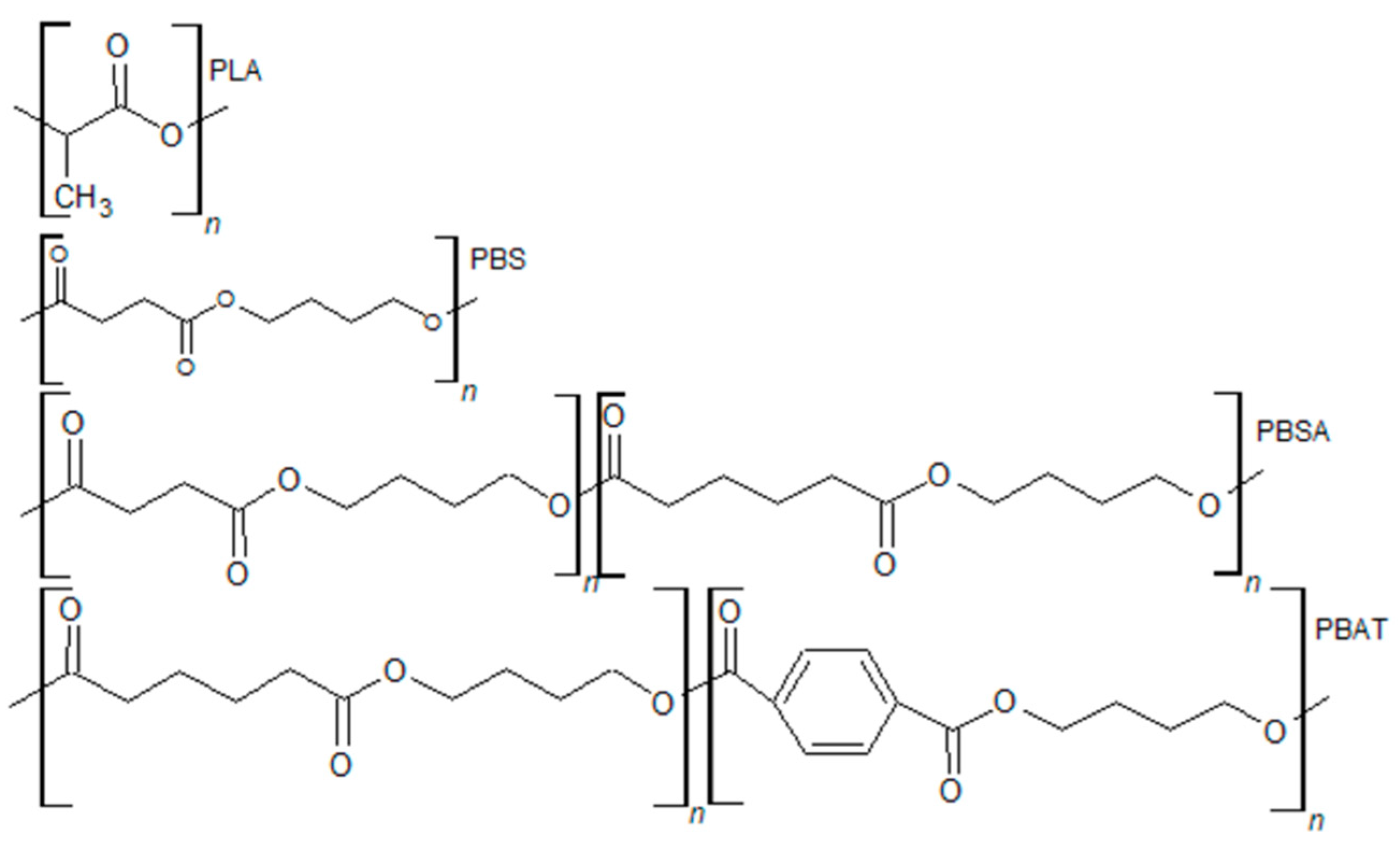

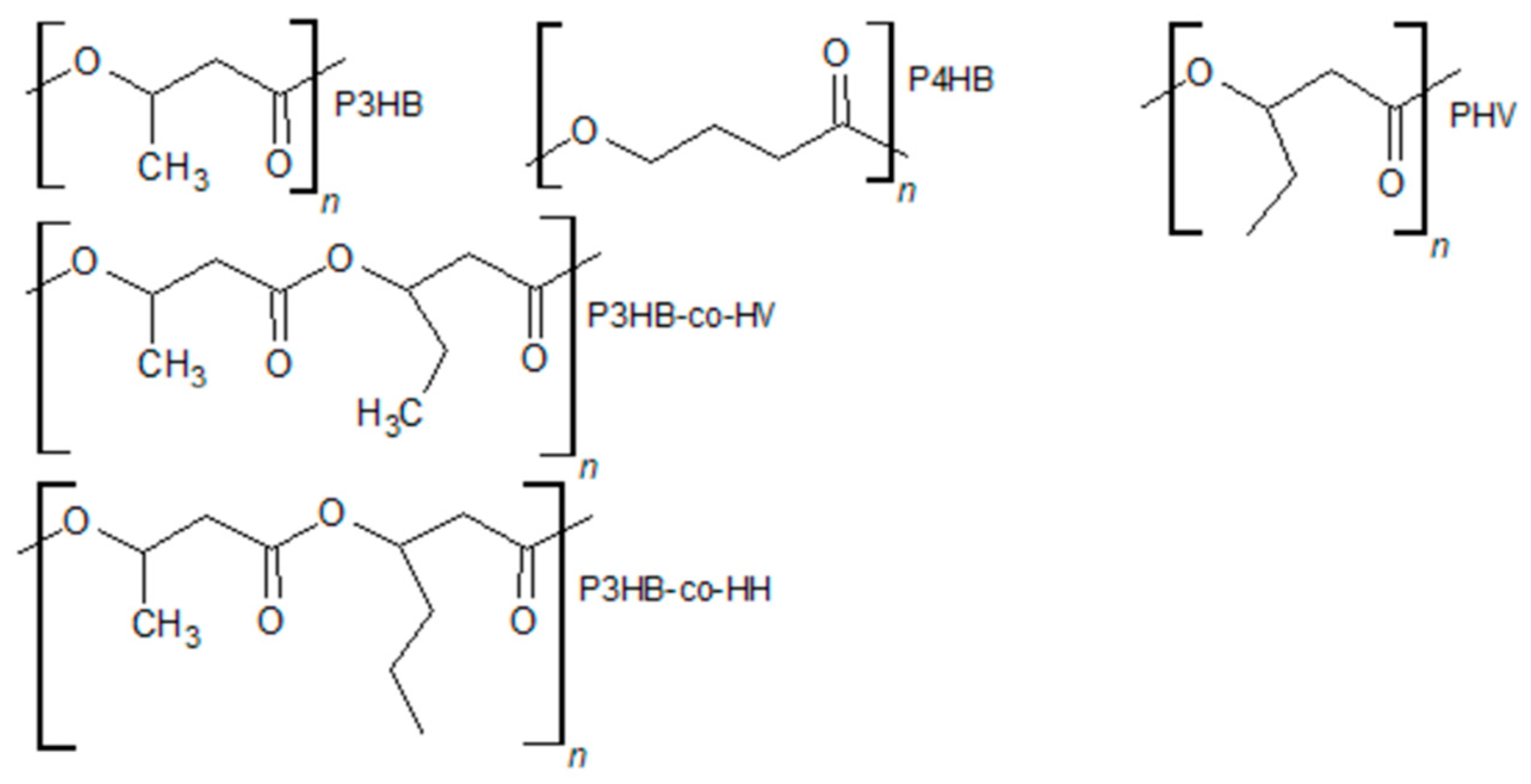

Regarding biodegradable polymers, one of the most studied classes is aliphatic polyesters, due to their wide variety of properties and synthetic versatility. In this class, poly(lactic acid) (PLA), poly(butylene-succinate) (PBS), poly(butylene-succinate-co-adipate) (PBSA), and poly(butylene adipate-co-terephthalate) (PBAT) are included (Figure 1). Lately, an emerging class of biopolymers of great interest is bacterial-origin polymers such as the poly(hydroxy alkanoates) (PHAs) (Figure 2).

Figure 1. Biodegradable aliphatic polyesters structures.

Figure 2. Different PHA structures.

In this case, the polymers are prepared directly from biomass exploitation, for example, genetically modified microorganisms. PHAs are produced directly through fermentation of the carbon-containing substrate within the microorganism cells. The type of biomass used as an energy source depends on the microorganisms employed. For instance, it is well established in the literature that for E. coli, lipids and polysaccharides are generally used, while for R. eutropha, glucose is used as a carbon source [28]. PHA accumulates in granule form within the cell cytoplasm, acting as an energy reserve for the cell.

The issue with these biopolymers is that, when used alone as structural materials, they fail to meet the requirements of traditional polymers such as PP, PE, or PET.

Polymer blends are widely used in industry since they allow combining the properties of its components into a new material, without the need to design and develop a new polymer, which would be much more expensive and time consuming. Thus, by modifying the composition of blends, materials with properties suitable for various applications can be obtained [29,30][29][30].

2. Packaging Application of PLA and Its Blends

Most of the plastic packaging and containers are made with polyethylene (PE), polypropylene (PP), polyethylene terephthalate (PET), polystyrene (PS), polyamides (PA) and polyvinyl chloride (PVC), derived from non-renewable and non-biodegradable petrochemical sources. In recent years, global plastic production has reached about 400 million tons per year and this represents an important source of waste [31]. More than 50% of this plastic packaging is used only one time before disposal [32]. Moreover, many traditional polymers are used to make multilayer, laminated, and mixed packaging in which aluminum foil or silica is inserted in the middle layer to improve barrier properties. At their end of life, only a small fraction of this waste is recycled as the multilayer separation process is expensive and a large part of plastic waste, especially from the food packaging sector, is disposed of in landfills. Furthermore, foodstuffs often contaminate the plastic containers, making their reuse or recycling process even less economically convenient and creating large quantities of waste at the end of its life, without energy and material recovery [33,34,35][33][34][35]. Currently, many biobased but non-biodegradable polymers are used in flexible and rigid packaging (e.g., bags and bottles) and are synthesized from renewable resources, such as Bio-PE, biopropylene (Bio-PP) or biopolyethylene terephthalate (Bio-PET) [36,37,38][36][37][38]. They have a greater application in the food industry than biodegradable and compostable biopolymers as they have the same properties and processing methods as conventional polymers and are therefore well known to the industry [39]. The problem with these bioplastics is that, even if they are derived from renewable resources, they are not biodegradable and therefore do not best meet the requirements of a sustainable circular economy. When considering the applications of short-life packaging (fruit, vegetables, and salad containers), disposable packaging for fresh food and ready meals and hygiene products, which do not require high barriers, these biobased but non-biodegradable bioplastics (Bio-PE, Bio-PP and Bio-PET) pose a major problem of management and disposal as they are used in large quantities in everyday life. One solution regarding the production of single-use and short-life packaging that is also eco-friendly are biodegradable and compostable bioplastics, which can play a crucial role in and have great potential for production from flexible films to rigid plastics, as they combine a renewable origin and the prerequisite of biodegradable end-of-life due to their susceptibility to microbial attack [40,41][40][41]. In food and non-food packaging applications, the most widely used biopolymers are PLA, PBS, PBSA, and PBAT, as well as the newly emerging class of PHAs. The function of food packaging is not only to contain the food but also to protect it throughout its supply chain (from the place of production to the table) from external abiotic and biotic agents by preventing chemical or microbiological contamination that can cause adulteration, as well as to increase shelf life [42,43,44][42][43][44]. This has generated the need in the food industry to develop new packaging systems to maintain both the safety and quality of packaged food [45]. The essential prerogatives that packaging needs vary according to different applications and uses. Among the most common properties are barriers to gases (CO2, N2, O2, or volatile compounds) and moisture, useful mechanical properties (flexible or rigid), sealing and thermo-perforation, processability and heat stability, transparency or opacity depending on the application, anti-fog, printability, and resistance to light, acids and grease, and, as the last but not the least important factor, the cost [46,47][46][47]. The changes in mechanical properties will be covered in the review, so we will also mention the other prerogatives to emphasize the importance they have for an application. As is well known, PLA has several benefits for these applications, as it is easy to process, transparent, has a high disintegration rate in compost, is nontoxic, and inexpensive, and has therefore been approved as a direct food contact material, and is currently being used to produce packaging for short-term applications. In addition, this biopolymer is in demand for a wide range of industries such as agricultural, medical, and pharmaceutical (e.g., drug delivery). Studies have reported that currently PLA and the rest of the biopolymers are used more for packaging short-life products that do not require a high barrier to gases and water vapor. PLA has a low heat deflection temperature, which is an excellent prerequisite for making food packages stored in freezers under refrigerated conditions [48]. Due to this property of PLA, there is no deformation of the packaging, which is why currently PLA is also used to produce thermoformed trays and to transport fruits and organic products in a refrigerated condition. However, this represents a limitation if one wants to broaden the range of applications in food packaging because, as explained, PLA has several problems compared to conventional polymers derived from oil resources that make it non-performing in several applications. As previously described, this biopolymer is characterized by low thermal, mechanical and gas barrier properties that are essential for food packaging to ensure its safety and preservation [49]. Therefore, an efficient and cost-effective solution to achieve desirable properties for films and packaging materials is blending with other biodegradable polymers, as it represents a valid strategy to increase and modulate their desired properties. More complex multilayer systems are still used on the market today, but they are largely made of conventional polymers, which pose a recycling and disposal problem [50]. The realization of a multilayer material consisting of only biodegradable or compostable biopolymers by means of an eco-friendly processing technology can lead to significant improvements not only in the final properties but also of the disposal benefits if the domestic compostability prerequisite is achieved, contributing to solve the problem of waste accumulation in landfills [51]. When considering barrier properties, an essential prerequisite for a food packaging material, it is known that most biodegradable biopolymers have lower moisture barrier properties than conventional plastics due to their chemical structure, but unlike them they exhibit similar oxygen barrier properties [52]. Therefore, the first applications to which this class of biopolymers is referred are food and short-life products. PLA exhibits low crystallinity and thus poor gas barrier properties [53], except for a lower oxygen transmission rate (OTR) than PET and PS [54]. If we think of moisture-sensitive products such as biscuits and bakery products, it is impossible to apply PLA-only packaging in this case [55]. Various methods are exploited in industry to improve the barrier properties of PLA, such as lamination with barrier materials, such as PP, PE and EVOH [55[55][56],56], or coating with silica dioxide (SiOx) and aluminum dioxide (AlOx) [56,57][56][57]. NatureWorks in collaboration with Metalvuoto have produced the first flexible, high-barrier PLA-based material that can be used for long-life foodstuffs. As a result, much academic and industrial effort has been put into increasing the crystallinity of PLA and making the material as eco-friendly as possible. Among the PHAs, PHB and PHBV have high crystallinity and thus good barrier properties towards O2, CO2 and moisture, similar to PE or PP [58,59,60][58][59][60]. Therefore, fusion with the PLA matrix can provide good gas barrier performance as well as adjusting its physical properties [61,62,63,64][61][62][63][64]. Furthermore, the production of PHAs is very expensive due to the fermentation and purification processes, so blending them with PLA can also lead to cost benefits [65,66][65][66]. From the point of view of barrier properties, Luzi et al. [67] formulated different mixtures of PLA/PBS (10, 20 and 30 wt%) to which cellulose nanocrystals (CNC) were added. The combination of both with PLA resulted in improved oxygen barrier properties, and the formulation with 77PLA/20PBS/3CNC was the best formulation, as it exhibited a 47% decrease in oxygen permeability. Furthermore, the migration levels of all composites produced were below European legislative limits and, therefore, they are useful as food packaging materials. Still in the area of food packaging for active packaging in direct contact with food, Songtipya et al. [68] studied different PLA/PBAT formulations for packaging and containers in direct contact with ground coffee and tea leaves. The study showed that the total migration values were below the maximum migration limit (10 mg/dm2) imposed by European Union (EU) regulations. Therefore, these PLA- and PBAT-based materials may have a positive effect on food safety. Hongsriphan and Sanga [69], after producing a PLA/PBS blend (90/10 wt%), developed an antibacterial food packaging towards E. coli and S. aureus by coating the PLA/PBS film with chitosan. It was observed that as the concentration of chitosan on the surface increased, from 0.25 to 2% w/v, bacterial growth decreased. The chitosan coating also decreased water vapor transmission rates compared to normal mixtures. This favorable phenomenon is due to the formation of intermolecular interactions between the chitosan and the polymer matrix. The literature shows that biopolymers belonging to the PHA family were initially used for applications in cosmetics and articles for everyday use (such as vials, bottles, and containers) [70,71][70][71]. Today, they are also proposed for applications in short-term food packaging [59,72,73,74][59][72][73][74], medical devices and tissue regeneration, household goods, hygiene products and compostable bags due to their mechanical properties, biocompatibility, and biodegradability [75,76,77][75][76][77]. Food manufacturers such as Nestlé (Vevey, Switzerland) and PepsiCo (New York, NY, USA), in collaboration with Danimer Scientific (Bainbridge, NY, USA) and Kaneca (Tokyo, Japan) (leading manufacturers of biodegradable plastics), have developed PHA-based water bottles and flexible packaging for their snacks [78,79][78][79]. Concerning PepsiCo, the goal was to make the final artefact home-compostable by adding PHA to PLA and to improve certain properties, such as the sound of a bag of chips when opened. The Taghleef Industries company (Dubai, United Arab Emirates) is involved in the production of PLA-based films: for example the NATIVIA portfolio of PLA films is in the market for different packaging applications, like bread bags, coffee capsules, frozen food, labels, fashion and luxury products, and so on. But in recent years it has been collaborating with leading biopolymer manufacturers to make PLA-based films mixed with different biopolymers, and thus make the film home compostable rather than industrially compostable [80]. Also, in 2019 Danimer Scientific collaborated with UrthPact (Leominster, MA, USA) to produce edible straws using the biopolymer NodaxTM. In addition, PHAs are also used to produce waste bags in which PHA film is laminated with paper and other polymers such as PVC [77]. The company Rivoira (a fruit producer and distributor, Verzuolo, Italy) in cooperation with Bio-On (Bologna, Italy) have created the company Zeropack (Bologna, Italy) to produce 100% natural and biodegradable PHA-based films, containers, and holders for fruit and labels [81]. As reported by the authors of [51[51][82],82], mixing PLA with PHB at 25 wt% resulted in an improvement in the oxygen and water barrier properties of a film, while at the same time reducing the transparency of the final film (an intrinsic property of PLA). The appearance and quality of the final packaging is a second essential prerequisite that can influence the buyer of a product during purchase, as it is essential to see through the packaging [47,49][47][49]. Since PLA is transparent, it is used as a single-layer packaging film, as biaxially oriented PLA (BOPLA) or in laminated films (barrier films) [55]. Another essential prerequisite is the cost of the final product. Regarding rigid packaging, PLA and PHA are stiffer than PS and therefore less plastic material would be required to produce the final manufactured product with the same stiffness, thus resulting in a lower final price [83]. In the agricultural sector, mulching is a widely used practice worldwide to maximize plant growth, allow water retention, regulate soil temperature, and protect agricultural soil from weeds. Normally, mulching films are made of PE and this has caused serious environmental problems as they are difficult to recycle and dispose of. This is why farmers prefer to leave the films in the fields and then burn them [84]. This procedure leads to negative effects that affect both crop growth, the environment and soil, as the accumulation of these films leads to a reduction in soil porosity as well as groundwater pollution [85]. Since biopolymers are non-toxic, biodegradable, and compostable, they are promising materials for mulching films as they can be degraded [86,87][86][87] and catabolized by the soil microbiota at their end of life [88]. Therefore, mulching films based on PHBH (NodaxTM) and PHB (MirelTM) have been produced [89,90][89][90]. In the work of Gao et al. [91], they produced mulching films based on PLA mixed with PBAT and directly field-tested these films on potato growth over a two-year period. They evaluated the effects on soil temperature dynamics and water retention and saw that crop yields did not change compared to the use of a PE-based film. They also evaluated the effects of the films during degradation in agricultural soils and the authors are very confident on the application of these films because in addition to improved crop yields, porosity and soil health also improved. BASF is promoting a PLA/PBAT blend, called Ecovio, for agricultural films [48]. In the work of Jandas et al. [92], they obtained mulching films by blending PLA with PHB and using maleic anhydride as a compatibilizer to improve polymer interaction. The addition of PHB to PLA not only improved the flexibility and impact strength of PLA, but also decreased the degradation time of PLA. Therefore, applied tests suggested that this type of film can be applied for short-term harvests (100–150 days). Furthermore, PHA is biodegradable in water, which is why Havens et al. [93] patented a fishing gear made partly of PHA that can biodegrade in a marine environment. In the biomedical field, these biopolymers and their blends have been extensively studied in various applications such as bone scaffolds and implants [94], sutures, drug delivery systems [95,96,97,98][95][96][97][98] and in tissue engineering [99,100,101][99][100][101]. This is due to their excellent properties such as biocompatibility, bioresorbability, biodegradability and non-toxicity. For example, polymer scaffolds provide sites for regeneration and functional restoration of tissues and for drug delivery. They require specific characteristics depending on the application and the tissue of interest. The key point of these biopolymer scaffolds is that once they have performed their restorative or structural function they biodegrade, eliminating the need for patient surgery [102]. By means of FDM printing and electrospinning, it is possible to produce different types of porous scaffolds useful for tissue regeneration due to the presence of pores that allow the transport of nutrients, oxygen and growth factors [103,104,105,106][103][104][105][106]. PLA has been blended with PHB to enhance its bioactivity and cell proliferation for medical use such as artificial muscles, wound dressings or drug delivery systems. An important field of application for PLA-based blends is that of intelligent materials capable of responding to different stimuli. With PLA/PHB blends, a system called ‘non-woven fabric’, that showed a controllable, thermally induced shape memory effect, is realized [107]. He et al. [108] formulated various PLA/PHBH and PLA/PHBV blends for the fabrication of medical sutures. Their results showed that these blends can be used as medical sutures as they had high tensile strength, good elasticity, and biocompatibility.References

- Persson, L.; Carney Almroth, B.M.; Collins, C.D.; Cornell, S.; de Wit, C.A.; Diamond, M.L.; Fantke, P.; Hassellöv, M.; MacLeod, M.; Ryberg, M.W.; et al. Outside the Safe Operating Space of the Planetary Boundary for Novel Entities. Environ. Sci. Technol. 2022, 56, 1510–1521.

- Thew, C.X.E.; Lee, Z.S.; Srinophakun, P.; Ooi, C.W. Recent Advances and Challenges in Sustainable Management of Plastic Waste Using Biodegradation Approach. Bioresour. Technol. 2023, 374, 128772.

- Goswami, M.; Rekhi, P.; Debnath, M.; Ramakrishna, S. Microbial Polyhydroxyalkanoates Granules: An Approach Targeting Biopolymer for Medical Applications and Developing Bone Scaffolds. Molecules 2021, 26, 860.

- Barnes, D.K.A.; Galgani, F.; Thompson, R.C.; Barlaz, M. Accumulation and Fragmentation of Plastic Debris in Global Environments. Philos. Trans. R. Soc. B Biol. Sci. 2009, 364, 1985–1998.

- Carus, M.; Dammer, L. The Circular Bioeconomy-Concepts, Opportunities, and Limitations. Ind. Biotechnol. 2018, 14, 83–91.

- WEF_The_New_Plastics_Economy. World Economic Forum. Available online: https://www.weforum.org/publications/the-new-plastics-economy-rethinking-the-future-of-plastics/ (accessed on 1 June 2023).

- A Sustainable Bioeconomy for Europe: Strengthening the Connection between Economy, Society and the Environment Updated Bioeconomy Strategy. Available online: https://op.europa.eu/en/publication-detail/-/publication/edace3e3-e189-11e8-b690-01aa75ed71a1/language-en (accessed on 15 June 2023).

- Ingrao, C.; Lo Giudice, A.; Bacenetti, J.; Mousavi Khaneghah, A.; Sant’Ana, A.d.S.; Rana, R.; Siracusa, V. Foamy Polystyrene Trays for Fresh-Meat Packaging: Life-Cycle Inventory Data Collection and Environmental Impact Assessment. Food Res. Int. 2015, 76, 418–426.

- Dassisti, M.; Intini, F.; Chimienti, M.; Starace, G. Thermography-Enhanced LCA (Life Cycle Assessment) for Manufacturing Sustainability Assessment. The Case Study of an HDPE (High Density Polyethylene) Net Company in Italy. Energy 2016, 108, 7–18.

- ISO 14040:2006; Environmental Management Life Cycle Assessment Principles and Framework. ISO (International Organization for Standardization): Geneva, Switzerland, 2006.

- ISO 14044:2006; Environmental Management Life Cycle Assessment Requirements and Guidelines. ISO (International Organization for Standardization): Geneva, Switzerland, 2006.

- Blanco, I.; Ingrao, C.; Siracusa, V. Life-Cycle Assessment in the Polymeric Sector: A Comprehensive Review of Application Experiences on the Italian Scale. Polymers 2020, 12, 1212.

- Jayawardane, H.; Davies, I.J.; Gamage, J.R.; John, M.; Biswas, W.K. Additive Manufacturing of Recycled Plastics: A ‘Techno-Eco-Efficiency’ Assessment. Int. J. Adv. Manuf. Technol. 2023, 126, 1471–1496.

- Gandini, A.; Lacerda, T.M. From Monomers to Polymers from Renewable Resources: Recent Advances. Prog. Polym. Sci. 2015, 48, 1–39.

- Wang, Z.; Ganewatta, M.S.; Tang, C. Sustainable Polymers from Biomass: Bridging Chemistry with Materials and Processing. Prog. Polym. Sci. 2020, 101, 101197.

- Saxon, D.J.; Luke, A.M.; Sajjad, H.; Tolman, W.B.; Reineke, T.M. Next-Generation Polymers: Isosorbide as a Renewable Alternative. Prog. Polym. Sci. 2020, 101, 101196.

- Zhang, C.; Garrison, T.F.; Madbouly, S.A.; Kessler, M.R. Recent Advances in Vegetable Oil-Based Polymers and Their Composites. Prog. Polym. Sci. 2017, 71, 91–143.

- Nanda, S.; Patra, B.R.; Patel, R.; Bakos, J.; Dalai, A.K. Innovations in Applications and Prospects of Bioplastics and Biopolymers: A Review. Environ. Chem. Lett. 2022, 20, 379–395.

- Vroman, I.; Tighzert, L. Biodegradable Polymers. Materials 2009, 2, 307–344.

- Carus, M.; Dammer, L.; Raschka, A.; Skoczinski, P.; vom Berg, C. Renewable Carbon—Key to a Sustainable and Future-Oriented Chemical and Plastic Industry. Greenhouse Gas Sci Technol 2020, 10, 488–505.

- Greene, J. Marine Biodegradation of PLA, PHA, and Bio-Additive Polyethylene Based on ASTM D7081. Available online: www.academia.edu/9639333/Marine_Biodegradation_of_PLA_PHA_and_Bio_additive_Polyetylene_Based_on_ASTM_D7081 (accessed on 10 June 2023).

- IPCC. Special Report on Global Warming of 1.5 °C. 2018. Available online: https://www.ipcc.ch/sr15 (accessed on 10 June 2023).

- Royer, S.J.; Ferrón, S.; Wilson, S.T.; Karl, D.M. Production of Methane and Ethylene from Plastic in the Environment. PLoS ONE 2018, 13, e0200574.

- PlasticsEurope. Plastics the Facts 2016. 2016. Available online: https://www.plasticseurope.org/en/resources/publications/3-plastics-facts-2016 (accessed on 1 July 2023).

- Working Group I of the IPCC. Climate Change 2013: The Physical Science Basis. Contr. Work 2013, 43, 866–871. Available online: https://www.ipcc.ch/report/ar5/wg1/ (accessed on 10 July 2023).

- Nolte, T.M.; Hartmann, N.B.; Kleijn, J.M.; Garnæs, J.; van de Meent, D.; Jan Hendriks, A.; Baun, A. The Toxicity of Plastic Nanoparticles to Green Algae as Influenced by Surface Modification, Medium Hardness and Cellular Adsorption. Aquat. Toxicol. 2017, 183, 11–20.

- Somanathan, H.; Sathasivam, R.; Sivaram, S.; Mariappan Kumaresan, S.; Muthuraman, M.S.; Park, S.U. An Update on Polyethylene and Biodegradable Plastic Mulch Films and Their Impact on the Environment. Chemosphere 2022, 307, 135839.

- Snell, K.D.; Peoples, O.P. Polyhydroxyalkanoate Polymers and Their Production in Transgenic Plants. Metab. Eng. 2002, 4, 29–40.

- Utracki, L.A. History of Commercial Polymer Alloys and Blends (From a Perspective of the Patent Literature). Polym. Eng. Sci. 1995, 35, 2–17.

- Guo, Q. Polymer Morphology; John Wiley & Sons: Hoboken, NJ, USA, 2016; p. 464.

- Plastic in the Ocean Statistics. 2020. Available online: https://www.condorferries.co.uk/plastic-in-the-ocean-statistics (accessed on 15 July 2023).

- Hopewell, J.; Dvorak, R.; Kosior, E. Plastics Recycling: Challenges and Opportunities. Philos. Trans. R. Soc. B Biol. Sci. 2009, 364, 2115–2126.

- Gross, M. Our Planet Wrapped in Plastic. Curr. Biol. 2017, 27, R785–R788.

- Briassoulis, D.; Dejean, C. Critical Review of Norms and Standards for Biodegradable Agricultural Plastics Part I. Biodegradation in Soil. J. Polym. Environ. 2010, 18, 384–400.

- Avérous, L. Biodegradable Multiphase Systems Based on Plasticized Starch: A Review. J. Macromol. Sci. Polym. Rev. 2004, 44, 231–274.

- Garcia-Garcia, D.; Carbonell-Verdu, A.; Jordá-Vilaplana, A.; Balart, R.; Garcia-Sanoguera, D. Development and Characterization of Green Composites from Bio-Based Polyethylene and Peanut Shell. J. Appl. Polym. Sci. 2016, 133, 43940.

- Briassoulis, D.; Giannoulis, A. Evaluation of the Functionality of Bio-Based Food Packaging Films. Polym. Test. 2018, 69, 39–51.

- Jariyasakoolroj, P.; Leelaphiwat, P.; Harnkarnsujarit, N. Advances in Research and Development of Bioplastic for Food Packaging. J. Sci. Food Agric. 2020, 100, 5032–5045.

- European Bioplastics: Benefits of Biobased Rigid Packaging. Available online: https://docs.european-bioplastics.org/2016/publications/bp/EUBP_bp_Rigid_Packaing.pdf (accessed on 20 July 2023).

- Peelman, N.; Ragaert, P.; De Meulenaer, B.; Adons, D.; Peeters, R.; Cardon, L.; Van Impe, F.; Devlieghere, F. Application of Bioplastics for Food Packaging. Trends Food Sci. Technol. 2013, 32, 128–141.

- Stloukal, P.; Kalendova, A.; Mattausch, H.; Laske, S.; Holzer, C.; Koutny, M. The Influence of a Hydrolysis-Inhibiting Additive on the Degradation and Biodegradation of PLA and Its Nanocomposites. Polym. Test. 2015, 41, 124–132.

- Castro López, M.D.M.; Dopico García, S.; Ares Pernas, A.; López Vilariño, J.M.; González Rodríguez, M.V. Effect of PPG-PEG-PPG on the Tocopherol-Controlled Release from Films Intended for Food-Packaging Applications. J. Agric. Food Chem. 2012, 60, 8163–8170.

- Arrieta, M.P.; Fortunati, E.; Dominici, F.; López, J.; Kenny, J.M. Bionanocomposite Films Based on Plasticized PLA-PHB/Cellulose Nanocrystal Blends. Carbohydr. Polym. 2015, 121, 265–275.

- Souza, V.G.L.; Fernando, A.L. Nanoparticles in Food Packaging: Biodegradability and Potential Migration to Food-A Review. Food Packag. Shelf Life 2016, 8, 63–70.

- Jin, T.; Zhang, H. Biodegradable Polylactic Acid Polymer with Nisin for Use in Antimicrobial Food Packaging. J. Food Sci. 2008, 73, M127–M134.

- Weber, C.J. Biobased Packaging Materials for the Food Industry: Status and Perspectives, A European Concerted Action; KVL. 2000. Available online: http://www.biodeg.net/fichiers/Book%20on%20biopolymers%20(Eng).pdf (accessed on 20 July 2023).

- Rhim, J.W.; Park, H.M.; Ha, C.S. Bio-Nanocomposites for Food Packaging Applications. Prog. Polym. Sci. 2013, 38, 1629–1652.

- Sustainable Biopolymers: A BCC Research Outlooks; Global Sustainable Biopolymers Market: Growth Research Report; BCC Publishing: Wellesley, MA, USA, 2019; Available online: bccresearch.com (accessed on 1 October 2023).

- Arrieta, M.P.; López, J.; Ferrándiz, S.; Peltzer, M.A. Characterization of PLA-Limonene Blends for Food Packaging Applications. Polym. Test. 2013, 32, 760–768.

- Lagaron, J.M.; Lopez-Rubio, A. Nanotechnology for Bioplastics: Opportunities, Challenges and Strategies. Trends Food Sci. Technol. 2011, 22, 611–617.

- Arrieta, M.P.; Samper, M.D.; López, J.; Jiménez, A. Combined Effect of Poly(hydroxybutyrate) and Plasticizers on Polylactic Acid Properties for Film Intended for Food Packaging. J. Polym. Environ. 2014, 22, 460–470.

- Pandey, A.; Kumar, P.; Singh, V. Applications of bioplastics in Bulk Packaging: A Revolutionary and Sustainable Approach. Trends Food Sci. Technol. 2010, 32, 128–141.

- Arrieta, M.P. Films de PLA y PLA-PHB Plastificados para su Aplicacion en Envases de Alimentos. Caracterizacion y Analisis de los Procesos de Degradacion. Ph.D. Thesis, Universitat Politecnica de Valencia, Valencia, Spain, 2014.

- Siracusa, V. Food Packaging Permeability Behaviour: A Report. Int. J. Polym. Sci. 2012, 2012, 302029.

- Kumar, Y.; Shukla, P.; Singh, P.; Prabhakaran, P.P.; Tanwar, V.K.; Kumar, Y. Bio-Plastics: A Perfect Tool for Eco-Friendly Food Packaging: A Review. J. Food Prod. Dev. Packag. 2014, 1, 1–6.

- Best of Plastics: Barrier Packaging. Available online: http://exclusive.multibriefs.com/content/best-of-plastics-barrier-packaging/engineering (accessed on 20 July 2023).

- Naitove, M. Conference Report: Bioplastics are Breaking Out of Their “Green” Niche. Plast. Technol. 2012, 58, 13–17.

- Garcia-Garcia, D.; Rayón, E.; Carbonell-Verdu, A.; Lopez-Martinez, J.; Balart, R. Improvement of the Compatibility between Poly(3-Hydroxybutyrate) and Poly(ε-Caprolactone) by Reactive Extrusion with Dicumyl Peroxide. Eur. Polym. J. 2017, 86, 41–57.

- Bucci, D.Z.; Tavares, L.B.B.; Sell, I. Biodegradation and Physical Evaluation of PHB Packaging. Polym. Test. 2007, 26, 908–915.

- Jost, V.; Langowski, H.C. Effect of Different Plasticisers on the Mechanical and Barrier Properties of Extruded Cast PHBV Films. Eur. Polym. J. 2015, 68, 302–312.

- González-Ausejo, J.; Sánchez-Safont, E.; Lagarón, J.M.; Balart, R.; Cabedo, L.; Gámez-Pérez, J. Compatibilization of Poly(3-Hydroxybutyrate-Co-3-Hydroxyvalerate)–Poly(Lactic Acid) Blends with Diisocyanates. J. Appl. Polym. Sci. 2017, 134, 44806.

- Arrieta, M.P.; Fortunati, E.; Dominici, F.; Rayón, E.; López, J.; Kenny, J.M. PLA-PHB/Cellulose Based Films: Mechanical, Barrier and Disintegration Properties. Polym. Degrad. Stab. 2014, 107, 139–149.

- Ferri, J.M.; Fenollar, O.; Jorda-Vilaplana, A.; García-Sanoguera, D.; Balart, R. Effect of Miscibility on Mechanical and Thermal Properties of Poly(Lactic Acid)/ Polycaprolactone Blends. Polym. Int. 2016, 65, 453–463.

- Zhang, M.; Thomas, N.L. Blending Polylactic Acid with Polyhydroxybutyrate: The Effect on Thermal, Mechanical, and Biodegradation Properties. Adv. Polym. Technol. 2011, 30, 67–79.

- Snell, K.D.; Peoples, O.P. PHA Bioplastic: A Value-Added Coproduct for Biomass Biorefineries. Biofuels Bioprod. Biorefin. 2009, 3, 456–467.

- Levett, I.; Birkett, G.; Davies, N.; Bell, A.; Langford, A.; Laycock, B.; Lant, P.; Pratt, S. Techno-Economic Assessment of Poly-3-Hydroxybutyrate (PHB) Production from Methane—The Case for Thermophilic Bioprocessing. J. Environ. Chem. Eng. 2016, 4, 3724–3733.

- Luzi, F.; Fortunati, E.; Jiménez, A.; Puglia, D.; Pezzolla, D.; Gigliotti, G.; Kenny, J.M.; Chiralt, A.; Torre, L. Production and Characterization of PLA_PBS Biodegradable Blends Reinforced with Cellulose Nanocrystals Extracted from Hemp Fibres. Ind. Crops Prod. 2016, 93, 276–289.

- Songtipya, L.; Limchu, T.; Phuttharak, S.; Songtipya, P.; Kalkornsurapranee, E. Poly(lactic acid)-Based Composites Incorporated with Spent Coffee Ground and Tea Leave for Food Packaging Application: A Waste to Wealth. IOP Conf. Ser. Mater. Sci. Eng. 2019, 553, 012047.

- Hongsriphan, N.; Sanga, S. Antibacterial Food Packaging Sheets Prepared by Coating Chitosan on Corona-Treated Extruded Poly(lactic acid)/Poly(butylene succinate) Blends. J. Plast. Film Sheeting 2018, 34, 160–178.

- Barrett, A. Frost & Sullivan Awards Bio-On for Best Cosmetic Innovation. 2018. Available online: https://bioplasticsnews.com/2018/10/08/frost-sullivan-awards-bio-best-cosmetic-innovation/ (accessed on 25 July 2023).

- Volova, T.G. Polyhydroxyalkanoates Plastic Materials of the 21st Century: Production, Properties and Application, 1st ed.; Nova Science Publishers: New York, NY, USA, 2004; pp. 206–207.

- Vandewijngaarden, J.; Wauters, R.; Murariu, M.; Dubois, P.; Carleer, R.; Yperman, J.; D’Haen, J.; Ruttens, B.; Schreurs, S.; Lepot, N.; et al. Poly(3-Hydroxybutyrate-Co-3-Hydroxyhexanoate)/Organomodified Montmorillonite Nanocomposites for Potential Food Packaging Applications. J. Polym. Environ. 2016, 24, 104–118.

- Qiu, Y.; Fu, J.; Sun, B.; Ma, X. Sustainable Nanocomposite Films Based on SiO2 and Biodegradable Poly(3-Hydroxybutyrate-Co-3-Hydroxyhexanoate) (PHBH) for Food Packaging. E-Polymers 2021, 21, 72–81.

- Yeo, J.C.C.; Muiruri, J.K.; Thitsartarn, W.; Li, Z.; He, C. Recent Advances in the Development of Biodegradable PHB-Based Toughening Materials: Approaches, Advantages and Applications. Mater. Sci. Eng. C 2018, 92, 1092–1116.

- Wu, Q.; Wang, Y.; Chen, G.Q. Medical Application of Microbial Biopolyesters Polyhydroxyalkanoates. Artif. Cells Blood Substit. Biotechnol. 2009, 37, 1–12.

- Chen, G.Q. A Microbial Polyhydroxyalkanoates (PHA) Based Bio- and Materials Industry. Chem. Soc. Rev. 2009, 38, 2434–2446.

- Chang, H.M.; Wang, Z.H.; Luo, H.N.; Xu, M.; Ren, X.Y.; Zheng, G.X.; Wu, B.J.; Zhang, X.H.; Lu, X.Y.; Chen, F.; et al. Poly(3-Hydroxybutyrate-Co-3-Hydroxyhexanoate)- Based Scaffolds for Tissue Engineering. Braz. J. Med. Biol. Res. 2014, 47, 533–539.

- PepsiCo, Danimer in PHA Collaboration. Available online: https://greenchemicalsblog.com/2017/03/01/pepsico-danimer-in-pha-collaboration/ (accessed on 1 October 2023).

- Kourmentza, K.; Kachrimanidou, V.; Psaki, O.; Pateraki, C.; Ladakis, D.; Koutinas, A. Competitive Advantage and Market Introduction of PHA Polymers and Potential use of PHA Monomers. In The Handbook of Polyhydroxyalkanoates; Koller, M., Ed.; CRC Press: Boca Raton, FL, USA, 2020; pp. 168–201.

- Nativia Project of Taghleef Industries. Available online: https://www.ti-films.com/brands/nativia/ (accessed on 1 October 2023).

- Bio-On and Rivoira Present Zeropack, Bioplastic for Food Packaging of Fruits and Vegetables. Available online: https://www.gualapack.com/sustainability-portfolio (accessed on 10 October 2023).

- Arrieta, M.P.; López, J.; Hernández, A.; Rayón, E. Ternary PLA-PHB-Limonene Blends Intended for Biodegradable Food Packaging Applications. Eur. Polym. J. 2014, 50, 255–270.

- Van Den Oever, M.; Molenveld, K.; Van Der Zee, M.; Bos, H. Bio-Based and Biodegradable Plastics-Facts and Figures Focus on Food Packaging in the Netherlands; Wageningen Food & Biobased Research: Wageningen, The Netherlands, 2017.

- Sintim, H.Y.; Flury, M. Is Biodegradable Plastic Mulch the Solution to Agriculture’s Plastic Problem? Environ. Sci. Technol. 2017, 51, 1068–1069.

- Hu, Q.; Li, X.; Gonçalves, J.M.; Shi, H.; Tian, T.; Chen, N. Effects of Residual Plastic-Film Mulch on Field Corn Growth and Productivity. Sci. Total Environ. 2020, 729, 138901.

- Sciancalepore, C.; Togliatti, E.; Giubilini, A.; Pugliese, D.; Moroni, F.; Messori, M.; Milanese, D. Preparation and Characterization of Innovative Poly(butylene adipate terephthalate)-Based Biocomposites for Agri-Food Packaging Application. J. Appl. Polym. Sci. 2022, 139, 52370.

- Togliatti, E.; Milanese, D.; Pugliese, D.; Sciancalepore, C. Viscoelastic Characterization and Degradation Stability Investigation of Poly(butylene-adipate-co-terephthalate)—Calcium-Phosphate Glass Composites. J. Polym. Environ. 2022, 30, 3914–3933.

- Bandopadhyay, S.; Martin-Closas, L.; Pelacho, A.M.; DeBruyn, J.M. Biodegradable Plastic Mulch Films: Impacts on Soil Microbial Communities and Ecosystem Functions. Front. Microbiol. 2018, 9, 819.

- Barrett, A. Danimer Scientifiv and UrthPact Launch New Compostable Straw. 2019. Available online: https://bioplasticsnews.com/2019/10/30/danimer-scientific-and-urthpact-launch-new-compostable-straw/ (accessed on 10 October 2023).

- Mirel Bioplastics. Biobased and Biodegradable. 2018. Available online: https://www.miljodirektoratet.no/globalassets/publikasjoner/m1206/m1206.pdf (accessed on 10 October 2023).

- Gao, X.; Xie, D.; Yang, C. Effects of a PLA/PBAT Biodegradable Film Mulch as a Replacement of Polyethylene Film and Their Residues on Crop and Soil Environment. Agric. Water Manag. 2021, 255, 107053.

- Jandas, P.J.; Mohanty, S.; Nayak, S.K. Sustainability, Compostability, and Specific Microbial Activity on Agricultural Mulch Films Prepared from Poly(Lactic Acid). Ind. Eng. Chem. Res. 2013, 52, 17714–17724.

- Havens, K.J.; Bilkovic, D.M.; Stanhope, D.M.; Angstadt, K.T. Fishing Gear with Degradable Component. U.S. Patent 20150135580A1, 21 May 2015.

- Nasrin, R.; Biswas, S.; Rashid, T.U.; Afrin, S.; Jahan, R.A.; Haque, P.; Rahman, M.M. Preparation of Chitin-PLA Laminated Composite for Implantable Application. Bioact. Mater. 2017, 2, 199–207.

- Qin, J.; Jiang, Y.; Fu, J.; Wan, Y.; Yang, R.; Gao, W.; Wang, H. Evaluation of Drug Release Property and Blood Compatibility of Aspirin-Loaded Electrospun PLA/RSF Composite Nanofibers. Iran. Polym. J. 2013, 22, 729–737.

- Macha, I.J.; Ben-Nissan, B.; Santos, J.; Cazalbou, S.; Stamboulis, A.; Grossin, D.; Giordano, G. Biocompatibility of a New Biodegradable Polymer-Hydroxyapatite Composite for Biomedical Applications. J. Drug Deliv. Sci. Technol. 2017, 38, 72–77.

- Tran, C.D.; Mututuvari, T.M. Cellulose, Chitosan, and Keratin Composite Materials. Controlled Drug Release. Langmuir 2015, 31, 1516–1526.

- Zhang, Z.; Liu, S.; Xiong, H.; Jing, X.; Xie, Z.; Chen, X.; Huang, Y. Electrospun PLA/MWCNTs Composite Nanofibers for Combined Chemo- and Photothermal Therapy. Acta Biomater. 2015, 26, 115–123.

- Raza, Z.A.; Khalil, S.; Abid, S. Recent Progress in Development and Chemical Modification of Poly(hydroxybutyrate)-Based Blends for Potential Medical Applications. Int. J. Biol. Macromol. 2020, 160, 77–100.

- Zinn, M.; Witholt, B.; Egli, T. Occurrence, Synthesis and Medical Application of Bacterial Polyhydroxyalkanoate. Adv. Drug Deliv. Rev. 2001, 53, 5–21.

- Sanhueza, C.; Acevedo, F.; Rocha, S.; Villegas, P.; Seeger, M.; Navia, R. Polyhydroxyalkanoates as Biomaterial for Electrospun Scaffolds. Int. J. Biol. Macromol. 2019, 124, 102–110.

- Gomes, M.E.; Ribeiro, A.S.; Malafaya, P.B.; Reis, R.L.; Cunha, A.M. A New Approach Based on Injection Moulding to Produce Biodegradable Starch-Based Polymeric Sca!Olds: Morphology, Mechanical and Degradation Behaviour. Biomaterials 2001, 22, 883–889.

- Alam, F.; Varadarajan, K.M.; Kumar, S. 3D Printed Polylactic Acid Nanocomposite Scaffolds for Tissue Engineering Applications. Polym. Test. 2020, 81, 106203.

- Wang, S.; Li, Y.; Zhao, R.; Jin, T.; Zhang, L.; Li, X. Chitosan Surface Modified Electrospun Poly(ε-Caprolactone)/Carbon Nanotube Composite Fibers with Enhanced Mechanical, Cell Proliferation and Antibacterial Properties. Int. J. Biol. Macromol. 2017, 104, 708–715.

- Farajikhah, S.; Runge, A.F.J.; Boumelhem, B.B.; Rukhlenko, I.D.; Stefani, A.; Sayyar, S.; Innis, P.C.; Fraser, S.T.; Fleming, S.; Large, M.C.J. Thermally Drawn Biodegradable Fibers with Tailored Topography for Biomedical Applications. J. Biomed. Mater. Res. B Appl. Biomater. 2021, 109, 733–743.

- Sciancalepore, C.; Togliatti, E.; Marozzi, M.; Rizzi, F.M.A.; Pugliese, D.; Cavazza, A.; Pitirollo, O.; Grimaldi, M.; Milanese, D. Flexible PBAT-Based Composite Filaments for Tunable FDM 3D Printing. ACS Appl. Bio Mater. 2022, 5, 3219–3229.

- Walczak, J.; Sobota, M.; Chrzanowski, M.; Krucinska, I. Application of the Melt-Blown Technique in the Production of Shape-Memory Nonwoven Fabrics from a Blend of Poly(L-Lactide) and Atactic Poly. Text. Res. J. 2018, 88, 2141–2152.

- He, Y.; Hu, Z.; Ren, M.; Ding, C.; Chen, P.; Gu, Q.; Wu, Q. Evaluation of PHBHHx and PHBV/PLA Fibers Used as Medical Sutures. J. Mater. Sci. Mater. Med. 2014, 25, 561–571.

More