Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is a comparison between Version 1 by Lukas Krupp and Version 3 by Fanny Huang.

The increasing demand for customized products is a core driver of novel automation concepts in Industry 4.0. For the case of machining complex free-form workpieces, e.g., in die making and mold making, individualized manufacturing is already the industrial practice. The varying process conditions and demanding machining processes lead to a high relevance of machining domain experts and a low degree of manufacturing flow automation. In order to increase the degree of automation, online process monitoring and the prediction of the quality-related remaining cutting tool life is indispensable.

- remaining tool life prediction

- individualized production

1. Introduction

With the advancement of Industry 4.0, the demand for highly customized products is increasing. A growing proportion of single-part and small-batch production manifests this in the manufacturing industry. The resulting frequent machine and process reconfigurations increase the susceptibility to process errors, which is unacceptable for applications requiring a high product quality and reliability. Die making and mold making combine high product quality requirements and a dominant share of individualized production [1][2][1,2]. The core technology in die making and mold making is machining, particularly multi-axis milling, for manufacturing complex free-form workpieces [3]. The decisive quality parameters are their dimensional accuracy and surface roughness, which are significantly influenced by the wear of the cutting tools [4][5][6][4,5,6]. Even minor deviations from the specification can lead to defective end products, e.g., in injection molding or die-casting processes. Therefore, monitoring the machining processes and tool wear is essential to avoid scrap and rework [7].

In recent years, remaining tool life prediction based on sensor-driven process monitoring has been increasingly investigated in this context [8]. The remaining tool life prediction enables a joint estimation of the current tool condition based on the monitoring data and the duration until quality-related specifications of the process are violated. Thus, the quality and productivity of machining processes become controllable and the job-shop scheduling is simplified due to increased plannability [9]. Simultaneously, process-integrated sensors allow for reductions in time-consuming measurements using manufacturing metrology.

However, single-part and small-batch production conditions have made the development of remaining tool life prediction methodologies considerably difficult [10]. In particular, frequent changes in the workpiece geometries and process parameters do not allow for the direct inference of the tool condition from the sensor data due to a lack of comparability. Furthermore, the prediction of the remaining tool life is affected by the increased uncertainty regarding future process conditions. Therefore, previous approaches mainly focus on series production under constant process conditions, implying that the used prediction models are not adaptable.

2. Remaining Tool Life Prediction

The state-of-the-art methods in sensor-driven remaining tool life prediction comprise two main approaches: direct [11] and criterion-based [12]. Direct methods use models generating a temporal output from the process-describing sensor data. The tool state and the decision threshold regarding the end of the tool life are, therefore, only implicitly part of the model and cannot be extracted or set separately. Criterion-based methods integrate an intermediate step via a tool life criterion to indicate the tool condition. The subsequent extrapolation of the tool life criterion allows for the setting of arbitrary decision thresholds. In addition, the tool condition is directly available for further applications, e.g., for integration into a simulation. Due to its comprehensive significance for the process quality, the tool condition and the end of tool life are usually determined based on tool wear [13]. Alternatively, quality parameters, such as the workpiece surface roughness, can be used as tool life criteria.

The data basis for the remaining tool life models is generated using the state-of-the-art sensor types in process monitoring [8]. The monitoring variables are the cutting force [14], vibration [15], drive current and power [16] or machine tool controller signals [17]. Since the sensor data provide the input for the predictions, either purely data-based [18] or hybrid physics- and data-based models [19] are used. In the area of data-based remaining tool life prediction, machine learning (ML) models and particularly neural network architectures, like convolutional neural networks (CNNs) [20], temporal convolutional networks (TCNs) [21] or long short-term memory (LSTM) networks [22], are current research topics due to their high adaptivity, accuracy and suitability for temporal predictions.

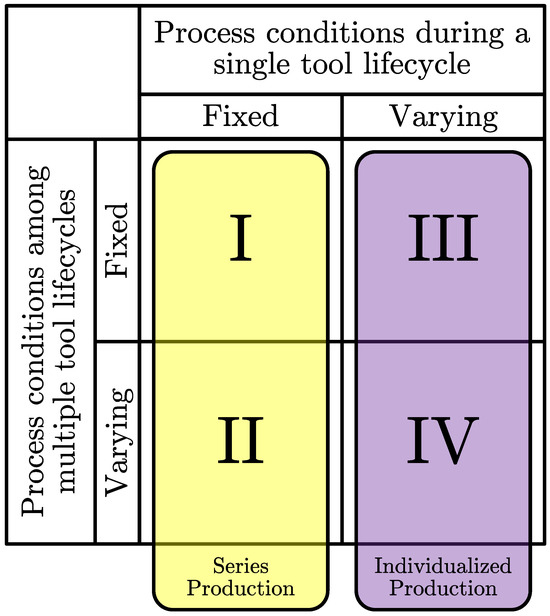

Their underlying production scenarios and datasets are the most significant distinguishing characteristics of the prediction models. A remaining tool life dataset comprises the sensor and target data over the life cycle of multiple tools. Possible variants of datasets are shown in Figure 1, depending on the respective degree of process condition variations during single and multiple tool life cycles. Process conditions refer to influencing factors, i.e., the tool shape and material; workpiece shape and material; cutting parameters; machine tool design and its condition or tool path; and process kinematics. While the dataset variants I, e.g., Ref. [23], and II, e.g., Ref. [24], mainly represent series production, the combinations III [25] and IV describe the individualized production scenario.

Figure 1. Possible dataset variants in the area of remaining tool life prediction depending on the degree of process condition variations during single and multiple tool life cycles.

Previous work on sensor-driven remaining tool life prediction mainly investigates series production scenarios [8]. Individualized production, i.e., the variation in process conditions during a tool life cycle, is hardly considered. A single approach analyzes varying cutting parameters during the tool life cycle [25]. However, the same workpiece is manufactured repeatedly. In [9], a methodology for small-batch production is developed using a dataset containing several identical cutting operation sequences. The approach of Matsumura et al. [26], while considering varying workpieces during the tool life cycle, requires direct wear measurements and is thus outside the scope of sensor-driven predictions.

Overall, sensor-driven remaining tool life prediction has not yet been analyzed under variable cutting parameters and workpiece geometries during single and multiple tool life cycles. Datasets according to variant III, like [25], do not include the implied degree of process condition variation, and datasets according to variant IV do not exist. Therefore, it is still unknown whether the feature extraction methodologies for sensor data under fixed process conditions are applicable. Furthermore, previous remaining tool life prediction models do not mitigate the uncertainty due to variable future process conditions.

Several papers investigate the use of AutoML methods to make the benefits of ML-based models even easier to apply to tool condition monitoring [6][27][28][29][6,27,28,29]. AutoML leverages the autonomous adaptation of models to changing process conditions, especially in individualized production. However, with increased autonomy in the generation of models, their validity must be ensured. Although the first approaches to explaining ML models in the context of machining process monitoring exist [30][31][32][33][30,31,32,33], methods combining AutoML and model explainability are missing so far.