Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is a comparison between Version 1 by Sidonio Miguel Silva and Version 2 by Rita Xu.

Food waste is a pressing global challenge leading to over $1 trillion lost annually and contributing up to 10% of global greenhouse gas emissions. Extensive study has been directed toward the use of active biodegradable packaging materials to improve food quality, minimize plastic use, and encourage sustainable packaging technology development.

- bionanocomposites

- food packaging

- silver nanoparticles

1. Introduction

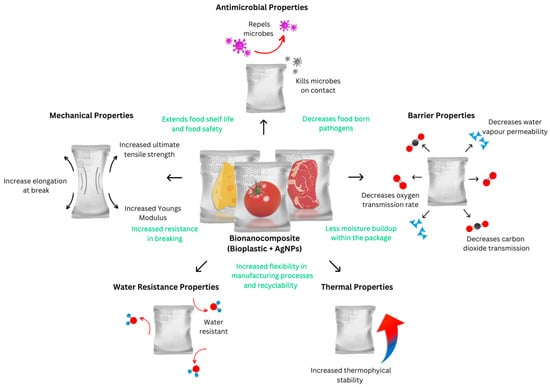

Food packaging is a critical component of food technology that deals with the protection and preservation of diverse food products [1]. It has been reported that food packaging represented a global market size of £303 Billion in 2021 with a compound annual growth rate (CAGR) of 5.5% until 2030, and formed about 69% of the overall consumer packaging market [2]. Petrochemical plastics have achieved widespread success as packaging materials in the sector, owning 99% of the market share due to optimal properties such as oxygen barrier capabilities, high tensile, and tear strength. Other characteristics, such as a high Water Vapor Transmission Rate and biodegradability, is less prevalent in packaging, with biodegradability found in only 0.64% of all plastic materials. All these properties guard against external degradation agents and prevent the internal loss of nutrition in food products, assuring food quality at every level of the supply chain, from producers to end users (Figure 1).

Figure 1. Visual abstract outlining the enhanced properties of bionanocomposites. Green text summarizes the key benefits of the bionanocomposites for food packaging applications.

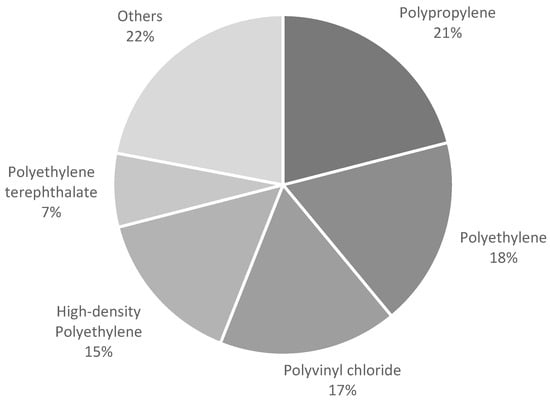

As shown in Figure 2, synthetic plastic polymers such as polypropylene (21%), polyethylene (18%), polyvinyl chloride (17%), high-density polyethylene (15%), and polyethylene terephthalate dominate the food packaging market globally [1]. Between 1950 and 2015, an estimated 7.8 billion tons of plastics were created worldwide, with approximately 4.6 billion tons ending up in landfill or being wasted [3]. Polyethylene, the most manufactured and discarded synthetic polymer globally, is the major generator of two greenhouse gases—methane and ethylene [4]. Methane emissions contribute to climate change and can harm aquatic life by changing the oxygen levels and pH of water, whereas ethylene emissions can be hazardous to plants and animals and have an impact on crops and biodiversity, and there is some evidence that it may play a role in cancer development [4].

Figure 2. Global market distribution of synthetic plastics.

Plastics account for 10% of the global oil output, with single-use plastics accounting for more than one third of all plastics produced in 2017 [5]. Several environmentally hazardous disposal methods, such as incineration and landfill, are currently being employed to deal with the overflow of plastics [4]. As a result, sustainable, safe, and non-toxic food packaging options are highly desirable to ensure a transition to more environmentally friendly packaging materials in the food industry.

Bioplastics represent an innovative category of plastics derived from natural sources, such as chitosan, agar, alginate, and polylactic acid (PLA), among others. They are positioned as an environmentally friendly alternative to non-biodegradable synthetic plastics due to their reduced reliance on fossil fuels, faster biodegradability, and lower carbon footprint [6]. Bioplastics are made of biopolymers and biodegradable reinforcing agents [7]. The ability of bioplastics to return to the ecosystem, either through the natural breakdown of organic waste by microorganisms or composting, rather than accumulating in landfills, is an important differentiating factor compared to non-biodegradable synthetic plastics.

Even though bioplastics provide an alternative to synthetic packaging, they are regularly combined with petrochemical plastics. This is due to their weak mechanical qualities and moisture sensitivity, which are listed as contributing causes to their restricted utilization in food packaging [6]. To overcome the challenges around bioplastics, extensive research has been conducted to embed nanomaterials in food packaging materials, leading to the development of active packaging materials. Several metallic nanoparticles, most notably silver, aluminum, and zinc, have been shown to improve qualities such as tensile strength, Water Vapor Permeability, and biocidal activity [8]. Moreover, silver nanoparticles (AgNPs) have been found to have a strong antibacterial effect against foodborne pathogens such as bacteria, parasites, and viruses [9].

The antimicrobial activity of AgNPs in food packaging can help tackle two major global challenges:

-

Food and beverage waste: Excess food production used to compensate for waste could be used to help feed the 811 million people worldwide experiencing chronic undernourishment [10];

-

Foodborne infections: 550 million cases and 230,000 deaths worldwide each year could be avoided by providing sustainable and effective food packaging technology [9].

These challenges are aligned with the United Nations Sustainable Development Goal 12 to reduce food waste along production and supply chains in order to promote a more sustainable economic model [11]. Food waste is typically generated by food products which have a short shelf-life; studies have shown a wide spectrum of microorganisms being responsible for food deterioration [9], increasing the challenge to finding a one-stop solution to prevent highly nutritious foods from degrading as quickly, especially in warmer climates. As a result, $1.2 trillion is wasted globally each year from food and beverage detorioration [10]. It is believed that over 1.3 billion tons, or one third of all food produced for human use, is wasted annually [10]. This accounts for up to 10% of global greenhouse gas emissions [10].

While the main focus of current research has been to investigate the incorporation of AgNPs in bioplastics to improve their physical properties, only a limited amount of studies have looked into how these improvements affect food packaging in a holistic manner.

Due to the excellent performance of silver bionanocomposites in antibacterial activity and their ability to improve the physico-chemical properties of bioplastics, the purpose of this tliterature review is to critically examine key technological advances that are relevant to food packaging. These properties include the antimicrobial activity, barrier properties (Water Vapor Transmission Rate (WVTR, WVP), and Oxygen Transmission Rate (OTR)), mechanical properties (Ultimate Tensile Strength (UTS) and Elongation at Break (EaB)), thermal properties, and water resistance (WS, CA) of bionanocomposites containing AgNPs.

2. Silver Nanoparticles as an Active Additive

A common approach to enhancing food safety is to embed an active ingredient within a packaging material which not only inhibits microbial growth, but also enhances Water Vapor Permeability to extend the shelf-life [9]. This is achievable through nanomaterials such as AgNPs, which have a higher surface area-to-volume ratio with respect to their bulk counterpart, allowing them to easily interact with and bond to other materials. Hence, when embedding silver nanoparticles in biopolymers, they interact with:-

The polymer matrix of the film, forming a network of strong bonds that improve mechanical and barrier properties through weak and covalent interaction, assuring their adhesion within the biopolymers [13];

-

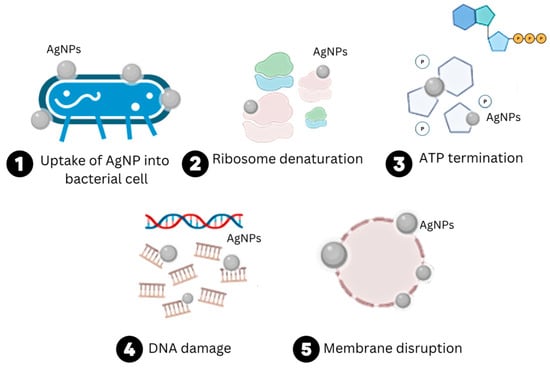

Bacteria and other microorganisms, which inhibit their growth [9]. The mechanism of action of AgNPs against bacteria is illustrated in Figure 3;

-

UV radiation, reducing the UV penetration through the biopolymer by means of their strong scattering behaviour [14].

Figure 3. Various antimicrobial activity mechanisms of AgNPs. (1) Entry of the AgNPs into the cell membrane of the bacterial cells; (2) ribosome denaturation; (3) ATP termination; (4,5) membrane disruption; DNA damage; (5) rupture of the cell membrane.

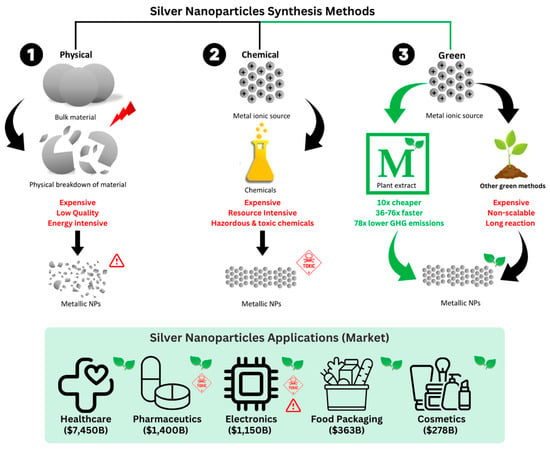

Figure 4. Methods for AgNPs synthesis. (1) Physical: In this method, the bulk material, such as silver foil, is broken down utilizing high energy and material resources; however, the produced AgNPs lack uniform size and shape, the most used methods comprise evaporation-condensation and laser ablation; (2) Chemical: This process commonly involves the metal ionic sources being reduced by a reducing agent and stabilized by a capping agent to produce AgNPs of defined size and shape. However, these use toxic chemicals such as sodium borohydride; (3) Biological: These methods either use microbes or plant extracts to carry out bio-reduction of ionic solutions as well as use biological molecules to stabilize the final AgNPs to produce defined shape/size NPs, without the use of hazardous chemicals.

3. Formulation and Bionanocomposites Manufacturing

Bionanocomposites are composite materials comprising two fundamental components: biopolymers that constitute the bioplastic matrix and embedded nanostructures capable of imparting unique properties which re-enforce the polymeric material. These nanostructures can be organic, encompassing polysaccharides, proteins, or synthetic colloids, or inorganic, including substances such as silica, noble metal oxides, or ceramics. Various bioplastic formulations have been produced in the literature. In particular, polysaccharide-based bionanocomposites are the most investigated due to their unique chemical–physical properties, and relative low cost provided by the abundance of their main sources. Indeed, polysaccharides are naturally abundant, are generally non-toxic and circular, and meet the criteria for packaging production [19]. These biopolymers, unlike lipids which are commonly subjected to peroxidation reactions leading to the loss of their main structure, exhibit a higher thermal stability. However, they are highly susceptible to moisture and have limited mechanical resilience [19]. These include agar [20], chitosan [13], and hydroxypropyl methylcellulose (HPMC) [21] in combination with multiple components such as gum tragacanth/HMPC/beeswaxes (GT/HMPC/BW) [22] and agar/banana powder [23]. Understanding their formulation is critical in order to develop optimal bionanocomposite materials, as their formulation will impact the final material properties as well as theour understanding of how AgNPs interact with the polymers themselves. Physical properties that affect food safety and shelf life must be considered when designing food packaging. To address these issues, three solutions have been suggested:-

The addition of different reinforcing chemicals into polysaccharide matrices such as cellulose, lignocellulose, or micro/nanocrystals [24];

- The inclusion of inorganic additives, such as AgNPs

- Sonication to break down agglomerates and ensure proper dispersion

-

The fine tuning of processing conditions, such as temperature, pressure, and mixing time to optimize AgNP dispersion.