Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is a comparison between Version 2 by Catherine Yang and Version 1 by Prasad K V.

Readiness for lean transformation is considered an essential requirement. Several studies have been conducted to identify lean readiness factors and develop assessment frameworks in other sectors such as manufacturing, healthcare, pharmaceutical, emergency, higher education, etc., but none in construction. The work assesses the criteria and factors of lean readiness.

- lean

- readiness

- factors

- change

- culture

- construction

- sustainability

1. Introduction

Construction projects underpin economic development [1] and the progress of all nations. The construction industry adds significantly to the Gross Domestic Product (GDP) in a vast majority of countries with nearly 13% of the global GDP [2,3][2][3]. However, construction projects are seldom completed within the planned time and cost [4]. Projects linger with management change problems, time overruns, cost escalations, claims, and disputes [5] resulting in huge wastages of time, effort, and all resources. It has also been a concern that over the years construction productivity has remained flat as compared to the manufacturing industry, and this lag translates to about USD 1.6 trillion of loss every year [6]. Research studies have indicated that construction sector productivity can be boosted by 5 to 10 times in some areas by adopting a manufacturing-style production approach [6].

The lean production system originated from Toyota’s production system which, when implemented properly, has provided significant dividends to organizations. Despite the huge benefits of the lean production system, many organizations have been unsuccessful in their journey towards lean transformation and most organizations failed to reach the summit stage [7]. Successful lean transformation requires a transformation in the organizational culture [8]. If not addressed appropriately, the project of introducing lean culture into an organization may not only end up as a failure but may also significantly impair the prevalent practices and routine business processes of the organization as well [9].

Organizational lean readiness reflects upon the organization’s ability to undergo a smooth and sustainable lean transition and is developed by setting up practices, conditions, and resources facilitating lean change [10]. Studies have indicated lean implementation failure is also attributed to the fact that little attention is paid to organizational lean readiness [11,12][11][12]. To eliminate/reduce the failures in lean implementation, there needs to be an assessment of the organizational readiness levels before committing [13,14][13][14]. To ensure successful lean transformation, there needs to be an assessment of the organizational readiness levels [14]. This prior assessment of organizational readiness is intended to cut down the wasted effort and any waste during the process of lean transformation and will help ensure minimum disruption to the organizational process and business [8]. A planned organizational change would be more effective and efficient and would help organizations to measure the ability within the organization and aid in improving organizational capabilities [15].

2. Readiness Themes and Factors for Lean Transformation

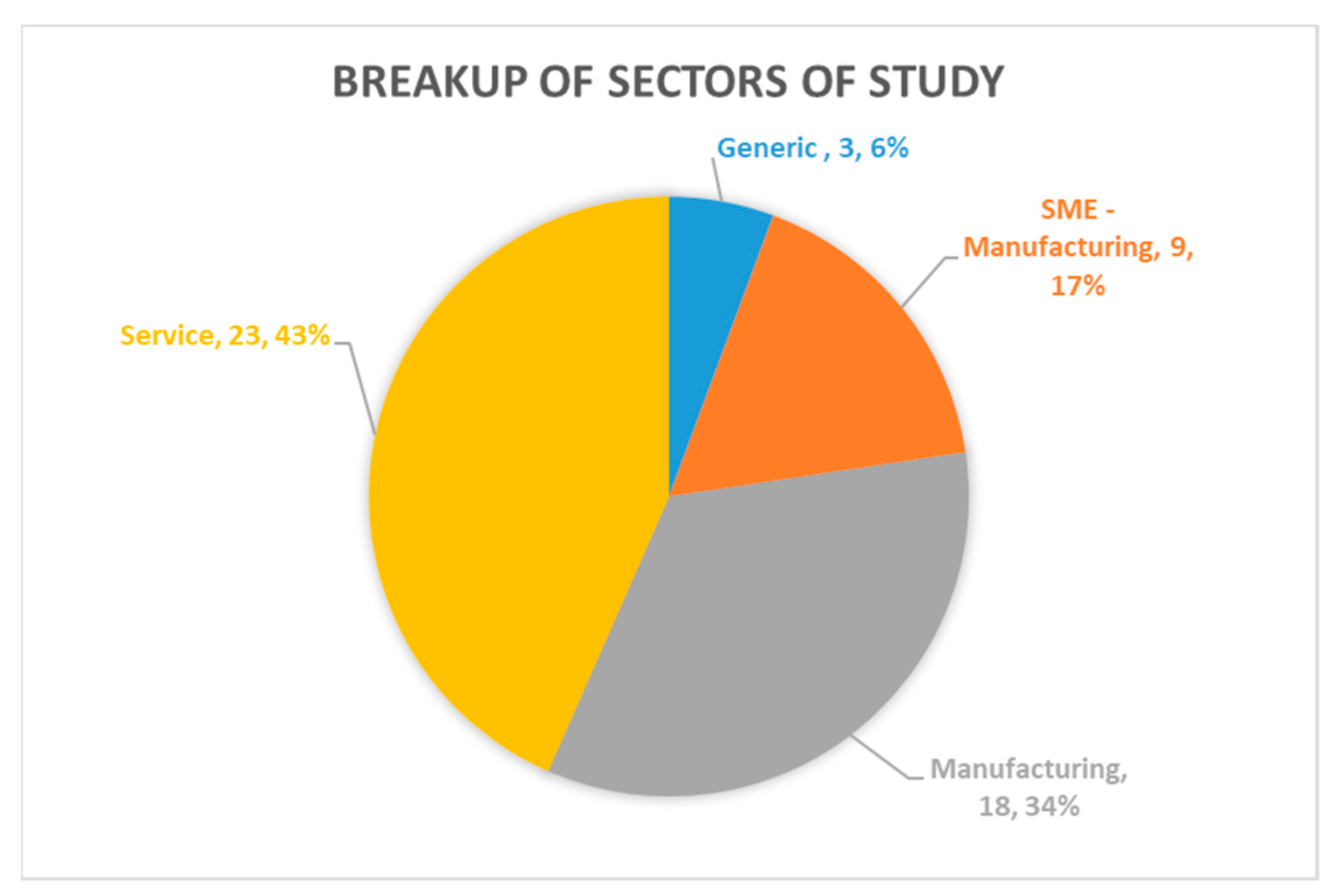

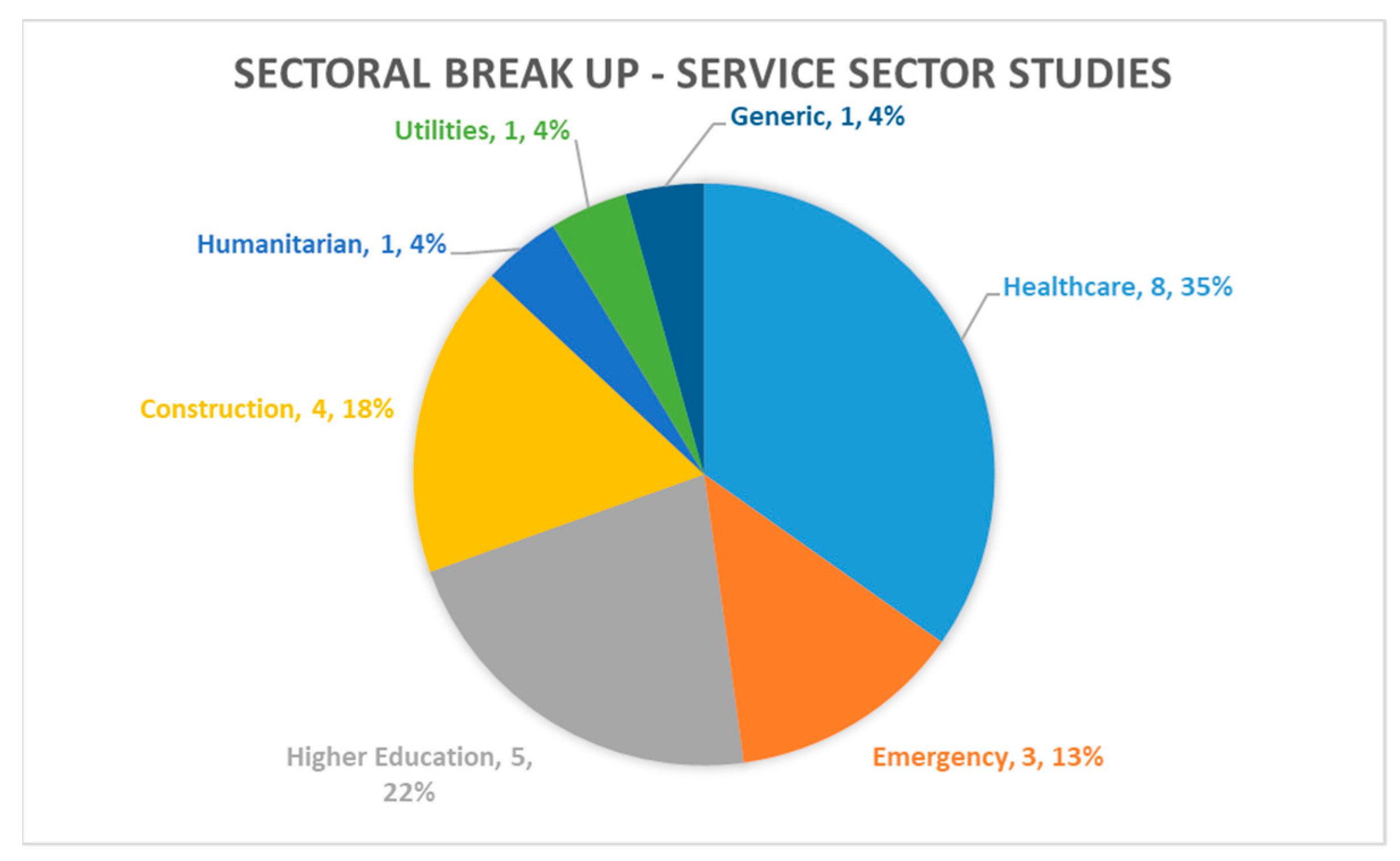

To assess the works that were carried out on lean readiness, a systematic literature review (SLR) was carried out. The search query string—“Lean readiness” OR “readiness for lean” OR “readiness for lean implementation” OR “lean readiness assessment”—was set to include all journal research articles on lean readiness published in the English language in the Scopus and Web of Science (WOS) databases over the last decade. The search string resulted in 260 documents from Scopus and 119 documents from the WOS database. The duplicates in the databases were removed with the help of Zotero software. A team of three experts from academia and industry helped to identify and narrow down the literature relevant to the objectives and eliminate any bias for further review. Finally, 53 research articles were selected for analysis. As may be seen from Figure 1 and Figure 2, out of the 53 articles, 27 of the studies (~51% of the studies) have focused on the manufacturing sector only. A total of 23 studies (43%) have been conducted in the service sectors. Again, as can be seen from Figure 2, these studies have been conducted in healthcare facilities [12,13[12][13][15][16][17][18][19][20],15,19,28,29,30,31], in emergency departments [16[21][22][23],18,32], higher education [23[24][25][26][27][28],33,34,35,36], and the construction industry [37,38,39,40][29][30][31][32]. The three service sectors—healthcare, higher education, and emergency—make up 70% of the studies within service sectors.

Figure 1.

Distribution of articles by sectors.

Figure 2.

Distribution of service sector articles.

Table 1.

Studies on lean readiness in the construction sector.

| Study | Focus Area of the Study | Limitations of the Study |

|---|---|---|

| [37][29] | Lean Culture | Focuses only on cultural readiness; no holistic study on all the aspects of lean readiness |

| [38][30] | Lean readiness of Azerbaijan construction industry | Themes and factors such as those of the manufacturing sector studies adopted as they are; not customized to the construction industry; the study does not address the construction project lifecycle or processes |

| [39][31] | Construction Operations | Focuses only on the implementation of lean construction principles, but not readiness; lacks focus on softer attributes of lean readiness; outdated |

| [40][32] | Lean procurement | Focuses on the procurement process alone |

2.1. Top Management Commitment and Leadership

Any change management programme, including lean, needs the management’s unwavering support throughout the implementation phases as well as the leadership’s willingness to mentor and mitigate the risks of failure. Leadership should be able to create a vision that enables the employees to internalize the anticipated change and shift from current practices to best-in-class practices [23][24]. Top management must be prepared and show a willingness to be involved in resolving challenges that develop throughout the implementation, and leadership must completely enable the lean implementation teams by providing the necessary resources and infrastructure [19,41][16][33].2.2. Organization Culture

Organizational culture can be defined as the shared assumptions regarding deep-rooted organization-wide values, norms, and beliefs [36][28], and the very definition of lean itself calls for a shift that relates to elements of cultural change. The culture of an organization greatly influences how well Lean transformations happen [42][34]. Organizational culture subtly directs the actions and behaviours of an organization’s members [43][35]. Organizations can accomplish strengthening the “soft aspects” required for firms to be more successful in their lean transformation by enhancing these positive behaviours and attributes.2.3. Employee/Human Resources Engagement

The success of lean implementation depends on the level of awareness of employees [44][36] on the concepts of lean, lean tools and techniques, and the benefits which can be realized from the implementation. Hence, educating and involving every employee in and around lean principles, methodologies, and practices is crucial [19][16]. One of the crucial key criteria for effective adoption is lean training [45][37]. Management should align organizational objectives with employee performance KPIs, motivate with reward systems, [46][38] and should encourage to take full ownership and corrective actions to improve the processes [41][33].2.4. Customer Focus/Customer Relationships

The capacity to define the customer is one of the crucial elements for successfully implementing lean practices in any firm [47][39]. A well-defined value for a given customer group prevents conflicting needs and objectives and reduces resistance to change [19][16]. Organizational processes must be structured with the needs of the customer at the centre, and all initiatives for improvement must systematically take customer feedback into account at every stage [23][24].2.5. Technology/Process Management

Organizations need to set up processes that can analyze the waste across the value stream, cut down on the non-value-adding activities, and improve the quality and value [14]. Organizations must make sure that performance is tracked to decrease variability and find ways to improve. There must be procedures in place to evaluate the costs and benefits of major undertakings and manage risks [12,41][12][33].2.6. Communication

Communication is one of the cornerstones of lean practices [48][40]. Lack of effective communication with the stakeholders of the lean initiative can lead to failure [49][41] and organizations need to establish clear and effective communication channels to ensure communication with all team members [50][42]. The organization should set up a communication process that encourages the horizontal and vertical exchange of information and also share lessons on failures and short-term wins [41][33].3. Readiness Themes and Factors from Lean Construction Studies

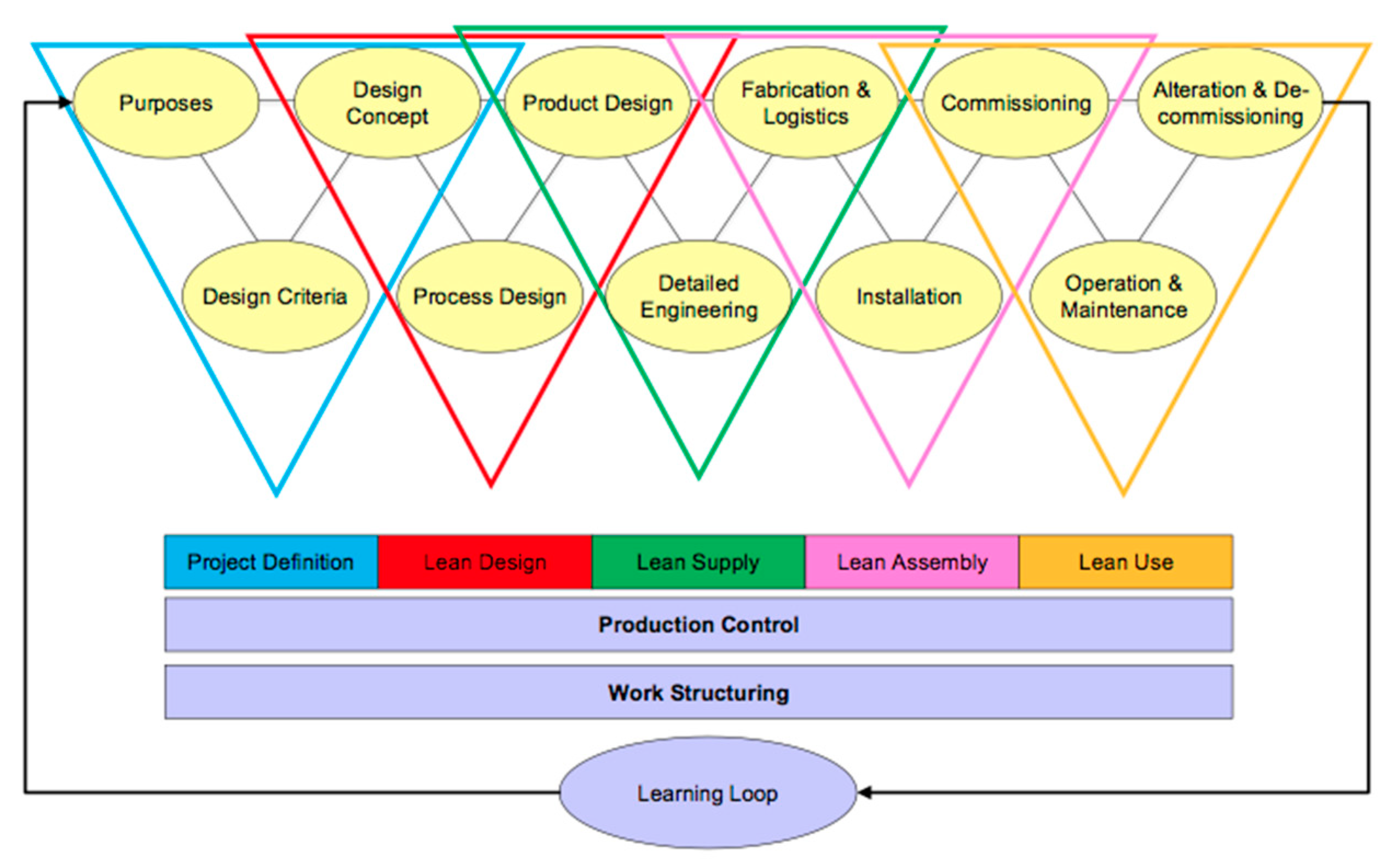

Having identified the lean readiness studies in other sectors, it was important to review the lean construction literature to identify lean readiness factors spanning the construction project lifecycle. The Lean Project Delivery System (LPDS) proposed by Prof. Ballard [51][43], shown in Figure 3, was taken up as a starting point.3.1. Engineering and Design

As can be seen from Figure 3, Project definition starts with the conceptual stage of engineering and design development and this process translated the project objectives to definitive outcomes. The study by [52][44] investigated the parameters that build lean ideology in the engineering and design management processes in construction projects. The factors identified by this study are selected for the study and listed in Table 3.3.2. Project Planning, Monitoring, and Control

The Last Planner System® (LPS) has been one of the most commonly adopted production control methodologies based on lean philosophy. LPS was proposed as a novel solution by [53][45] to increase workflow predictability and increase work plan predictability by controlling the quality of assignments in weekly work plans. Studies by [54,55][46][47] identified parameters for planning and production control processes based on the LPS philosophy. The recently updated guideline [56][48], which was also considered, has touched upon the factors of work structuring and the visual management of plans in great detail.3.3. Procurement and Inventory Management

Integrating lean practices with the supply chain, procurement, and material management, has been the interest of many studies [40,57,58,59][32][49][50][51]. These studies have advocated pull-based procurement, the use of automation and IT to minimise material requirements, standardized procurements, waste control, material reconciliation, housekeeping, and 5S methodologies in construction projects.3.4. Contract Management

The other aspect of integrated lean project delivery is the aspect of work structuring, a process that designs and connects the project deliverables with suppliers, subcontractors, and other vendors. Towards this, studies [60,61,62][52][53][54] have advocated the practice of a relational contracting system that promotes balanced risk and opportunity sharing between the parties, transparency, and trust, and develops partnerships to build these in the supply chain contracts with all the vendors and contractors. Twenty-five lean readiness factors were identified through a review of lean construction literature and are summarized in Table 3.Table 2.

Lean readiness themes and factors from the literature (organizational readiness themes).

| Theme | Lean Readiness Factors |

|---|

Table 3.

Lean readiness themes and factors from lean construction studies (lean project delivery themes).

| Stage of Project Development | Lean Readiness Factors | ||

|---|---|---|---|

| Top Management Commitment and Leadership |

|

||

|

|

Organization Culture |

|

| Project Planning |

|

||

|

|

Employee Engagement/HR |

|

| Project monitoring |

|

||

|

Customer Focus |

| |

| Procurement and Inventory Management | |||

| Communication |

| ||

| Contract Management |

|

||

|

Technology and Process Management |

|

* This attribute was revised further based on expert opinion.

| Engineering and Design |

|

References

- Prasad, K.V.; Vasugi, V.; Venkatesan, R.; Bhat, N.S. Critical causes of time overrun in Indian construction projects and mitigation measures. Int. J. Constr. Educ. Res. 2019, 15, 216–238.

- International Labour Organization. Impact of COVID-19 on the construction sector. In ILO Sectoral Brief; International Labour Organization: Geneva, Switzerland, 2021; pp. 1–12.

- Organisation for Economic Co-operation and Development. The global construction sector needs a big push on corporate responsibility. In OECD Insights; OECD: Paris, France, 2016; pp. 1–8.

- Prasad, K.V.; Vasugi, V.; Venkatesan, R.; Bhat, N. Analysis of causes of delay in Indian construction projects and mitigation measures. J. Financ. Manag. Prop. Constr. 2019, 24, 58–78.

- Padala, S.P.S.; Maheswari, J.U.; Hirani, H. Identification and classification of change causes and effects in construction projects. Int. J. Constr. Manag. 2020, 22, 2788–2807.

- McKinsey Global Institute. Reinventing Construction: A Route to Higher Productivity; Mckinsey Global Insititute: New York, NY, USA, 2017; p. 168. Available online: http://www.mckinsey.com/industries/capital-projects-and-infrastructure/our-insights/reinventing-construction-through-a-productivity-revolution (accessed on 15 February 2023).

- Bhasin, S. Measuring the Leanness of an organisation. Int. J. Lean Six Sigma 2011, 2, 55–74.

- Shafiq, M.; Soratana, K. Lean readiness assessment model—A tool for Humanitarian Organizations’ social and economic sustainability. J. Humanit. Logist. Supply Chain Manag. 2020, 10, 77–99.

- Cimermančič, D.; Kušar, J.; Berlec, T. A Procedure for the Introduction of Leanness into a Company; Springer: Berlin/Heidelberg, Germany, 2021.

- Leite, H.; Radnor, Z.; Bateman, N. Meaningful inhibitors of the lean journey: A systematic review and categorisation of over 20 years of literature. Prod. Plan. Control 2022, 33, 403–426.

- Azalanzazllay, N.N.; Lim, S.A.H.; Abidin, U.F.U.Z.; Anass, C. Uncovering Readiness Factors Influencing the Lean Six Sigma Pre-Implementation Phase in the Food Industry. Sustainability 2022, 14, 8941.

- Narayanamurthy, G.; Gurumurthy, A.; Subramanian, N.; Moser, R. Assessing the readiness to implement lean in healthcare institutions—A case study. Int. J. Prod. Econ. 2018, 197, 123–142.

- Awang, M.; Idris, R.; Zakaria, Z. Lean Readiness Index for Malaysian Hospitals: An Exploratory Study. Int. J. Ind. Eng. Prod. Res. 2022, 33, 1–11.

- Al-Najem, M.; Dhakal, H.; Labib, A.; Bennett, N. Lean readiness level within Kuwaiti manufacturing industries. Int. J. Lean Six Sigma 2013, 4, 280–320.

- Vaishnavi, V.; Suresh, M. Assessment of readiness level for implementing lean six sigma in healthcare organization using fuzzy logic approach. Int. J. Lean Six Sigma 2021, 12, 175–209.

- Al-Balushi, S.; Sohal, A.S.; Singh, P.J.; Al Hajri, A.; Farsi, Y.M.A.; Al Abri, R. Readiness factors for lean implementation in healthcare settings—A literature review. J. Health Organ. Manag. 2014, 28, 135–153.

- Sohal, A.; de Vass, T.; Singh, P.; Al Balushi, S.; Al Hajri, A.S.; Al Farsi, Y.; Al Arbi, R. Assessing readiness for lean thinking in healthcare settings: The case for Oman. Ind. Manag. Data Syst. 2021, 121, 2338–2361.

- Patri, R.; Suresh, M.; Prasad, R. Modelling the leadership characteristics for organizational readiness: A context of lean implementation in healthcare. Leadersh. Health Serv. 2021, 34, 181–197.

- Vaishnavi, V.; Suresh, M. Modelling of readiness factors for the implementation of Lean Six Sigma in healthcare organizations. Int. J. Lean Six Sigma 2020, 11, 597–633.

- Ajmera, P.; Jain, V. A fuzzy interpretive structural modeling approach for evaluating the factors affecting lean implementation in Indian healthcare industry. Int. J. Lean Six Sigma 2020, 11, 376–397.

- Alnajem, M.; Garza-Reyes, J.A.; Antony, J. Lean readiness within emergency departments: A conceptual framework. Benchmarking 2019, 26, 1874–1904.

- Poole, T.; Mazur, L.M. Assessing readiness for lean change in emergency department. In Proceedings of the IIE Annual Conference and Expo 2010 Proceedings, Expo Cancún, Mexico, 5–9 June 2010.

- Rees, G.H. Organisational readiness and Lean Thinking implementation: Findings from three emergency department case studies in New Zealand. Health Serv. Manag. Res. 2014, 27, 1–9.

- Antony, J. Readiness factors for the Lean Six Sigma journey in the higher education sector. Int. J. Product. Perform. Manag. 2014, 63, 257–264.

- Allaoui, A.; Benmoussa, R. Employees’ attitudes toward change with Lean Higher Education in Moroccan public universities. J. Organ. Change Manag. 2020, 33, 253–288.

- Sunder, V.M.; Antony, J. A conceptual Lean Six Sigma framework for quality excellence in higher education institutions. Int. J. Qual. Reliab. Manag. 2018, 35, 857–874.

- Okfalisa; Insani, F.; Abdillah, R.; Anggraini, W.; Saktioto. Smart Performance Measurement Tool in Measuring the Readiness of Lean Higher Education Institution. In Proceedings of the EECSI 2019, Bandung, Indonesia, 18–20 September 2019; pp. 422–427.

- Douglas, J.; Muturi, D.; Douglas, A.; Ochieng, J. The role of organisational climate in readiness for change to Lean Six Sigma. TQM J. 2017, 29, 666–676.

- Kallassy, J.; Hamzeh, F. Developing a Lean Culture Index in Construction. In Proceedings of the IGLC 2021—29th Annual Conference of the International Group for Lean Construction—Lean Construction in Crisis Times: Responding to the Post-Pandemic AEC Industry Challenges, Lima, Peru, 12–18 July 2021; pp. 504–513.

- Aghayev, H.; Garza-Reyes, J.A.; Nadeem, S.P.; Kumar, A.; Rocha-Lona, L.; Aleu, F.G. Lean Readiness Level of the Azerbaijan Construction Industry. In Proceedings of the International Conference on Industrial Engineering and Operations Management, Dubai, United Arab Emirates, 10–12 March 2020.

- Abduh, M.; Roza, H.A. Indonesian Contractors’ Readiness Towards Lean Construction. In Proceedings of the Annual Conference of International Group of Lean Construction-14; International Group for Lean Construction: Santiago, Chile, 2006; pp. 543–549.

- Suresh, M.; Arun Ram Nathan, R.B. Readiness for lean procurement in construction projects. Constr. Innov. 2020, 20, 587–608.

- Kumar, M.; Murugan, V. Lean Readiness Index: Assessing Organization Preparedness to Implement Lean; Springer International Publishing: Berlin/Heidelberg, Germany, 2019.

- Fadnavis, S.; Najarzadeh, A.; Badurdeen, F. An Assessment of Organizational Culture Traits Impacting Problem Solving for Lean Transformation; Elsevier B.V.: Amsterdam, The Netherlands, 2020; pp. 31–42.

- Laubengaier, D.; Hahn, G.J.; Wagner, H.-T.; German Graduate School of Management. Organizational Culture and Knowledge Exchange and Combination: A Systematic Literature Review. In Proceedings of the 52nd Hawaii International Conference on System Sciences, Grand Wailea, HI, USA, 8–11 January 2019; pp. 5498–5507. Available online: https://hdl.handle.net/10125/59986 (accessed on 15 February 2023).

- Anandh, K.S.; Gunasekaran, K. Constructing a model to examine the influence of quality of work-life on work-life balance—Discernment of civil engineers from construction industry in Chennai. Indian J. Sci. Technol. 2016, 9, 1–12.

- Dinis-Carvalho, J. The role of lean training in lean implementation. Prod. Plan. Control 2021, 32, 441–442.

- Alefari, M.; Almanei, M.; Salonitis, K. Lean manufacturing, leadership and employees: The case of UAE SME manufacturing companies. Prod. Manuf. Res. 2020, 8, 222–243.

- Womack, J.P.; Jones, D.T.; Roos, D. The Machine that Changed the World; Rawson Associates, Macmillan Publishing Company: New York, NY, USA, 1990.

- Amin, M.A.; Alam, M.R.; Alidrisi, H.; Karim, M.A. A fuzzy-based leanness evaluation model for manufacturing organisations. Prod. Plan. Control 2020, 32, 959–974.

- Albliwi, S.; Antony, J.; Halim-Lim, S.A.; van der Wiele, T. Critical failure factors of Lean Six Sigma: A systematic literature review. Eletronic Libr. 2014, 31, 1012–1030.

- Antony, J.; Downey-Ennis, K.; Antony, F.; Seow, C. Can Six Sigma be the ‘cure’ for our ‘ailing’ NHS? Leadersh. Health Serv. 2007, 20, 242–253.

- Ballard, G. The lean project delivery system: An update. Lean Constr. J. 2008, 1–19.

- Herrera, R.F.; Mourgues, C.; Alarcón, L.F.; Pellicer, E. An assessment of lean design management practices in construction projects. Sustainability 2020, 12, 19.

- Ballard, H.G. The Last Planner System of Production Control; The University of Birmingham, Edgbaston: Birmingham, UK, 2000.

- Sterzi, M.P.; Isatto, E.L.; Formoso, C.T. Integrating strategic project supply chain members in production planning and control. In Proceedings of the Lean Construction: A New Paradigm for Managing Capital Projects—15th IGLC Conference, East Lansing, MI, USA, 18–20 July 2007; pp. 159–169.

- Viana, D.D.; Mota, B.; Formoso, C.T.; Echeveste, M.; Peixoto, M.; Rodrigues, C.L. A survey on the last planner system: Impacts and difficulties for implementation in brazilian companies. In Proceedings of the 18th Annual Conference of the International Group for Lean Construction, IGLC 18, Haifa, Israel, 14–16 July 2010; pp. 497–507.

- Ballard, G.; Tommelein, I.D. 2020 Current Process Benchmark for the Last Planner® System of Project Planning and Control; University of California, Berkeley: Berkeley, CA, USA, 2021.

- Arbulu, R.; Ballard, G. Lean Supply Systems in Construction. In Proceedings of the 12th Annual Conference of the International Group for Lean Construction, Helsingør, Denmark, 3–5 August 2004; p. 13. Available online: http://iglc.net/Papers/Details/291/pdf%5Cnhttp://iglc.net/Papers/Details/291 (accessed on 15 February 2023).

- Dakhli, Z.; Lafhaj, Z. Considering Materials Management in Construction: An Exploratory Study. Logistics 2018, 2, 7.

- Sivaraman, A.; Varghese, K. Pull Planning System to Coordinate the Engineering Procurement and Construction on Process Plant Projects. In Proceedings of the Construction Research Congress, San Juan, Puerto Rico, 31 May–2 June 2016; pp. 2039–2049.

- Young, B.K.; Hosseini, A.; Lædre, O. Project alliances and lean construction principles. In Proceedings of the IGLC 2016—24th Annual Conference of the International Group for Lean Construction, Boston, MA, USA, 20–22 July 2016; pp. 33–42.

- Lamming, R.C.; Caldwell, N.D.; Harrison, D.A.; Phillips, W. Transparency in supply relationships: Concept and practice. J. Supply Chain Manag. 2001, 37, 4–10.

- Chan, D.W.M.; Chan, J.H.L. Developing a Performance Measurement Index (PMI) for Target Cost Contracts in Construction: A Delphi Study. Constr. Law J. (CLJ) 2012, 28, 590–613.

- Garza-Reyes, J.A.; Ates, E.M.; Kumar, V. Measuring lean readiness through the understanding of quality practices in the Turkish automotive suppliers industry. Int. J. Product. Perform. Manag. 2015, 64, 1092–1112.

- Alnajem, M.; Garza-Reyes, J.A.; Elmelegy, A. Measuring the lean readiness of Kuwaiti manufacturing industries. Int. J. Bus. Perform. Manag. 2019, 20, 70–92.

- Raghavan, V.A.; Testani, M.; Lam, S.S.; Srihari, K.; Ramakrishnan, S.; Testani, M.V. A Methodology for Assessing the Adoption Rates of an Organization’s Lean Transformation. 2013. Available online: https://www.researchgate.net/publication/289296761 (accessed on 15 February 2023).

- Vaishnavi, V.; Suresh, M. Assessment of healthcare organizational readiness for change: A fuzzy logic approach. J. King Saud Univ. Eng. Sci. 2022, 34, 189–197.

- Alkhoraif, A.A.; McLaughlin, P.; Rashid, H. A framework to improve lean implementation by review leveraging aspects of organisational culture: The case of Saudi Arabia. Int. J. Agil. Syst. Manag. 2019, 12, 124–179.

- Cherrafi, A.; Garza-Reyes, J.A.; Belhadi, A.; Kamble, S.S.; Elbaz, J. A readiness self-assessment model for implementing green lean initiatives. J. Clean Prod. 2021, 309, 127401.

- Sreedharan, R.V.; Raju, R.; Sunder, V.M.; Antony, J. Assessment of Lean Six Sigma Readiness (LESIRE) for manufacturing industries using fuzzy logic. Int. J. Qual. Reliab. Manag. 2019, 36, 137–161.

- Baskaran, S.M.; Lakshmanan, A.R. A framework for lean readiness evaluation using a hierarchical fuzzy system. South Afr. J. Ind. Eng. 2019, 30, 220–234.

More