Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is a comparison between Version 2 by Catherine Yang and Version 3 by Peter Tang.

Carbon neutrality is a requisite for industrial development in modern times. The most efficient source of biomass is energy crops, and Miscanthus has been globally recognized as one of the most significant among them. Miscanthus is basically utilized for the production of heat and electric power, and it is actively displacing wood in papermaking and natural cellulose isolation technologies. However, the range of potential applications of Miscanthus is much broader.

- Miscanthus

- carbon footprint

- cellulose

- industrial processing

1. Benefits of Energy Crop Miscanthus as a Tool towards Carbon Neutrality

The Miscanthus yield capacity attains a 40 t/ha cultivation area and exhibits a high energy release (140–560 Gj/ha) compared to other raw materials [1][2]. In a more severe Russian climate, the biomass yield is also rather high: about 10–16 t/ha a year [3][4]. Miscanthus can perfectly grow on marginal or unused lands. In doing so, Miscanthus has no tendency of overgrowing in uncontrolled fashion across the entire available territory, and it will thus not supersede the other plants that are customary in that location or disturb the biotic communities [5][6][7][8]. Moreover, Miscanthus successfully performs functions that improve the ecology and the environment: it protects landscapes from erosion; it favors organic matter storage in soil, considerably reducing CO2 emission [9]; it contributes to phytoremediation of contaminated soils [10]; and, finally, it supports both an active degradation of aliphatic compounds in oil-polluted soils and an increase in bacterial diversity [11]. As it grows, Miscanthus enriches the soil with organic substances and enhances the soil respiration. Thus, Miscanthus cultivation allows the sequestration of a significant quantity of soil carbon. It has been discovered that Miscanthus cultivation can be carbon-negative (i.e., the accumulation of more carbon aboveground and underground than is emitted into the atmosphere) under certain conditions [12][13][14]. This can be particularly relevant to marginal lands where soils are low in carbon, and, hence, the carbon sequestration probability is high. The agronomic, energetic, and ecological efficiencies of Miscanthus cultivation are high, then, and there are experimental data on a humus increment in the top soil during Miscanthus cultivation and on a higher ratio of energy that is contained in the aboveground biomass when compared to the overall inputs of technical energy for cultivation and harvesting [15][16][17]. The benefits of the energy crop Miscanthus as a tool to attain carbon neutrality are listed in Table 1.

Table 1. Benefits of energy crop Miscanthus as a tool towards carbon neutrality.

| Benefits | Description | Ref. |

|---|---|---|

| High yield capacity | Up to 40 tons dry biomass a hectare per annum | [1][2] |

| Perennial crop | Single planting Plantation operates for 20–25 years |

[18][19][20] |

| Simple agricultural practices | It grows on marginal lands It requires no special agronomical practices It remediates soils It is a non-invasive crop |

[5][6][7][8] |

| C4 photosynthesis | It fixates much of CO2 as it grows when compared to C3 photosynthesis | [9][21][22] |

| Chemical composition | 50% cellulose 20% lignin 20% hemicelluloses |

[18][23][24][25][26][27][28][29][30][31][32] |

| Carbon-negative crop | It fixates more CO2 during photosynthesis than it releases when converted It builds up the same biomass volume in the underground part as in the aboveground part |

[9] |

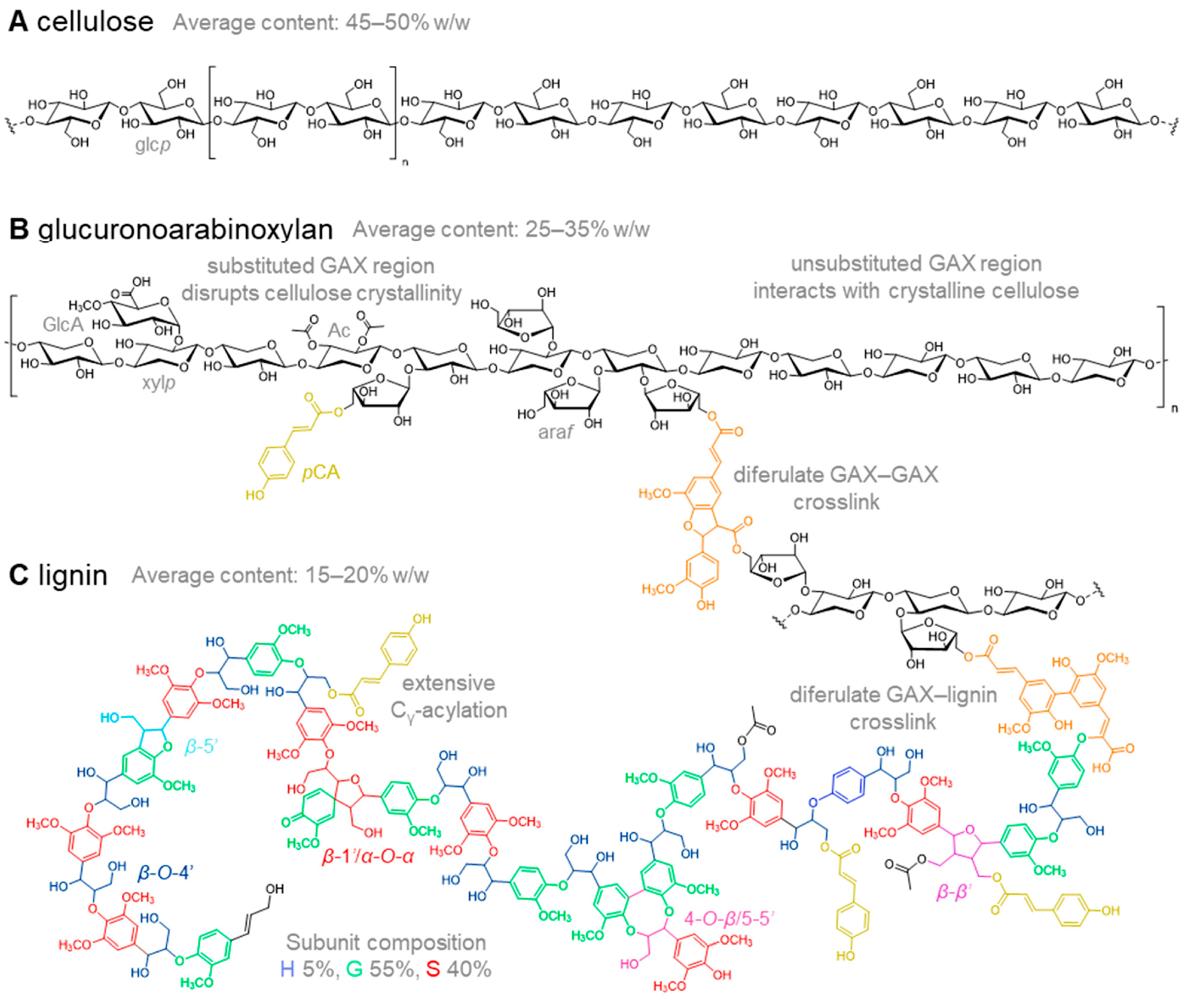

The essential merit of Miscanthus is its high cellulose content ranging from 36 to 55%, according to different data [18][23][24][25][26][27][28][29][30][31][32]. Moreover, the Miscanthus biomass contains valuable constituents, such as hemicelluloses and lignin (Figure 1). Therefore, Miscanthus is viewed as the most valuable feedstock for the manufacture of a wide spectrum of reagents and polymers [30][33][34].

Figure 1. Schematic representation of the major constituents of the Miscanthus secondary cell wall: cellulose (A), glucuronoarabinoxylan (GAX) (B), and lignin (C) (reproduced with permission from [30], MDPI, 2021).

According to some forecasts, the utilization of the Miscanthus biomass for energy needs will result in a carbon footprint reduction to 30.6 tons CO2-eq./ha a year in Central Europe, while this positive trend will constitute about 19 tons CO2-eq./ha a year in countries with a cold climate (including Russia) [35]. As per the reported estimate [19], Miscanthus cultivation would compensate for greenhouse gas emissions as high as 4.08 tons CO2-eq./ha, affecting the global environmental situation favorably.

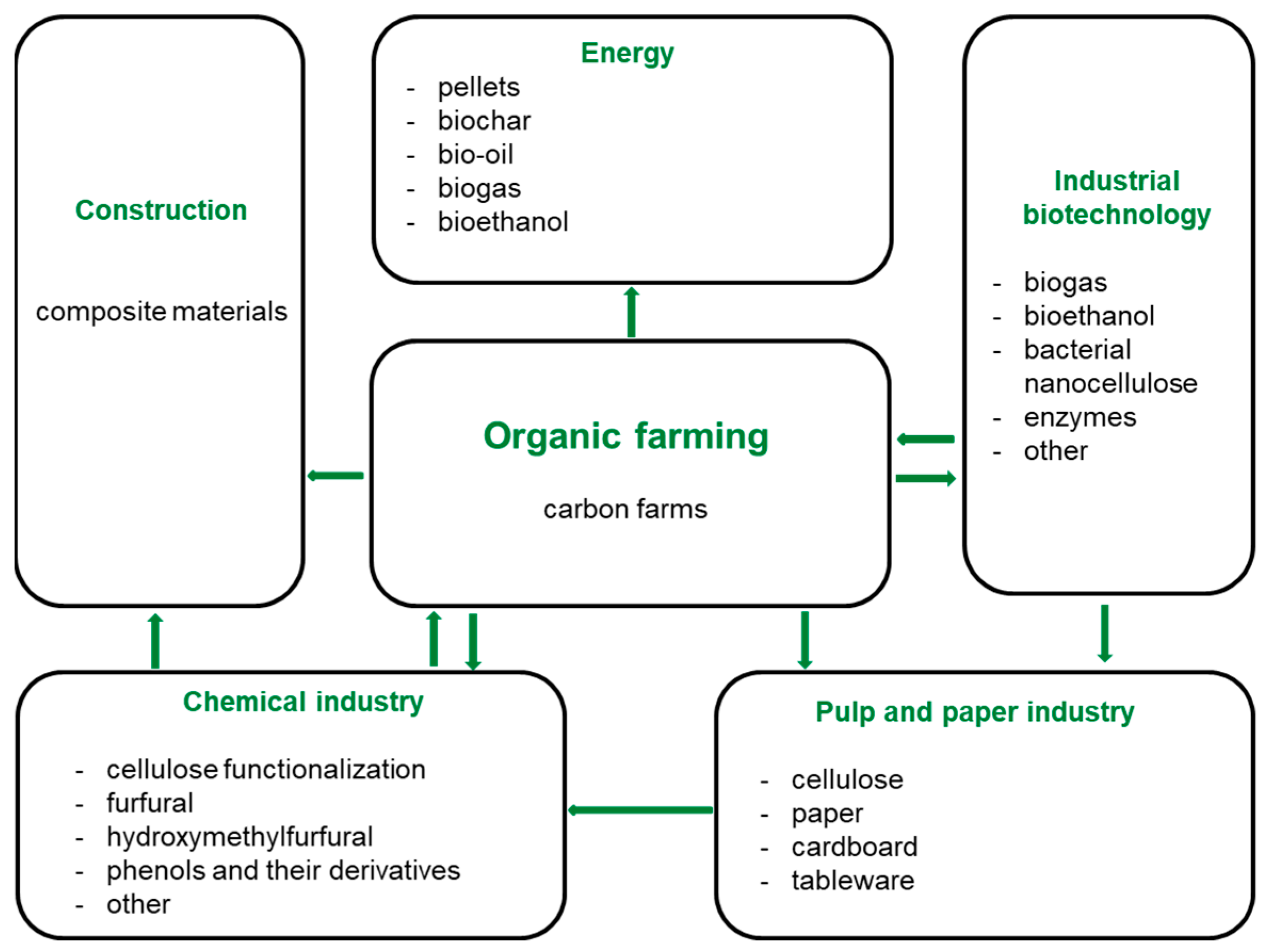

Miscanthus would help reach the carbon-neutral bioeconomy. The core applications of Miscanthus are depicted in Figure 2.

Figure 2. Miscanthus in the global carbon-neutral bioeconomy.

24. Miscanthus in Energy Production

The simplest energetic application of the Miscanthus biomass is the manufacture of fuel pellets. The studies [20][23][24] show that the Miscanthus pellets have a lower environmental impact compared to the wood ones, mainly because of less energy consumption during granulation: 1 ton of the Miscanthus pellets produce a carbon footprint of 121.6 kg CO2-eq., which is about 8% lower than that of the wood pellets [36][37][38]. In order to enhance the heating value, transgenic Miscanthus lines with enhanced lignin content were derived [39].

Perić et al. [40] carefully evaluated the pyrolysis process of Miscanthus from the viewpoint of ecology and performed an in-depth analysis of three well-to-pump pathways for the production of pyrolytic diesel: a conventional diesel production pathway, a distributed–external pathway in which the diesel stabilization and upgrading processes are separated and hydrogen is generated from natural gas, and an integrated internal pathway in which stabilization and upgrading are combined and hydrogen is generated from the pyrolytic oil fraction. The conventional diesel production pathway had the highest resource consumption, and the distributed-H2 external pathway had the highest pollutant emissions. The integrated-H2 internal pyrolytic pathway had the lowest specific environmental impact per consumed power unit, but the yield of the resultant diesel in this case was 38% lower than that in the distributed external pathway.

Apart from energy production, Miscanthus-derived biocoal can also be utilized for other purposes. Bartocci et al. [41] described a process for biocoal from Miscanthus by slow pyrolysis followed by granulation. The estimations showed that the total carbon footprint dropped by 737 kg CO2-eq./t dried feedstock. It was also indicated that the obtained biocoal, when used as a soil additive, would be able to greatly improve the soil characteristics: improvements in soil health and fertility, structure, nutrient availability, and water-holding ability, and such a treatment favored a prolonged preservation of soil carbon. Soil carbon sequestration can be viewed not only as a strategy for global climate change mitigation but also as a source of corporate profits through carbon emission trading.

There are research developments that afford bio-oil from the Miscanthus biomass by ablative fast pyrolysis [42], and the bio-oil can also be used as a biofuel alone.

Another promising direction in the transformation of Miscanthus into biofuel is the pretreatment of Miscanthus biomass followed by methane fermentation in order to generate biogas [29][43][44][45]. Dębowski et al. [46] reported a study in which microalgae biomass and Miscanthus giganteus were co-fermented. The Miscanthus giganteus silage combined with the microbial biomass was found to provide a better C/N ratio than either of the substrates used separately.

Furthermore, because Miscanthus biomass has a significant content of cellulose (about 50%), it can be hydrolyzed to monosugars after pretreatment, and, afterwards, alcoholic fermentation can be employed to obtain bioethanol, which can be used as an energy carrier [47] or a platform for further transformation into other industrially valuable components [48].

For the biomass-to-fuel transformation, Agostini et al. [49] used the top of crops that were purposely planted across the banks of basins bordering the croplands to prevent eutrophication. It was noted that the cultivation of Miscanthus and willow tree on the buffer strips could remove nutrients from the environment and fixate atmospheric carbon by creating an additional ground absorber. Bioethanol derived from that biomass also had less environmental impact compared to the fossil gasoline that was used [49].

3. Miscanthus in Construction

An interesting and promising approach to energy efficiency problematics is the development of lightweight and durable composite materials, such as thermal insulation for buildings and constructions, due to the considerable amount of power that is consumed to heat them. It is known that roughly 45% of the global greenhouse gas emissions are caused by building construction and operation [50]. The thermal insulation of buildings under the current conditions of climate change is a well-known strategy for enhancing energy efficiency in buildings. The development of a renewable thermal insulation material can overcome the drawbacks of commonly used insulation systems based on polystyrene or mineral wool. Witzleben [50] evaluated the stability and the thermal conductivity of new insulation materials composed of Miscanthus giganteus fibers, a foaming agent, and an alkali-activated binding agent. The data published over the recent years show that the carbon footprint quantity widely ranges from 300 to 3300 kg CO2-eq./t. The total carbon footprint of the isolation system based on Miscanthus fibers, having properties compliant with the current thermal insulation standards, comes up to 95% of the CO2 emissions saving compared to the common systems. Ntimugura et al. [51] proposed the use of Miscanthus straw in the manufacture of lightweight concrete blocks for use in wall structures. Another interesting development is the preparation of a self-growing, building insulation, biocomposite material based on Miscanthus × giganteus and mycelium [52]. The 0.3:1:0.1 composite was composed of Ganoderma Resinaceum mycelium, Miscanthus × giganteus fibers, and potato starch exhibited the best properties. The obtained new composite was found to have comparatively better qualities than the conventional isolation materials—more specifically, a mean density of 122 kg/m3, which characterizes the composite as being a lightweight porous material; a high thermal conductivity up to 0.104 W m−1 K−1, which indicates a high insulating ability; and a significant fire resistance, referring to fire rating EI15 as per the EN13501-2:2003 standard. The new composite thus meets most indoor use requirements.

Lemaire et al. [53] reported the study results for properties of a biocomposite material based on Miscanthus × giganteus fibers and microbial polyhydroxyalkanoates, fabricated by extrusion and pressure casting. It was pointed out that the addition of reinforcement to the polymeric matrix resulted in composites with higher elastic moduli on the one hand, and a lower tensile strength, on the other hand.

To improve the acoustic performance, Ntimugura et al. [51] prepared composites comprising Miscanthus × giganteus fibers and lime. Emphasis was made on the particle size of the composites, and it was established that small-size particles afforded Miscanthus-lime composites with higher sound absorption factors.

Wu et al. [54] reported the study results of making biocomposite plastics based on Miscanthus fibers and oat hulls. The green composites were found to exhibit a relatively high impact ductility and resistance of the melt resulting from the formation of a nanostructured matrix of ultra-high strength.

4. Miscanthus in Pulp and Paper Industry

Miscanthus refers to cellulosic raw material resources, and its biomass contains about 50% cellulose [30][31][32][55]. Cellulose is the most valuable component of Miscanthus, and a global trend towards replacing wood cellulose by Miscanthus cellulose in the manufacture of cupboards, disposable tableware, and paper is currently being observed worldwide. That being said, it is evident that wood technology cannot be carried over to Miscanthus. Over the last 50 years, only ten non-woody plants, including Miscanthus, have demonstrated good results from an evaluation of the feasibility of producing cellulose for making paper products [56][57]. Two countries in the world, China and India, have been using about 70% of non-woody plants for paper production since 1990, with Miscanthus taking the lead among the plants [58]. Therefore, processes for cellulose isolation from Miscanthus biomass are being extensively devised. Tu et al. [59] proposed the pulping of Miscanthus × giganteus biomass by using a protonic ionic liquid of triethylammonium hydrogen sulfate and 20% water added as the co-solvent. Conditions were found that remove hemicelluloses and lignin, and the pulp contained up to 82% cellulose, which had a high degree of crystallinity (73%) but a lowered degree of polymerization (DP) (a number-average DP of 257).

Tsalagkas et al. [58] reported that the preparation of cellulose pulps from Miscanthus × giganteus stalks by using hydrodynamic cavitation following an alkaline pretreatment method was able to lower the lignin content by 41.5% and raise the α-cellulose content by 13.87%. The hydrodynamic cavitation was noted to preserve the cellulose fiber length but to concurrently increase the amount of intertwined and twisted fibers.

Barbash et al. [60] obtained Miscanthus cellulose by an eco-benign organosolv process in which Miscanthus was pulped in a peracetic acid solution as the first step and then alkali-treated as the second step. Nanocellulose (particle size of 10 to 20 nm) was then derived from the resultant material by hydrolysis in a sulfuric acid solution followed by ultrasonic treatment. That study also pointed out that the use of nanocellulose had a positive effect on the physicomechanical properties of paper.

Danielewicz et al. [18] obtained pulps from Miscanthus × giganteus biomass by the two techniques, soda and kraft pulping. It was eventually found that both the processes yielded cellulose similar in properties to unbleached hardwood kraft pulps (birch, poplar, and hornbeam), and this will make it possible to replace the latter in the manufacture of packaging paper. “The tear strength and Gurley air-resistance of paper handsheets made from Miscanthus soda and kraft pulps at freeness of 35–50° SR were good and comparable with those of birch kraft pulp, respectively. All of the Miscanthus kraft pulps and the hard and regular Miscanthus soda pulps, due to the similarity of their properties to the properties of hardwood kraft pulps (birch, poplar, hornbeam) could probably replace the latter pulps in the production of packaging papers (e.g., sack paper).” Tsalagkas et al. [58] reported that the intermixing of long-fiber (softwood pulp) with short-fiber cellulose (Miscanthus pulp) improved paper properties, as the fine particle populated voids to form smoother paper sheets, which is good for printing.

Tsalagkas et al. [58] also reported that delignification combined with ultrasonic treatment allowed for a 41.5% decline in the lignin content and a 13.87% increase in the α-cellulose content. The resultant pulp was fit for papermaking—the average Miscanthus fiber length was relatively short (0.45 (±0.28) mm), while the slenderness ratio, the flexibility coefficient, and Runkel ratio values were 28.13, 38.16, and 1.62, respectively. The estimated physical properties of Miscanthus pulp handsheets were 24.88 (±3.09) N m g−1 as the tensile index, 0.92 (±0.06) kPa m2 g−1 as the burst index, and 4.0 (±0.37) mN m2 g−1 as the tear index. Thus, Miscanthus can successfully replace hardwood.

There is a process for producing long-fiber cellulose from Miscanthus by the hydrotropic method using a saturated solution of sodium benzoate as the solvent of lignin. This method is interesting because it can isolate both cellulose and lignin at the same time [61][62][63]. The hydrotropic method of pulp production involves cooking plant raw materials in neutral concentrated aqueous solutions of sodium salts of various (benzoic, naphthoic, benzenesulfonic, and naphthalenesulfonic) acids, their homologs and derivatives, sodium thiophene carboxylates, hydroaromatic derivatives (e.g., sodium naphtha enates and abietic acids), and salts of various aliphatic aromatic and aliphatic acids. All hydrotropes have a salt-forming effect, and the solubilizing ability of the hydrotropic solution increases with an increase in the salt concentration. The use of water soluble and safe hydrotropic agents meets the “green chemistry” principles. Hydrotropic processing under optimized conditions (180 °C, 5 h) produces pulps in a 42.3% yield, and the lignin, pentosan, and ash contents are 6.1, 6.4, and 3.0%, respectively.

The peculiar feature of Miscanthus is its enhanced lignin content, which must be taken into account in its conversion technology [64]. Very attractive results were reported by Singh et al. [65], who devised a method by which paper sheets derived from Miscanthus × giganteus cellulose fibers were prepared for potential contact with foods. Paper was hydrophobized with modified lignin, which was also isolated from Miscanthus × giganteus biomass via hydroxyethylation with ethylene carbonate, followed by esterification with propionic acid. The results from that study showed that the Miscanthus paper coated with esterified lignin holds promise as a hydrophobic food packaging material that can be an alternative to conventional thermoplastics based on fossil fuel.

5. Miscanthus in Chemical Industry

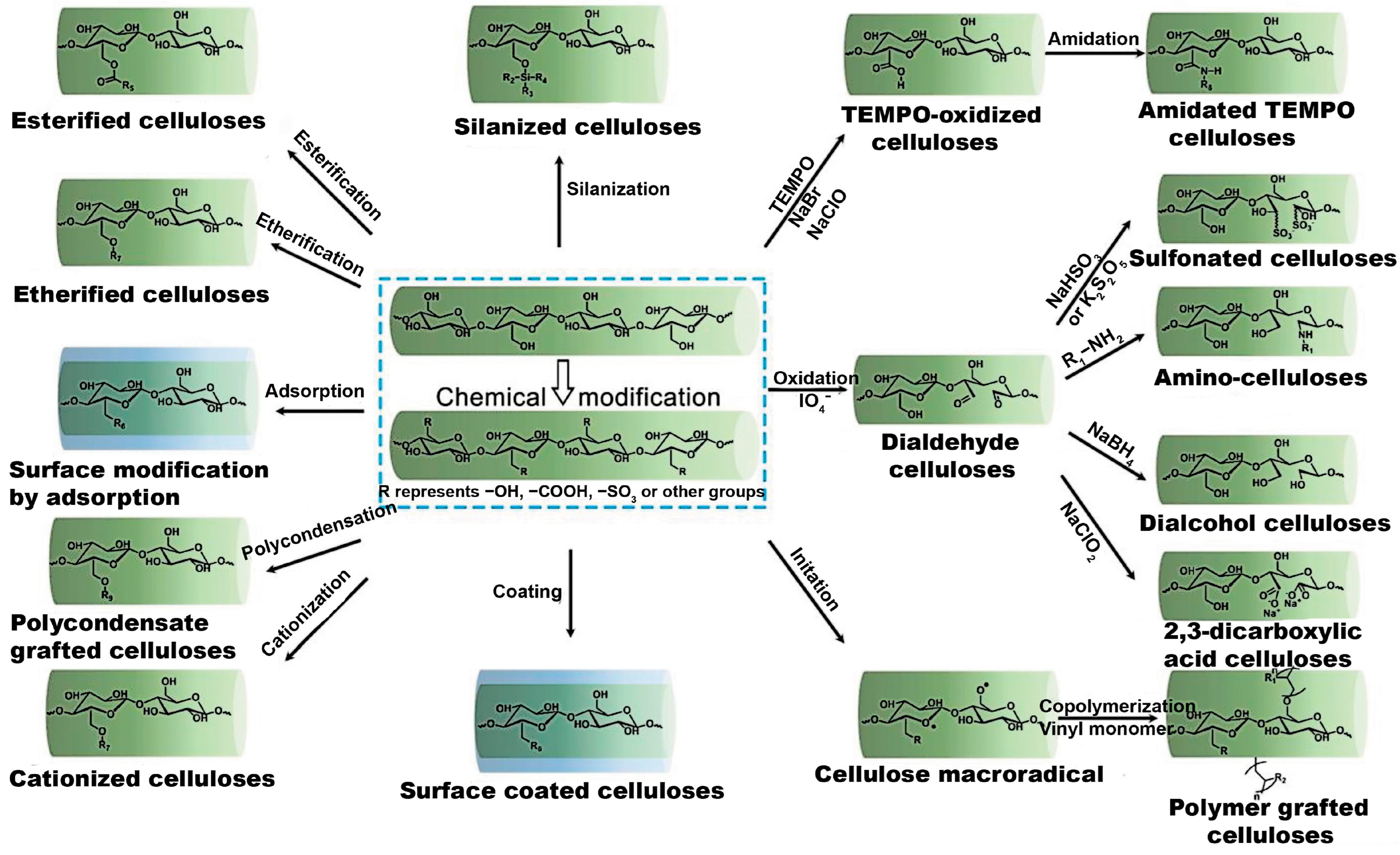

The essential application of cellulose is tailoring its functionality. The main applications are depicted in Figure 3 [66][67][68][69].

Figure 3. An overview of tailoring the functionality of cellulose (reproduced with permission from [66], MDPI, 2023).

Miscanthus can also be involved in various projects as part of the biomass refining concept to produce valuable chemicals, such as 5-hydroxymethyl furfural and furfural, as well as chemicals from mixed phenols [70][71] if emphasis is placed on Miscanthus as the source of lignocellulosic biomass. Hydroxymethyl furfural is a promising platform molecule as a substitute for toxic formaldehyde, and it can serve as a feedstock for fungicides or be a part of electron-transfer catalysts [72]. There are data that fuel and food additives can be made with hydroxymethyl furfural as the platform. 5-Hydroxymethylfurfural (5-HMF) is bio-based and can produce polymers with a low refractory deformation temperature, which is a clear advantage for biopolymers. “5-HMF conversion to monomers and polymers can be categorized into three main groups: (1) polymers containing a furan ring: e.g., furan-2,5-dicarboxylic acid (FDCA), 2,5-dihydroxymethylfuran (DHMF), or 5-hydroxymethylfuran-2-carboxylic acid (HMFCA); (2) polymers containing C6 carbon chains with adipic acid or 1,6 hexanediol as building blocks; (3) other polymers made from FDCA with ethylene via the Diels-Alder-reaction e.g., promising building blocks levulinic acid and terephthalic acid” [73]. Hydroxymethyl furfural is also a building block in the manufacture of polyesters, polyamides, and other plastics [74].

Furfural is another bio-based chemical and an essential furan derivative for biochemistry [75]. It is produced from hemicellulose, and it can be a substitute for formaldehyde as well. Among the core applications of furfural is the hydrogenation to furfuryl alcohol. The annual output of furfural ranges from 300 to 700 Kt [76]. Other promising furfural derivatives have also been synthesized in recent years. For instance, a bio-based polyethylene-furanoate (PEF) was obtained by bioconversion of furfural and is able to generate fibers and films, and it can be used for the fabrication of a disposable biodegradable package. 5-Hydroxymethylfurfural derivatives are potential building blocks for step-growth polymers. The aromatic nature of the furan ring gives access to conjugated polymers, especially for optoelectronic applications [75][77]. The phenol mixture that basically contains phenol, catechol, eugenol, and so forth from the lignin fraction also has significant potential, especially in the pharmaceutical industry, for the synthesis of drugs, the manufacture of insecticides, and so on [78].

There are data on the development of a modular concept of biorefinery for the production of hydroxymethyl furfural (HMF), furfural, and phenols from the perennial lignocellulosic Miscanthus, which is cultivatable on marginal and dehydrated territories. As per the techno-economic estimations by Götz et al. [79], “regional biorefineries could already offer platform chemicals at prices of 2.21–2.90 EUR/kg HMF at the current stage of development. This corresponds to three to four times the price of today’s comparative fossil base chemicals.” From the standpoint of these authors, such a concept is a competitive option of biorefinery for the conversion of Miscanthus into valuable chemicals.

References

- Turner, W.; Greetham, D.; Mos, M.; Squance, M.; Kam, J.; Du, C. Exploring the bioethanol production potential of Miscanthus cultivars. Appl. Sci. 2021, 11, 9949.

- Chandel, H.; Kumar, P.; Chandel, A.K.; Verma, M.L. Biotechnological advances in biomass pretreatment for bio-renewable production through nanotechnological intervention. Biomass Convers. Biorefinery 2022, 1–23.

- Kapustyanchik, S.Y.; Yakimenko, V.N.; Gismatulina, Y.A.; Budaeva, V.V. Miscanthus—A Promising Energy Crop for Industrial Processing. Ecol. Ind. Russ. 2021, 25, 66–71. (In Russian)

- Dorogina, O.V.; Vasil’eva, O.Y.; Nuzhdina, N.S.; Buglova, L.V.; Zhmud, E.V.; Zueva, G.A.; Dudkin, R.V. Formation and study of the collection gene pool of resource species of the genus Miscanthus Anderss in the conditions of the forest–steppe of Western Siberia. Vavilov. Zh. Genet. Selekts. 2019, 23, 926–932.

- Schorling, M.; Enders, C.; Voigt, C.A. Assessing the cultivation potential of the energy crop Miscanthus × giganteus for Germany. GCB Bioenerg. 2015, 7, 763–773.

- Nakajima, T.; Yamada, T.; Anzoua, K.G.; Kokubo, R.; Noborio, K. Carbon sequestration and yield performances of Miscanthus × giganteus and Miscanthus× sinensis. Carbon Manag. 2018, 9, 415–423.

- Shepherd, A.; Awty-Carroll, D.; Kam, J.; Ashman, C.; Magenau, E.; Martani, E.; Hastings, A. Novel Miscanthus hybrids-Modelling productivity on marginal land in Europe using dynamics of canopy development determined by light interception. GCB Bioenergy 2023, 15, 444–461.

- Feng, H.; Lin, C.; Liu, W.; Xiao, L.; Zhao, X.; Kang, L.; Liu, X.; Sang, T.; Yi, Z.; Yan, J.; et al. Transcriptomic Characterization of Miscanthus sacchariflorus × M. lutarioriparius and Its Implications for Energy Crop Development in the Semiarid Mine Area. Plants 2022, 11, 1568.

- Briones, M.J.; Massey, A.; Elias, D.M.; McCalmont, J.P.; Farrar, K.; Donnison, I.; McNamara, N.P. Species selection determines carbon allocation and turnover in Miscanthus crops: Implications for biomass production and C sequestration. Sci. Total Environ. 2023, 887, 164003.

- Andrejić, G.; Šinžar-Sekulić, J.; Prica, M.; Dželetović, Ž.; Rakić, T. Phytoremediation potential and physiological response of Miscanthus× giganteus cultivated on fertilized and non-fertilized flotation tailings. Environ. Sci. Pollut. Res. 2019, 26, 34658–34669.

- Nebeská, D.; Trögl, J.; Ševců, A.; Špánek, R.; Marková, K.; Davis, L.; Pidlisnyuk, V. Miscanthus× giganteus role in phytodegradation and changes in bacterial community of soil contaminated by petroleum industry. Ecotoxicol. Environ. Saf. 2021, 224, 112630.

- Dželetović, Ž.; Andrejić, G.Z.; Simić, A.; Geren, H. Influence of rhizome mass on the crop establishment and dry matter yield of Miscanthus× giganteus over ten seasons. J. Agric. Sci. 2019, 64, 21–35.

- Al Souki, K.S.; Burdová, H.; Trubač, J.; Štojdl, J.; Kuráň, P.; Kříženecká, S.; Machová, I.; Kubát, K.; Popelka, J.; Malinská, H.A.; et al. Enhanced carbon sequestration in marginal land upon shift towards perennial C4 Miscanthus× giganteus: A case study in North-Western Czechia. Agronomy 2021, 11, 293.

- Iordan, C.M.; Giroux, B.; Næss, J.S.; Hu, X.; Cavalett, O.; Cherubini, F. Energy potentials, negative emissions, and spatially explicit environmental impacts of perennial grasses on abandoned cropland in Europe. Environ. Impact Assess. Rev. 2023, 98, 106942.

- Kasanke, C.P.; Zhao, Q.; Bell, S.; Thompson, A.M.; Hofmockel, K.S. Can switchgrass increase carbon accrual in marginal soils? The importance of site selection. GCB Bioenergy 2021, 13, 320–335.

- Kapustyanchik, S.Y.; Danilova, A.A.; Likhenko, I.E. Miscanthus sacchariflorus in Siberia—Biological yield parameters and dynamics of biofilic elements. Agric. Biol. 2021, 56, 121–134.

- Dorogina, O.V.; Nuzhdina, N.S.; Zueva, G.A.; Gismatulina, Y.A.; Vasilyeva, O.Y. Features of shoot formation in populations of Miscanthus sacchariflorus (Poaceae) under the influence of environmental factors and certification using ISSR markers. Vavilovskii Zhurnal Genet. I Sel. Vavilov J. Genet. Breed. 2022, 26, 22–29.

- Danielewicz, D.; Surma-Ślusarska, B. Miscanthus× giganteus stalks as a potential non-wood raw material for the pulp and paper industry. Influence of pulping and beating conditions on the fibre and paper properties. Ind. Crops Prod. 2019, 141, 111744.

- Wang, C.; Kong, Y.; Hu, R.; Zhou, G. Miscanthus: A fast-growing crop for environmental remediation and biofuel production. GCB Bioenergy 2021, 13, 58–69.

- Bergs, M.; Monakhova, Y.; Diehl, B.W.; Konow, C.; Völkering, G.; Pude, R.; Schulze, M. Lignins Isolated via Catalyst-free Organosolv Pulping from Miscanthus× giganteus, M. sinensis, M. robustus and M. nagara: A Comparative Study. Molecules 2021, 26, 842.

- Blätke, M.A.; Bräutigam, A. Evolution of C4 photosynthesis predicted by constraint-based modelling. Elife 2019, 8, e49305.

- Dorogina, O.V.; Nuzhdina, N.S.; Kozlova, M.V.; Zueva, G.A.; Vasilyeva, O.Y. Identification of Populations by ISSR Markers and a Histochemical Determination of Transient Starch in Species of the Genus Miscanthus Anderss. Contemp. Probl. Ecol. 2023, 16, 67–75.

- Allison, G.G.; Morris, C.; Clifton-Brown, J.; Lister, S.J.; Donnison, I.S. Genotypic variation in cell wall composition in a diverse set of 244 accessions of Miscanthus. Biomass Bioenergy 2011, 35, 4740–4747.

- Hodgson, E.M.; Nowakowski, D.J.; Shield, I.; Riche, A.; Bridgwater, A.V.; Clifton-Brown, J.C.; Donnison, I.S. Variation in Miscanthus chemical composition and implications for conversion by pyrolysis and thermo-chemical bio-refining for fuels and chemicals. Bioresour. Technol. 2011, 102, 3411–3418.

- Lee, W.C.; Kuan, W.C. Miscanthus as cellulosic biomass for bioethanol production. Biotechnol. J. 2015, 10, 840–854.

- Arnoult, S.; Brancourt-Hulmel, M. A review on Miscanthus biomass production and composition for bioenergy use: Genotypic and environmental variability and implications for breeding. BioEnergy Res. 2015, 8, 502–526.

- Vanderghem, C.; Brostaux, Y.; Jacquet, N.; Blecker, C.; Paquot, M. Optimization of formic/acetic acid delignification of Miscanthus giganteus for enzymatic hydrolysis using response surface methodology. Ind. Crops Prod. 2012, 35, 280–286.

- Schläfle, S.; Tervahartiala, T.; Senn, T.; Kölling-Paternoga, R. Quantitative and visual analysis of enzymatic lignocellulose degradation. Biocatal. Agric. Biotechnol. 2017, 11, 42–49.

- Wahid, R.; Nielsen, S.F.; Hernandez, V.M.; Ward, A.J.; Gislum, R.; Jørgensen, U.; Møller, H.B. Methane production potential from Miscanthus sp.: Effect of harvesting time, genotypes and plant fractions. Biosyst. Eng. 2015, 133, 71–80.

- Van der Cruijsen, K.; Al Hassan, M.; van Erven, G.; Dolstra, O.; Trindade, L.M. Breeding targets to improve biomass quality in Miscanthus. Molecules 2021, 26, 254.

- Gismatulina, Y.A.; Budaeva, V.V. Chemical composition of five Miscanthus sinensis harvests and nitric-acid cellulose therefrom. Ind. Crops Prod. 2017, 109, 227–232.

- Gismatulina, Y.A.; Budaeva, V.V.; Kortusov, A.N.; Kashcheyeva, E.I.; Gladysheva, E.K.; Mironova, G.F.; Skiba, E.A.; Shavyrkina, N.A.; Korchagina, A.A.; Zolotukhin, V.N.; et al. Evaluation of Chemical Composition of Miscanthus × giganteus Raised in Different Climate Regions in Russia. Plants 2022, 11, 2791.

- Sanchez, N.; Ruiz, R.; Plazas, A.; Vasquez, J.; Cobo, M. Effect of pretreatment on the ethanol and fusel alcohol production during fermentation of sugarcane press-mud. Biochem. Eng. J. 2020, 161, 107668.

- Isikgor, F.H.; Becer, C.R. Lignocellulosic biomass: A sustainable platform for the production of bio-based chemicals and polymers. Polym. Chem. 2015, 6, 4497–4559.

- Lewandowski, I.; Clifton-Brown, J.; Trindade, L.M.; Van Der Linden, G.C.; Schwarz, K.-U.; Müller-Sämann, K.; Anisimov, A.; Chen, C.-L.; Dolstra, O.; Donnison, I.S.; et al. Progress on optimizing Miscanthus biomass production for the European bioeconomy: Results of the EU FP7 project OPTIMISC. Front. Plant Sci. 2016, 7, 1620.

- Fusi, A.; Bacenetti, J.; Proto, A.R.; Tedesco, D.E.; Pessina, D.; Facchinetti, D. Pellet production from Miscanthus: Energy and environmental assessment. Energies 2020, 14, 73.

- Francik, S.; Knapczyk, A.; Knapczyk, A.; Francik, R. Decision Support System for the Production of Miscanthus and Willow Briquettes. Energies 2020, 13, 1364.

- Perić, M.; Komatina, M.; Antonijević, D.; Bugarski, B.; Dželetović, Ž. Life cycle impact assessment of Miscanthus crop for sustainable household heating in Serbia. Forests 2018, 9, 654.

- Bhatia, R.; Timms-Taravella, E.; Roberts, L.A.; Moron-Garcia, O.M.; Hauck, B.; Dalton, S.; Gallagher, J.A.; Wagner, M.; Clifton-Brown, J.; Bosch, M. Transgenic ZmMYB167 Miscanthus sinensis with increased lignin to boost bioenergy generation for the bioeconomy. Biotechnol. Biofuels Bioprod. 2023, 16, 29.

- Perić, M.; Komatina, M.; Antonijević, D.; Bugarski, B.; Dzeletović, Ž.S. Diesel production by fast pyrolysis of Miscanthus giganteus, well-to-pump analysis using the greet model. Therm. Sci. 2019, 23, 365–378.

- Bartocci, P.; Bidini, G.; Saputo, P.; Fantozzi, F. Biochar pellet carbon footprint. Chem. Eng. 2016, 50, 217–222.

- Conrad, S.; Blajin, C.; Schulzke, T.; Deerberg, G. Improved fast pyrolysis bio-oils from straw and Miscanthus by fractionated condensation. Environ. Prog. Sustain. Energy 2022, 41, e13708.

- Baldini, M.; da Borso, F.; Ferfuia, C.; Zuliani, F.; Danuso, F. Ensilage suitability and bio-methane yield of Arundo donax and Miscanthus× giganteus. Ind. Crops Prod. 2017, 95, 264–275.

- Thomas, H.L.; Arnoult, S.; Brancourt-Hulmel, M.; Carrère, H. Methane production variability according to Miscanthus genotype and alkaline pretreatments at high solid content. BioEnergy Res. 2019, 12, 325–337.

- Wang, Q.; Xia, C.; Alagumalai, K.; Le, T.T.N.; Yuan, Y.; Khademi, T.; Berkani, M.; Lu, H. Biogas generation from biomass as a cleaner alternative towards a circular bioeconomy: Artificial intelligence, challenges, and future insights. Fuel 2023, 333, 126456.

- Dębowski, M.; Kazimierowicz, J.; Zieliński, M.; Bartkowska, I. Co-Fermentation of microalgae biomass and Miscanthus × giganteus silage—Assessment of the substrate, biogas production and digestate characteristics. Appl. Sci. 2022, 12, 7291.

- Von Cossel, M.; Winkler, B.; Mangold, A.; Lask, J.; Wagner, M.; Lewandowski, I.; Elbersen, B.; Eupen, M.; Mantel, S.; Kiesel, A. Bridging the gap between biofuels and biodiversity through monetizing environmental services of Miscanthus cultivation. Earth’s Future 2020, 8, e2020EF001478.

- Skiba, E.A.; Ovchinnikova, E.V.; Budaeva, V.V.; Banzaraktsaeva, S.P.; Kovgan, M.A.; Chumachenko, V.A.; Mironova, G.F.; Kortusov, A.N.; Parmon, V.N.; Sakovich, G.V. Miscanthus bioprocessing using HNO3-pretreatment to improve productivity and quality of bioethanol and downstream ethylene. Ind. Crops Prod. 2022, 177, 114448.

- Agostini, A.; Serra, P.; Giuntoli, J.; Martani, E.; Ferrarini, A.; Amaducci, S. Biofuels from perennial energy crops on buffer strips: A win-win strategy. J. Clean. Prod. 2021, 297, 126703.

- Witzleben, S. Minimizing the Global Warming Potential with Geopolymer-Based Insulation Material with Miscanthus Fiber. Polymers 2022, 14, 3191.

- Ntimugura, F.; Vinai, R.; Harper, A.B.; Walker, P. Environmental performance of Miscanthus-lime lightweight concrete using life cycle assessment: Application in external wall assemblies. Sustain. Mater. Technol. 2021, 28, e00253.

- Dias, P.P.; Jayasinghe, L.B.; Waldmann, D. Investigation of Mycelium-Miscanthus composites as building insulation material. Results Mater. 2021, 10, 100189.

- Lemaire, T.; Rodi, E.G.; Langlois, V.; Renard, E.; Sansalone, V. Study of Mechanical Properties of PHBHV/Miscanthus Green Composites Using Combined Experimental and Micromechanical Approaches. Polymers 2021, 13, 2650.

- Wu, F.; Misra, M.; Mohanty, A.K. Sustainable green composites from biodegradable plastics blend and natural fibre with balanced performance: Synergy of nano-structured blend and reactive extrusion. Compos. Sci. Technol. 2020, 200, 108369.

- Brosse, N.; El Hage, R.; Sannigrahi, P.; Ragauskas, A. Dilute sulphuric acid and ethanol organosolv pretreatment of Miscanthus × giganteus. Cellul. Chem. Technol. 2010, 44, 71–78.

- Gonzalo, A.; Bimbela, F.; Sánchez, J.L.; Labidi, J.; Marín, F.; Arauzo, J. Evaluation of different agricultural residues as raw materials for pulp and paper production using a semichemical process. J. Clean. Prod. 2017, 156, 184–193.

- Sapuan, S.M.; Ainun, Z.M.A.; Zakiah, S.; Nazrin, A.; Ilyas, R.A. Introduction to nonwood plant fibers for pulp and papermaking production. In Pulping and Papermaking of Nonwood Plant Fibers; Academic Press: Cambridge, MA, USA, 2023; pp. 1–15.

- Tsalagkas, D.; Börcsök, Z.; Pásztory, Z.; Gogate, P.; Csóka, L. Assessment of the papermaking potential of processed Miscanthus× giganteus stalks using alkaline pre-treatment and hydrodynamic cavitation for delignification. Ultrason. Sonochemistry 2021, 72, 105462.

- Tu, W.-C.; Weigand, L.; Hummel, M.; Sixta, H.; Brandt-Talbot, A.; Hallett, J.P. Characterisation of cellulose pulps isolated from Miscanthus using a low-cost acidic ionic liquid. Cellulose 2020, 27, 4745–4761.

- Barbash, V.A.; Yashchenko, O.V.; Vasylieva, O.A. Preparation and application of nanocellulose from Miscanthus× giganteus to improve the quality of paper for bags. SN Appl. Sci. 2020, 2, 727.

- Pavlov, I.N.; Denisova, M.N.; Makarova, E.I.; Budaeva, V.V.; Sakovich, G.V. Versatile thermobaric setup and production of hydrotropic cellulose therein. Cellul. Chem. Technol. 2015, 49, 847–852.

- Denisova, M.N.; Kukhlenko, A.A.; Orlov, S.E.; Sakovich, G.V. The characteristics of the hydrotropic Miscanthus pulp. Russ. Chem. Bull. 2015, 64, 2182–2188.

- Pavlov, I.N.; Kukhlenko, A.A.; Sevastyanova, Y.V. Hydrotropic cooking of Miscanthus to obtain pulp. J. Sib. Fed. Univ. Chem. 2019, 12, 483–493.

- Podgorbunskikh, E.M.; Bychkov, A.L.; Ryabchikova, E.I.; Lomovsky, O.I. The effect of thermomechanical pretreatment on the structure and properties of lignin-rich plant biomass. Molecules 2020, 25, 995.

- Singh, S.S.; Zaitoon, A.; Sharma, S.; Manickavasagan, A.; Lim, L.T. Enhanced hydrophobic paper-sheet derived from Miscanthus× giganteus cellulose fibers coated with esterified lignin and cellulose acetate blend. Int. J. Biol. Macromol. 2022, 223, 1243–1256.

- Zhang, Y.; Deng, W.; Wu, M.; Rahmaninia, M.; Xu, C.; Li, B. Tailoring Functionality of Nanocellulose: Current Status and Critical Challenges. Nanomaterials 2023, 13, 1489.

- Gismatulina, Y.A.; Budaeva, V.V.; Sakovich, G.V. Nitrocellulose synthesis from Miscanthus cellulose. Propellants Explos. Pyrotech. 2018, 43, 96–100.

- Korchagina, A.A.; Gismatulina, Y.A.; Budaeva, V.V.; Zolotukhin, V.N.; Bychin, N.V.; Sakovich, G.V. Miscanthus giant grade “KAMIS”—A new raw material for cellulose nitrates. J. Sib. Fed. Univ. Chem. 2020, 13, 565–577.

- Tang, R.; Xie, M.Y.; Li, M.; Cao, L.; Feng, S.; Li, Z.; Xu, F. Nitrocellulose Membrane for Paper-based Biosensor. Appl. Mater. Today 2022, 26, 101305.

- Dahmen, N.; Lewandowski, I.; Zibek, S.; Weidtmann, A. Integrated lignocellulosic value chains in a growing bioeconomy: Status quo and perspectives. GCB Bioenergy 2019, 11, 107–117.

- Świątek, K.; Gaag, S.; Klier, A.; Kruse, A.; Sauer, J.; Steinbach, D. Acid hydrolysis of lignocellulosic biomass: Sugars and furfurals formation. Catalysts 2020, 10, 437.

- Bozell, J.J.; Petersen, G.R. Technology development for the production of biobased products from biorefinery carbohydrates—The US Department of Energy’s “Top 10” revisited. Green Chem. 2010, 12, 539.

- Krawielitzki, S.; Kläusli, T.M. Modified hydrothermal carbonization process for producing biobased 5-HMF platform chemical. Ind. Biotechnol. 2015, 11, 6–8.

- Dutta, S.; De, S.; Saha, B. A brief summary of the synthesis of polyester building-block chemicals and biofuels from 5-hydroxymethylfurfural. ChemPlusChem 2012, 77, 259–272.

- Alphy, M.P.; Balakumaran, P.A.; Sindhu, R.; Pandey, A.; Binod, P. Chapter 6—Integrated bio-based processes for the production of industrially important chemicals. In Biomass, Biofuels, Biochemicals—Circular Bioeconomy: Technologies for Biofuels and Biochemicals; Varjani, V., Pandey, A., Bhaskar, T., Mohan, S.V., Tsang, D.C.W., Eds.; Elsevier: Amsterdam, The Netherlands, 2022; pp. 163–187.

- Schwiderski, M.; Kruse, A. Process design and economics of an aluminium chloride catalysed organosolv process. Biomass Convers. Biorefinery 2016, 6, 335–345.

- Lee, S.Y.; Kim, H.U.; Chae, T.U.; Cho, J.S.; Kim, J.W.; Shin, J.H.; Kim, D.I.; Ko, Y.-S.; Jang, W.D.; Jang, Y.-S. A comprehensive metabolic map for production of bio-based chemicals. Nat. Catal. 2019, 2, 18–33.

- Barboza, J.N.; da Silva Maia Bezerra Filho, C.; Silva, R.O.; Medeiros, J.V.R.; de Sousa, D.P. An overview on the anti-inflammatory potential and antioxidant profile of eugenol. Oxidative Med. Cell. Longev. 2018, 2018, 3957262.

- Götz, M.; Rudi, A.; Heck, R.; Schultmann, F.; Kruse, A. Processing Miscanthus to high-value chemicals: A techno-economic analysis based on process simulation. GCB Bioenergy 2022, 14, 447–462.

More