You're using an outdated browser. Please upgrade to a modern browser for the best experience.

Please note this is a comparison between Version 2 by Wendy Huang and Version 1 by Ruan Carlos Alves Pereira.

Sensors play a crucial role in Industry 4.0 by enabling machines to collect and analyze data in real time, which can be used to improve production processes and increase efficiency. Smart sensors can monitor a variety of parameters in an electric motor, such as temperature, vibration, and electric tension, providing valuable insight into its performance and condition. These data can be used to identify potential issues before they escalate, reducing downtime and increasing productivity.

- Industry 4.0

- smart sensors

- integrated sensor

- microprocessor

- application

1. Introduction

The Industrial Revolution marked a turning point in the history of humanity, leading to the development of new technologies and innovations that changed the way we live and work. One of the key advancements of the Industrial Revolution was the development of sensors for machines [1[1][2][3][4],2,3,4], which helped to increase efficiency and productivity in manufacturing. With the advent of the Fourth Industrial Revolution, or Industry 4.0, the use of sensors has become even more widespread, leading to the creation of smart factories and the integration of advanced technologies such as the Internet of Things (IoT) and artificial intelligence (AI) [1,5][1][5].

Scholars and practitioners [6,7,8,9][6][7][8][9] have started to analyze relationships between Industry 4.0 technologies and environmental management. In the manufacturing sector specifically, some companies are implementing solutions based on smart sensors and AI, especially to improve energy consumption, while others are focusing on additive manufacturing to conserve and reuse resources [3]. Although some companies are implementing Industry 4.0 technologies to address waste management, it is unclear what kind of Industry 4.0 technologies may assist with this or with air and water pollution. On this uncertain ground, authors such as [10] believe that Industry 4.0 technologies may hamper environmental performance.

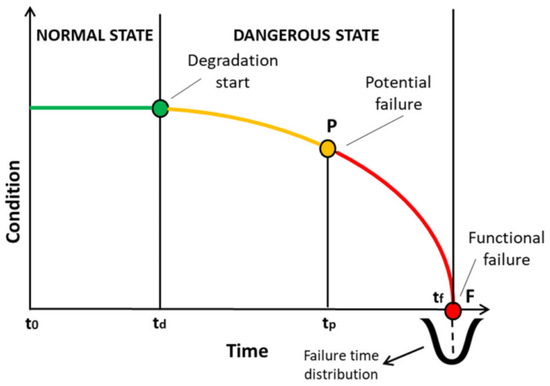

Sensors play a crucial role in Industry 4.0 by enabling machines to collect and analyze data in real time, which can be used to improve production processes and increase efficiency [11,12,13,14,15,16,17,18,19][11][12][13][14][15][16][17][18][19]. The research of [20] confirms that sensors can perform such roles. According to Refs. [21[21][22],22], the sooner the electrical anomaly is identified, the longer the best performance of the electric motor will be maintained. This concept is characterized by bringing the preventive maintenance intervention, by predictive methods, to point P of the P-F curve, as found in Ref. [23] and shown in Figure 1. Thus, we can monitor the performance of machines, detect potential problems, and trigger maintenance activities before they become critical. This proactive approach to industrial maintenance can help by reducing downtime, minimizing the risk of equipment failure, and extending the lifespan of important parts of machines, such as electric motors [21,24,25][21][24][25].

Figure 1.

P-F curve.

The objective of such predictive maintenance is to reduce maintenance costs and increase the availability of the machine in an attempt to identify various issues in a system from the start of the degradation. Based on this information, the manager can decide which type of maintenance intervention would be better [23].

The Figure 1 show three examples of conditions of machine or system. The first condition, indicated by the green line is a perfect condition of the system, after the green line, the system start to decrease their functions condition. The point “P” represent the increase probability point of potential failure. Without maintenance or any intervention, the system could present a functional failure, generating stops or loss of productivities in the system.

In addition, among the industrial equipment currently used, those that have electric motors as an integral part of the equipment or system are significant in quantity and criticality, allowing machines to perform the required tasks [26]. Electric motors are important devices for many industrial processes, as they are widely used as primary movers of most of the loads involved in these applications [27]. According to Refs. [10[10][28],28], their vast usage can represent, in terms of electrical consumption, between 40% and 60% of the total consumption on any industrial site.

Smart sensors can monitor a variety of parameters in an electric motor, such as temperature, vibration, and electric tension, providing valuable insight into its performance and condition [10]. These data can be used to identify potential issues before they escalate, reducing downtime and increasing productivity [29,30][29][30].

Additionally, the use of smart sensors can also help companies to optimize their energy usage, as well as track and manage their carbon footprint [7,31][7][31]. With this information, companies can make informed decisions about how to reduce their environmental impact while improving their bottom line, as reported by Ref. [31]. However, there are several types of smart sensors available on the market. It is necessary to evaluate which sensor is most suitable for a specific operation, considering physical parameters of the process, such as temperature and vibration range, and aspects such as the financial ability to purchase these sensors [32,33,34][32][33][34].

2. Smart Sensors Application

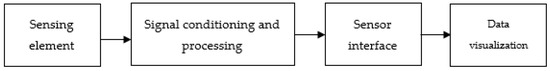

Smart sensors can be found in a wide range of applications, from industrial machinery, subway stations, and smart homes to wearable devices and medical equipment. They can measure a variety of parameters, such as temperature, humidity, light, and motion, providing real-time data to help monitor and control systems [35,36][35][36]. According to Ref. [37], in the conventional approach, the sheer number of accompanying wires, fiber optic cables, or other physical transmission mediums may be prohibitive, particularly for structures such as long-span bridges or tall buildings. Consequently, global wireless communication technologies, which will facilitate low-cost, densely distributed sensing, have been investigated [38]. A sensor is a device designed to take information from an object and convert it into an electrical signal [38,39][38][39]. According to Ref. [40], conventional integrated sensors can be divided into three parts (Figure 2): (i) the sensing element; (ii) signal conditioning and processing (e.g., amplification, linearization, compensation, and filtering); and (iii) sensor interfaces (e.g., wires, plugs, and sockets for communication with other electronic components).

Figure 2.

Traditional sensors logic diagram.

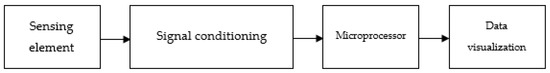

Figure 3.

Smart sensor logic diagram.

Table 1.

Functions of a smart sensor.

| Characteristics | Description |

|---|---|

| Multi-functionality | Smart sensors are capable of not only detecting and measuring physical variables, but also processing, storing, and transmitting data. |

| Connectivity | Smart sensors can communicate wirelessly with other devices and systems, allowing for real-time data exchange and control. |

| Autonomy | Smart sensors can make decisions based on their measurements, without the need for human intervention. |

| Intelligence | Smart sensors use algorithms and machine learning techniques used to analyze data, identify patterns, and make predictions. |

| Integration | Smart sensors can be used to integrate systems that were previously installed. |

| Miniaturization | Smart sensors are often designed to be small and compact, making them suitable for use in a variety of applications and environments. |

| Cost-effectiveness | Smart sensors offer a cost-effective solution for monitoring and controlling physical processes, compared to traditional approaches that require multiple sensors, data loggers, and other hardware. |

References

- Alaloul, W.S.; Liew, M.S.; Zawawi, N.A.W.A.; Mohammed, B.S. Industry revolution IR 4.0: Future opportunities and challenges in Construction Industry. MATEC Web Conf. 2018, 203, 02010.

- Favennec, J. Smart sensors in industry. J. Phys. E 1987, 20, 1087–1090.

- Zaidan, A.A.; Zaidan, B.B.; Qahtan, M.Y.; Albahri, O.S.; Albahri, A.S.; Alaa, M.; Jumaah, F.M.; Talal, M.; Tan, K.L.; Shir, W.L.; et al. A survey on communication components for IoTbased technologies in smart. Telecommun. Syst. 2018, 69, 1–25.

- Siow, E.; Tiropanis, T.; Hall, W. Analytics for the Internet of Things. ACM Comput. Surv. 2019, 51, 1–36.

- Alaloul, W.S.; Liew, M.S.; Zawawi, N.A.W.A.; Kennedy, I.B. Industrial Revolution 4.0 in the construction industry: Challenges and opportunities for stakeholders. Ain Shams Eng. J. 2020, 11, 225–230.

- Chiarini, A. Industry 4.0 technologies in the manufacturing sector: Are we sure they are all relevant for environmental performance? Bus. Strat. Environ. 2021, 30, 3194–3207.

- Grzybowska, K.; Awasthi, A.; Sawhney, R. Sustainable Logistics and Production in Industry 4.0, 1st ed.; Springer Nature: Cham, Switzerland, 2019.

- Kalsoom, T.; Ramzan, N.; Ahmed, S.; UrRehman, M. Advances in sensor technologies in the era of smart factory and Industry. Sensors 2020, 20, 6783.

- Poza-Lujan, J.; Posadas-Yagüe, J.; Simó-Ten, J.; Blanes, F. Distributed architecture to integrate sensor information: Object recognition for smart cities. Sensors 2019, 20, 112.

- Corsi, C.; Razeghi, M.; Tournié, E.; Brown, G.J. Smart Sensors: Why and when the origin was and why and where the future will be. In Quantum Sensing and Nanophotonic Devices XI; SPIE: Philadelphia, PA, USA, 2013.

- Lasi, H.; Fettke, P.; Kemper, H.; Feld, T.; Hoffmann, M. Industry 4.0. Bus. Inf. Syst. Eng. 2014, 6, 239–242.

- Cui, L.; Zhang, Z.; Gao, N.; Meng, Z.; Li, Z. Radio Frequency Identification and Sensing Techniques and Their Applications—A Review of the State-of-the-Art. Sensors 2019, 19, 4012.

- Leticia, M.; Padilla, M.; Province, B. Assessment of teaching English Language Skills: Input to Digitized. Int. Multidiscip. Res. J. 2023, 4.

- Mikalef, P.; Boura, M.; Lekakos, G.; Krogstie, J. Big data analytics and firm performance: Findings from a mixed-method approach. J. Bus. Res. 2019, 98, 261–276.

- Franklin, C.S.; Dominguez, E.G.; Fryman, J.D.; Lewandowski, M.L. Collaborative robotics: New era of human–robot cooperation in the workplace. J. Safety Res. 2020, 74, 153–160.

- Lee, Y.; Na, Y. Application of heuristic control technique to path planning of an autonomous guided vehicle. Int. J. Comput. Integr. Manuf. 1994, 7, 123–128.

- Esengün, M.; İnce, G. The role of augmented reality in the age of industry 4.0. In Springer Series in Advanced Manufacturing; Springer International Publishing: Cham, Switzerland, 2018; pp. 201–215.

- Kietzmann, J.; Pitt, L.; Berthon, P. Disruptions, decisions, and destinations: Enter the age of 3D printing and additive manufacturing. Bus. Horiz. 2015, 58, 209215.

- Gunal, M.M. Simulation for Industry 4.0, 1st ed.; Springer Nature: Cham, Switzerland, 2019; p. 288.

- Hamrita, T.K.; Kaluskar, N.P.; Wolfe, K.L. Advances in smart sensor technology. In Proceedings of the Fourtieth IAS Annual Meeting. Conference Record of the 2005 Industry Applications Conference, Hong Kong, China, 2–6 October 2005.

- Mahmud, M.; Wang, W. A smart sensorbased cEMD technique for rotor bar fault detection in induction motors. IEEE Trans. Instrum. Meas. 2021, 70, 111.

- Derbel, F.; Strakosch, F. Integrated sensor based smart diagnostic and online monitoring of Industrial Systems. In Proceedings of the 2022 4th International Conference on Applied Automation and Industrial Diagnostics (ICAAID), Hail, Saudi Arabia, 29–31 March 2022.

- Postolache, O.; Freire, J.; Girão, P.S.; Miguel, J. Smart sensor architecture for vital signs and motor activity monitoring of wheelchair’ users. In Proceedings of the 2012 Sixth International Conference on Sensing Technology (ICST), Kolkata, India, 18–21 December 2012.

- Sadiki, S.; Faccio, M.; Ramadany, M.; Amgouz, D.; Boutahar, S. Impact of intelligent wireless sensor network on predictive maintenance cost. In Proceedings of the 2018 4th International Conference on Optimization and Applications (ICOA), Mohammedia, Morocco, 26–27 April 2018.

- Bousdekis, A.; Mentzas, G. Enterprise Integration and Interoperability for big data-driven processes in the Frame of Industry 4.0. Front. Big Data 2021, 4, 644–651.

- Rajagopal, M.S.; Seetharamu, K.N.; Ashwathnarayana, P.A. Transient thermal analysis of induction motors. IEEE Trans. Energy Convers. 1998, 13, 62–69.

- Pech, M.; Vrchota, J.; Bednář, J. Predictive maintenance and intelligent sensors in smart factory: Review. Sensors 2021, 21, 1470.

- Zamudio-Ramírez, I.; Osornio-Ríos, R.A.; Antonino-Daviu, J.A.; Quijano-Lopez, A. Smart-sensor for the automatic detection of electromechanical faults in induction motors based on the transient stray flux analysis. Sensors 2020, 20, 1477.

- Luong, P.; Wang, W. Smart sensorbased synergistic analysis for rotor bar fault detection of induction motors. IEEE ASME Trans. Mechatron. 2020, 25, 1067–1075.

- Zamudio-Ramirez, I.; Osornio-Rios, R.A.; Antonino-Daviu, J. Triaxial smart sensor based on the advanced analysis of stray flux and currents for the reliable fault detection in induction motors. In Proceedings of the 2020 IEEE Energy Conversion Congress and Exposition (ECCE), Detroit, MI, USA, 11–15 October 2020.

- Yang, G.; Wang, F.; Deng, F.; Xiang, X. Impact of digital transformation on enterprise carbon intensity: The Moderating Role of Digital Information Resources. Int. J. Environ. Res. Public Health 2023, 20, 2178.

- Philipp, F.; Martinez, J.; Glesner, M.; Arkkio, A. A smart wireless sensor for the diagnosis of broken bars in induction motors. In Proceedings of the 2012 13th Biennial Baltic Electronics Conference, Tallinn, Estonia, 3–5 October 2012.

- Zamudio-Ramirez, I.; Osornio-Rios, R.A.; Trejo-Hernandez, M.; Romero-Troncoso RD, J.; Antonino-Daviu, J.A. Smart-sensors to estimate insulation health in induction motors via analysis of stray flux. Energies 2019, 12, 1658.

- Khan, H.U.; Nazir, S. Assessing the Role of AI-Based Smart Sensors in Smart Cities Using AHP and MOORA. Sensors 2023, 23, 494.

- Bouchabou, D.; Nguyen, S.M.; Lohr, C.; LeDuc, B.; Kanellos, I. A survey of human activity recognition in smart homes based on IoT sensors algorithms: Taxonomies, challenges, and opportunities with deep learning. Sensors 2021, 21, 6037.

- Chen, L.; Hoey, J.; Nugent, C.D.; Cook, D.J.; Yu, Z. Sensor-Based Activity Recognition. IEEE Trans. Syst. Man Cybern. C Appl. Rev. 2012, 42, 790–808.

- Zamudio-Ramírez, I.; Osornio-Rios, R.A.; Antonino-Daviu, J.A. Smart sensor for fault detection in induction motors based on the combined analysis of stray-flux and current signals: A flexible, robust approach. IEEE Ind. Appl. Mag. 2022, 28, 56–66.

- Spencer, B.F.; Ruiz-Sandoval, M.E.; Kurata, N. Smart sensing technology: Opportunities and challenges. Struct. Contr. Health Monit. 2004, 11, 349–368.

- Prosser, S.J.; Schmidt, E.D. Smart sensors for industrial applications. Sens. Rev. 1997, 17, 217–222.

- Alonso, M.; Amaris, H.; Alcala, D.; Diana, M.F. Smart Sensors for Smart Grid Reliability. Sensors 2020, 20, 2187.

- Ukil, A. Towards networked smart digital sensors: A review. In Proceedings of the 2008 34th Annual Conference of IEEE Industrial Electronics, Orlando, FL, USA, 10–13 November 2008.

- Betts, B. Smart sensors. IEEE Spectr. 2007, 44, 50–53.

- Rafferty, J.; Nugent, C.D.; Liu, J.; Chen, L. From activity recognition to intention recognition for assisted living within smart homes. IEEE Trans. Hum. Mach. Syst. 2017, 47, 368–379.

More