Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is a comparison between Version 2 by Catherine Yang and Version 1 by Oludunsin Tunrayo Arodudu.

Carbon stored in harvested wood products (HWPs) can play an important role in climate change mitigation and needs to be accounted for accurately and consistently. Carbon stored in harvested wood products (HWP) is an important component of global and national greenhouse gas (GHG) inventories and can mitigate climate change by offsetting carbon emissions through carbon storage, materials substitution, and fossil energy displacement. HWPs include all wood-derived products, in the form of raw materials, semi-finished products, finished products, or final use.

- carbon accounting framework

- harvested wood product

- net zero carbon targets

1. Features of HWP Carbon Accounting Frameworks

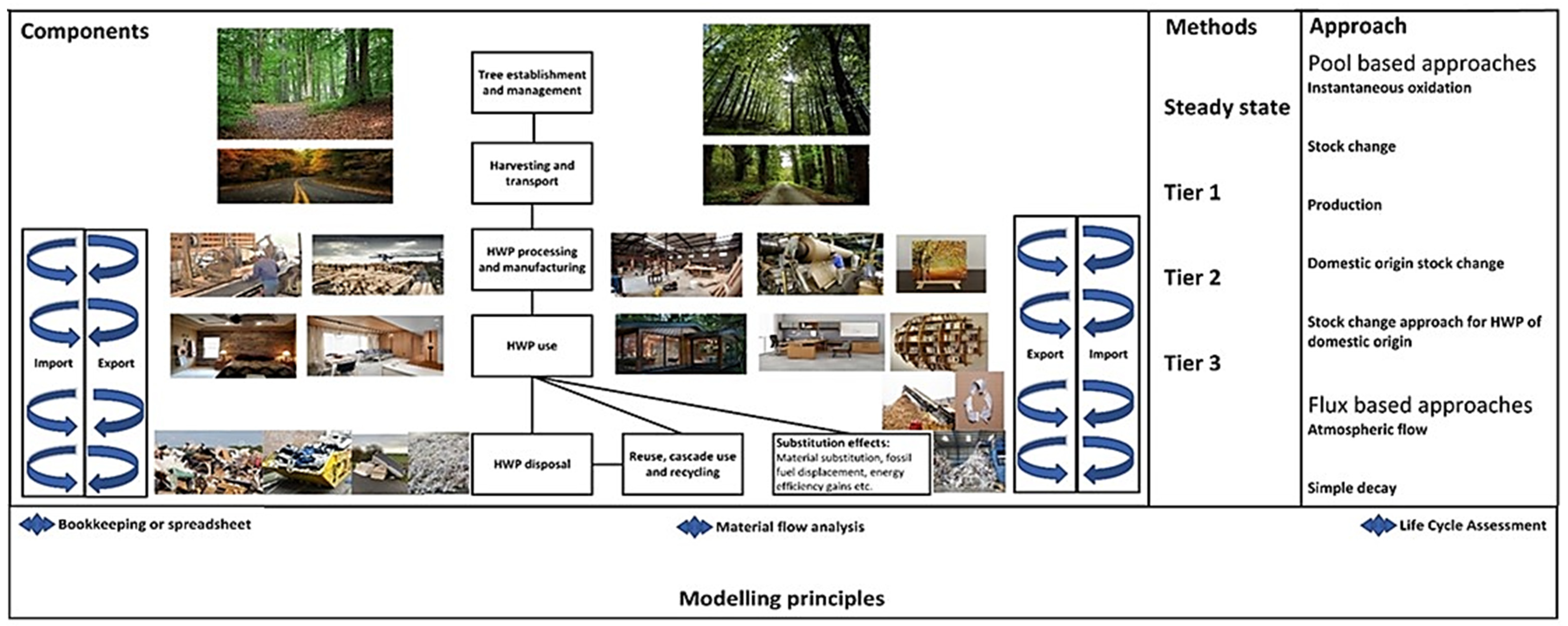

The basic features of all HWP carbon accounting frameworks are the components (also referred to as boundaries), the methods (also referred to as method classifications), the approaches, and the modeling principles (also referred to as models) [1][2]. This is illustrated in Figure 21. Components refer to various carbon stocks stored within HWP, carbon lost from HWPs due to decay over time, or carbon attributable to HWPs (e.g., material substitution effects, fossil energy replacements, energy efficiency gains, circular economy impacts etc.) [3][4]. Methods refer to the entirety of choices regarding HWP activity data (product category and process data), conversion factors, and calculation procedures applied for the estimation of HWP C [5][6]. Approaches are spatial accounting boundaries delineated for HWP C estimation, i.e., they constitute the different ways of delineating HWP carbon stocks and flows, either at national or subnational unit levels [7][8]. Approaches delineate the different components of carbon stocks or flows included in or excluded from HWP C estimation [1][9]. Examples of components included or excluded from different approaches may include in-region or out-region production and consumption of HWPs, emissions associated with HWP production and consumption, and substitution effects of in-region or out-region production or consumption of HWPs, etc. Modeling principles refer to tools or systems applied for HWP C estimation [10][11]. These four features (i.e., components, methods, approaches, and modeling principles) together make up an HWP carbon accounting framework as described in successive IPCC guidelines and other works from the literature on HWP C estimation.

2. Components

Components in HWP C accounting refer to relevant individual C stocks and flows that make up the total HWP C estimate [6][12]. Pre-2006 IPCC guidelines assumed all HWPs had their carbon oxidized within the first year of harvest. Subsequent IPCC guidelines recognized HWP C benefits and identified the following components: carbon flows associated with HWP production, use and disposal, and carbon stored in HWPs in use and in SWDS [10][13]. It is recommended to define carbon stock and flows within region (domestic), to other regions (export), and from other regions (import). The 2019 refinements of IPCC guidelines for HWP carbon accounting [13] recommended further estimation of carbon stocks based on product removal options (i.e., with or without obsolescence). Other important components of HWP C accounting put up for consideration by the IPCC 2019 refinement guidelines [13] include carbon stock and flows at shelf-life, over lifetime, and the frequency of local fire incidences in buildings and elsewhere where HWPs are in use or dumped. Estimating these components will involve local or regional data collection on the average shelf-life and lifetime of different HWP categories and information on the frequency of fire incidence, as well as their respective obsolescence rates (usually at tier 2 level assessment and upward). Obsolescence rates could be influenced by rapid change in technology (e.g., change from paper-based economy to fully digital economy) and the adoption of circular economy principles by enterprises and households (i.e., change in company policy or family traditions to increase or reduce the average lifetime of furniture). Accounting for shelf-life, lifetime, frequency of fire incidences and/or obsolescence however requires special attention to accurately represent the subnational unit conditions.

Figure 21. Graphical illustrations of the key features (components, methods, approach, and modelling principles) of HWP carbon accounting framework.

Several HWP C assessments at national and subnational levels focus on carbon storage stocks and flows [14][15]. However, there are additional HWP accounting components recognized by experts that are not yet officially recommended or made mandatory by IPCC primarily due to limited data. These components are carbon savings from substitution effects such as recycling and cascading uses, direct material substitution effects, fossil energy displacements, and improved energy efficiencies [16][17]. Substitution effects from improved energy efficiencies may result from better insulation and reduction in energy consumption due to internal changes in building properties from concrete and steel to mass timber [3][9]. All of these need to be included in HWP C accounting frameworks for examining HWP contributions to climate change mitigation and net zero carbon targets.

3. Approaches

HWP C approaches are different implementations of HWP C assessment or accounting boundaries [7][18]. Each approach has the HWP C components (i.e., stocks and flows) they include or exclude clearly stated [6][19]. Approaches usually mark the boundaries of inclusions and exclusions of domestic production and consumption of HWPs, as well as import and export of HWPs for consumption in-region or out-region. There are seven major approaches recognized in successive IPCC guidelines [10][13] and the literature [5][20]. Of the seven approaches, five are pool-based (instantaneous oxidation, stock change, production, stock change approach for HWPs of domestic origin, and domestic origin-stock change), while only two are flux-based (atmospheric flow and simple decay). All approaches are discussed in this section as follows, as well as in Table 21.Table 21.

HWP accounting approaches based on their respective included and excluded boundaries.

| HWP Approaches | Components and Boundaries | ||||

|---|---|---|---|---|---|

| Pool-Based Approaches | Flux-Based Approaches | Forest Land Carbon Pool/Fluxes | HWP Pool Domestically Produced and Utilized | HWP Pool Exported and Utilized in Other Regions | HWP Pool Imported and Utilized Domestically |

| Instantaneous oxidation (IO) | - | √ | |||

| Stock change approach for HWP of domestic origin (SCAD) | - | √ | √ | ||

| Production (P) | Simple decay (SD) | √ | √ | √ | |

| Stock change (SC) | Atmospheric flow (AF) | √ | √ | √ | |

| Domestic origin-stock change (DOSC) | - | √ | √ | √ | √ |

Source: Adapted from [5][20] (√-components included within the boundary).

The instantaneous oxidation (IO) approach counts all carbon from HWPs as removed and oxidized within one year of harvest. This is also known as the default IPCC approach, and it is often applied when there are no activity data. The stock change (SC) approach estimates change in the HWP C pool (inclusive of logs, pulpwood, and chips) within the consuming region only. It accounts for all wood products produced and consumed within the region and those imported and consumed within the region. However, it excludes HWPs exported to other regions. It is a consumption-oriented HWP C accounting approach. The production approach estimates the HWP C pool within the producing region only. It accounts for all wood products produced and consumed within the region and those produced and exported to other regions. However, it excludes wood products imported from other regions. It is a production-oriented HWP C accounting approach. The atmospheric flow (AF) approach is consumption-oriented. It involves the estimation of CO2 fluxes from and to the atmosphere associated with HWPs within the region of consumption by accounting for all wood products produced and consumed within the region and those imported and consumed within the region, but it excludes those exported to other regions. The simple decay (SD) approach is another production-oriented accounting approach. It involves the estimation of CO2 fluxes from and to the atmosphere associated with HWPs within the region of production. It accounts for wood products produced and consumed within the region and those produced and exported to other regions, while excluding those imported from other regions. Please note that the CO2 fluxes from the atmosphere accounted for in atmospheric flow and simple decay approaches are the net annual CO2 sequestered in trees, as well as CO2 stored in HWPs in use and in SWDS. The domestic-origin-stock change (DOSC) is a hybrid HWP C approach that estimates all HWP C pools associated with the region. This approach accounts for HWPs produced and consumed within the region, those imported and consumed by the region, and those exported to and consumed in other regions. It is a combination of production and stock change approaches. Even though it exhaustively accounts for HWPs pertaining to particular regions, it subjects HWP C accounting under the KP and UNFCCC framework to double counting, as both exporting and importing regions may take ownership of stored carbon at the same time. The stock change approach for HWPs of domestic origin (SCAD) is a unique HWP C approach that estimates only HWP C pools produced and consumed within a region. This approach allocates HWP C stocks and flows imported and consumed by one region to the source regions, and HWP C stocks and flows exported to and consumed by other regions to the destination regions. SCAD is a HWP C accounting approach that encourages local production and consumption to maximize the C benefits of HWP within the region rather than exporting it to other regions or importing it from other regions.

While most of the previous subnational HWP C assessment frameworks adopt the production approach as recommended by the IPCC, it is noteworthy that the production approach as currently constituted does not meet the requirement for assessing other contributions of HWPs to net zero carbon targets. While the production approach as currently constituted accounts for carbon storage, any HWP C assessment framework for assessing the contributions of HWPs to net zero carbon targets also ought to account for substitution effects of HWPs such as recycling and cascading use activities, material replacement, fossil fuel displacement, and energy efficiency gains, hence, the need for a new approach. Adopting a modified DOSC approach is recommended because it is the only HWP C approach that allows for accounting for import and export within the same framework. While accounting for carbon storages of export and import within the same framework amounts to double counting, the modified DOSC approach recommended by this study prescribes the exclusion of carbon storages of imports in accordance with IPCC-recommended production approach applied by previous subnational HWP C studies but proposes the inclusion of the assessment of all substitution activities associated with all HWP flows (i.e., retained production, export and import), since they are all associated with the region under consideration.

References

- Jasinevičius, G.; Lindner, M.; Pingoud, K.; Tykkylainen, M. Review of Models for Carbon Accounting in Harvested Wood Products. Int. Wood Prod. J. 2016, 6, 198–212.

- IPCC. 2006 IPCC Guidelines for National Greenhouse Gas Inventories; Eggleston, H.S., Buendia, L., Miwa, K., Ngara, T., Tanabe, K., Eds.; Institute for Global Environmental Strategies: Hayama, Japan, 2006. Available online: https://www.ipcc-nggip.iges.or.jp/support/Primer_2006GLs.pdf (accessed on 15 July 2022).

- Bais-Moleman, A.L.; Sikkema, R.; Vis, M.; Reumerman, P.; Theurl, M.C.; Erb, K.-H. Assessing wood use efficiency and greenhouse gas emissions of wood product cascading in the European Union. J. Clean. Prod. 2018, 172, 3942–3954.

- Sathre, R.; O’Connor, J. Meta-analysis of greenhouse gas displacement factors of wood product substitution. Environ. Sci. Policy 2010, 13, 104–114.

- Grêt-Regamey, A.; Hendrick, E.; Hetsch, S.; Pingoud, K.; Rüter, S. Challenges and Opportunities of Accounting for Harvested Wood Products. In Background Paper to the Workshop on “Harvested Wood Products in the Context of Climate Change Policies”; Swiss Federal Office for the Environment (FOEN), UNECE/FAO and MCPFE: Geneva, Switzerland, 2008.

- Wakelin, S.J.; Searles, N.; Lawrence, D.; Paul, T.S.H. Estimating New Zealand’s harvested wood products carbon stocks and stock changes. Carbon Balance Manag. 2020, 15, 10–24.

- Brunet-Navarro, P.; Jochheim, H.; Muys, B. Modelling carbon stocks and fluxes in the wood product sector: A comparative review. Glob. Change Biol. 2006, 22, 2555–2569.

- Walters, B.F.; Domke, G.M.; Nowak, D.J.; Smith, J.E.; Ogle, S.M. Greenhouse Gas Emissions and Removals from Forest Land, Woodlands, and Urban Trees in the United States, 1990–2019: Estimates and Quantitative Uncertainty for Individual States; Forest Service Research Data Archive: Fort Collins, CO, USA, 2021.

- Ximenes, F.; Bi, H.; Cameron, N.; Coburn, R.; Maclean, M.; Sargeant, D.; Mo, M.; Roxburgh, S.; Ryan, M.; Williams, J.; et al. Carbon Stocks and Flows in Native Forests and Harvested Wood Products in SE Australia; Project Number: PNC285-1112; Forest & Wood Products Australia: Melbourne, Australia, 2016; 201p.

- IPCC. 2013 Revised Supplementary Methods and Good Practice Guidance Arising from the Kyoto Protocol; Hiraishi, T., Krug, T., Tanabe, K., Srivastava, N., Baasansuren, J., Fukuda, M., Troxler, T.G., Eds.; The Intergovernmental Panel on Climate Change: Geneva, Switzerland, 2014; p. 148. Available online: https://www.ipcc.ch/site/assets/uploads/2018/03/KP_Supplement_Entire_Report.pdf (accessed on 15 July 2022).

- Aleinikovas, M.; Jasinevičius, G.; Škėma, M.; Beniušienė, L.; Šilinskas, B.; Varnagirytė-Kabašinskienė, I. Assessing the Effects of Accounting Methods for Carbon Storage in Harvested Wood Products on the National Carbon Budget of Lithuania. Forests 2018, 9, 737.

- Krausmann, F.; Erb, K.-H.; Gingrich, S.; Haberl, H.; Bondeau, A.; Gaube, V.; Lauk, C.; Plutzar, C.; Searchinger, T.D. Global human appropriation of net primary production doubled in the 20th century. Proc. Natl. Acad. Sci. USA 2013, 110, 10324–10329.

- IPCC. 2019 Refinement to the 2006 IPCC Guidelines for National Greenhouse Gas Inventories; Buendia, C.E., Tanabe, K., Kranjc, A., Baasansuren, J., Fukuda, M., Ngarize, S., Osako, A., Pyrozhenko, Y., Shermanau, P., Federici, S., Eds.; The Intergovernmental Panel on Climate Change: Geneva, Switzerland, 2019; Available online: https://www.ipcc-nggip.iges.or.jp/public/2019rf/pdf/4_Volume4/19R_V4_Ch12_HarvestedWoodProducts.pdf (accessed on 15 July 2022).

- Nichols, M.C.; Morgan, T.A.; Christensen, G.; Tase, N. Estimated Carbon Stored in Harvested Wood Products in Washington, USA: 1906–2018; Draft Report; Forest Service and the Washington Department of Natural Resources: Olympia, WA, USA, 2020; 31p.

- Morgan, T.A.; Donahue, S.T.; Dillon, T.; Yost, A.; Groom, J. Oregon Harvested Wood Products Carbon Inventory 1906–2018; Draft Report for Forest Inventory and Analysis Program; USDA Forest Service: Portland, OR, USA; Oregon Department of Forestry: Salem, OR, USA, 2022; 61p.

- Laurent, A.B.; Menard, J.F.; Lesage, P.; Beauregard, R. Cradle-to-gate- life cycle assessment of the portfolio of an innovative forest products manufacturing unit. Bioresources 2016, 11, 8981–9001.

- Chen, J.; Ter-Mikaelian, M.T.; Yang, H.; Colombo, S.J. Assessing the greenhouse gas effects of harvested wood products manufactured from managed forests in Canada. Forestry 2018, 91, 193–205.

- Li, L.; Wei, X.; Zhao, J.; Hayes, D.; Daigneault, A.; Weiskittel, A.; Kizha, A.R.; O’Neill, S.R. Technological advancement expands carbon storage in harvested wood products in Maine, USA. Biomass Bioenergy 2022, 161, 106457.

- Yu, Z.; Zhang, H.; Tu, Q.; Yang, H. Methodological Comparison of the Production Approach 2013 and 2019 for Quantifying the Carbon Stock in Harvested Wood Products in China. Front. Environ. Sci. 2022, 10, 758857.

- Sato, A.; Nojiri, Y. Assessing the contribution of harvested wood products under greenhouse gas estimation: Accounting under the Paris Agreement and the potential for double-counting among the choice of approaches. Carbon Balance Manag. 2019, 14, 15–34.

More