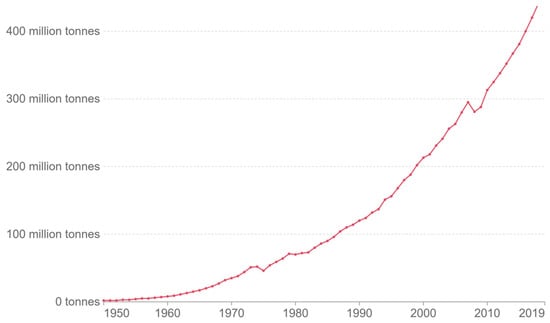

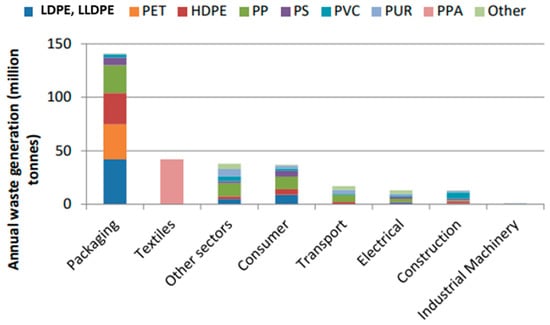

Plastic materials have gathered attention recently due to their omnipresence in the global economy. The transition towards a circular economy is the only way to prevent the environment from landfilling and incineration.

- mechanical recycling

- sorting technologies

- decontamination process

- polyolefins

- engineering (PET, PA6) and bio-sourced polymer (PLA and PHB)

1. Introduction

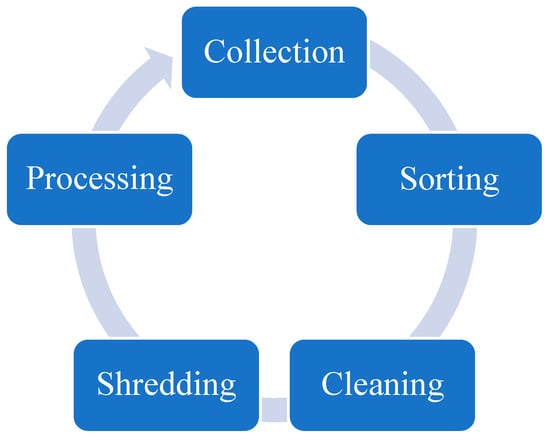

2. Sorting Technologies

|

Sorting Method |

Characteristics |

Drawbacks |

Reference |

||

|---|---|---|---|---|---|

Limits |

References |

||||

|

Manual |

|||||

|

Primary recycling (Re-extrusion) |

Hand based sorting |

Laborious, bad working environment |

[ |

It is a process based on the extrusion of plastics. It does not require too much equipment and high investment. 5] |

|

It is adapted for plastic scrap with less contamination |

Tribo-electric |

||||

|

Secondary recycling (Mechanical recycling) |

Based on electrostatic charge |

The technique begins in the sorting center by separating, washing, and grinding plastics. After these steps, plastic materials are processed with extruders and pelletized. Only for clean, dry, and non-surface-treated products. |

Degradation of thermomechanical properties of plastics [6] |

||

[ |

Near-infrared Radiation (NIR) |

||||

|

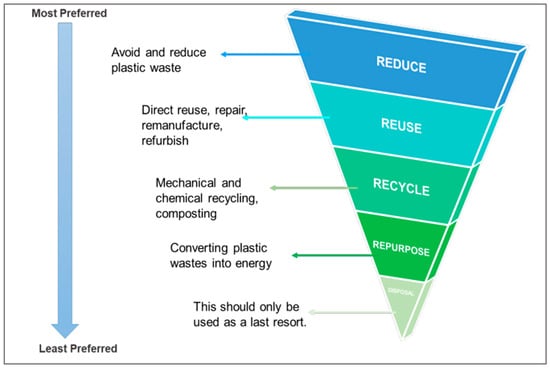

Tertiary recycling (Chemical recycling) |

Fundamental vibration |

Chemical recycling consists of converting polymer into molecules or monomers that can be used to manufacture new polymers. It is not adapted for dark plastics and is very expensive. |

It is an expensive process with a negative impact on the environment [7] |

||

[ | ][17] |

Flotation |

|||

|

Quaternary recycling (Energy recovery) |

It is related to a specific gravity of material. |

Quaternary recycling aims to generate energy heat or electricity from plastic scraps [20][11]. It is not applied to High-density Polyethylene (HDPE) and Low-density Polyethylene (LDPE). |

[8] |

||

|

X-ray fluorescence (XRF) |

Uses X-rays as a source |

It is very expensive |

[9] |

3. Recycling Techniques: Overview

|

Type of Recycling |

Process | ||

|---|---|---|---|

The emission of toxic gases. |

4. Sources of Contaminations

4.1. Structural Inhomogeneities

4.2. Impurities

5. Decontamination Techniques

5.1. Degassing System

5.1.1. Without Chemical Agent

5.1.2. With Chemical Agent

5.2. Filtration System

|

Filtration System |

Advantages/Disadvantages |

References |

|---|---|---|

|

Manual screen changers |

It helps minimize labor and downtime for screen changes during line shutdown. The compact design eliminates the need for line disassembly and uses a hand lever to manually index the slide plate for screen change. |

|

|

Hydraulic screen changer |

It’s used in industry due to its wide range of sizes. It can reach 450 mm. Single screen operation limits filtration area, and the use of seals add to maintenance and the probability of leakage. The mesh size can reach 100 µm in some applications. |

|

|

Rotary Disc type filtration system |

This system offers high pressure with a lower residence time. System size can reach 250 mm and offer constant pressure operation but relatively high-pressure drops, with a lower residence time. It is a highly automated system with sophisticated controls and a backflush option. Leakage and disc lockup concerns are related to the clamping force of housing plates. It may require attention and to adapt system setup. |

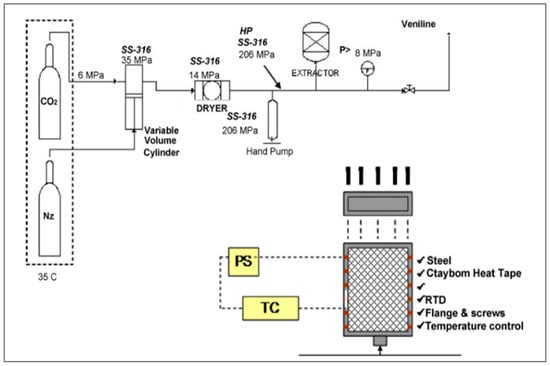

5.3. Supercritical Fluid

6. Identification and Quantification of Contamination Rate

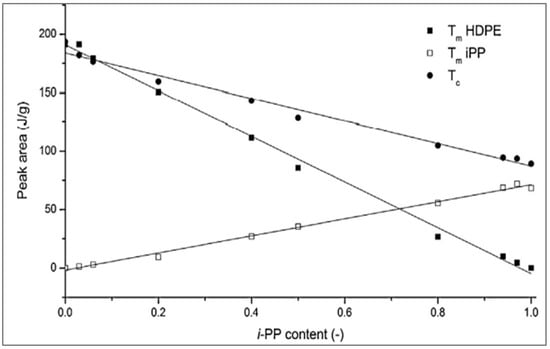

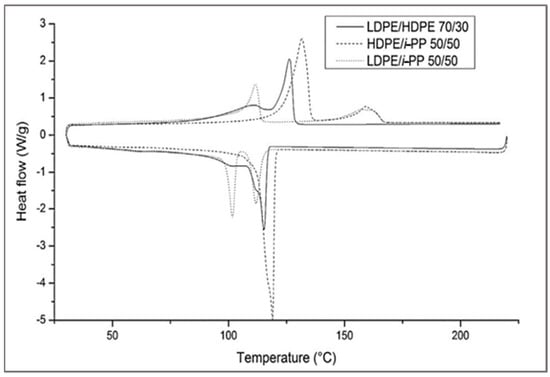

6.1. Differential Scanning Calorimetry (DSC)

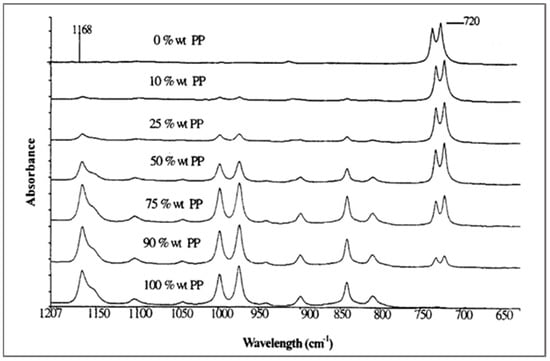

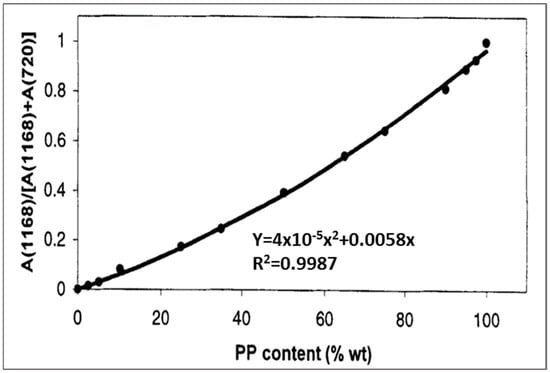

6.2. Fourier Transform Infrared Spectroscopy (FTIR)

6.3. Chromatography Analysis

References

- Geyer, R.; Jambeck, J.; Law, K. Production, use, and fate of all plastics ever made. Sci. Adv. 2017, 3, e1700782.

- Ellen MacArthur Foundation. The New Plastics Economy: Rethinking the Future of Plastics & Catalysing Action; Ellen MacArthur Foundation: Cowes, UK, 2017; Volume 68.

- Hopewell, J.; Dvorak, R.; Kosior, E. Plastics recycling: Challenges and opportunities. Philos. Trans. R. Soc. B Biol. Sci. 2009, 364, 2115–2126.

- Umeozor, E.; Vypovska, A.; Bararpour, T.; Adeyemo, T.; Zamzadeh, M. Towards a Circular Economy of Plastic Products in Canada; Canadian Energy Research Institute: Calgary, AB, Canada, 2021.

- Karlsson, S. Recycled Polyolefins. Material Properties and Means for Quality Determination. In Long Term Properties of Polyolefins; Albertsson, A.-C., Ed.; Advances in Polymer Science; Springer: Berlin/Heidelberg, Germany, 2004; Volume 169, pp. 201–230.

- Bendimerad, S.; Tilmatine, A.; Ziane, M.; Dascalescu, L. Plastic wastes recovery using free-fall tribo electric separator. Int. J. Environ. Stud. 2009, 66, 529–538.

- Masoumi, H.; Safavi, S.; Khani, Z. Identification and classification of plastics resins using Near Infrared Reflectance Spectroscopy. Int. J. Mech. Ind. Eng. 2012, 6, 213–220.

- Censori, M.; La Marca, F.; Carvalho, M.T. Separation of plastics: The importance of kinetics knowledge in the evaluation of froth flotation. Waste Manag. 2016, 54, 39–43.

- Singh, N.; Hui, D.; Singh, R.; Ahuja, I.P.S.; Feo, L.; Fraternali, F. Recycling of plastic solid waste: A state of art review and future applications. Compos. Part B Eng. 2017, 115, 409–422.

- Al-Salem, S.M.; Lettieri, P.; Baeyens, J. The valorization of plastic solid waste (PSW) by primary to quaternary routes: From re-use to energy and chemicals. Prog. Energy Combust. Sci. 2010, 36, 103–129.

- Subramanian, P. Plastics recycling and waste management in the US. Resour. Conserv. Recycl. 2000, 28, 253–263.

- NAM Polymers. 2016. Products. 2016. Available online: http://nampolymers.ca/products/ (accessed on 1 January 2021).

- Oblak, P.; Gonzalez-Gutierrez, J.; Zupančič, B.; Aulova, A.; Emri, I. Processability and mechanical properties of extensively recycled high density polyethylene. Polym. Degrad. Stab. 2015, 114, 133–145.

- La Mantia, F.P.; Vinci, M. Recycling of heterogeneous plastics wastes. II—The role of modifier agents. Polym. Degrad. Stab. 1994, 42, 213.

- Vlachopoulos, J.; Polychronopoulos, N.D. Polychonopoulos, Understanding Rheology and Technology of Polymer Extrusion, 1st ed.; Polydynamics Inc.: Dundas, On, Canada, 2019.

- Al-Salem, S.M.; Lettieri, P.; Baeyens, J. Recycling and recovery routes of plastic solid waste (PSW): A review. Waste Manag. 2009, 29, 2625–2643.

- Mastellone, M.L. Thermal Treatments of Plastic Wastes by Means of Fluidized Bed Reactors; Department of chemical Engineering University of Naples: Naples, Italy, 1999.

- Denisov, E.T. Mechanism of regeneration of hindered nitroxyl and aromatic amines. Polym. Degrad. Stab. 1989, 25, 209–215.

- Liu, S.S.; Hu, J.Y.; Qin, D.; Gao, L.L.; Chen, Y.; Ke, F.Y.; Wang, C.S.; Wang, H.P. Analysis of the Volatile Organic Compounds (VOCs) during the Regeneration of Post-Consumed Poly(Ethylene Terephthalate) Using HS-GC-MS Method. Mater. Sci. Forum 2019, 944, 1208–1214.

- Yamashita, K.; Kumaga, K.; Noguchi, M.; Yamamoto, N.; Mizukoshi, A.; Yanagisawa, Y.; Ni, Y. Voc Emssion from waste plastics during melting process, présenté à International conference indoor air quality. In Proceedings of the 6th International Conference on Indoor Air Quality, Ventilation and Energy Conservation in Buildings: Sustainable Built Environment, Sendai, Japan, 28–31 October 2007; pp. 407–412.

- Bledzki, A.K.; Kessler, A.; Lieser, J. Odour reduction on plastics and its measurement. Polym. Test. 1999, 18, 63–71.

- Cabanes, A.; Valdes, F.J.; Fullana, A. A review on VOCs from recycled plastics. Sustain. Mater. Technol. 2020, 25, e00179.

- Villberg, K.; Veijanen, A.; Gustafsson, I. Identification of off-flavor compounds in high-density polyethylene (HDPE) with different amounts of abscents. Polym. Eng. Sci. 1998, 38, 922–925.

- Ravindranath, K.; Mashelkar, R.A. Analysis of the role of stripping agents in polymer devolatilization. Chem. Eng. Sci. 1988, 43, 429–442.

- Yang, C.T.; Smith, T.G.; Bigio, D.I.; Anolick, C. Polymer trace Devolatilization: I. foaming experiments and model development. Aiche J. 1997, 43, 1861–1872.

- Vrentas, J.S.; Duda, J.L.; Ling, H.-C. Enhancement of impurity removal from polymer films. J. Appl. Polym. Sci. 1985, 30, 4499–4516.

- Darley, D. Polymer filtration options: Screen Changers or large area. In Proceedings of the Third International Polymer Filtration Conference, Stuttgart, Germany. 1997. Available online: http://www.extrusionauxiliary.com/sitebuildercontent/sitebuilderfiles/screenchangers.pdf (accessed on 18 July 2023).

- Available online: https://psi-polymersystems.com/products/screen-changer-overview/manual-screen-changer/ (accessed on 1 January 2021).

- Cristancho, D.E.; Guzman, J.D.; Taylor, C.; Ortiz-Vega, D.; Acosta, H.; Hall, K.R. Supercritical extraction of volatile organic components from polyethylene pellets. J. Supercrit. Fluids 2012, 69, 124–130.

- Luijsterburg, B.; Goossens, H. Assessment of plastic packaging waste: Material origin, methods, properties. Ressour. Conserv. Recycl. 2013, 85, 88–97.

- Camacho, W.; Karlsson, S. NIR, DSC, and FTlR as Quantitative Methods for Compositional Analysis of Blends of Polymers Obtained From Recycled Mixed Plastic Waste. Polym. Eng. Sci. 2001, 41, 1626–1635.

- Kleine-Benne, E.; Rose, B. Versatile Automated Pyrolysis GC Combining a Filament Type Pyrolyzer with a Thermal Desorption Unit. Gerstel Appl.note 11. 2011. Available online: www.gerstel.de/pdf/p-gc-an-2011-04.pdf (accessed on 18 July 2023).

- Fries, E.; Dekiff, J.H.; Willmeyer, J.; Nuelle, M.-T.; Ebert, M.; Remy, D. Identification of polymer types and additives in marine microplastic particles using pyrolysis-GC/MS and scanning electron microscopy. Environ. Sci. Process. Impacts 2013, 15, 1949–1956.

- Rood, D. Gas chromatography problem solving and troubleshooting. J. Chromatogr. A 1995, 33, 347.