This study focuses on the wear effects of nano-sized titania as a potential engine lubricant additive. Titanium dioxide nanoparticles have promising wear-reducing properties and significant tribological potential. TIn this article, titania nanoparticles were homogenized in Group III automotive oil at five different concentrations (0.1; 0.2... . . . 0.5 wt%). The nanodoped oil samples were tested on a linear oscillating tribometer with oil circulation. Based on the tribological results, titania nanoparticles increased friction by 20–32% but can reduce the wear area by up to 32%. According to the confocal microscopic examination, wear volume can be reduced by up to 57% with titania nanoparticles. Titania nanoparticles improved the repeatability of tribological measurements. A scanning electron microscopy examination of the wear track revealed that the characteristic wear of the tribological system was abrasive, but a significant amount of adhesive wear was also observed. Energy dispersive X-ray spectroscopy analysis found that the nanoparticles fill the deeper trenches of the wear. The worn surface uniformly contains TiO2 particles and the quantified normalized titanium concentration was between 0.56 and 0.62%.

- tribology

- titanium dioxide

- nanoparticle

1. Introduction

2. Nano-Sized Titania Particles as Additives in Automotive Lubricants

Numerous studies have already covered the use of nanoparticles as a lubricant additive in the automotive industry that examine their effect as a function of tribological performance, depending on the tribological system, material, morphology, size and thermophysical properties [1]. Rajaganapathy et al. reported the friction and wear-decreasing effect of nano-sized titania particles as lubricant additives in palm and brassica oil during pin-on-disc tribometer tests [2]. The studies report improvements in mechanical efficiency by decreasing the coefficient of friction (COF) and heat losses, which led to using nanoparticles in grease and/or liquid lubrication [3]. Several methods are used to prepare the additive, such as stearic acid, which is used to formulate high-purity TiO2 with a 40 nm diameter [4]. Many researchers enhance nanoparticles through surface modification. Using tetrafluorobenzoic acid is also a preparation method for much smaller partials (10 nm); employing this method, the lubricant is tested and characterized to reduce the wear and friction for mechanical parts under high pressure [5]. Other methods, such as oleic acid (OA) and lanthanum, are also used, prepared by sol-gel. This method remarkably improved the anti-wear properties in the sliding steel surfaces [6]. Harshvardhan et al. also enhanced the dispersion of titania nanoparticles using oleic acid as a surfactant. In the research, SN-500 (solvent-neutral) base oil was doped with titania nanoparticles, and the resulting mixture was tested at three different loads. Their results showed that using titanium nanoparticles in concentrations of 0.5 wt% and 0.75 wt%, friction can be reduced by 21–85%, while wear can be reduced by 25–50% [7]. The nanoparticle preparation method is not the only factor that affects heat absorption—the concentrations of the nanoparticles and the density and size factor in the results. A small concentration, such as 0.01 wt% of TiO2, reduces, resulting in reducing the wear scaring up to 20% [8]. In addition, adding nanoparticles has an almost 32% positive effect more than base lubricant [9]. However, maintaining the size and the density at as small a size as possible works to our advantage by not only decreasing the coefficient of friction (COF) [10][11][10,11] but also stabilizing it to reach the minimum value of COF (0.006). By using 1% TiO2 nanoparticles, the lifespan, compared with commercial lubricants, can be increased [12][13][12,13]. TiO2 nanoparticles showed a 49.5% COF reduction and a 97.5% wear scar reduction in four-ball tests under dry conditions and using a water solution, respectively [14]. Replacing the water-based lubricants with oil will work to improve the results, using a reciprocating sliding tribology tester; cupric oxide with a base oil lubricant has a reduction percentage of 5.8% for COF and 78.8% for wear scar depth. Meanwhile, an API-SF lubricant with a CuO nanoadditive will reduce the COF by 18.4% and the wear scar depth by 16.7% [15]. Using rice bran oil and adding cerium dioxide (CeO2), titanium dioxide (TiO2) and zirconium dioxide (ZrO2) will vary the concentration of each nanoparticle between 0.1 and 1 wt%. At 0.7 wt%, ZrO2 showed the minimum COF and wear scar diameter (WSD), the highest needed concentration. Meanwhile, 0.5 wt% CeO2 showed the maximum COF reduction and an 8% wear-scar diameter reduction. However, the TiO2 showed tribological proprieties at 0.3 wt%, which made it the minor concentration needed, and by increasing the concentration, the tribological proprieties increased. The best concentration for TiO2 was 0.8 wt% [3][16][17][3,16,17]. Hamisa et al. used a titania and silica nanoparticle hybrid in a polyol-ester-based lubricant. The stability of the oil sample was confirmed through a zeta potential measurement and visually. The stable oil sample provided a suitable basis for reducing friction by up to 37.5% and wear by up to 26.4% [18]. Ismail et al. reached similar results when they performed measurements using PVE-modified lubricant as a base [19]. As mentioned earlier, the nanoparticles tend to improve grease lubricants, and the benzoic acid/stearic acid titanium complex and the sebacic acid/stearic acid titanium complex were doped with TiO2 and SiO3. Compared with nanoparticle-free grease, TiO2 with benzoic/stearic acid reduced the COF by 22.97% and the WSD by 4.35%. TiO2 with Sebacic/stearic acid reduced the COF by 35.98% and the WSD by 8.95%. SiO3 with a benzoic/stearic acid titanium complex reduced the COF and the wear scar diameter by 24.47% and 1.8%, respectively. However, SiO3 with a sebacic/stearic acid titanium complex reduced the COF and the WSD by 29.58% and 4.55%, respectively [20]. Kuo et al. also used titania to improve the tribological properties of greases. During their tests, they compared the effect of micro- and nano-sized titania particles (contact resistance, friction, wear) on a laser-textured surface. A synergistic effect was established due to the laser-structured surface, which could carry the lubricant and collect wear debris, helping the particles act in the tribosystem [21]. To reduce the WSD by 0.65 mm, 11% of the nano-sized TiO2 and 6.1% of the micro-TiO2 are needed. However, micro-TiO2 reduces the COF by 6.9%; meanwhile, nano-TiO2 reduces the COF by 15.2% and this variation in results happens due to the spherical shape of the titania nanoparticles [22]. The spherical shape of the TiO2 nanoparticles acts as nanobearing between the sliding surfaces, which reduces the friction. Moreover, the nanoparticles fill the wear valleys in the surfaces, reducing the scaring up to 80.84%, filling the scar [23]. It also reduces COF by creating a tribofilm containing the nanoparticles [24][25][26][24,25,26]. Sharma et al. investigated the combined effect of zinc dialkyl dithiophosphate and titania and focused on tribofilm formation. It was found that they are excellent additives individually, but when they are used together, an adequate tribofilm does not form and the wear increases. They also presented a method in which the surface of the titania nanoparticles is modified with boron atoms using plasma functionalization—this helped to improve the tribofilm formation [27]. When CeO2 and TiO2 are combined in the lubricant, less TiO2 is required to achieve the intended results [28]. Some researchers have investigated nanoparticles as engine oil additives when measuring internal combustion engines. When using nano graphite below 50 nm, engine performance increased, and fuel consumption and emissions decreased [29]. In a full stroke in the internal combustion engine, when the lubricant contained only a concentration of 1.75 wt% oleic acids, the COF was slightly reduced mainly due to the chemical reaction. When adding Al2O3 to the lubricant and measuring the COF at the top dead center and the bottom dead center, the COF is lower by 35%, and the wear scar on both the piston ring and cylinder liner is 30–33% less than when using an engine lubricant without nano additives. However, when using nano-sized TiO2, the COF reduction is 51% and the wear scar is reduced by 16–18% [3][16][30][3,16,30]. Theoretically, it is possible to estimate the pressure and load-carrying capacity for TiO2 concentration using the Reynolds equation2 concentration. Having TiO2 in the lubricant, even with a minor concentration (0.001 v/v%), increases the load-carrying capacity by 40% more compared with the reference lubricant (without TiO2) [14]. The increase of (0.0015 TiO2 volume fraction) in the particle packing fraction from 7.77 to 10 leads to an increase in the load-carrying capacity by up to 35%. Realistically, an accurate shear viscosity simulation is possible using the Krieger–Dougherty viscosity model [31]. Using a numerical method, Mubashar et al. investigated the rotational and sliding properties of hybrid nanofluid-based engine oils with other substances [32]. The concentration effect of the nano-sized TiO2 additive was studied and the results were established. Pan et al. investigated the lubrication conditions of a lubricant film containing titania nano-additives for micro-deep drawing. Using the glycerine-based nanolubricant, the pulling force could be reduced by up to 36.6%. They also found that too much nano-additive (~4 wt%) already creates many agglomerations in the lubricant, hurting the tribological systems' performance [33]. It is essential to study the effect of nano-sized TiO2 under different loads. When applying other loads (40, 80, 120 and 160 kg) for 10 min at 1200 rpm, the TiO2 reduced the COF by 15% and the WSD by 11%. Meanwhile, when the load was minimal, the TiO2 worked as a protective layer [34]. Maintaining a 4 kg load, 0.3 wt% TiO2 reduced the COF of aluminum alloy metals by 86.48% [35]. Ilie et al. investigated titanium dioxide as a solid lubricant. A control volume fractional coverage theoretical model was prepared for the tests. Their results established the surface self-healing ability of titania nanopowder. The results of the theoretical model and the actual measurement were promisingly close [13].3. Investigation Rresults

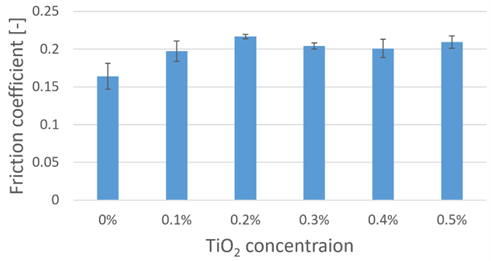

The main goal of this paper is to investigate the tribological impact of nanoscale titania particles inside automotive lubricants as tribological additives. As a reference, neat Group III base oil with 4 cSt kinematic viscosity (measured at 100°C) was used. The nanoparticles were homogenized into this liquid with the testing concentrations of 0.1 - 0.5 wt% with 0.1 wt% steps. A magnetic stirrer and ultrasonic homogenizer were used to produce the investigated oil samples in the Tribological laboratory of the Széchenyi István University. The tribological tests were carried out with an Optimol SRV5 tribometer using standardized (ISO 19291:2016) specimens. The experiments were executed with a sinusoidal 1 mm 50 Hz oscillation movement with 100 N load and 100°C temperature. The machine was extended with a peristaltic pump, which provided a continuous 225 ml/h oil flow with preheated (100°C) lubricant samples.Figure 1 illustrates the evaluation of the measured friction coefficient integral average values of the investigated nano lubricant samples in the function of their titania concentration. An evident tendency can be defined from this bar chart: TiO2 nanoparticles homogenized into neat Group III base oil do not positively affect the lubricant regarding friction reduction. Each prepared sample presented a friction coefficient increase of 20 to 32%. However, it can also be observed that the measured error bars have reduced in each titania concentration, indicating the investigated nanoparticles' positive stabilizing effect.

Figure 1. Comparison of the Friction coefficient values of lubricant samples with various titania nanoparticle concentrations.

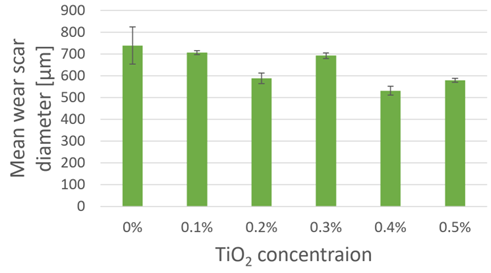

Figure 2 compares the measured and calculated Mean Wear Scar Diameter (MWSD) values in µm dimension. All the prepared nano lubricant samples decreased the measurable wear scar diameter values at each of the prepared TiO2 concentrations. The measured tendency shows that the samples with higher titania concentrations (especially 0.4 and 0.5 wt%) work the best from the investigated samples. However, the 0.2 wt% sample also provides similar wear reduction properties as the 0.5 wt% sample. It is also clear that the error bars decreased compared to the reference results. The sample, including 0.4 wt% titania nanoparticles, showed the lowest MWSD results with a decreasing value of 32%.

Figure 2. Comparison of lubricant samples' Mean wear scar diameter values with various titania nanoparticle concentrations.

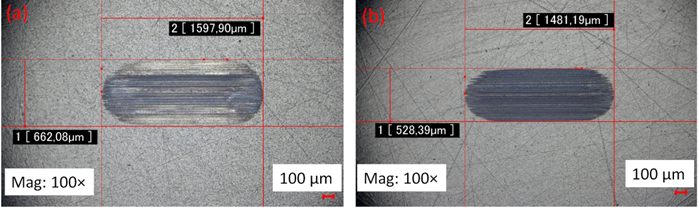

The acquired digital microscope images of the worn disc surfaces with 0 and 0.4 wt% titania concentrations can be observed in Figure 3. The difference can clearly be defined: adding titania nanoparticles into the neat Group 3 base oil decreased the wear scar width. During a drastic wear process, the usually burned lubricant molecules (dark color on the surface) are removed by the connecting specimen and the worn surface becomes shinier. These shiny wear areas cannot be found in the wear scars in the case of titania-added samples, which leads to the deduction that the investigated TiO2 nanoparticle eliminated the establishment of the drastic deep wear grooves since no metal-shining areas can be seen in the wear scar image acquired with 0.4 wt% of titania containing nanolubricants.

Figure 3. Acquired digital microscope images of the worn surfaces on the disc specimens with 0% (a) and 0.4% (b) titania NP concentrations.

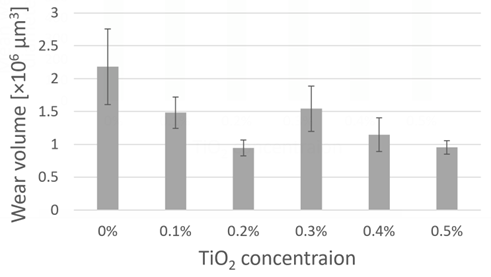

Figure 4 compares the nanolubricants to the wear volume generated during the tribological experiments. The bar chart clearly illustrates the differences between the lubricant samples with different titania concentrations and the positive antiwear effect of the titania nanoparticles. The tendencies according to wear volume and mean wear scar diameter are similar. The highest wear volume reduction was accomplished in the case of the 0.2 wt% titania containing oil sample with a decrease of 57%, but the 0.5 wt% sample also shows identical wear-decreasing properties.

Figure 4. Comparison of the Wear volume values of lubricant samples with various titania nanoparticle concentrations.

According to the acquired tribological results, the main influencing factors of the titania nanoparticles can be defined. Adding TiO2 nanoparticles into the neat Group III base oil significantly increases frictional losses2 nanoparticles into the neat Group III base oil increases the frictional losses significantly (at least 20% of friction coefficient increase). However, the wear reduction effect of the investigated oil samples is impressive: the measured MWSD values were reduced by 32% in the case of 0.4 wt% titania-containing lubricant and the calculated wear volume values were also dropped by 57% in the case of 0.2 and 0.5 wt% sample. Combining this information, the optimum concentration can be defined at 0.4 wt% because it provides the lowest possible friction coefficient and excellent wear reduction effect.

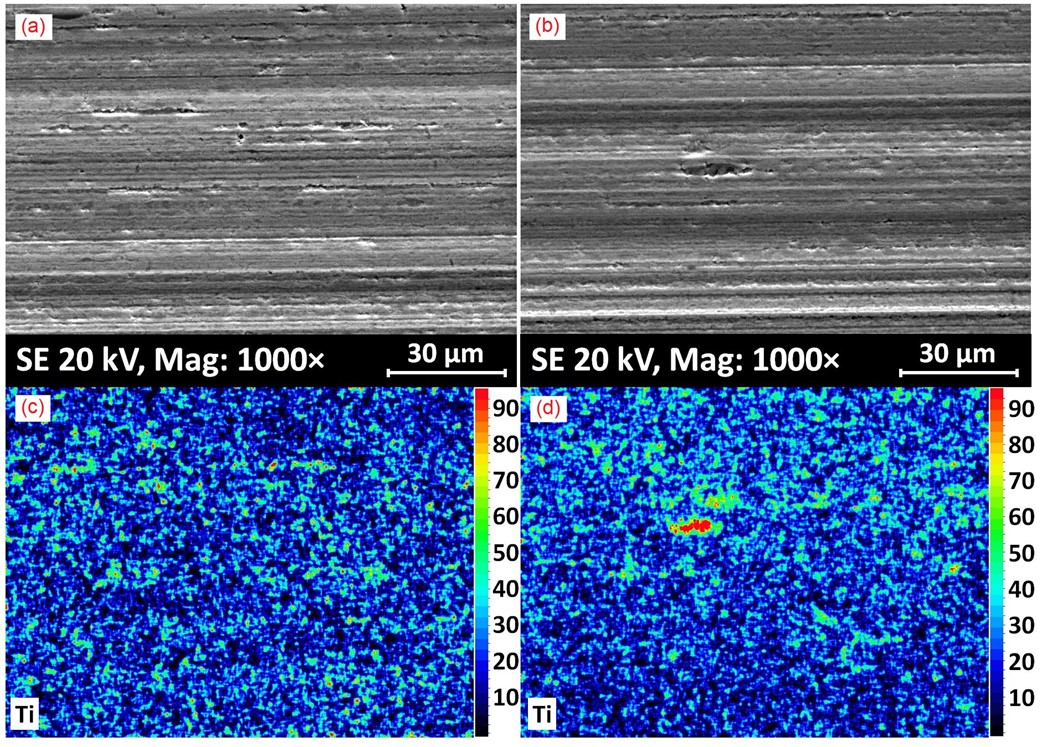

The scanning electron micrographs were taken with an accelerating voltage of 20 kV in secondary electron mode at a magnification 1000. Figure 5 shows scanning electron micrographs and titanium intensity images of the wear tracks of a disc tested using an oil sample containing 0.4 wt% (optimum) nano-sized titania. The SEM images were taken on the center line of the wear track of the disc in the direction of movement. Picture (a) shows an image taken at the center of the disc, where the relative speed between the test bodies is the highest and the formation of mixed friction is the most likely. Figure (b) shows an image taken in the middle of the dead center of the wear track of the disc. At this point, the relative speed is the lowest and reaches zero, so boundary layer friction is formed. Figures (c) and (d) show the intensity of the titanium element at the center of the wear mark (c) and the center of the dead center of the wear mark (d).

Figure 5. (a) SEM image taken at the center of the wear track. (b) SEM image was taken at the dead center of the wear track. (c) titanium intensity image in the center of the wear track belonging to (a). (d) titanium intensity image in the center of the dead center of the wear track belonging to (b).

Based on the SEM images (Figure 5 (a) and (b)), it can be established that the abrasion wear type is dominant on the entire wear track, the grooves of which are visible in the direction of movement. Traces of adhesive wear can be detected in both positions. However, it occurs in a higher proportion in the center of the wear track. EDX is a device suitable only for detecting elements. In the tribology system used during the tests, the titania nano additive is the only component that contains titanium. Therefore, it can be concluded that all titanium signals entering the detector originate from the titania nano additive. The figures showing titanium intensity indicate in red the areas from which titanium radiates with greater intensity. Red sites contain more titanium than green, blue and black areas. Comparing Figures 5 (a) and (c), as well as Figures 5 (b) and (d), it can be concluded that small amounts of titanium occur uniformly in all areas of the wear track. It is mainly found in significant quantities in the deepest grooves of wear marks. Based on the images, it can be established that the nano-sized titania additive fills the grooves of the wear track during its operation.

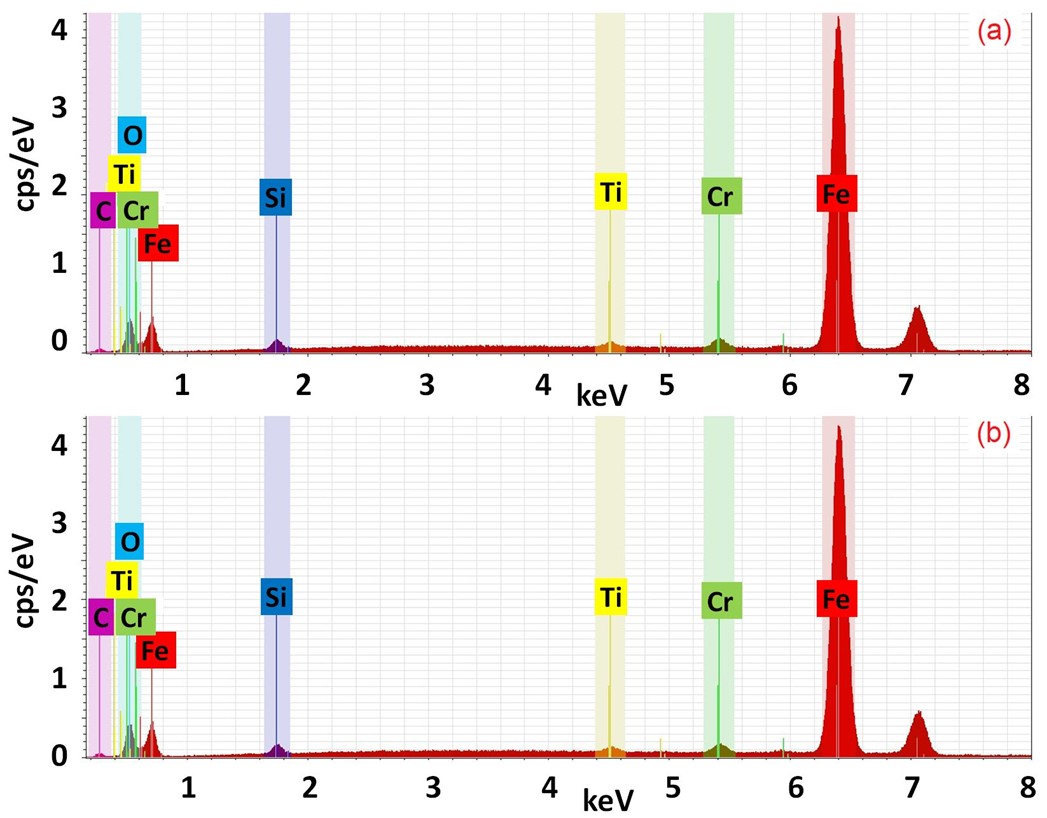

Figure 6 shows EDX spectra recorded at different points of the wear track of the disc. Figure 6 (a) shows the EDX spectrum taken at the center of the wear track of the disc, while Figure 6 (b) shows the spectrum taken at the dead center of the wear track of the disc.

Figure 6. The upper figure (a) shows the EDX spectrum taken at the center of the disk (belongs to Figures 5 (a) and 9 (c)). The lower figure (b) shows the EDX spectrum taken at the dead center of the disk (belongs to Figures 5 (b) and 9 (d)).

The EDX spectra (a) and (b) show similar results; from that, it can be concluded that the elemental composition of the worn surfaces is identical; it is independent of the position. The iron tip is the highest because it provides most of the disc's material. The primary alloying elements of the disc material are silicon and chromium. Carbon can also be found in the disc's material, but it was mainly incorporated into the surface from the lubricating oil during the measurement. The origin of the oxygen peak can come from several sources: the disc's steel material may contain it, from surface oxidation, from the titania nano additive. Since the origin of the oxygen is not clear, it is therefore not suitable for detecting TiO2. The signal of the titanium peak, marked in yellow in the spectrum, can only come from the presence of the titania additive, so it is used to determine the amount. Based on the intensity of the EDX signals, the titania content of the surface can be calculated; a summary is shown in Table 1.

Table 1. The table compares the titanium content of the unworn reference surface at the center of the wear track and the center of the dead center of the wear track.

|

Position on the disc |

Ti content [norm. wt%] |

|

reference |

0 |

|

middle point of the wear track |

0.62 |

|

middle point of the dead center |

0.56 |

From the quantification results, it can be concluded that a similar amount of titania nano-additives are found (settled in the valleys or embedded in the worn surface) in the entire area of the wear track. The unworn surface did not contain titania. The normalized titanium content of the center of the wear track is 0.62 wt%, while 0.56 wt% is found at the dead center.

4. CDiscussion and conclusions

IThis article demonstrated the homogenization process of titanium dioxide nanoparticles to create a stable dispersion in Group III-based lubricants. Using the titania nanoparticles, five Group III-based lubricating oil samples were prepared (0.1; 0.2...0.5 wt% in concentration), suitable for tribology tests.

The tribological tests of the lubricating oil samples were carried out by the Department of Propulsion Technology, Széchenyi István University, Győr. Lubricating oils were tested on a ball-on-disc oscillating tribometer using continuous oil circulation. The friction was recorded during the measurements; then, worn surfaces were evaluated using a standard evaluation.

- Based on the tribological results, applying the titanium dioxide nanoparticles increases the friction by 20 to 32%.

- Titania nanoparticles could reduce the size of wear diameters even by 32%. Titania protected the surface from forming deep grooves and reduced the wear volume parameters by 57%.

- Titania increases the measurements' repeatability, as the measured values' standard deviation is significantly lower in every aspect.

- The optimum titania concentration in the used tribosystem can be defined at 0.4 wt%.

- Scanning electron microscopy revealed that abrasive wear is the primary wear type on the worn surface. Adhesive wear was found on the whole wear track, but it occurs more in the middle point of the wear track (highest relative speed area).

- Titanium intensity images revealed that all the worn area contains titania, but most can be found in the bottom of the deep wear grooves. EDX quantification defined titanium content on the worn surface as 0.56 to 0.62%.

It can be stated that specific properties of the Group III lubricating oil doped with titanium dioxide nanoparticles have yet to be discovered and require further investigation.