Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is a comparison between Version 2 by Dean Liu and Version 1 by Suprava Chakraborty.

Hydrogen fuel for sustainable mobility has its own effectiveness in terms of its generation and refueling processes. As the fuel requirement of vehicles cannot be anticipated because it depends on its utilization, choosing hydrogen refueling and onboard generation can be a point of major concern.

- hydrogen fuel

- sustainability

- green fuel

- sustainable transportation

1. Introduction

The advancement of technology and increasing demand for electrical power have motivated all nations to find alternate energy sources for power generation [1,2,3][1][2][3]. It is estimated that the drastic increase in power demand will deplete fossil fuel for power production [4,5,6][4][5][6]. Moreover, the environmental impacts of fossil fuel utilization in various sectors include to the emission of greenhouse gases (GHGs) and the generation of pollutants in the environment [7,8,9][7][8][9]. The aforementioned causes justify the increase in demand for renewable and sustainable energy-based power stations and the dependency of various sectors on them [10,11,12][10][11][12].

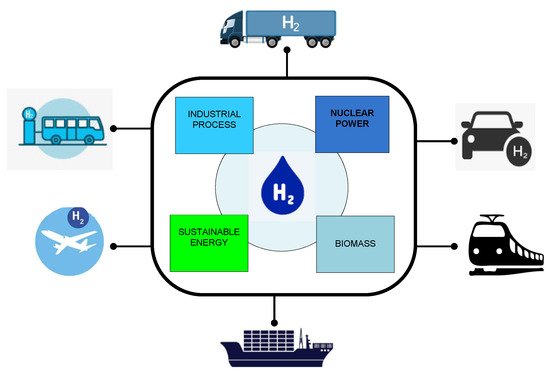

The negative environmental impact of the increase in fossil fuel-based transportation mechanisms has forced the automobile industry to find alternative fuel options. The transportation sector is responsible for 28% of greenhouse gas emissions [13,14][13][14]. Therefore, electric vehicles have gained popularity due to the fact they emit zero emissions into the environment, low refueling cost, and low maintenance cost [14]. However, electric vehicles also have some disadvantages such as a long battery charging time, limited driving range, and high purchasing costs. Therefore, more public awareness of electric vehicle utilization and technological advancement is required to overcome the aforementioned problems. Various category of mobility sectors which utilize hydrogen fuel has been presented in Figure 1.

Figure 1. Structure of hydrogen generation sources at various transportation sectors.

The development of hybrid cars that can minimize the time between two consecutive refueling procedures is one potential way to mitigate the mentioned drawbacks. The addition of a second energy storage vector to a vehicle, which allows the battery to charge while driving, extends the period between refueling while also improving trip autonomy [13,14,15][13][14][15]. The tandem hydrogen and proton-exchange membrane fuel cell is one example of a hybrid device. The hydrogen-based fuel cell has demonstrated its ability to store and transform chemical energy directly into electricity, as well as several other benefits. The challenge of adopting hydrogen and fuel cell-based technologies has been added to the agenda of the world’s largest car manufacturers. Despite the committed efforts made to date, an additional and more in-depth study is required for the development and application of hydrogen-based fuel cells for electric cars as well as pure hydrogen vehicles [16]. The goal of choosing hydrogen fuel is due to its clean energy feature with zero-emission and high energy transfer capability. The hydrogen fuel-based vehicle in comparison to the electric vehicle shows advantages in terms of refueling time and costs which can attract a large number of consumers [17,18][17][18].

Recently, high prices, limited power density, and a lack of hydrogen infrastructure have become the primary barriers to the widespread adoption of these cars. The most significant barrier is arguably the lack of hydrogen production and distribution infrastructure, as well as the difficulty in effectively and swiftly building it up. In the near and medium term, an on-board fuel processor enabling direct in-vehicle hydrogen conversion from hydrocarbon fuels is thus the only means of allowing FCVs to gain a market share that is acceptable. This concept is particularly appealing for safety reasons: the entire system takes up less space than a compressed hydrogen tank and facilitates refilling by utilizing existing infrastructure. Furthermore, unlike internal combustion engines, which are limited to bi-fuel operation, the same reformer may be fed by a variety of fuels, needing only minor adjustments to the operating conditions while maintaining the processor’s integrity.

Hydrogen has long been recognized as a possible low-carbon transportation fuel, but it has proven challenging to integrate into the transportation fuel mix.

Fuel cells directly convert the chemical energy in hydrogen to electricity, with pure water and potentially useful heat as the only byproducts [4,19][4][19].

Hydrogen-powered fuel cells are not only pollution free, but can also have from two to three times the efficiency of traditional combustion technologies. A conventional combustion-based power plant typically generates electricity at efficiencies of 33–35%, while fuel cell systems can generate electricity at efficiencies of up to 60% (even higher with cogeneration) [19].

The gasoline engine in a conventional car is less than 20% efficient in converting the chemical energy in gasoline into power that moves the vehicle under normal driving conditions. Hydrogen fuel cell vehicles, using electric motors, are much more energy efficient and use 40–60% of the fuel’s energy, corresponding to more than a 50% reduction in fuel consumption, compared to a conventional vehicle with a gasoline internal combustion engine [19].

In addition, fuel cells operate quietly, have fewer moving parts, and are well suited to a variety of applications.

Fuel cell electric vehicles (FCEVs) made up a relatively small fraction of the worldwide stock of total cars in 2020, and hydrogen consumption in the industry has been confined to less than 0.01 percent of the energy used, as have electric automobiles (0.3%). However, as a result of events in Asia and the United States, the FCEV market is starting to take off. By the end of June 2021, more than 40,000 FCEVs were on the road throughout the world. From 2017 to 2020, stocks expanded by an average of 70% each year, but in 2020, stock growth slowed to 40%, and new fuel cell car registrations plummeted by 15%, matching the broader car market downturn caused by the COVID-19 pandemic. However, 2021 is a candidate to be a new record year, with over 8000 FCEVs sold in the first half of the year and monthly sales in California reaching new highs [20,21,22][20][21][22].

FCEVs are today largely compared with battery electric vehicles (BEVs) [23,24,25,26,27,28][23][24][25][26][27][28]. The related literature reveals important differences between the two technologies. BEVs are preferable due to the cheaper infrastructure investment cost and a lower vehicle cost [24]. Despite that, the relatively low autonomy makes BEV mostly suited for short-distance trips such as urban use, which is a large segment of the road market. The developments and efficiency gains in battery technology together with subsidies for public charging stations are expected to facilitate the BEV growth [24]. FCEV is still in an early deployment stage due to a higher infrastructure investment cost and higher vehicle cost. The relatively high autonomy combined with fast refueling make FCEV mostly suited for long-distance and interurban usage. In terms of efficiency, the overall efficiency of BEV is much higher than that of FCEV due to the FCEV energy losses in the entire well-to-tank–tank-to-wheel process phases [19,23,25][19][23][25].

2. Issues and Concerns of Present Vehicle Fuel

Nowadays, considering that climate-friendly means of transport and fossil fuels are incompatible, many countries are favoring the transition from conventionally fueled vehicles to low-emission vehicles to tackle environmental pollution issues. In particular, the European Commission has defined a mobility agenda based on sustainable targets to be achieved by 2030 [24,25][24][25] in Europe. Among the objectives of the agenda, in 2025, it is expected that the average CO2 emissions of new heavy trucks will be reduced by approximately 15% with respect to the emissions of 2019. Moreover, a CO2 emissions reduction of approximately 30% compared to 2019 is expected to be achieved by 2030. These targets are consistent with the European Union’s commitments under the Paris Agreement and, besides the environmental benefits, will allow transport companies to achieve significant savings thanks to lower fuel consumption [25]. To reach the above goals, several legislative, research, and innovation initiatives have been put in place by the European Commission for road mobility and transport [24]. Particular attention is paid to enhancing a more diffused use of new generation vehicles such as electric and automated vehicles. It has been demonstrated that the large use of EVs instead of conventional vehicles can save approximately 60% of GHG emissions in most EU countries [26]. In particular, the use of EVs leads to an average saving of GHG emissions of approximately 50% compared to diesel in Europe [27]. Despite those important benefits, the environmental impact of battery EVs (BEVs) is not null due to the following reasons: (1) in most cases, EV batteries are charged by using non-green energy; (2) the EV’s entire life cycle is responsible for some GHG emissions, also considering that the batteries need to be disposed at the end of their life. Nevertheless, there are studies comparing the BEV life cycle impact with conventional vehicles’ impact on the environment, showing that BEVs can nevertheless lead to total GHG emissions that are lower than those of traditional vehicles (ICE) [28]. Moreover, if renewable energy sources are used for battery charging, the advantages and benefits for the environment of using BEVs are even more evident. However, even though BEVs are spreading across Europe and the rest of the world, we are still far from the goal of finalizing the substitution of conventional cars, motorbikes, buses, and heavy trucks with such vehicles. Further actions are needed both from governments and technology providers in order to overcome socio-economic and technological limitations.

Indeed, the diffusion of BEVs across the world is currently limited by some critical aspects and issues due to both socio-economic and technological factors.

Regarding the socio-economic and political aspects and actions to be undertaken for EV advancement, public engagement is important to effectively design and manage the passage to sustainable transport technologies. National policy directives such as guidelines for use in public roads and car parks, incentives for parking and purchasing new mobility means can contribute to the diffusion of such sustainable technologies. In this framework, the study in [29] concludes that the EV adoption rate is strongly affected by the local policy instruments of public charging infrastructure that is higher in urban municipalities than in suburban and rural cities. Furthermore, as a natural consequence, the diffusion of EVs is faster where the expansion of public charging infrastructure is higher. In this context, there are still significant differences among cities in terms of charging infrastructure investments that can limit the EV diffusion locally [29].

In addition, a qualitative comparative analysis was conducted in [30] for 15 European cities, comparing the local policies and their socio-economic effects, in order to identify the optimal configurations to foster the expansion of EVs [30]. It is remarked that single action will not succeed because the research shows that the transition towards sustainable mobility can only occur through various, place-specific configurations of measures.

Analogously, Wang et al. [31] performed a correlation analysis and multiple linear regression analyses to evaluate the relationship between incentive policies and socio-economic factors for electric vehicle adoption across 30 countries in 2015.

From the performed analysis, the authors concluded how the governments’ first action should be to expand charging infrastructure and provide road priority for electric vehicles. In addition, governments could increase fuel tax to disincentivize the use of conventional vehicles and retain tax breaks, waivers on fees (e.g., parking, tolls, and ferries), and electricity supply cost reduction for EVs.

In addition, from one side, BEVs are still expensive with respect to internal combustion engine vehicles even though, more recently, many countries, such as Italy, are providing incentives to smooth the final cost for users. On the other hand, even though fast and ultra-fast charging solutions are currently available, they are not sufficiently diffused across the countries, partly due to long approval procedures, to solve the problem of BEV charging times that are still significantly longer than refueling times [24]. Moreover, in a transnational corridor that can guarantee accessibility to all EVs, implementing the direct current charging can be desirable but is far from being implemented. Additionally, other solutions such as battery swapping are being introduced onto the market today. This consists of the real-time swapping of the discharged/low charged battery with a fully charged compatible one in dedicated stations. This can be an effective technique to overcome the charging time issue, but its efficacy and long-term sustainable use are still to be adequately investigated and demonstrated. Looking at the driver experience, driving an electric car still causes range anxiety to the users that can fear that their vehicles do not have enough autonomy to reach the next charge point [32]. This is mainly due to the low range autonomy that generally affects most current BEVs on the market and the limited available charging infrastructures in many countries [33].

3. Motivation for Hydrogen Energy

In order to address the discussed issues related to BEVs, in particular the technological ones, the use of fuel cells for electricity storage has been investigated. Hydrogen is considered a clean and efficient energy carrier that can ensure energy security and sustainability [34]. Three dimensions must be considered when promoting hydrogen according to [35]: (1) Market requirements: price must be competitive compared to other environmentally friendly energy carrier-like batteries; refueling infrastructure must allow the autonomy range required by users; fast and easy storage processes are needed to enable a great autonomy for mobility; safety levels that are equal to or better than carbon-based energy sources are necessary. (2) Sustainability and climate requirements: hydrogen energy has to comply with the objectives of governments; hydrogen cars must also comply with existing legal requirements to prevent and limit waste from end-of-life vehicles and their components, ensuring that where possible, these are reused, recycled or recovered. (3) Hydrogen technology requirements: to achieve a mass-market in hydrogen mobility, there is the need to reduce the cost of cars and hydrogen fueling stations. The technology development aims to lower or replace the use of noble materials such as platinum in fuel cells and electrolyzers and achieve higher storage densities (higher car autonomy range) whilst simultaneously lowering storage pressures.

From a technological point of view, the fuel cell (FC) is an energy conversion device that can efficiently capture and use the power of hydrogen [19,28,30][19][28][30]. The fuel cell generates electricity through an electrochemical reaction in which hydrogen and oxygen are combined to generate electricity, heat, and water. The fuel cell is composed of an anode, cathode, and an electrolyte membrane [31,36][31][36]. In general terms, hydrogen enters the fuel cell through the anode, where it is split into electrons and protons. Hydrogen ions pass through the electrolyte which forces the electrons through a circuit, generating an electric current and excess heat. Oxygen entering at the cathode combines with electrons from the electrical circuit and the hydrogen ions that passed through the electrolyte from the anode, generating water [19,31,36][19][31][36]. This union is an exothermic reaction, generating heat that can be used outside the fuel cell. Stationary FCs can be used for backup power, power for remote locations, distributed power generation, and cogeneration (in which the excess heat released during electricity generation is used for other applications). FCs can power almost any portable application that typically uses batteries, from hand-held devices to portable generators, and can also power our transportation, including personal vehicles, trucks, buses, and marine vessels, as well as provide auxiliary power to traditional transportation technologies. In this context, hydrogen can play a particularly important role in the future by replacing the imported petroleum we currently use in our cars and trucks [31,36][31][36].

In particular, hydrogen technology only emits water vapor into the environment, leading to the benefit of having zero GHG emissions during use [19,36][19][36]. However, on the other hand, more energy than other technologies are necessary to produce hydrogen since it is an element not present in its natural state.

4. Comparative Analysis (On-Board Hydrogen Vehicle vs. Hydrogen-Fueled ICEs)

Based on the requirement of environmental safety, hydrogen fuel has been considered as the most environmentally friendly vehicle fuel. However, the way that the hydrogen fuel vehicle utilizes hydrogen has complicated the scenario. Onboard hydrogen generation and its utilization for vehicles require various stages to generate the DC voltage as energy. However, internal combustion engine-based hydrogen fuel vehicles require a hydrogen storage tank which supplies the required fuel for the internal combustion engine [144,145,146][37][38][39]. Hydrogen, a zero-carbon fuel, may be used to power both internal combustion engines and on-board hydrogen vehicles. Internal combustion engines are most efficient when they are under high load. On-board hydrogen vehicles perform best at lower loads. In highly transitory duty cycles, on-board hydrogen vehicles may also recover energy through regenerative braking, enhancing their overall efficiency. On-board hydrogen vehicles, except for water vapor, create no emissions at all [147][40]. This is a particularly appealing feature for cars that operate in cramped places or with limited ventilation. Internal combustion hydrogen engines create nitrogen oxides, or NOx, but emit only trace quantities of CO2 (from ambient air and lubricant oil). As a result, they are not suitable for indoor usage and need exhausting after treatments in order to decrease the NOx emissions. Internal combustion hydrogen engines may frequently run on lower-grade hydrogen. This is useful in some situations as, without the requirement for purification, hydrogen can be used in hydrogen engines [148,149][41][42]. However, high-quality hydrogen is required when on board on-board hydrogen vehicles. Finally, the maturity of hydrogen engines and hydrogen fuel cell technology varies. For decades, internal combustion engines have been widely utilized and backed by large service networks. Rugged engines are available in a variety of sizes and configurations, and may function in dusty settings or be subjected to high vibrations. Switching to hydrogen engine drive trains requires common parts and technology for car makers and fleet operators. The tried-and-true, dependable character of internal combustion engines will provide reassurance to risk-averse end-users [150,151,152][43][44][45]. As a result, on-board hydrogen vehicles and hydrogen ICEs are not in direct competition with one another. On the contrary, because both drive the development of shared hydrogen production, transportation, and distribution infrastructure, the growth of one aids the development of the other. They are complementary technologies that are part of the current effort to reduce the automotive and transportation emissions to zero. Most customers are unfamiliar with the on-board hydrogen propulsion technology, which is fundamentally different from internal combustion engine automobiles. However, the fuel cell stack and hydrogen storage systems are distinctive and costly, and other components in on-board hydrogen generation require considerable cost reductions as well [153,154][46][47]. The module that controls the operation of the fuel cell stack and the entering air, hydrogen streams, electric drive motors and controls that drive the vehicle, and high voltage batteries that store regenerative braking energy while also assisting in fuel cell operation are all examples of these. On-board hydrogen generation subsystems must compete in terms of performance, cost, and longevity with what automotive makers and consumers have grown to expect in modern cars [155][48]. Automotive manufacturers and purchasers will not be willing to invest in fuel cell technology until the technologies that make up the different components of a fuel cell car have evolved to acceptable levels of cost, performance, dependability, durability, and safety. Above all, tremendous progress must be made in the fuel cell stack.References

- Igliński, B.; Pietrzak, M.B.; Kiełkowska, U.; Skrzatek, M.; Gajdos, A.; Zyadin, A.; Natarajan, K. How to Meet the Green Deal Objectives—Is It Possible to Obtain 100% RES at the Regional Level in the EU? Energies 2022, 15, 2296.

- Saarloos, B.A.; Quinn, J.C. Achieving Optimal Value of Solar: A Municipal Utility Rate Analysis. Solar 2022, 2, 7.

- Saidin, M.I.S.; O’Neill, J. Climate Change and the Diversification of Green Social Capital in the International Political Economy of the Middle East and North Africa: A Review Article. Sustainability 2022, 14, 3756.

- Ruiz Duarte, J.L.; Fan, N. Operation of a Power Grid with Embedded Networked Microgrids and Onsite Renewable Technologies. Energies 2022, 15, 2350.

- Wang, Y.; Chen, C.; Wang, J.; Baldick, R. Research on resilience of power systems under natural disasters—A review. IEEE Trans. Smart Grid 2016, 31, 1604–1613.

- Yue, C.-D.; Wang, I.-C.; Huang, J.-S. Feasibility of Replacing Nuclear and Fossil Fuel Energy with Offshore Wind Energy: A Case for Taiwan. Energies 2022, 15, 2385.

- Chen, F.; Lu, S.-M.; Tseng, K.-T.; Lee, S.-C.; Wang, E. Assessment of renewable energy reserves in Taiwan. Renew. Sustain. Energy Rev. 2010, 14, 2511–2528.

- Mikkili, S.; Kanjune, A.; Bonthagorla, P.K.; Senjyu, T. Non-Symmetrical (NS) Reconfiguration Techniques to Enhance Power Generation Capability of Solar PV System. Energies 2022, 15, 2124.

- Jordehi, A.R. Maximum power point tracking in photovoltaic (PV) systems: A review of different approaches. Renew. Sustain. Energy Rev. 2016, 65, 1127–1138.

- Dash, S.K.; Ray, P.K. A New PV-Open-UPQC Configuration for Voltage Sensitive Loads Utilizing Novel Adaptive Controllers". IEEE Trans. Ind. Inform. 2021, 17, 421–429.

- Malathy, S.; Ramaprabha, R. Reconfiguration strategies to extract maximum power from photovoltaic array under partially shaded conditions. Renew. Sustain. Energy Rev. 2018, 81, 2922–2934.

- Priyanka, G.; Dash, S.K. A Detailed Review on Intelligent Maximum Power Point Tracking Algorithms. In Proceedings of the 2020 2nd International Conference on Innovative Mechanisms for Industry Applications (ICIMIA), Bangalore, India, 5–7 March 2020; pp. 47–53.

- Balat, M. Potential importance of hydrogen as a future solution to environmental and transportation problems. Int. J. Hydrogen Energy 2008, 33, 4013–4029.

- European Economic Area. Renewable Energy in Europe 2016; European Environment Agency, EU Publication: Copenhagen, Denmark, 2016.

- Dincer, I.; Acar, C. Review and evaluation of hydrogen production methods for better sustainability. Int. J. Hydrogen Energy 2015, 40, 11094–11111.

- Piela, P.; Mitzel, J. Polymer electrolyte membrane fuel cell efficiency at the stack level. J. Power Sources 2015, 292, 95–103.

- Pavelka, M.; Marsik, F. Detailed thermodynamic analysis of polymer electrolyte membrane fuel cell efficiency. Int. J. Hydrogen Energy 2013, 38, 7102–7113.

- Hwang, J.-J. Effect of hydrogen delivery schemes on fuel cell efficiency. J. Power Sources 2013, 239, 54–63.

- Fuel Cells. Available online: https://www.energy.gov/eere/fuelcells/fuel-cells (accessed on 5 May 2022).

- Larminie, J.; Lowry, J. Front matter. In Electric Vehicle Technology Explained, 2nd ed.; John Wiley & Sons, Ltd.: Chichester, UK, 2012.

- Bowers, B.J.; Zhao, J.L.; Ruffo, M.; Khan, R.; Dattatraya, D.; Dushman, N.; Beziat, J.C.; Boudjemaa, F. Onboard fuel processor for PEM fuel cell vehicles. Int. J. Hydrogen Energy 2007, 32, 1437–1442.

- Global Hydrogen Review. 2021. Available online: https://www.iea.org/reports/global-hydrogen-review-2021 (accessed on 5 May 2022).

- Li, M.; Zhang, X.; Li, G. A comparative assessment of battery and fuel cell electric vehicles using a well-to-wheel analysis. Energy 2016, 94, 693–704.

- Brunet, J.; Kotelnikova, A.; Ponssard, J.P. The deployment of BEV and FCEV in 2015. Available online: https://www.researchgate.net/profile/Jean-Ponssard/publication/282865470_The_deployment_of_BEV_and_FCEV_in_2015/links/5bbf165692851c4efd5651dd/The-deployment-of-BEV-and-FCEV-in-2015.pdf (accessed on 5 May 2022).

- Hydrogen or Battery? A Clear Case, Until Further Notice (2019). VolksWagen Website. Available online: https://www.volkswagenag.com/en/news/stories/2019/08/hydrogen-or-battery--that-is-the-question.html (accessed on 5 May 2022).

- Cano, Z.P.; Banham, D.; Ye, S.; Hintennach, A.; Lu, J.; Fowler, M.; Chen, Z. Batteries and fuel cells for emerging electric vehicle markets. Nat. Energy 2018, 3, 279–289.

- Van Mierlo, J.; Maggetto, G. Fuel cell or battery: Electric cars are the future. Fuel Cells 2007, 7, 165–173.

- Chen, Y.; Melaina, M. Model-based techno-economic evaluation of fuel cell vehicles considering technology uncertainties. Transp. Res. Part D Transp. Environ. 2019, 74, 234–244.

- Hasan, M.K.; Mahmud, M.; Habib, A.A.; Motakabber, S.M.A.; Islam, S. Review of electric vehicle energy storage and management system: Standards, issues, and challenges. J. Energy Storage 2021, 41, 102940.

- Mongird, K.; Viswanathan, V.; Alam, J.; Vartanian, C.; Sprenkle, V.; Baxter, R. 2020 Grid Energy Storage Technology Cost and Performance Assessment. Energy. 2020. Available online: https://esmap.org/sites/default/files/resources-document/final-esgc-cost-performance-report-12-11-2020_0.pdf (accessed on 5 May 2022).

- Battery Electric, vs. Hydrogen—Which Is the Future for Electric Vehicles? Available online: https://www.lexology.com/library/detail.aspx?g=1bf1cbf0-ac2f-4b39-a3de-2df77a9a515e (accessed on 5 May 2022).

- Gnann, T.; Plötz, P.; Kühn, A.; Wietschel, M. How to decarbonise heavy road transport. In Proceedings of the ECEEE 2017 Summer Study, Hyères, France, 13 August 2017.

- Chakraborty, S.; Kumar, N.M.; Jayakumar, A.; Dash, S.K.; Elangovan, D. Selected Aspects of Sustainable Mobility Reveals Implementable Approaches and Conceivable Actions. Sustainability 2021, 13, 12918.

- Dash, S.K.; Ray, P.K. Photovoltaic tied unified power quality conditioner topology based on a novel notch filter utilized control algorithm for power quality improvement. Trans. Inst. Meas. Control 2019, 41, 1912–1922.

- Ala, G.; Castiglia, V.; Di Filippo, G.; Miceli, R.; Romano, P.; Viola, F. From electric mobility to hydrogen mobility: Current state and possible future expansions. In Proceedings of the 2020 IEEE 20th Mediterranean Electrotechnical Conference (MELECON), Palermo, Italiy, 16–18 June 2020; IEEE: Piscataway, NJ, USA; pp. 1–6.

- Fuel Cell Technologies Office. Fuel Cells. 2015. Available online: https://www.energy.gov/sites/prod/files/2015/11/f27/fcto_fuel_cells_fact_sheet.pdf (accessed on 22 February 2022).

- Cruccolini, V.; Discepoli, G.; Cimarello, A.; Battistoni, M.; Mariani, F.; Grimaldi, C.N.; Dal Re, M. Lean Combustion Analysis Using a Corona Discharge Igniter in an Optical Engine Fueled with Methane and a Hydrogen-Methane Blend. Fuel 2020, 259, 116290.

- Dimitriou, P.; Kumar, M.; Tsujimura, T.; Suzuki, Y. Combustion and Emission Characteristics of a Hydrogen-Diesel Dual-Fuel Engine. Int. J. Hydrogen Energy 2018, 43, 13605–13617.

- Nag, S.; Dhar, A.; Gupta, A. Hydrogen-Diesel Co-Combustion Characteristics, Vibro-Acoustics and Unregulated Emissions in EGR Assisted Dual Fuel Engine. Fuel 2022, 307, 121925.

- Nag, S.; Sharma, P.; Gupta, A.; Dhar, A. Experimental Study of Engine Performance and Emissions for Hydrogen Diesel Dual Fuel Engine with Exhaust Gas Recirculation. Int. J. Hydrogen Energy 2019, 44, 12163–12175.

- Di Battista, D.; Di Bartolomeo, M.; Cipollone, R. Flow and Thermal Management of Engine Intake Air for Fuel and Emissions Saving. Energy Convers. Manag. 2018, 173, 46–55.

- Ouchikh, S.; Lounici, M.S.; Tarabet, L.; Loubar, K.; Tazerout, M. Effect of Natural Gas Enrichment with Hydrogen on Combustion Characteristics of a Dual Fuel Diesel Engine. Int. J. Hydrogen Energy 2019, 44, 13974–13987.

- Huang, Z.; Wang, J.; Liu, B.; Zeng, K.; Yu, J.; Jiang, D. Combustion Characteristics of a Direct-Injection Engine Fueled with Natural Gas−Hydrogen Mixtures. Energy Fuels 2006, 20, 540–546.

- Fan, B.; Pan, J.; Liu, Y.; Chen, W.; Lu, Y.; Otchere, P. Numerical Investigation of Mixture Formation and Combustion in a Hydrogen Direct Injection plus Natural Gas Port Injection (HDI + NGPI) Rotary Engine. Int. J. Hydrogen Energy 2018, 43, 4632–4644.

- Moon, S.; Lee, Y.; Seo, D.; Lee, S.; Hong, S.; Ahn, Y.-H.; Park, Y. Critical Hydrogen Concentration of Hydrogen-Natural Gas Blends in Clathrate Hydrates for Blue Hydrogen Storage. Renew. Sustain. Energy Rev. 2021, 141, 110789.

- Ishaq, H.; Dincer, I. A Comprehensive Study on Using New Hydrogen-Natural Gas and Ammonia-Natural Gas Blends for Better Performance. J. Nat. Gas Sci. Eng. 2020, 81, 103362.

- Hydrogen Internal Combustion Engines and Hydrogen Fuel Cells. Available online: https://www.cummins.com/news/2022/01/27/hydrogen-internal-combustion-engines-and-hydrogen-fuel-cells (accessed on 20 April 2022).

- Ahmed, S.F.; Mofijur, M.; Nuzhat, S.; Rafa, N.; Musharrat, A.; Lam, S.S.; Boretti, A. Sustainable Hydrogen Production: Technological Advancements and Economic Analysis. Int. J. Hydrogen Energy 2021, in press.

More