Ground robots have been developed for a variety of agricultural applications, with autonomous and safe navigation being one of the most difficult hurdles in this development. When a mobile platform moves autonomously, it must perform a variety of tasks, including localization, route planning, motion control, and mapping, which is a critical stage in autonomous operations.

- path planning

- agriculture

- ground robot

1. Introduction

Robotic platforms will increase farm efficiency, according to the strategic European research agenda for robotics [23][1]. Even though this field is becoming more popular in research [24][2], only a few commercial solutions are available [25][3]. Planting, harvesting, monitoring, spraying, and trimming are just a few of the agricultural chores that have been automated. Autonomous robot navigation is required for all of these procedures. This stage, which is a crucial aspect of autonomous robot navigation: localization, mapping, motion control, and path planning are the four prerequisites. Path planning for a robot requires a series of calculations for the translation and rotational motions of the robot to avoid obstacles from the initial point to the end point in the operating environment [26][4]. Agricultural areas provide a number of difficulties for robotic navigation. Agrarian fields, unlike interior surroundings, are complex, unstructured, and unpredictable. Path planning tactics that are well suited for indoor areas may not be suitable for agricultural needs, necessitating the development of sophisticated agricultural path planning strategies. Path planning for UGVs is drawing a lot of attention owing to the Industry 4.0 revolution and exponential growth in machine learning. There are various publications on this topic in the literature, with the first originating in 1989 when Palmer et al. [27][5] proposed a problem with efficient field paths around an obstruction prompted by agricultural sector concerns. Bochtis et al. [28][6] presented research on agricultural machinery improvements, with path planning algorithms for farm area coverage being one of the topics covered. A smart farm should rely on autonomous decision-making to ensure (i) system efficiency, (ii) better product quality, (iii) lower costs, (iv) improved product safety and environmental sustainability, (v) reduced consumer delivery time, and (vi) increased market share and profitability while stabilizing the labor force. When the robot detects an unexpected obstacle, it is forced to change course. To safely avoid the barrier, the robot must either design a short-term time-dependent trajectory and subsequently return to the original path or compute a new path and follow it autonomously.

3. Path Planning

3. Application of Routing in Agriculture

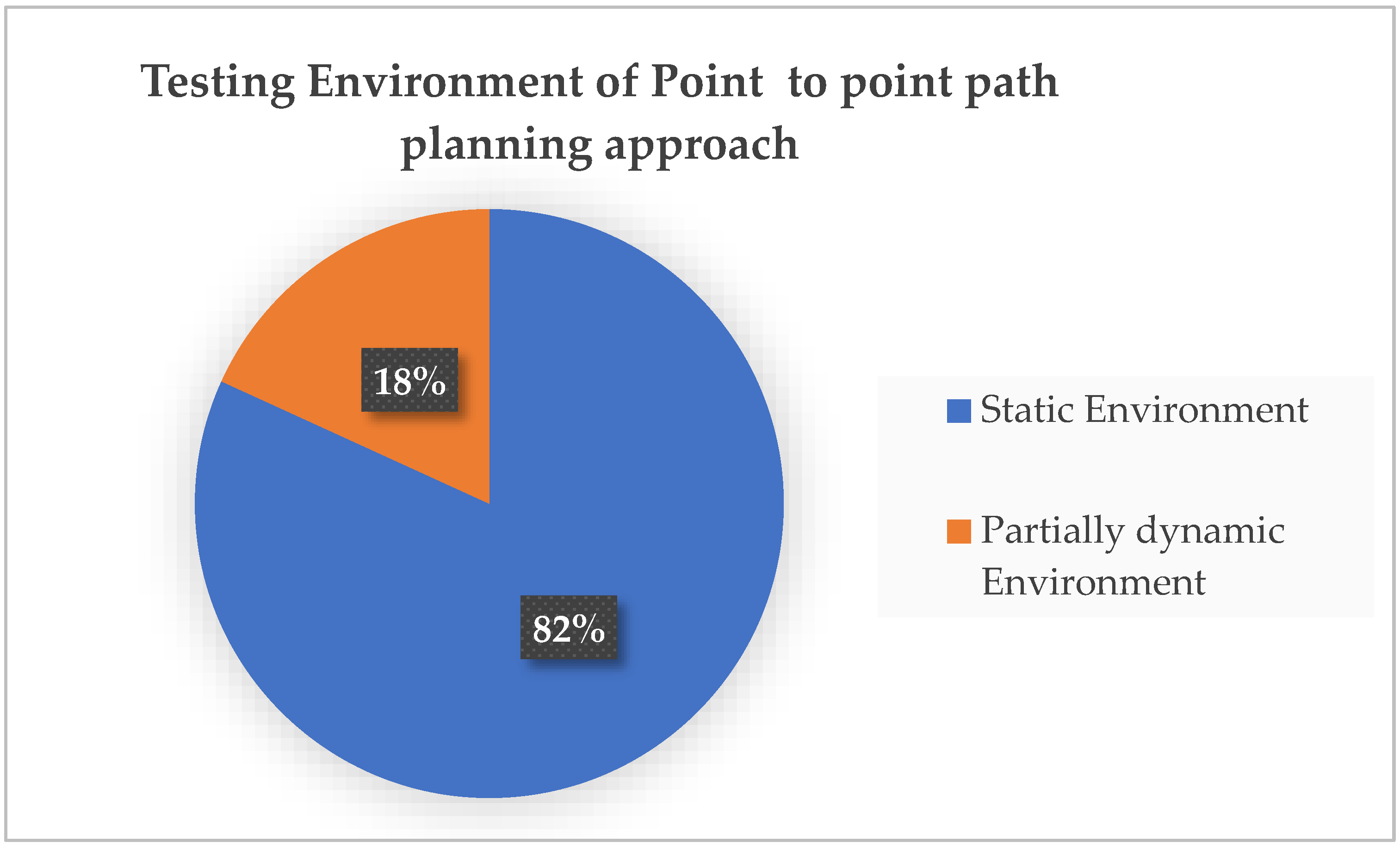

Agricultural applications include navigation in vineyards, orchards, greenhouses, and wheat farms, among others. Monitoring, targeted spraying, and harvesting are only some of the uses for navigation. Some authors, on the other hand, propose a path planning algorithm that is tailored for agricultural areas and/or machinery but does not apply to a specific purpose. For agriculture applications, there is no widely used path planning algorithm, with different methods for each job, whether in 2D/3D surroundings. The first paper listed in point-to-point route planning is from 1997 [84][14], and it provides a GA for building a path for robots used in the agricultural field, while taking into account the limits of the location. Linker et al. [85][15] released a paper in 2008 with a modified cell decomposition utilizing the A* method for orchard navigation. They took into account the limits that are unique to the vehicle and environment, such as a limited steering angle, a restricted range of pitch and roll degrees, a preference for forward motion, and reluctance for frequent turning. Although the claim by authors indicates that the path they have devised is the best, some of the limitations may lead to a less-than-ideal path. Santos et al. [86][16] employed a similar technique considering the center of mass of the robot, for safe navigation in a steep slope vineyard, in which the algorithm limits roll, pitch, and yaw angles. They took into account the limits that are unique to the vehicle and environment in question, such as a limited steering angle, a restricted range of pitch and roll degrees, a preference for forward motion, and reluctance for frequent turning. Other characteristics, such as soil compaction and automated recharge systems, are taken into account in certain variants of this technique. Another work uses D* cell decomposition, that is built based on A* but incorporates robot dynamics. The goal of this work is to navigate around an unknown oil palm plantation [87][17]. In an unstructured 3D terrain, an artificial potential field planner is used for energy optimization [88][18], and Mai et al. [89][19] employs multi-point measurement in potato cultivation using ACO. Point-to-point path routing approach is mainly tested in a static environment rather than the practical field condition of agricultural land as shown in Figure 32.

References

- EuRobotics. Strategic Research Agenda for Robotics in Europe. 2013. Available online: http://relaunch.eu-robotics.net/eurobotics/activities/eurobotics-alliances/ (accessed on 29 May 2022).

- Roldán, J.J.; Cerro, J.D.E.L.; Garzón-Ramos, D.; Garcia-Aunon, P.; Garzón, M.; León, J.D.E.; Barrientos, A. Robots in Agriculture: State of Art and Practical Experiences. In Service Robots; CRC: Boca Raton, FL, USA, 2018; ISBN 9789535137221.

- Dos Santos, F.N.; Sobreira, H.; Campos, D.; Morais, R.; Paulo Moreira, A.; Contente, O. Towards a Reliable Robot for Steep Slope Vineyards Monitoring. J. Intell. Robot. Syst. 2016, 83, 429–444.

- Mac, T.T.; Copot, C.; Tran, D.T.; De Keyser, R. Heuristic Approaches in Robot Path Planning: A Survey. Rob. Auton. Syst. 2016, 86, 13–28.

- Liu, G.; Palmer, R.J. Efficient Field Courses around an Obstacle. J. Agric. Eng. Res. 1989, 44, 87–95.

- Bochtis, D.D.; Sørensen, C.G.C.; Busato, P. Advances in Agricultural Machinery Management: A Review. Biosyst. Eng. 2014, 126, 69–81.

- Julian, A.P. Design and Performance of a Steering Control System for Agricultural Tractors. J. Agric. Eng. Res. 1971, 16, 324–336.

- Reid, J.; Searcy, S. Vision-Based Guidance of an Agriculture Tractor. IEEE Control Syst. 1987, 7, 39–43.

- Hiremath, S.A.; van der Heijden, G.W.A.M.; van Evert, F.K.; Stein, A.; ter Braak, C.J.F. Laser Range Finder Model for Autonomous Navigation of a Robot in a Maize Field Using a Particle Filter. Comput. Electron. Agric. 2014, 100, 41–50.

- Eschenbach, R. GPS Applications in General Aviation. In Global Positioning System: Theory and Applications, Volume II; American Institute of Aeronautics and Astronautics: Washington, DC, USA, 1996; pp. 375–395. ISBN 9781563471070.

- Bell, T. Automatic Tractor Guidance Using Carrier-Phase Differential GPS. Comput. Electron. Agric. 2000, 25, 53–66.

- Bevly, D.M.; Parkinson, B. Cascaded Kalman Filters for Accurate Estimation of Multiple Biases, Dead-Reckoning Navigation, and Full State Feedback Control of Ground Vehicles. IEEE Trans. Control Syst. Technol. 2007, 15, 199–208.

- Raja, P. Optimal Path Planning of Mobile Robots: A Review. Int. J. Phys. Sci. 2012, 7, 1314–1320.

- Noguchi, N.; Terao, H. Path Planning of an Agricultural Mobile Robot by Neural Network and Genetic Algorithm. Comput. Electron. Agric. 1997, 18, 187–204.

- Linker, R.; Blass, T. Path-Planning Algorithm for Vehicles Operating in Orchards. Biosyst. Eng. 2008, 101, 152–160.

- Santos, L.; Santos, F.; Mendes, J.; Costa, P.; Lima, J.; Reis, R.; Shinde, P. Path Planning Aware of Robot’s Center of Mass for Steep Slope Vineyards. Robotica 2019, 38, 684–689.

- Juman, M.A.; Wong, Y.W.; Rajkumar, R.K.; H’ng, C.Y. An Integrated Path Planning System for a Robot Designed for Oil Palm Plantations. In Proceedings of the TENCON 2017–2017 IEEE Region 10 Conference, Penang, Malaysia, 5–8 November 2017.

- Yan, X.-T.; Bianco, A.; Niu, C.; Palazzetti, R.; Henry, G.; Li, Y.; Tubby, W.; Kisdi, A.; Irshad, R.; Sanders, S.; et al. The AgriRover: A Reinvented Mechatronic Platform from Space Robotics for Precision Farming. In Reinventing Mechatronics; Springer: Berlin/Heidelberg, Germany, 2020; pp. 55–73. ISBN 9783030291303.

- Mai, T.; Shao, S.; Yun, Z. The Path Planning of Agricultural AGV in Potato Ridge Cultivation. Ann. Adv. Agric. Sci. 2019, 3, 21–30.

- Taïx, M.; Souères, P.; Frayssinet, H.; Cordesses, L. Path Planning for Complete Coverage with Agricultural Machines. In Springer Tracts in Advanced Robotics; Springer: Berlin/Heidelberg, Germany, 2006; pp. 549–558. ISBN 9783540328018.

- Oksanen, T.; Visala, A. Coverage Path Planning Algorithms for Agricultural Field Machines. J. Field Robot. 2009, 26, 651–668.

- Hameed, I.A. Intelligent Coverage Path Planning for Agricultural Robots and Autonomous Machines on Three-Dimensional Terrain. J. Intell. Robot. Syst. 2014, 74, 965–983.

- Blender, T.; Buchner, T.; Fernandez, B.; Pichlmaier, B.; Schlegel, C. Managing a Mobile Agricultural Robot Swarm for a Seeding Task. In Proceedings of the IECON 2016-42nd Annual Conference of the IEEE Industrial Electronics Society, Florence, Italy, 23–26 October 2016.

- Ohi, N.; Lassak, K.; Watson, R.; Strader, J.; Du, Y.; Yang, C.; Hedrick, G.; Nguyen, J.; Harper, S.; Reynolds, D.; et al. Design of an Autonomous Precision Pollination Robot. In Proceedings of the 2018 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Madrid, Spain, 29 August 2018.

- Cook, S.A. The Complexity of Theorem-Proving Procedures (1971). In Ideas That Created the Future; The MIT Press: Cambridge, MA, USA, 2021; pp. 333–338. ISBN 9780262363174.