Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is a comparison between Version 2 by Lindsay Dong and Version 1 by Hung-Lung Lin.

COVID-19 vaccines have become pivotal in combating the pandemic since 2019. However, risks stemming from human errors, equipment malfunctions, and emergencies during cold-chain transportation can jeopardize vaccine security without effective safety standards.

- cold-chain transportation

- transportation safety and quality

- Cold-chain logistics

1. Standards for Cold-Chain Logistics and Transportation Safety

Cold-chain logistics are strongly tied to human needs, such as the transportation of vaccines or food freshness, and there are temperature requirements and the need for cold-chain transportation in order to ensure quality. The significance of cold-chain logistics lies in the supply-chain activities that constantly maintain a low temperature from production to consumption and that may affect the safety of vaccines or food products when the temperature is not properly controlled. Although the air-conditioning system in transportation vehicles (e.g., trucks, ships, and airplanes) is set at the required temperature during actual transportation in cold-chain logistics, the actual temperature of the goods may vary due to factors such as the placement of the goods, fluctuations in the temperature caused by the opening and closing of the back door when the driver handles the goods, whether air conditioning in the refrigerator is operational or not, etc., which ultimately leads to poor quality of the transported goods. It is, therefore, worth emphasizing risk management to reduce the impact of any possible temperature fluctuations, to promote logistics development, to improve transport efficiency and quality, and to contribute to socio-economic development.

There have been different views among scholars on the definition of cold chain in recent years. Chen et al. [10][1] concluded that cold-chain systems are mainly applied to perishable food products to maintain their freshness during storage, transportation, and distribution. Thakur and Foras [11][2] emphasized that the key to the cold chain is to continuously maintain the temperature required for the product to ensure product quality and safety, while Kim et al. [12][3] stated that the cold chain includes production and product distribution control to meet the needs of the customers. Regardless of the definition, scholars are unanimous in emphasizing the importance of temperature control. This is because different commodities require different safe temperatures to maintain their quality, freshness, and safety. Cold-chain systems play a key role in modern logistics, especially in areas such as food and pharmaceuticals. In the case of pharmaceuticals, it is imperative that the successful development and administration of temperature-sensitive vaccines or medicines be carried out with the utmost care, especially under extreme temperature conditions. This makes cold-chain management an extremely important issue. Medicine or vaccines must be handled with care, or there may be detrimental impacts on public health. With cold-chain systems, food, medicine, and even vaccines are able to maintain proper temperatures at all times during transportation, storage, and distribution to ensure the quality and safety of the product while meeting the needs of the consumer [13][4]. However, there are a number of challenges associated with the cold-chain transport of both medicines and vaccines. Factors such as complex natural environments, unstable transportation conditions, regional differences in infrastructure, and human operations may affect the quality and safe transportation of medicine or vaccines. In terms of cold-chain logistics, it can be defined as the process with which pharmaceuticals, vaccines, or food products, for example, are maintained in a constant temperature-controlled environment during the various stages of their value-added activities, such as production, storage, and distribution, in order to protect them from temperature fluctuations that could lead to ineffective control, thus ensuring the quality and safety of the product. The goal of this process’ system engineering is to maintain a constant temperature to prevent situations that could potentially adversely affect product quality [14][5].

The attention paid to the cold chain has been increasing internationally in recent years, and in 2003, the Cool Chain Association (CCA) was established in Europe; it is dedicated to the integration of the cold-chain industry and the establishment of the Cool Chain Quality Indicator (CCQI). This is a quality management system of reviews for risk assessment and management systems, with a particular focus on ensuring that perishable products in the cold chain maintain appropriate early warning measures in the presence of specific environmental factors [15][6]. The British Standards Institution (BSI) developed a standard called “Specification for the transport of chilled and frozen parcels” in 2017 that sets out specific standards for the safety of cold-chain transportation [16][7]. This standard contains temperature control requirements for the delivery of refrigerated or frozen packages by land transportation vehicles, as well as requirements for the resources, equipment, operations, and communications of distribution service providers. Furthermore, the standard defines the requirements and safety matters related to the handling of refrigerated parcels, the conditions of workplaces, refrigerated trucks, and cold-storage and cooling materials, as well as work instructions for operators, operation manuals, and employee training. The objective of this standard is to ensure that the quality and safety of refrigerated and frozen packages are effectively safeguarded during the cold-chain transportation process. It focuses in particular on all aspects of the transportation of such packages by land transport vehicles, including temperature control of the vehicles, appropriate facilities and equipment, and appropriate operation and training, to improve the efficiency and reliability of cold-chain transportation, to reduce damage to packages and quality problems, and to diminish the security risks that may arise during transportation.

For regulating the cold-chain market, China has also established many relevant laws and regulations for market supervision, such as the Technical Management Code for Food Cold-Chain Logistics, the Technical Code for Management of Cold-Chain Transportation of Livestock and Poultry Meat, and the Code of Practice for Cold-Chain Logistics Services for Aquatic Products. As a biological product, vaccines must be stored and transported under defined cold-chain conditions to ensure their quality. The National Medical Products Administration of China [17][8] has established “Requirements for the cold-chain transportation of Vaccines” for the transportation of COVID-19 vaccines. This document sets out the specific regulations and standards developed by the Chinese government and relevant authorities to ensure that the quality, safety, and efficacy of vaccines are guaranteed throughout the transportation process. These norms and requirements are all aimed at enhancing the safety and reliability of cold-chain transportation to safeguard the effectiveness of vaccines, and the health and safety of the people.

The quality and safety of cold-chain logistics are closely related to transportation in areas such as vaccines and food. The assurance of commodity quality and safety through supply-chain activities at constant low temperatures is critical. The establishment of standards and codes, such as the requirements of the International Cold-Chain Association and the British Standards Institution in Europe, as well as China’s cold-chain transportation requirements for COVID-19 vaccines, has highlighted the importance of temperature control, supervision, and training. Adhering to these standards can effectively reduce temperature fluctuations and safety risks in transportation, improve the quality and reliability of cold-chain logistics, and ensure the quality of commodities and the safety of people’s health. Countries should continue to prioritize cold-chain logistics and promote their development to meet people’s demand for the quality and safety of goods.

2. Risk Management and Transportation Safety

Risk is a very fundamental issue that takes many different forms. These risks are as minor as delays or can be natural disasters, covering a very wide range of areas, and the impact of a risk can be short-lived, lasting only a few minutes, or can cause permanent damage. Risks may pose a threat to one part of the supply chain or may affect an industry’s supply-chain system as a whole [18][9]. As a consequence, there is a need to pay close attention to risks in logistics and supply-chain management and to take measures to address and mitigate these risks in order to ensure the safety and reliability of the transportation process.

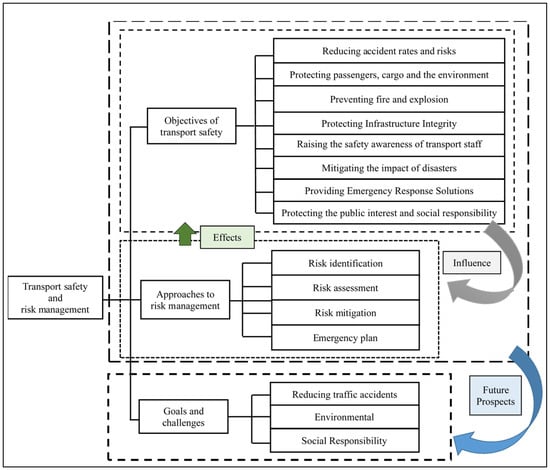

Risk management is a significant process in logistics and supply-chain management, which can be simply categorized into the following three categories [19,20,21][10][11][12]: (1) Risk identification: to identify the risk factors that may pose a threat or cause damage to the transportation process. (2) Risk assessment: to determine the possibility of a risk occurring and the extent of its impact. (3) Risk control and monitoring: to take measures to address and mitigate identified risks, to track changes in risks on an ongoing basis, and to implement control measures. In brief, risk management aims at identifying, assessing, and controlling risks that may adversely affect cold-chain transportation in order to ensure the safety and reliability of the transportation process. This involves the main steps of risk identification, assessment, control, and monitoring, to ensure an effective response to the risks to which different transport carriers may be exposed. The relationship between transportation security and risk management is that risk management is a systematic approach and measures are taken to achieve the goal of transportation security. Risk management methods are aimed at identifying, assessing, and mitigating the various potential risks associated with transportation in order to ensure the safety of people, goods, and the environment during transportation activities. Transportation safety requires effective risk management to improve the overall safety of the transportation system by preventing accidents, mitigating the effects of disasters, and so on. Thus, transportation safety and risk management are mutually reinforcing, and the safety and reliability of transportation activities can be promoted and maintained with a rational risk management approach [19,20,21][10][11][12]. In summary, the study integrates scholars’ views on the relationship between transportation safety and risk management by drawing a mind map (Figure 1), which clearly demonstrates the interrelationship between transportation safety and risk management as well as the connotations of related concepts. (1) Relationship: The relationship between transportation safety and risk management is described. Risk management is emphasized as a way to achieve transport security by linking transport security objectives, risk management approaches, and cross-influencing impacts, while the interplay between the two is highlighted. (2) Transport safety objectives: The objectives of transport safety cover all aspects of transportation, including the reduction in the rate of traffic accidents, the protection of passengers and cargo, and environmental and social responsibility. These objectives are the core elements to be pursued in transportation activities. (3) Risk management methodology: Risk management is a series of strategies to achieve transportation safety objectives, including risk identification, risk assessment, risk mitigation, and contingency planning. (4) Cross-influence: The interplay between transportation safety and risk management is emphasized. Transportation safety can be enhanced by adopting effective risk management methods, while the achievement of transportation safety is one of the objectives of risk management.

Figure 1.

The relationship between transportation security and risk management.

In addition to the above 2.1 Standard Requirements for cold-chain Logistics and Transportation Security, the issue of transportation security and quality requirements is also a topic of concern for governments or scholars, and the scope of transportation security involves the security of transportation carriers, the security of the transportation process, the security of cargoes, the security of transportation documents and information, the security of transportation personnel, the security of transportation infrastructure, the security of the transportation network, and so on. For example, the characteristics (technical and structural) of truck tanks and carriers must comply with the requirements of international agreements when transporting hazardous materials and need to be regularly inspected and monitored to ensure the safety performance of transportation [22,23][13][14]. The safety of transport carriers is of paramount importance in the transportation industry, especially during transportation involving hazardous materials, because of the potential for serious damage to people and the environment in the event of an accident. In terms of truck characteristics (technical and structural) and the importance of technical vehicle inspections, there is a need to clarify their role in preventing human error and reducing the risk of accidents. According to the definition given by Ghaleh et al. [24][15], the improper functioning of vehicle equipment (which may be caused by technical and structural problems of the vehicle) can be considered a background condition for human error, which can increase the probability of driver error and thus increase the risk of accidents. These technical and structural problems may relate to the truck’s handling performance, braking systems, airbags, etc. If these problems are not recognized and dealt with in a timely manner, they could have a significant impact on the driver’s operation and the overall transportation process. Hence, to ensure safe transportation, vehicle technology must be regularly inspected to address potential problems and reduce the risk of accidents. Similarly, the focus may be different for different modes of transportation; e.g., quality and safety considerations and possible risk events involving sea, air, and land transportation may also vary. Nowadays, many scholars have proposed corresponding safety management measures; for example, for maritime transportation, Shang et al. [25][16] proposed transport quality and safety standards integrating safety and quality functions in Indonesian ferry services. Wu et al. [26][17] suggested the key factors for the assessment of the risk of liquefaction in maritime transport, and Ellis [27][18] analyzed the accidents and incidents that occurred during the maritime transport of packaged dangerous goods and pointed out the influencing factors that may occur when a risk event arises. For air transportation, Shen et al. [28][19] analyzed the impacts of lithium batteries on air transportation safety and also pointed out the factors that should be considered. Zhou et al. [29][20] introduced a Bayesian network-based model to reduce the safety risk of commercial air transportation systems, and Braude et al. [30][21] suggested the safety guidelines and preventive countermeasures for COVID-19 patients undergoing aeromedical transportation for air passenger transportation. For land transport, Sangiorgio et al. [15][6] put forward new safety standards for the infrastructure of the railroad transport system and train equipment, while Kozhukhovskaya et al. [31][22] carried out an analysis of the factors that contribute to the process of transporting goods by vehicle and the safety of vehicular traffic, as well as specific countermeasures for the risk of possible incidents. Epifanov et al. [32][23] conducted a quantitative evaluation of the passenger motor transport system with respect to indicators of transport quality and safety level and proposed to improve the efficiency and safety of the passenger motor transport system. Torres-Rubira et al. [33][24] evaluated the safety and quality of the passenger motor transportation system and presented a series of enhancements, including continuous improvements in risk management, employee health, environmental protection, emergency preparedness and response, equipment inspections, and ensuring that all operations are safe and fulfill customers’ needs.

The studies summarized above show that risk is a fundamental issue in logistics and supply-chain management that may present itself in many different forms and pose a threat to all parts of the supply chain. Risk management is a necessary and important process to ensure the safety and reliability of the transportation process. The safety of the cold chain is often distinguished from general transportation safety in past governmental or organizational standards and norms, as well as in research by scholars, and if there are aspects of the cold chain that are addressed, they are often not comprehensive enough [34][25]. There has been little research, especially in areas involving the safety of cold-chain vaccine transportation. Risk management is a major concern in the transportation of vaccines. There is relatively little relevant research in the area of cold-chain transportation, particularly relating to the safe transportation of cold-chain vaccines; therefore, specialized transportation standards and measures are needed to prevent risky events.

References

- Chen, Y.Y.; Wang, Y.J.; Jan, J.K. A novel deployment of smart cold-chain system using 2G-RFID-Sys. J. Food Eng. 2014, 141, 113–121.

- Thakur, M.; Forås, E. EPCIS based online temperature monitoring and traceability in a cold meat chain. Comput. Electron. Agric. 2015, 117, 22–30.

- Kim, K.; Kim, H.; Kim, S.K.; Jung, J.Y. i-RM: An intelligent risk management framework for context-aware ubiquitous cold-chain logistics. Expert Syst. Appl. 2016, 46, 463–473.

- Defraeye, T.; Cronjé, P.; Berry, T.; Opara, U.L.; East, A.; Hertog, M.; Nicolai, B. Towards integrated performance evaluation of future packaging for fresh produce in the cold-chain. Trends Food Sci. Technol. 2015, 44, 201–225.

- Xiao, X.; He, Q.; Fu, Z.; Xu, M.; Zhang, X. Applying CS and WSN methods for improving efficiency of frozen and chilled aquatic products monitoring system in cold-chain logistics. Food Control 2016, 60, 656–666.

- Sangiorgio, V.; Mangini, A.M.; Precchiazzi, I. A new index to evaluate the safety performance level of railway transportation systems. Saf. Sci. 2020, 131, 104921.

- British Standard Institute. PAS 1018:2017 Indirect, Temperature-Controlled Refrigerated Delivery Services–Land Transport of Refrigerated Parcels with Intermediate Transfer. 2017. Available online: www.bsigroup.com/en-GB/about-bsi/media-centre/press-releases/2017/march/Specification-for-the-transport-of-chilled-and-frozen-parcels-launched (accessed on 18 March 2023).

- The National Medical Products Administration of China. Provisions on Administration of Vaccine Manufacturing and Distribution; The National Medical Products Administration of China: Beijing, China, 2022.

- Fan, Y.; Stevenson, M. A review of supply chain risk management: Definition, theory, and research agenda. Int. J. Phys. Distrib. Logist. Manag. 2018, 48, 205–230.

- De Oliveira, U.R.; Marins, F.A.S.; Rocha, H.M.; Salomon, V.A.P. The ISO 31000 standard in supply chain risk management. J. Clean. Prod. 2017, 151, 616–633.

- DuHadway, S.; Carnovale, S.; Hazen, B. Understanding risk management for intentional supply chain disruptions: Risk detection, risk mitigation, and risk recovery. Ann. Oper. Res. 2019, 283, 179–198.

- Lei, X.; MacKenzie, C.A. Assessing risk in different types of supply chains with a dynamic fault tree. Comput. Ind. Eng. 2019, 137, 106061.

- Ambituuni, A.; Amezaga, J.M.; Werner, D. Risk assessment of petroleum product transportation by road: A framework for regulatory improvement. Saf. Sci. 2015, 79, 324–335.

- Conca, A.; Ridella, C.; Sapori, E. A risk assessment for road transportation of dangerous goods: A routing solution. Transp. Res. Procedia 2016, 14, 2890–2899.

- Ghaleh, S.; Omidvari, M.; Nassiri, P.; Momeni, M.; Lavasani, S.M.M. Pattern of safety risk assessment in road fleet transportation of hazardous materials (oil materials). Saf. Sci. 2019, 116, 1–12.

- Shang, K.C.; Huang, S.T.; Buchari, E.; Lirn, T.C.; Della, R.H. Integration of safety quality function deployment in ferry services: Empirical study of Indonesia. Res. Transp. Bus. Manag. 2023, 47, 100938.

- Wu, W.; Li, Y.; Zhao, Z.; Zheng, Q.; Zhang, C.; Ji, H.; Yu, S. Quantitative analysis of liquefaction risk of liquefiable solid bulk cargoes during sea transport. Ocean Eng. 2022, 258, 111751.

- Ellis, J. Analysis of accidents and incidents occurring during transport of packaged dangerous goods by sea. Saf. Sci. 2011, 49, 1231–1237.

- Shen, H.; Zhang, Y.; Wu, Y. A comparative study on air transport safety of lithium-ion batteries with different SOCs. Appl. Therm. Eng. 2020, 179, 115679.

- Zhou, Z.; Yu, X.; Zhu, Z.; Zhou, D.; Qi, H. Development and application of a Bayesian network-based model for systematically reducing safety risks in the commercial air transportation system. Saf. Sci. 2023, 157, 105942.

- Braude, D.; Lauria, M.; Humpheries, A.; O’Donnell, M.; Shelly, J.; Berve, M.; Dixon, D. Safety of Air Medical Transport of Patients With COVID-19 by Personnel Utilizing Routine Personal Protective Equipment. Air Med. J. 2022, 41, 25–26.

- Kozhukhovskaya, L.; Baskov, V.; Ignatov, A. Modular management of indicators of efficiency and safety of transportation processes. Transp. Res. Procedia 2017, 20, 361–366.

- Epifanov, V.; Obshivalкin, M.; Lukonkina, K. Management of quality and security level of transportation in the system of regular passenger motor transport. Transp. Res. Procedia 2018, 36, 141–148.

- Torres-Rubira, J.L.; Escrig-Tena, A.B.; López-Navarro, M.A. Internalization of the ‘Safety & Quality Assessment for Sustainability’System Motivations and performance in Spanish road transport firms. Res. Transp. Bus. Manag. 2023, 49, 100990.

- Ding, J.F.; Weng, J.H.; Chou, C.C. Assessment of key risk factors in the cold-chain logistics operations of container carriers using best worst method. Int. J. Refrig. 2023, in press.

More