Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is a comparison between Version 2 by Jason Zhu and Version 1 by Heung Soo Kim.

Structural prognostics and health management (SPHM), a vital discipline in aerospace engineering, emphasizes the importance of continuous monitoring, diagnosis, and prediction of the health of aircraft structural systems. By capturing and analyzing data from a wide array of sensors and monitoring systems, SPHM systems play an instrumental role in facilitating the real-time evaluation of an aircraft’s structural integrity throughout its operational lifespan.

- structural prognostics

- health management

- aircraft maintenance

1. Overview of Traditional SPHM Approaches

Aircraft SPHM is an integral aspect of aviation safety and performance. Traditional methods, rooted in the early days of the aviation industry, have primarily revolved around routine inspections, scheduled maintenance, and NDT techniques.

- (1)

-

Inspection and Maintenance Schedules: In these highly systematic and standardized procedures, technicians conduct meticulous physical examinations of aircraft structures at predetermined intervals [36,37][1][2]. The purpose of these checks is to identify any observable signs of structural degradation, such as corrosion, distortion, cracks, or even loose parts [38][3]. Given the fundamental nature of these inspections, they constitute the primary line of defense against possible structural failure, ensuring the aircraft’s physical condition is maintained at its optimal state.

- (2)

-

Non-Destructive Testing (NDT): As the aviation industry evolved, the need for more sophisticated methods to inspect structural components without causing damage led to the widespread use of NDT techniques [39][4]. These encompass ultrasonic testing [40][5], radiographic testing [41][6], eddy current testing [42][7], magnetic particle inspection, and dye penetrant inspection. Through these methods, technicians can detect, locate, and measure defects that may not be visible to the naked eye, enhancing their ability to maintain structural integrity.

- (3)

-

Usage Monitoring Systems (UMS): Traditional SPHM also includes the utilization of usage monitoring systems, which record various operational parameters such as load factors, airspeed, and temperature. These parameters, which are critical to understanding the performance and endurance of an aircraft’s structure, help in evaluating the health of the aircraft and its components [43,44][8][9].

- (4)

-

Damage Assessment and Classification: Traditional SPHM methodologies involve manual evaluation and classification to ascertain the severity and type of damage or defects. Trained personnel visually inspect and categorize the damage according to set criteria, thereby prioritizing repairs based on the criticality of the identified issues [45,46,47][10][11][12].

- (5)

-

Structural Health Monitoring (SHM): SHM is a fundamental part of traditional SPHM methodologies. Sensors placed at strategic locations monitor various parameters to provide data on structural behavior, allowing operators to detect any deviations from normal behavior, thereby ensuring continuous airworthiness [48,49,50,51][13][14][15][16].

- (6)

-

Experience-based Decision making: Traditional SPHM methodologies often rely on the expertise of maintenance personnel to make informed decisions about inspections, repairs, or component replacements. Years of operational and maintenance experience underpin the assessment of aircraft structures and appropriate maintenance action [52,53,54][17][18][19].

2. Challenges and Limitations of Traditional SPHM Approaches

While traditional SPHM methodologies are invaluable, they are not devoid of challenges and limitations that can affect their effectiveness and accuracy. Acknowledging and addressing these limitations can improve SPHM implementation overall. Key challenges and limitations include:

- ▪

-

Reactive Maintenance Strategies and Scheduled Inspections: Traditional SPHM methodologies often hinge on reactive maintenance, with maintenance actions triggered by scheduled intervals or visible damage detection. This approach can lead to unforeseen failure and the potential for undetected early-stage damage, resulting in heightened costs and safety risks [55,56][20][21].

- ▪

-

Limited Predictive Capabilities: Traditional methodologies may not accurately project the RUL of components or future degradation. Relying on historical data and scheduled maintenance may lack the necessary insights to optimize maintenance planning or identify critical structural issues [57][22].

- ▪

-

Reliance on Human Judgment: Traditional SPHM methodologies heavily depend on maintenance personnel’s expertise and judgment. This dependence introduces variability and subjectivity in the decision-making process, which can affect the consistency and effectiveness of maintenance actions [58][23].

- ▪

-

Concealed or Subsurface Damage: Traditional inspection methods may have difficulty detecting concealed or subsurface damage that is not apparent during routine inspections. Undetected defects beneath coatings or within complex structures could compromise the aircraft’s structural integrity [59][24].

- ▪

-

Incomplete Exploitation of Advanced Data Analysis Approaches: Traditional SPHM methodologies may not fully harness the potential of state-of-the-art techniques for data analysis. The analysis of collected data might be restricted to basic trend analysis or manual assessment methods, which can impede the identification of subtle degradation patterns or anomalies [60][25].

3. Evolution from Traditional Methods to Modern Techniques

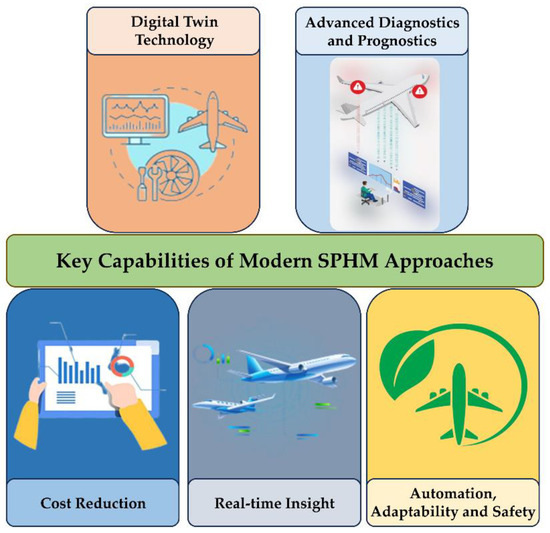

The inherent limitations of traditional SPHM approaches have sparked a drive toward more advanced methods. With the development of the digital revolution, the aviation sector has seen a paradigm shift in SPHM. Data-driven techniques, propelled by innovations in artificial intelligence (AI), specifically machine learning and deep learning, have ushered in a new era of SPHM. These modern methods provide comprehensive, real-time analysis of aircraft structural health data, enabling the early detection and prediction of potential issues before they turn into significant problems. Consequently, these techniques can drastically reduce unscheduled maintenance and improve aircraft availability. Furthermore, the application of model-based and hybrid methods has added another layer of sophistication to modern SPHM. Model-based methods offer valuable insights into the underlying physics of aircraft structures, while hybrid methods leverage the strengths of both data-driven and model-based approaches to offer further robust predictions and diagnostics. Modern SPHM approaches present a significant leap forward from traditional methods. Figure 31 distinguishes the vital capabilities of modern SPHM approaches, which the following discussion elaborates upon:

Figure 31.

Modern SPHM Approaches: Highlighting the pivotal capabilities and advancements.

- ▪

-

Use of Digital Twins: Digital twin technology enables the creation of a virtual replica of an aircraft’s structural components. This allows for accurate simulations of various operational scenarios and a better understanding of potential structural issues [61,62][26][27].

- ▪

-

Advanced Diagnostics and Prognostics: Modern SPHM systems leverage advanced AI algorithms for the real-time analysis of sensor data. These tools provide superior capabilities for predicting and diagnosing potential structural issues well in advance, allowing for more timely maintenance and avoiding unexpected downtime [63][28].

- ▪

-

Reduced Costs: By identifying potential problems early, allowing for predictive maintenance, and minimizing unplanned downtime, modern SPHM methods can lead to significant cost savings in aircraft operations and maintenance [64][29].

Overall, the evolution from traditional to modern techniques in SPHM represents a significant step towards more proactive and efficient aircraft health management. It demonstrates the potential of emerging technologies and methodologies to enhance the safety and performance of aircraft while minimizing maintenance costs and downtime. This exciting progression sets the stage for future advancements in the field of SPHM, promising a new era in aviation safety and reliability.

References

- Rice, M.; Li, L.; Ying, G.; Wan, M.; Lim, E.T.; Feng, G.; Ng, J.; Teoh Jin-Li, M.; Babu, V.S. Automating the Visual Inspection of Aircraft. In Proceedings of the Singapore Aerospace Technology and Engineering Conference (SATEC), Singapore, 7 February 2018; Volume 7.

- Khalid, S.; Kim, H.-S.; Kim, H.S.; Choi, J.-H. Inspection Interval Optimization for Aircraft Composite Tail Wing Structure Using Numerical-Analysis-Based Approach. Mathematics 2022, 10, 3836.

- Zhang, Z.; Mao, H.; Liu, Y.; Jia, P.; Hu, W.; Shen, P. A Risk Assessment Method of Aircraft Structure Damage Maintenance Interval Indexed by: Considering Fatigue Crack Growth and Detection Rate. Maint. Reliab. Niezawodn. 2023, 25, 3.

- Abdo, S.; Hovanec, M.; Korba, P.; Šváb, P. Utilization of NDT Methods in Aircraft Maintenance. In Proceedings of the 2021 New Trends in Aviation Development (NTAD), Košice, Slovakia, 25–26 November 2021; pp. 9–12.

- Tran, T.; Samant, P.; Xiang, L.; Liu, Y. X-ray Induced Acoustic Computed Tomography for Non-Destructive Testing of Aircraft Structure. Am. Soc. Mech. Eng. 2019, 59360, V001T03A005.

- Chen, Z.-H.; Juang, J.-C. Attention-Based YOLOv4 Algorithm in Non-Destructive Radiographic Testing for Civic Aviation Maintenance. Preprints 2021, 2021040653.

- Karanfiloğlu, B.; Erden, N.V.; Gültekin, E.E. Inspection of Aircraft Parts by Eddy Current Method. Int. J. Aeronaut. Astronaut. 2023, 4, 36–42.

- Kim, J.-H.; Park, Y.; Kim, Y.-Y.; Shrestha, P.; Kim, C.-G. Aircraft Health and Usage Monitoring System for In-Flight Strain Measurement of a Wing Structure. Smart Mater. Struct. 2015, 24, 105003.

- Boller, C.; Staszewski, W. Aircraft Structural Health and Usage Monitoring. In Health Monitoring of Aerospace Structures: Smart Sensor Technologies and Signal Processing; Wiley: Hoboken, NJ, USA, 2004; pp. 29–73.

- Ibarra-Castanedo, C.; Avdelidis, N.P.; Grinzato, E.G.; Bison, P.G.; Marinetti, S.; Plescanu, C.C.; Bendada, A.; Maldague, X.P. Delamination Detection and Impact Damage Assessment of GLARE by Active Thermography. Int. J. Mater. Prod. Technol. 2011, 41, 5–16.

- Moix-Bonet, M.; Wierach, P.; Loendersloot, R.; Bach, M. Damage Assessment in Composite Structures Based on Acousto-Ultrasonics—Evaluation of Performance; Springer: Berlin/Heidelberg, Germany, 2015; pp. 617–629.

- Wang, F.; Ji, Y.; Yu, X.; Chen, H.; Yue, Z. Ablation Damage Assessment of Aircraft Carbon Fiber/Epoxy Composite and Its Protection Structures Suffered from Lightning Strike. Compos. Struct. 2016, 145, 226–241.

- Ghoshal, A.; Martin, W.; Schulz, M.; Chattopadhyay, A.; Prosser, W.; Kim, H. Health Monitoring of Composite Plates Using Acoustic Wave Propagation, Continuous Sensors and Wavelet Analysis. J. Reinf. Plast. Compos. 2007, 26, 95–112.

- Kim, H.S.; Ghoshal, A.; Chattopadhyay, A.; Prosser, W.H. Development of Embedded Sensor Models in Composite Laminates for Structural Health Monitoring. J. Reinf. Plast. Compos. 2004, 23, 1207–1240.

- Rocha, B.; Silva, C.; Keulen, C.; Yildiz, M.; Suleman, A. Structural Health Monitoring of Aircraft Structures; Springer: Berlin/Heidelberg, Germany, 2013; ISBN 3-7091-1389-X.

- Diamanti, K.; Soutis, C. Structural Health Monitoring Techniques for Aircraft Composite Structures. Prog. Aerosp. Sci. 2010, 46, 342–352.

- Harjanti, W.; Wahjoedi, T.; Sari, A.K.; Setiadi, P.B. Work Experience, Interpersonal Communication on Performance and Use of Information Technology, Aircraft Maintenance Companies. Ekuitas J. Ekon. Dan Keuang. 2021, 5, 513–533.

- Taylor, J.; Robertson, M. The Effects of Crew Resource Management (CRM) Training in Airline Maintenance: Results Following Three Year’s Experience; NASA: Moffett Field, CA, USA, 1995.

- Hemingway, D. Aviation Maintenance Technician Decision-Making. Ph.D. Thesis, Walden University, Minneapolis, MN, USA, 2020.

- Zhang, Y.; Li, C.; Su, X.; Cui, R.; Wan, B. A Baseline-Reactive Scheduling Method for Carrier-Based Aircraft Maintenance Tasks. Complex Intell. Syst. 2023, 9, 367–397.

- Ma, H.-L.; Sun, Y.; Chung, S.-H.; Chan, H.K. Tackling Uncertainties in Aircraft Maintenance Routing: A Review of Emerging Technologies. Transp. Res. Part E Logist. Transp. Rev. 2022, 164, 102805.

- Sriram, C.; Haghani, A. An Optimization Model for Aircraft Maintenance Scheduling and Re-Assignment. Transp. Res. Part Policy Pract. 2003, 37, 29–48.

- Latorella, K.A.; Prabhu, P.V. A Review of Human Error in Aviation Maintenance and Inspection. Int. J. Ind. Ergon. 2000, 26, 133–161.

- Virovac, D.; Domitrović, A.; Bazijanac, E. The Influence of Human Factor in Aircraft Maintenance. Promet. Traffic Transp. 2017, 29, 257–266.

- Chung, S.-H.; Ma, H.-L.; Hansen, M.; Choi, T.-M. Data Science and Analytics in Aviation. Transp. Res. Part E Logist. Transp. Rev. 2020, 134, 101837.

- Tuegel, E.J.; Ingraffea, A.R.; Eason, T.G.; Spottswood, S.M. Reengineering Aircraft Structural Life Prediction Using a Digital Twin. Int. J. Aerosp. Eng. 2011, 2011, 154798.

- Li, C.; Mahadevan, S.; Ling, Y.; Choze, S.; Wang, L. Dynamic Bayesian Network for Aircraft Wing Health Monitoring Digital Twin. Aiaa J. 2017, 55, 930–941.

- Adhikari, P.; Rao, H.G.; Buderath, M. Machine Learning Based Data Driven Diagnostics & Prognostics Framework for Aircraft Predictive Maintenance. In Proceedings of the 10th International Symposium on NDT in Aerospace, Dresden, Germany, 24–26 October 2018; pp. 24–26.

- Leão, B.P.; Fitzgibbon, K.T.; Puttini, L.C.; de Melo, G.P. Cost-Benefit Analysis Methodology for PHM Applied to Legacy Commercial Aircraft. In Proceedings of the IEEE Aerospace Conference, Big Sky, MT, USA, 1–8 March 2008; pp. 1–13.

- Li, S.; Zhang, G.; Wang, J. Civil Aircraft Health Management Research Based on Big Data and Deep Learning Technologies. In Proceedings of the 2017 IEEE International Conference on Prognostics and Health Management (ICPHM), Dallas, TX, USA, 19–21 June 2017; pp. 154–159.

- Rastogi, M. Probabilistic Method to Predict Remaining Usage Life of Aircraft Structures. In Proceedings of the PHM Society European Conference, Bilbao, Spain, 5–8 July 2016; Volume 3.

- Cheng, H.; Kong, X.; Wang, Q.; Ma, H.; Yang, S.; Chen, G. Deep Transfer Learning Based on Dynamic Domain Adaptation for Remaining Useful Life Prediction under Different Working Conditions. J. Intell. Manuf. 2023, 34, 587–613.

- Kordestani, M.; Orchard, M.E.; Khorasan, K.; Saif, M. An Overview of the State-of-the-Art in Aircraft Prognostic and Health Management Strategies. IEEE Trans. Instrum. Meas. 2023, 72, 3505215.

More