You're using an outdated browser. Please upgrade to a modern browser for the best experience.

Please note this is a comparison between Version 1 by Mauro D'Arco and Version 2 by Wendy Huang.

Power line communication (PLC) is a technology that exploits existing electrical transmission and distribution networks as guiding structures for electromagnetic signal propagation. This facilitates low-rate data transmission for signaling and control operations. As the demand in terms of data rate has greatly increased in the last years, the attention paid to broadband PLC (BPLC) has also greatly increased. This concept also extended to railways as broadband traction power line communication (BTPLC), aiming to offer railway operators an alternative data network in areas where other technologies are lacking.

- power line communication

- power grid

- current

- voltage

- frequency range

- transmission distance

1. Introduction

The fourth industrial revolution has brought forth a plethora of technological advancements that are enabling and/or improving new paradigms, which seem deemed to transform the lives of individuals [1]. Among these, the Internet of Things (IoT) [2], artificial intelligence (AI) [3], machine and deep learning (ML/DL) [4], cloud computing [5], additive manufacturing [6], and augmented and virtual reality (AR/VR) [7] are the most popular. These paradigms rely on several data communication solutions, which are selected according to their specific advantages to face costs, installation, and time-to-market issues. Unexpectedly, even some unusual proposals have been revitalized, such as the power line communication (PLC) technology [8].

PLC harnesses the inherent potential of the electrical distribution network to facilitate data transmission capabilities. By exploiting the existing infrastructure of the power grid, PLC enables the communication of data signals through the electrical power lines [9], allowing for the simultaneous transfer of electrical power and data for signaling and remote control [10][11][10,11].

Similarly to the transmission and distribution network, other infrastructures can be exploited as guiding structures to propagate electromagnetic signals. A relevant example is the electrical railway system, where the catenary and the railway tracks can transmit both the power needed to the traction operations as well as the data.

Actually, the growing focus on safety and maintenance of the railway network, and the increase in services offered on board, raise the demand for robust communication technologies. These should grant high data rates, low latency, and coverage and service continuity to enable high-speed internet connection for service management and entertainment [12][13][12,13]. Railway operators are paying attention to broadband power line communication (BPLC) technologies. These exploit the high-frequency range, namely, the HF band of the electromagnetic spectrum, and employ suitable solutions to transmit a relevant amount of data in a reduced time interval [14]. More specifically, railway operators have fostered the concept of broadband traction power line communication (BTPLC), where the electric traction line is exploited as a channel for broadband communications rather than for simple signaling and control operations [15].

PLC is a concept born at the beginning of the 20th century, developed for signaling and control operations [16][26]. As mentioned above, it refers to technology that allows for data communication over existing electrical power lines, providing for the simultaneous transfer of electrical power and data. PLC technologies effectively utilize the existing infrastructure, enabling a cost-efficient and streamlined deployment approach. They represent an appealing alternative to those solutions that necessitate the installation of new networks for several reasons. First of all, the use of an already installed cable network allows cost and installation time reductions in the deployment of the communication system [17][27]. PLC solutions are not affected by the typical problems of systems that exploit the free propagation of the electromagnetic signal, which means they perform better in those scenarios of the rural area or where obstacles limit wireless communications [18][28]. In fact, wireless setups are generally more delicate and vulnerable than power lines [19][29]. It is worth highlighting that the aforementioned issues have already paved the way to the implementation of communication channels that are integrated into the existing electrical transmission and distribution network. These communication channels have shown to be a viable solution for the service providers to afford important managing tasks and meet the stringent service delivery demands. In a believable way, for a wide range of application scenarios, including railways, the PLC technology still has a role to play.

Transmission distance: The distinction is made between short-range PLC systems, with transmission distances of up to 80 km; medium-range systems, spanning between 80 km and 250 km; and long-range systems, designed for transmission distances exceeding 250 km [26][36].

Indoor/outdoor environment: Indoor PLC refers to the use of power line communication technology within indoor environments such as homes, offices, or industrial buildings. It typically operates within a confined space and utilizes the existing electrical wiring infrastructure to transmit data signals [27][37]. Outdoor PLC involves the deployment of power line communication technology in outdoor settings, such as urban lighting or surveillance systems, or smart grid applications. Much more than indoor systems, outdoor PLC systems are designed to withstand harsh environmental conditions. These can be due to large temperature variations, moisture, dust, and potential electrical interference caused by nearby power lines or other outdoor equipment [28][38].

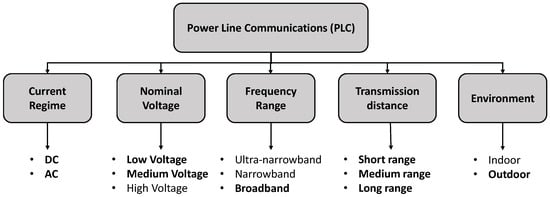

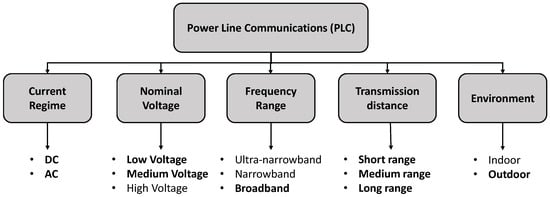

For clarity, Figure 1 illustrates a schematic representation of the categorization of PLC systems, highlighting the relevant categories in which BTPLC technology falls, as indicated in bold.

2. Taxonomy

PLC technologies can be classified based on the characteristics of the underlying electrical system and/or specific features as described in the following. Current regime: It is a distinction based on the utilization of the direct current (DC) or alternating current (AC) regime. The first is often preferred due to its simpler structure as the AC regime requires phase and reactive power control; for PLC applications, the installation seems facilitated upon lines operated in the DC regime [20][30]. Nominal voltage: It is a distinction based on the operating voltage value of the power grid on which the PLC is installed. According to the European norm EN 50160 [21][31], power grids can be classified as low-voltage (LV) if the nominal voltage is less than 1 kV, medium voltage (MV) if it is within the range (1–35) kV, and high voltage (HV) if it is above 35 kV. LV and MV power grids are generally used for electricity supply in urban and suburban areas, while HV grids are used for long-distance power transmission. Frequency range: PLC technologies can be categorized according to the range of operating frequency values of transmitted signals [22][32]. This feature is indicative of data transmission speed and distance. According to the literature, the frequency range in which PLC systems can operate covers frequencies from 125 Hz to 100 MHz [23][24][25][33,34,35]. PLC systems are usually referred to as shown in Table 1:Table 1.

PLC systems according to the frequency range.

| Ultra-narrowband | Identified by the operating frequency range (125–3000) Hz. Ultra-narrowband PLC (UN-PLC) technology typically guarantees transmission over long distances, although the data rate is typically in the order of kbps [18][28]. Examples of UN-PLC are the home automation system by Pico Electronics X10 deployed since 1975 [24][34] and the two-way automatic communication system (TWACS) by Aclara [18][28]. |

| Narrowband | Identified by the operating frequency range (3–500) kHz. Narrowband PLC (NPLC) technologies are characterized by variable data rates from 1 kbps up to 1 Mbps and are capable of guaranteeing medium/long transmission distances [18][28]. In Europe, they are distinguished into four frequency bands, standardized by the European Committee for Electrotechnical Standardization (CENELEC) in 1992 [18][28]: CENELEC-A (3–95 kHz), CENELEC-B (95–125 kHz), CENELEC-C (125–140 kHz), and CENELEC-D (140.0–148.5 kHz). According to the data transmission rate, NPLC systems are also referred to as low data rate (LDR) and high data rate (HDR). LDR systems adopt single-carrier modulations, whereas HDR exploit multi-carrier modulations to achieve data rates up to 1 Mbps [18][28]. |

| Broadband | Characterized by a data rate above 200 Mbps and shorter transmission distance than NB-PLC [14]. The operating frequency range is not uniformly established: according to the Institute of Electrical and Electronic Engineers (IEEE) [25][35], it ranges from 1.8 MHz up to 100.0 MHz. The International Telecommunication Union (ITU) instead specifies a frequency range up to 300 MHz [26][36]; the standards developed by the HomePlug Powerline Alliance use the frequency ranges (1.8–30.0) MHz and (1.8–86.0) MHz [26][36]. |

Figure 1.

Details of the PLC categorizations: the categories in which BTPLC technology falls are indicated in bold.