You're using an outdated browser. Please upgrade to a modern browser for the best experience.

Please note this is a comparison between Version 4 by Conner Chen and Version 3 by Conner Chen.

Robotic exoskeletons are wearable devices with rigid links and mechanical joints corresponding to the anatomy of the human body. Even though different body locations have different anatomical properties and complexities that might require different design choices, the main variable defining an exoskeleton design is its application field.

- exoskeleton

- design

- optimization

1. Introduction

Exoskeletons can be observed in many terrestrial and marine organisms (such as bugs and shellfish) as a rigid, resistant component to provide protection, support, and sensation. Inspired by nature, wearable robotic devices can be designed to create exoskeletons for humans—either for their whole body [1] or for specific body limbs, such as arms [2], hands [3], legs [4], knees [5], wrists [6], etc.

Exoskeletons are used in many applications. When designed with no powered actuation, namely passive exoskeletons, they follow and/or track users’ movements [7]. Tracked movements can be visually expressed in virtual environments [8] or used as the controller reference for a secondary robotic device during teleoperation tasks [9]. Alternatively, passive exoskeletons can distribute the weight of heavy objects on anatomical joints more equally to avoid potential injuries [10]. When equipped with batteries and actuators, namely active exoskeletons, they are used to augment and improve users’ physical capabilities; examples range from performing heavy workload tasks [11] and completing sports activities [12] to assisting patients with physical/neurological disabilities while performing activities of daily living [13].

However, all these benefits come at a cost: exoskeletons are very challenging to be designed, implemented, and controlled [14]. Safety is the first and most important issue. Exoskeleton joints must align perfectly with anatomical joints to avoid potential harm, and their mechanical links and joints should work effectively within the workspace of human anatomical joints and natural degrees of freedom (DoFs). Depending on the targeted application, exoskeletons must be adjustable for users of any size and ability level. The movements allowed by the exoskeleton should follow users’ behavior naturally and without creating discomfort. Finally, these devices—especially assistive devices—should be as compact and lightweight as possible to enhance wearability. Thus, designs should include small actuator sizes, high output forces (in relation to the size of the actuator), and effective power transmission through the links. These issues and limitations can be overcome either by alternative design solutions (e.g., using softer rather than rigid mechanical links) or by exploiting optimization algorithms as tools for decision making. The integration between design and optimization techniques brings an open question: how do engineers decide which method or algorithm best optimizes different design criteria?

Mathematical optimization is the search for the best element within a set of alternatives based on specific criteria, and it is a common tool for solving engineering problems [15][16][17]. While the most conventional strategies focus on numerical and calculus-based methods [18], they might not be the best solution for engineering designs due to the properties of these problems: non-discrete domains, non-differentiability, multimodality, discontinuity, reliability, and robustness pose a challenge to classical methods. Alternative optimization methods exist to overcome these difficulties; among them, the nature-inspired methods of evolutionary computation (EC) [19][20] appear to be a common and effective way to deal with engineering optimization problems.

2. Background on Exoskeletons

Robotic exoskeletons are wearable devices with rigid links and mechanical joints corresponding to the anatomy of the human body. Even though different body locations have different anatomical properties and complexities that might require different design choices, the main variable defining an exoskeleton design is its application field. These application fields can be summarized as follows:-

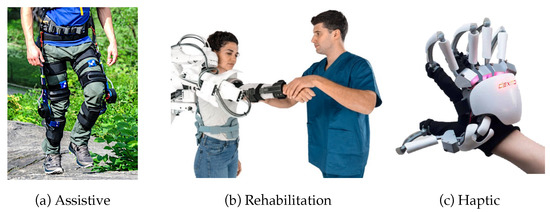

Assistance: Assistive exoskeletons augment users’ physical abilities to help them perform real-time activities that might be challenging to be completed alone. These devices can be used by (i) people with disabilities in their daily lives or (ii) healthy workers while performing physically demanding tasks in a workspace. (seeRegardless of the target users, these devices must be capable of adapting their operation to perform different tasks or to interact with different objects. They must be portable, lightweight, and easy to wear while applying high interaction forces. They must achieve the range of motion of the anatomical joints without harming users when functionality limits are reached. Finally, these devices should feel highly transparent to follow the physical guidance of users. Observing/tracking movement performance is neither mandatory Figure 2a). Regardless of the target users, these devices must be capable of adapting their operation to perform different tasks or to interact with different objects. They must be portable, lightweight, and easy to wear while applying high interaction forces. They must achieve the range of motion of the anatomical joints without harming users when functionality limits are reached. Finally, these devices should feel highly transparent to follow the physical guidance of users. Observing/tracking movement performance is neither mandatory nor favorable.nor favorable.

| Requirement | Metrics |

|---|---|

| Adaptability to different tasks | |

| Workspace, force transmission | |

-

Workspace: The workspace is the range of motion the user is allowed while wearing an exoskeleton. Exoskeletons must respect the natural movements of users’ limbs to ensure safety, and their mechanical limits must not exert force on human joints once they reach their natural limits. An exoskeleton must be comfortable, as users wear the device during operation. The kinematic and ergonomic design must be ensured not to cause any pain or fatigue.

- –

-

While designing an exoskeleton, the mechanical joints must be aligned with the anatomical joints with minimal mechanical changes and cover the overall range of motion for the anatomical joints they are aligned with. This allows the exoskeleton to be inherently safe, ergonomic, and comfortable. To achieve this outcome, an optimization algorithm must retrieve the best link lengths and the actuated motion to either (i) maximize the operational workspace for each assisted joint or (ii) maximize a different design requirement and simultaneously ensure that the natural workspace is covered via constraints.

-

Physical Rehabilitation: Rehabilitative exoskeletons are used in clinical settings to treat patients suffering from physical or neurological disabilities. Due (seeto users’ limited functional capabilities, rehabilitative exoskeletons must be easy to wear without a predefined initial orientation (i.e., the device adapts to the patient’s Figure 2b). Due to users’ limited functional capabilities, rehabilitative exoskeletons must be easy to wear without a predefined initial orientation (i.e., the device adapts to the patient’s position rather than the opposite) and provide high output forces with respect to the actuator size adopted for the exoskeleton. The range of motion of anatomical joints must be achieved without harming patients when functionality limits are reached. Patients should be able to perform different actions with no prior control or mechanical design change thanks to the devices’ instant adaptability. Rehabilitation exoskeletons allow patients to actively participate in therapy exercises and monitor their progress in muscular activity. Unlike assistive devices, they are often grounded and do not need to be portable.position rather than the opposite) and provide high output forces with respect to the actuator size adopted for the exoskeleton. The range of motion of anatomical joints must be achieved without harming patients when functionality limits are reached. Patients should be able to perform different actions with no prior control or mechanical design change thanks to the devices’ instant adaptability. Rehabilitation exoskeletons allow patients to actively participate in therapy exercises and monitor their progress in muscular activity. Unlike assistive devices, they are often grounded and do not need to be portable.

-

Haptic Rendering: Haptic exoskeletons render an artificial sense of touch in response to virtual interactions or remotely operated real interactions (see Figure 1c). They must be wearable to track users’ joint movements to control the interactions performed by virtual avatars or remote robots. Similarly to assistive devices, portability and instant adaptability are crucial. Haptic exoskeletons must feel highly transparent to follow users’ physical guidance, especially when there is no interaction at the virtual/remote site. Since the target user profile is assumed to be healthy, the wearability or the amount of output forces is not as crucial as for other applications but is preferred.

Table 1. Mapping between design requirements and metrics to be optimized.

| User safety | Workspace, calibration |

| High output forces | |

| Force transmission | |

| Portability | Force transmission, size |

- ]

- (one for the distal interphalangeal joint, one for the proximal interphalangeal joint, and two for the metacarpophalangeal joint), etc. The anatomic joints’ complexity (and their proximity to each other) has led designers to decouple the actuators from the joints and transmit the actuator forces through linkage-based mechanical devices—whether they are made of rigid or soft materials. In addition, linkage-based transmission allows designers to augment the transmitted forces through effective kinematic chains and lower the actuator size. The efficacy of its force transmission should be evaluated based on (i) the size of the wearable actuator components, (ii) the amount of force/torque rendered on the user’s joints safely and comfortably, and (iii) the ratio between the actuated and output forces for each independent joint.

- –

-

While designing an exoskeleton, an optimization algorithm should retrieve the best link lengths to maximize the force transmission for each assisted joint or for the overall targeted task (e.g., grasping a one-liter water bottle or lifting a five-kilogram storage box). Using such optimization techniques could also yield the same output forces with smaller actuators, improving the portability/wearability of the system as well.

| Wearability | |

| Calibration, size | |

| Joint tracking | Calibration |

- Adjustability/Calibration: Unlike prosthesis devices, exoskeletons are not custom-made for each potential user with different limb sizes. This lack of customization might cause misalignment, harm users, or work with a limited operational workspace or performance. In addition, especially for rehabilitative applications, wearing an exoskeleton should be equal and pain-free for every user.

- –

-

While designing an exoskeleton, an optimization algorithm should ensure the same performance for users of all sizes. There are three ways of achieving this outcome: (i) maximize the allowed range of limb sizes with no focus on other metrics, (ii) maximize the allowed range of limb sizes while optimizing another design requirement simultaneously, or (iii) maximize one of the previously detailed design requirements while ensuring an acceptable range of adjustability to different limb sizes via constraints.

-

Size: While some full-arm exoskeletons need to be carried by a base due to their high weight [13], there is a great deal of research on reducing their weight and making them portable [26]. Exoskeletons can have improved portability by minimizing the mechanical components’ size or weight.

- –

-

While designing an exoskeleton, an optimization algorithm should ensure the same performance with the smallest set of link lengths as much as possible by (i) minimizing the link lengths while other performance measures are fixed at a reasonable and predefined level via constraints or (ii) maximizing a different design requirement and simultaneously ensuring the acceptable set of link lengths to be covered via constraints.

References

- Marcheschi, S.; Salsedo, F.; Fontana, M.; Bergamasco, M. Body Extender: Whole Body Exoskeleton for Human Power Augmentation. In Proceedings of the IEEE International Conference on Robotics and Automation (ICRA), Shanghai, China, 9–13 May 2011; pp. 611–616.

- Gijbels, D.; Lamers, I.; Kerkhofs, L.; Alders, G.; Knippenberg, E.; Feys, P. The Armeo Spring as Training Tool to Improve Upper Limb Functionality in Multiple Sclerosis: A Pilot Study. J. Neuroeng. Rehabil. 2011, 8, 5.

- Sarac, M.; Solazzi, M.; Sotgiu, E.; Bergamasco, M.; Frisoli, A. Design and Kinematic Optimization of a Novel Underactuated Robotic Hand Exoskeleton. Meccanica 2017, 52, 749–761.

- Zoss, A.B.; Kazerooni, H.; Chu, A. Biomechanical Design of the Berkeley Lower Extremity Exoskeleton (BLEEX). IEEE/ASME Trans. Mechatron. 2006, 11, 128–138.

- Chen, B.; Zi, B.; Wang, Z.; Qin, L.; Liao, W.H. Knee Exoskeletons for Gait Rehabilitation and Human Performance Augmentation: A State-of-the-art. Mech. Mach. Theory 2019, 134, 499–511.

- Buongiorno, D.; Sotgiu, E.; Leonardis, D.; Marcheschi, S.; Solazzi, M.; Frisoli, A. WRES: A novel 3 DoF WRist ExoSkeleton with Tendon-driven Differential Transmission for Neuro-rehabilitation and Teleoperation. IEEE Robot. Autom. Lett. 2018, 3, 2152–2159.

- Lenzo, B.; Fontana, M.; Marcheschi, S.; Salsedo, F.; Frisoli, A.; Bergamasco, M. Trackhold: A Novel Passive Arm-support Device. J. Mech. Robot. 2016, 8, 021007.

- Casas, R.; Martin, K.; Sandison, M.; Lum, P.S. A Tracking Device for a Wearable High-DOF Passive Hand Exoskeleton. In Proceedings of the IEEE Annual International Conference of the Engineering in Medicine & Biology Society (EMBC), Virtual, 1–5 November 2021; pp. 6643–6646.

- Koyama, T.; Yamano, I.; Takemura, K.; Maeno, T. Multi-fingered Exoskeleton Haptic Device using Passive Force Feedback for Dexterous Teleoperation. In Proceedings of the IEEE/RSJ International Conference on Intelligent Robots and Systems, Lausanne, Switzerland, 30 September–4 October 2002; Volume 3, pp. 2905–2910.

- Zhou, N.; Liu, Y.; Song, Q.; Wu, D. A Compatible Design of a Passive Exoskeleton to Reduce the Body—Exoskeleton Interaction Force. Machines 2022, 10, 371.

- Looze, M.; Bosch, T.; Krause, F.; Stadler, K.; O’Sullivan, L. Exoskeletons for Industrial Application and Their Potential Effects on Physical Work Load. Ergonomics 2015, 59, 671–681.

- Sado, F.; Yap, H.J.; Ghazilla, R.A.R.; Ahmad, N. Design and Control of a Wearable Lower-body Exoskeleton for Squatting and Walking Assistance in Manual Handling Works. Mechatronics 2019, 63, 102272.

- Stroppa, F.; Loconsole, C.; Marcheschi, S.; Frisoli, A. A Robot-assisted Neuro-rehabilitation System for Post-stroke Patients’ Motor Skill Evaluation with ALEx Exoskeleton. In Proceedings of the Proceedings of the International Conference on NeuroRehabilitation (ICNR), Segovia, Spain, 18–21 October 2016; pp. 501–505.

- Sarac, M.; Solazzi, M.; Frisoli, A. Design Requirements of Generic Hand Exoskeletons and Survey of Hand Exoskeletons for Rehabilitation, Assistive, or Haptic Use. IEEE Trans. Haptics 2019, 12, 400–413.

- Sioshansi, R.; Conejo, A.J. Optimization in Engineering; Springer International Publishing: Cham, Switzerland, 2017; Volume 120.

- Statnikov, R.B.; Matusov, J.B. Multicriteria Optimization and Engineering; Springer Science & Business Media: Dordrecht, The Netherlands, 2012.

- Andersson, J. A Survey of Multiobjective Optimization in Engineering Design; Department of Mechanical Engineering, Linköping University: Linköping, Sweden, 2000.

- Bonnans, J.F.; Gilbert, J.C.; Lemaréchal, C.; Sagastizábal, C.A. Numerical Optimization: Theoretical and Practical Aspects; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2006.

- Deb, K. Evolutionary Algorithms for Multi-criterion Optimization in Engineering Design. Evol. Algorithms Eng. Comput. Sci. 1999, 2, 135–161.

- Dumitrescu, D.; Lazzerini, B.; Jain, L.C.; Dumitrescu, A. Evolutionary Computation; CRC Press: Boca Raton, FL, USA, 2000.

- Lee, D.; Kwak, E.C.; McLain, B.J.; Kang, I.; Young, A.J. Effects of Assistance During Early Stance Phase Using a Robotic Knee Orthosis on Energetics, Muscle Activity, and Joint Mechanics During Incline and Decline Walking. IEEE Trans. Neural Syst. Rehabil. Eng. 2020, 28, 914–923.

- Buccelli, S.; Tessari, F.; Fanin, F.; De Guglielmo, L.; Capitta, G.; Piezzo, C.; Bruschi, A.; Van Son, F.; Scarpetta, S.; Succi, A.; et al. A Gravity-Compensated Upper-Limb Exoskeleton for Functional Rehabilitation of the Shoulder Complex. Appl. Sci. 2022, 12, 3364.

- Gu, X.; Zhang, Y.; Sun, W.; Bian, Y.; Zhou, D.; Kristensson, P.O. Dexmo: An Inexpensive and Lightweight Mechanical Exoskeleton for Motion Capture and Force Feedback in VR. In Proceedings of the Conference on Human Factors in Computing Systems (CHI), San Jose, CA, USA, 7–12 May 2016; pp. 1991–1995.

- Eschweiler, J.; Praster, M.; Quack, V.; Michalik, R.; Hildebrand, F.; Rath, B.; Migliorini, F. Musculoskeletal Modeling of the Wrist via a Multi-body Simulation. Life 2022, 12, 581.

- Gustus, A.; Stillfried, G.; Visser, J.; Jörntell, H.; van der Smagt, P. Human Hand Modelling: Kinematics, Dynamics, Applications. Biol. Cybern. 2012, 106, 741–755.

- Pérez Vidal, A.F.; Rumbo Morales, J.Y.; Ortiz Torres, G.; Sorcia Vázquez, F.d.J.; Cruz Rojas, A.; Brizuela Mendoza, J.A.; Rodríguez Cerda, J.C. Soft Exoskeletons: Development, Requirements, and Challenges of the Last Decade. Actuators 2021, 10, 166.

More