Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is a comparison between Version 2 by Muhammad Azhar Ansari and Version 1 by Muhammad Azhar Ansari.

Organic solar cells present distinct advantages including transparency, cost-effective manufacturing potential, and tunable light absorption properties. Recent years have witnessed the development of various strategies aimed at enhancing the performance of Organic solar cells. Utilizing the high optical selectivity and tunability of organic semiconductors, the application of organic photovoltaics in greenhouse integration has also been explored. Tackling the efficiency challenges could be the pivotal factor that shifts organic photovoltaics from a promising technology to a commercial reality.

- Polymer/Organic solar cells

- energy band gap

- Greenhouse-Integrated Photovoltaics (GIPV)

1. Introduction

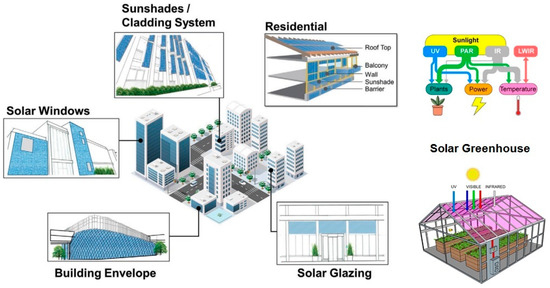

Addressing global challenges such as the escalating need for food, triggered by the population surge, and mitigating the effects of global warming, resulting from fossil fuel-based energy generation, has become an urgent priority [1]. In recent years, solar energy has become an appealing option for the development of cleaner and more sustainable power sources [2]. Solar energy utilizes sunlight to produce electricity, offering a renewable and eco-friendly alternative to conventional energy sources. Photovoltaic (PV) cells, the key components of solar panels, convert sunlight into electricity [3]. Over time, various PV technologies have been developed, including silicon-based solar cells, perovskite photovoltaics, and organic photovoltaics or organic solar cells (OSCs), each with its unique advantages and challenges aimed at enhancing efficiency and reducing manufacturing costs [4]. Among the numerous PV technologies, OSCs are a promising option due to their unique features such as tunable optoelectronics, cost-effectiveness, lightweight, transparency, and flexible applications [5][6]. OSCs can be fabricated on lighter-weight substrates with high transparency and good flexibility, allowing for diverse applications. Transparent solar cells have gained tremendous interest in the last few decades because of the compatibility of the technology with many other applications (Figure 1), such as greenhouse-integrated photovoltaics (GIPV) and building-integrated photovoltaics (BIPVs) [7][8][9]. A solar greenhouse allows the transmission of a selective wavelength needed for photosynthesis and absorbs the remaining solar radiation for electricity generation. Worldwide, approximately 9 million acres of agricultural land is used for better crop production in greenhouses. The same land can also be used for the conversion of solar energy into electricity to reduce the dependency on fossil fuel combustion if a transparent solar cell is integrated with the greenhouse. Similarly, transparent photovoltaic windows can be integrated with buildings. In this way, a building can convert solar energy into electricity.

Figure 1. Integrated photovoltaics applications.

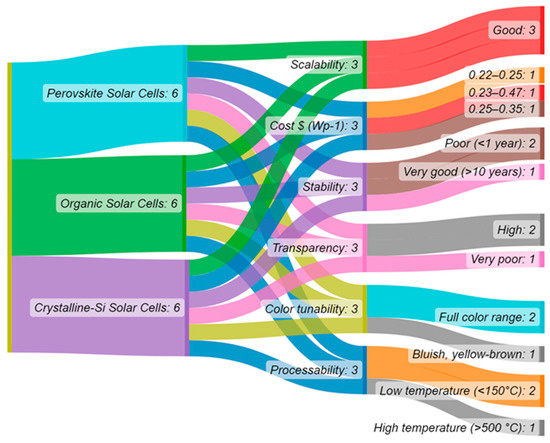

The role of optoelectronic materials is crucial in defining solar cell efficiency, stability, transparency, processability, and cost. Solar cells based on different materials are summarized in Figure 2 with different parameters for comparison. There are several components of sunlight, including ultraviolet (UV), visible, and near-infrared (IR) or Long wavelength Infrared (LWIR) radiation. Optically active materials should have high visible spectrum transparency and high UV or near-IR spectra absorptivity for integrated photovoltaics applications.

Figure 2. Comparison of different optoelectronic material-based solar cells.

Organic photovoltaics (OPVs), which consists of organic polymers and small molecules (SM), is a better photovoltaic technology compared to silicon solar cells due to several benefits [10]. Organic materials are abundant, optically modifiable, and their synthesis is relatively low-cost, making OSCs an attractive option for large-scale deployment and integration with many other technologies [11]. OSCs are easy to fabricate by the roll-to-roll method of printing, which enables large-scale high-speed manufacturing on flexible and transparent substrates with good mechanical resilience, rendering them suitable for integration into diverse environments and applications [6][12][13]. The absorption properties of OSCs can be easily tailored for targeted applications by modifying the molecular structure of organic materials, resulting in enhanced light-harvesting capabilities and unique utilization with other technologies, such as smart greenhouses and the smart windows of a building [14].

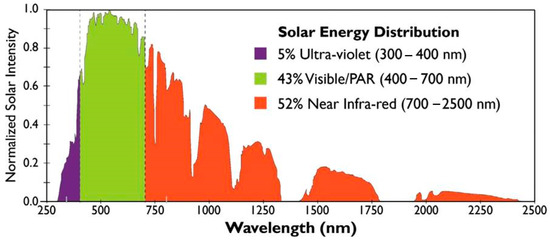

Transparency is a crucial factor for GIPV. Transparent OSCs can transmit selective wavelengths necessary for photosynthesis while absorbing the remaining solar radiation for electricity generation [8][15]. The solar spectrum, shown in Figure 3, encompasses various radiation types, including ultraviolet (UV), visible, and infrared (IR) radiation [12][16]. Infrared absorption profiles contribute 52% of the total energy in the solar spectrum, making IR-absorbing donors ideal for agricultural applications of transparent OSCs [17]. The optimization of OSCs is vital for GIPV applications, as it enables optimized light management, improved energy efficiency, enhanced space utilization, reduced overheating risks, and customizable transparency to cater to diverse requirements [14][17][18][19].

Figure 3. Solar radiation spectrum ranges from ultraviolet (UV) to infrared (IR) wavelengths.

Evolution of Organic Solar Cell (OSC)

As described by Brabec et al. [20], the early stages of OSC development were mainly focused on understanding the fundamental principles, exploring suitable materials, and optimizing device architectures. The progress made during this period laid the foundation for subsequent research and advancements in the field of OSCs. There are three types of OSCs based on the active layer architectures.

-

Single-Layer OSC → In this layer of the OSC, a thin layer of organic semiconductor material is placed between two conducting layers called electrodes, with one layer that can allow the radiation to transmit. There are two types of active materials in the organic layer, such as an electron donor and electron acceptor. The organic layer serves both as an electron-donating and an electron-accepting layer. Single-layer OSCs typically exhibit low PCE because of their small exciton diffusion length and inefficient charge separation. In 1986, Tang et al. presented the first single-layer system using copper phthalocyanine as the active material [21].

-

Bilayer OSC → Bilayer OSCs were developed to address the limitations of single-layer OSCs. These devices consist of double organic layers: one electron-donating material and one electron-accepting material stacked in a planar hetero-junction configuration [3]. This arrangement allows for the better separation of charges at the donor–acceptor interface, leading to higher efficiency than in single-layer OSCs. However, the diffusion length is still a restricting factor for the performance of these devices [21]. Bilayer OSCs demonstrate improved charge separation compared to single-layer devices but still suffer from limited exciton diffusion and sub-optimal donor–acceptor interfaces [22].

-

Bulk Heterojunction (BHJ) OSC → A BHJ OSC is produced from the blending of electron-donating and electron-accepting materials, which creates an inter-penetrating network in the active layer. This network gives a greater interfacial region between the electron-donating material and electron-accepting material, facilitating good exciton dissociation and the separation of charges. In 1995, the idea of BHJ OSCs was first described by Yu et al., who used [6][6]-phenyl-C61-butyric acid methyl ester (PCBM) as an electron acceptor and poly(3-hexylthiophene) (P3HT) as an electron donor [23]. BHJ OSCs have become the most widely researched and promising OSC architectures due to their superior performance and potential for further optimization [24].

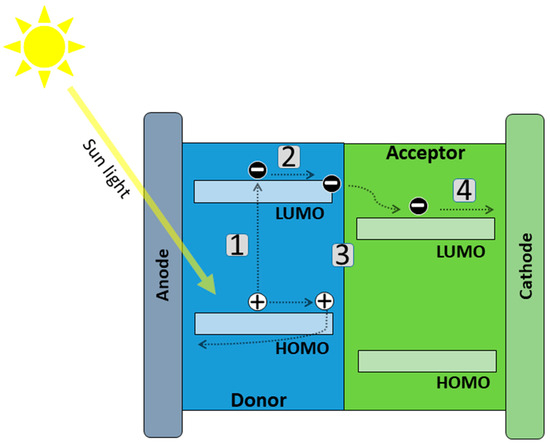

The operation mechanism (Figure 4) of OSCs involves several critical steps, such as the absorption of radiation, the generation and diffusion of excitons, separation, and the collection of charges [20]. In particular, it is possible to schematize the operation mechanism as four steps.

Figure 4. Operation mechanism of OSC.

-

Radiation absorption → when light is incident on the OSC, optical absorption is caused by the active material layer, which comprises donor and acceptor materials (for example, a P3HT and PCBM, respectively) [10]. Upon absorbing a specific wavelength of light compatible with the bandgap of the donor, an electron excites from one molecular energy level (such as HOMO) to another molecular energy level (such as LUMO) of the donor material, generating an excited state with excitons (pairs of holes and electrons) [14]

-

Exciton generation and diffusion → excitons are bound pairs of electron–holes created upon light absorption [25]. They are mobile and can diffuse through the donor material. Generally, the exciton diffusion length in organic materials is approximately 10–20 nm, limiting the active layer’s thickness [26]. The morphology of the active materials has a vital role in facilitating the diffusion of excitons and charge separation [27].

-

Charge collection → following charge separation, the excitons migrate through the active materials, to their corresponding electrodes [30]. The charge transport efficiency depends on factors such as the charge carrier’s mobility, the active layer’s morphology, and the presence of charge traps [31]. After the pairs of electrons and holes have migrated toward their respective electrodes, they are collected, generating an external current [32].

2. Greenhouse-Integrated Photovoltaics (GIPV)

Sustainable agriculture necessitates the attainment of high crop yields within the confines of limited agricultural land while reducing the reliance on non-renewable energy sources [33]. Greenhouse farming offers advantages such as reduced water consumption and controlled temperatures, irrespective of external conditions [34]. Although greenhouse-based farming can enhance crop production compared to conventional agriculture, it requires electricity [35]. The system cannot be deemed sustainable if the electricity source is non-renewable. The necessity of sustainable agriculture and renewable energy source utilization has driven rapid advancements in GIPV [2].

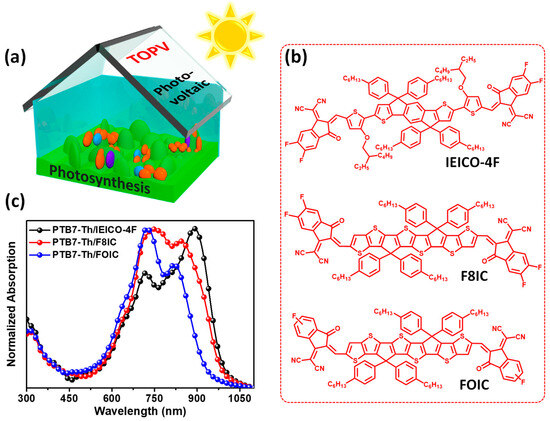

PCE of 15–16% for some OSC systems for greenhouse applications has been achieved [7]. This efficiency is low compared to silicon (Si)-based solar cells, but transparency is the key feature in the integration of OSCs with greenhouses. Numerous combinations of active materials have been described in scientific papers for the integration of OSCs with greenhouses. Liu et al. first reported the greenhouse application of a flexible OSC based on infrared (IR) active acceptors (such as F8IC, IEICO-4F, and FOIC) combined with PTB7-Th as the donating material, reaching good PCE (9.26, 10.03, and 8.92%, respectively) [36]. The growth of mung bean plants over a thirteen-day period in a greenhouse powered by PTB7-Th:IEICO-4F OSCs was found to be similar to growth under normal sunlight conditions (Figure 5).

Figure 5. (a) Integration of OSC in a greenhouse; (b) molecular structures of IEICO-4F, F8IC, and FOIC; (c) absorption spectra of donor and acceptor materials.

O’Connor et al. [37] reported on the electricity distribution generated from a GIPV with a combination of two active layers (FTAZ:IT-M and PTB7-Th: IEICO-4F). This system achieved PCE of 12.8%. Interestingly, only 50% of the electricity generated in this system was consumed by the greenhouse (for lettuce cultivation) in hot climate conditions, leaving the remaining 50% of electricity available for storage. Additionally, it was observed that in mixed humid weather conditions, energy consumption by the greenhouse was higher, yet the produced energy remained in surplus [37][38][39].

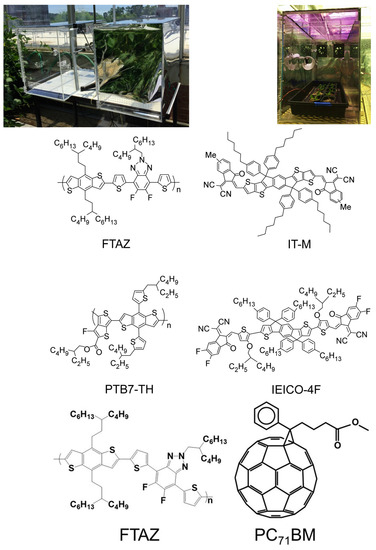

O’Connor et al. [38] also showcased an OSC featuring an active material layer with absorption properties that complemented the absorption of chlorophyll in red leaf lettuce. The fresh and dry weights of red leaf lettuce cultivated under semitransparent OSCs were comparable to those of the control treatment. OSC filters (shown in Figure 6), integrated with a greenhouse, were composed of three BHJ layers, namely FTAZ:IT-M, FTAZ:PC71BM, and PTB7-TH:IEICO-4F. They exhibited average visible transmittance (AVT) in the spectrum of photosynthetically active radiation (PAR) at 29, 31, and 38% and PCE of 11, 6, and 12%, respectively.

Figure 6. Experimental setup of plant growth and chemical structures for photovoltaic systems FTAZ:IT-M, FTAZ:PC71BM, and PTB7-TH:IEICO-4F.

Hu et al. [40] reported on the development of semitransparent ternary materials (BDT-Th: IT-4F and IEICO-4F as the alloyed acceptor) in solar cells that displayed both high PCE of 9.40% and AVT of 24.6% [36][41]. Li et al. [42] also developed an innovative OSC for integration in a greenhouse using a non-halogenated green solvent. This OSC was based on a potent polymer donor (PM6). Acceptor materials (such as A-2ThCl and A-4Cl) were combined with PM6 donors by the strategical alignment of the HOMO–LUMO energy levels. It was observed that there were high offsets of energy of approximately 0.2 eV (∆HOMO) and 0.35 eV (∆LUMO) between the donor (PM6) and A-4Cl near-IR acceptor. After the mixing of another near-IR acceptor, A-2ThCl with A-4Cl showed single oxidation potential (−5.70 eV) and reduction potential (−3.98eV) on a cyclic voltammogram that proved that they had good miscibility. The combination of these two miscible acceptors and a fullerene acceptor (PC71BM) with donor PM6 resulted in a unique electricity-generating light filtering system for greenhouse integration. These OSCs reached PCE of 13.08%, along with a growth factor of 24.7% for plants. The study focused on mung bean sprouts, which were observed to thrive under the OSC-filtered light. After 90 h, the sprouts grown under the OSC-filtered light reached a height of approximately 7.6 cm, demonstrating growth characteristics similar to those grown under traditional glass in the context of height, branching, and leaf development [42]. In a study by C. Zisis et al., a photoactive layer of P3HT:PCBM, featuring transparency of 19.4% in the region of PAR, was implemented in a greenhouse. Notably, better plant growth was observed beneath the integrated photovoltaic covering on the greenhouse [43]. Cao et al. [43] designed a J52:IEICO-4F:PC71BM ternary blend OSC for greenhouse integration application. They observed 7.75% PCE for the OSC, with a 24.8% crop growth factor [44]. An OSC composed of a P3HT donor and naphthobisthiadiazole-based acceptor showed good performance for energy generation and strawberry plant growth [45]. An OSC composed of donor D2 and acceptor A26 exhibited PCE of 9.3 with AVT of 31%, resulting in the comparable growth of mung bean under both natural sunlight and an OSC covering [36]. The use of OSCs in greenhouses not only supports environmentally friendly agricultural practices but also offers substantial financial benefits. An experiment performed by O’Connor et al. [46] revealed that the net present value (NPV) of OSC-integrated greenhouses can be increased by up to $320/m², particularly for tomato production at latitudes below 35°, compared to traditional greenhouses. In colder climates, OSCs have been found to offset up to 65% of the greenhouse energy demand, significantly reducing energy consumption and the associated costs. Additionally, OSC-integrated greenhouses provide optimal lighting conditions for plant growth. The selective transmission of light through the OSCs allows for the absorption of wavelengths most conducive to photosynthesis, thereby promoting enhanced crop growth [46]. The adoption of an optimized design for OSCs brings particular advantages, especially in the context of GIPV, as it guarantees efficient energy conversion and effective energy management. These factors are vital in maximizing the overall efficiency and productivity of greenhouse systems.

43. Conclusion and outlook:

Organic solar cells represent a promising avenue for renewable energy, particularly well-suited for integration into greenhouses. Significant advancements have been achieved in enhancing both the efficiency and stability of Organic photovoltaics. However, hurdles in large-scale manufacturing, durability, and cost-effectiveness persist. Navigating these challenges is essential for transitioning this promising technology to widespread commercial use. The future of organic solar cells largely rests on the development of innovative materials that maintain high efficiency while withstanding the environmental conditions commonly encountered in a greenhouse.References

- Rockström, J.; Steffen, W.; Noone, K.; Persson, Å.; Chapin, F.S.; Lambin, E.F.; Lenton, T.M.; Scheffer, M.; Folke, C.; Schellnhuber, H.J. A safe operating space for humanity. Nature 2009, 461, 472–475.

- Agency, I.E. World Energy Outlook 2020; OECD Publishing: Paris, France, 2020.

- Green, M.A.; Hishikawa, Y.; Dunlop, E.; Levi, D.; Hohl-Ebinger, J.; Yoshita, M.; Ho-Baillie, A. Solar cell efficiency tables (version 53) Progress in Photovoltaics. Res. Appl 2019, 27, 3–12.

- Brabec, C.; Scherf, U.; Dyakonov, V. Organic Photovoltaics: Materials, Device Physics, and Manufacturing Technologies; John Wiley & Sons: Hoboken, NJ, USA, 2011.

- Li, S.; Li, Z.; Wan, X.; Chen, Y. Recent progress in flexible organic solar cells. eScience 2023, 3, 100085.

- Kaltenbrunner, M.; White, M.S.; Głowacki, E.D.; Sekitani, T.; Someya, T.; Sariciftci, N.S.; Bauer, S. Ultrathin and lightweight organic solar cells with high flexibility. Nat. Commun. 2012, 3, 770.

- La Notte, L.; Giordano, L.; Calabrò, E.; Bedini, R.; Colla, G.; Puglisi, G.; Reale, A. Hybrid and organic photovoltaics for greenhouse applications. Appl. Energy 2020, 278, 115582.

- Zhao, Y.; Zhu, Y.; Cheng, H.-W.; Zheng, R.; Meng, D.; Yang, Y. A review on semitransparent solar cells for agricultural application. Mater. Today Energy 2021, 22, 100852.

- Traverse, C.J.; Pandey, R.; Barr, M.C.; Lunt, R.R. Emergence of highly transparent photovoltaics for distributed applications. Nat. Energy 2017, 2, 849–860.

- Li, G.; Zhu, R.; Yang, Y. Polymer solar cells. Nat. Photon. 2012, 6, 153–161.

- Dang, M.T.; Hirsch, L.; Wantz, G. P3HT: PCBM, best seller in polymer photovoltaic research. Adv. Mater. 2011, 23, 3597–3602.

- Søndergaard, R.R.; Hösel, M.; Krebs, F.C. Roll-to-Roll fabrication of large area functional organic materials. J. Polym. Sci. B Polym. 2013, 51, 16–34.

- Kim, J.Y.; Kim, S.H.; Lee, H.H.; Lee, K.; Ma, W.; Gong, X.; Heeger, A.J. New architecture for high-efficiency polymer photovoltaic cells using solution-based titanium oxide as an optical spacer. Adv. Mater. 2006, 18, 572–576.

- Park, S.H.; Roy, A.; Beaupré, S.; Cho, S.; Coates, N.; Moon, J.S.; Moses, D.; Leclerc, M.; Lee, K.; Heeger, A.J. Bulk heterojunction solar cells with internal quantum efficiency approaching 100%. Nat. Photon. 2009, 3, 297–302.

- Song, W.; Fanady, B.; Peng, R.; Hong, L.; Wu, L.; Zhang, W.; Yan, T.; Wu, T.; Chen, S.; Ge, Z. Foldable semitransparent organic solar cells for photovoltaic and photosynthesis. Adv. Energy Mater. 2020, 10, 2000136.

- Mishra, K.; Stanghellini, C.; Hemming, S. Technology and Materials for Passive Manipulation of the Solar Spectrum in Greenhouses. Adv. Sustain. Syst. 2023, 7, 2200503.

- Betancur, R.; Romero-Gomez, P.; Martinez-Otero, A.; Elias, X.; Maymó, M.; Martorell, J. Transparent polymer solar cells employing a layered light-trapping architecture. Nat. Photon. 2013, 7, 995–1000.

- Ercilla-Montserrat, M.; Izquierdo, R.; Belmonte, J.; Montero, J.I.; Muñoz, P.; De Linares, C.; Rieradevall, J. Building-integrated agriculture: A first assessment of aerobiological air quality in rooftop greenhouses (i-RTGs). Sci. Total Environ. 2017, 598, 109–120.

- Jelle, B.P. Building integrated photovoltaics: A concise description of the current state of the art and possible research pathways. Energies 2015, 9, 21.

- Brabec, C.J. Organic photovoltaics: Technology and market. Sol. Energy Mater Sol. Cells 2004, 83, 273–292.

- Tang, C.W. Two-layer organic photovoltaic cell. Appl. Phys. Lett. 1986, 48, 183–185.

- Kippelen, B.; Brédas, J.-L. Organic photovoltaics. Energy Environ. Sci. 2009, 2, 251–261.

- Yu, G.; Gao, J.; Hummelen, J.C.; Wudl, F.; Heeger, A.J. Polymer photovoltaic cells: Enhanced efficiencies via a network of internal donor-acceptor heterojunctions. Science 1995, 270, 1789–1791.

- Liao, H.-C.; Ho, C.-C.; Chang, C.-Y.; Jao, M.-H.; Darling, S.B.; Su, W.-F. Additives for morphology control in high-efficiency organic solar cells. Mater. Today 2013, 16, 326–336.

- Clarke, T.M.; Durrant, J.R. Charge photogeneration in organic solar cells. Chem. Rev. 2010, 110, 6736–6767.

- Lunt, R.R.; Bulovic, V. Transparent, near-infrared organic photovoltaic solar cells for window and energy-scavenging applications. Appl. Phys. Lett. 2011, 98, 61.

- Scharber, M.C.; Sariciftci, N.S. Efficiency of bulk-heterojunction organic solar cells. Prog. Polym. Sci. 2013, 38, 1929–1940.

- Vandewal, K.; Albrecht, S.; Hoke, E.T.; Graham, K.R.; Widmer, J.; Douglas, J.D.; Schubert, M.; Mateker, W.R.; Bloking, J.T.; Burkhard, G.F. Efficient charge generation by relaxed charge-transfer states at organic interfaces. Nat. Mater. 2014, 13, 63–68.

- Liu, J.; Chen, S.; Qian, D.; Gautam, B.; Yang, G.; Zhao, J.; Bergqvist, J.; Zhang, F.; Ma, W.; Ade, H. Fast charge separation in a non-fullerene organic solar cell with a small driving force. Nat. Energy 2016, 1, 1–7.

- He, Z.; Zhong, C.; Su, S.; Xu, M.; Wu, H.; Cao, Y. Enhanced power-conversion efficiency in polymer solar cells using an inverted device structure. Nat. Photon. 2012, 6, 591–595.

- Nielsen, C.B.; Turbiez, M.; McCulloch, I. Recent advances in the development of semiconducting DPP-containing polymers for transistor applications. Adv. Mater. 2013, 25, 1859–1880.

- Ameri, T.; Dennler, G.; Lungenschmied, C.; Brabec, C.J. Organic tandem solar cells: A review. Energy Environ. Sci. 2009, 2, 347–363.

- Foley, J.A.; Ramankutty, N.; Brauman, K.A.; Cassidy, E.S.; Gerber, J.S.; Johnston, M.; Mueller, N.D.; O’Connell, C.; Ray, D.K.; West, P.C. Solutions for a cultivated planet. Nature 2011, 478, 337–342.

- Lages Barbosa, G.; Almeida Gadelha, F.D.; Kublik, N.; Proctor, A.; Reichelm, L.; Weissinger, E.; Wohlleb, G.M.; Halden, R.U. Comparison of land, water, and energy requirements of lettuce grown using hydroponic vs. conventional agricultural methods. Int. J. Environ. Res. Public Health 2015, 12, 6879–6891.

- Albright, L.D. Environment Control for Animals and Plants; American Society of Agricultural Engineers: St. Joseph, MI, USA, 1990.

- Liu, Y.; Cheng, P.; Li, T.; Wang, R.; Li, Y.; Chang, S.-Y.; Zhu, Y.; Cheng, H.-W.; Wei, K.-H.; Zhan, X. Unraveling sunlight by transparent organic semiconductors toward photovoltaic and photosynthesis. ACS nano 2019, 13, 1071–1077.

- Ravishankar, E.; Booth, R.E.; Saravitz, C.; Sederoff, H.; Ade, H.W.; O’Connor, B.T. Achieving net zero energy greenhouses by integrating semitransparent organic solar cells. Joule 2020, 4, 490–506.

- Ravishankar, E.; Charles, M.; Xiong, Y.; Henry, R.; Swift, J.; Rech, J.; Calero, J.; Cho, S.; Booth, R.E.; Kim, T. Balancing crop production and energy harvesting in organic solar-powered greenhouses. Cell Rep. 2021, 2, 100381.

- Ho, C.H.Y.; Kim, T.; Xiong, Y.; Firdaus, Y.; Yi, X.; Dong, Q.; Rech, J.J.; Gadisa, A.; Booth, R.; O’Connor, B.T. High-Performance Tandem Organic Solar Cells Using HSolar as the Interconnecting Layer. Adv. Energy Mater. 2020, 10, 2000823.

- Hu, Z.; Wang, J.; Wang, Z.; Gao, W.; An, Q.; Zhang, M.; Ma, X.; Wang, J.; Miao, J.; Yang, C. Semitransparent ternary nonfullerene polymer solar cells exhibiting 9.40% efficiency and 24.6% average visible transmittance. Nano Energy 2019, 55, 424–432.

- Zang, Y.; Chen, L.; Zhou, J.; Xu, R.; Liu, Z. Enhanced light utilization in semitransparent organic solar cells based on a nonfullerene acceptor of IEICO-4F. Appl. Phys. A 2021, 127, 1–11.

- Wang, D.; Liu, H.; Li, Y.; Zhou, G.; Zhan, L.; Zhu, H.; Lu, X.; Chen, H.; Li, C.Z. High-performance and eco-friendly semitransparent organic solar cells for greenhouse applications. Joule 2021, 5, 945–957.

- Zisis, C.; Pechlivani, E.M.; Tsimikli, S.; Mekeridis, E.; Laskarakis, A.; Logothetidis, S. Organic Photovoltaics on Greenhouse Rooftops: Effects on Plant Growth. Mater. Today: Proc. 2019, 19, 65–72.

- Kini, G.P.; Jeon, S.J.; Moon, D.K. Latest Progress on Photoabsorbent Materials for Multifunctional Semitransparent Organic Solar Cells. Adv. Funct. Mater. 2021, 31, 2007931.

- Jinnai, S.; Oi, A.; Seo, T.; Moriyama, T.; Terashima, M.; Suzuki, M.; Nakayama, K.-i.; Watanabe, Y.; Ie, Y. Green-Light Wavelength-Selective Organic Solar Cells Based on Poly (3-hexylthiophene) and Naphthobisthiadiazole-Containing Acceptors toward Agrivoltaics. ACS Sustain. Chem. Eng. 2023, 11, 1548–1556.

- Ravishankar, E.; Booth, R.E.; Hollingsworth, J.A.; Ade, H.; Sederoff, H.; DeCarolis, J.F.; O’Connor, B.T. Organic solar powered greenhouse performance optimization and global economic opportunity. Energy Environ. Sci. 2022, 15, 1659–1671.

More