1. Evolution of Morel Cultivation

In the exploration of morel domestication and cultivation, three main cultivation technology systems have been invented: The “indoor cultivation” carried out by American scientist R.D. Ower in the 1980s

[12,20[1][2][3][4],

21,22], the so-called “bionic cultivation using stump trees” carried out in Yunnan, China, at the beginning of this century

[45][5], and the “field cultivation” originated from Sichuan and Chongqing regions in the last two decades

[1,23,26][6][7][8] (

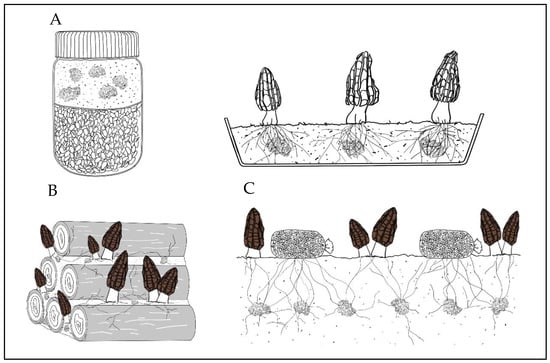

Figure 1). Although the management of the three cultivation technology systems is different, their basic nutrient metabolism principles share similarities. The idea of indoor cultivation by Ower was to cultivate sclerotia through the production process of “layered cultivation of sclerotia”, use mature sclerotia as spawn to directly sow and soak, and then induce fruiting. Thus, the emphasis of this method was placed on the cultivation of sclerotia and the direct induction of them to induce fruiting (

Figure 1A). This technology was patented by Ower in the United States from 1986 to 1989

[20[2][3][4],

21,22], and afterwards it was also adopted by some companies for morel (

M. rufobrunnea) commercial cultivation, but it was stalled due to a lack of cultivation stability

[23][7]. The so-called “bionic cultivation” using stump wood, invented in Yunnan, China, is a unique cultivation mode that originated from the folk. The operation process consists of stacking layers of stump wood inoculated with morel spawn and then covering them with soil. The inoculated mycelia vigorously grow, forming abundant mycelial networks that absorb the nutrients from the stump wood and, relying on natural conditions, eventually form ascomata (

Figure 1B). The key point of this technique was to use stump wood of

Populus sp. as the nutrient material in order to grow mycelia of

Morchella, which fed on wood nutrients and eventually induced ascomata formation

[45][5]. Despite the fact that there was some success, its weakness was that it was necessary to use great amounts of wood, which was against the protection of forest resources and therefore gradually decreased

[1][6].

Figure 1. Schematic diagram of the three successful cultivation technologies of morels: (A) Ower’s indoor method, using sclerotia as “seeds”, sown in shallow trays; (B) Yunnan’s stump wood outdoor method, using the addition of inoculated mycelia and soil among the cavities of Populus sp. stumps, which promotes mycelial growth by nutrient absorption from bark, sclerotia formation, and finally achieves ascomata development; and (C) field cultivation method, where the addition of external nutrition bags boosts the ascomata formation.

The current morel field cultivation technology, which originated in Sichuan and Chongqing, China, in the early 20th century, was gradually explored and enhanced by both scientists and amateur morel cultivation enthusiasts

[1][6]. Its unique feature was the addition of an external feeding source, constituted by external nutrition bags. When the mycelium starts growing and, with time, establishes a mycelium network inside or on the soil surface, the external nutrition bags are placed over the abundant mycelial network, and the mycelium on the soil surface quickly colonizes the external nutrition bags. The assimilation and absorption of nutrients begin, and the nutrients in the nutrient bags are finally transferred to the mycelial network and sclerotia cells in the soil to meet the energy requirements for sexual reproduction, forming abundant ascomata (

Figure 1C)

[1,26][6][8].

There were two main steps in the method invented by Ower

[12,20,21,22][1][2][3][4]. The first one, described frequently and mentioned above, was the production and cultivation of abundant sclerotia and the use of them as “seeds” for sowing, germination, and finally ascomata induction formation. This technology was also successfully adopted by other scientists

[24,25][9][10]. The second one, mentioned but not discussed in detail by Ower, was that after sclerotia sowing, plastic bags containing rags or scraps of paper were placed on the germinating substrate, and in addition, a nutritive solution containing urea was added to the bags as nutrients to meet the needs of later fruiting formation. Due to the limited data left by Ower, these details of paramount importance have usually remained hidden from the public domain

[20,21,22][2][3][4]. However, with the boosting of research related to the growth and development of sclerotia as a model for morel cultivation, it is possible to trace back the basic principles of the success of this technology

[1,16,17,18,19,26,29][6][8][11][12][13][14][15]. First, studies on sclerotia formation showed that sclerotia mostly occurred in nutrient-poor environments and that sclerotia was an important lipid reservoir

[16,17,18,19,29][11][12][13][14][15]. Second, during the cultivation process, no ascomata can be produced without the addition of external nutrient bags or nutrients added directly to the soil

[36][16]. Additionally, it is currently known that the number of sclerotial cells and the lipid contents of the soil increase significantly with time when exogenous nutrition is added. It can be inferred that, in terms of nutrient assimilation and absorption, the process of sclerotia formation is similar to the current successful morel field cultivation. Nutrients can be stored in sclerotial cells in the soil in “rich” and “poor” areas to satisfy the appropriate amounts of energy reserve necessary for sexual reproduction in the last stage of cultivation

[1][6]. The knowledge of these basic principles related to the differential nutrient distribution in space and their consequent energy transfer and storage in the different fungal compartments is of fundamental relevance for successful morel cultivation

[1,36][6][16].

The morel nutrient demand, absorption, and storage during the different cultivation steps are different compared with other widely cultivated mushrooms, each with its own peculiarities. Although the nutrition supply methods of the three morel cultivation models are different, the basic mechanisms and dynamics involved are similar. In “Ower’s indoor” method, sclerotia are formed in the “poor” soil areas, while the nutrient “rich” organic matter layer is the energy provider, and the high-energy sclerotia structure is used to induce and stimulate ascomata formation (Figure 1A). In the “Yunnan’s stump wood outdoor” method, the stump woods are stacked in layers, or pyramids. The spawn and soil fill the gaps between the stump woods. The stump woods, including bark as a relevant source, are rich nutrient sources, and the spawn and soil inoculated between the stump wood cavities constitute “poor nutrient” areas, creating a barren nutrient condition, satisfying the assimilation and absorption nutrient requirements for morel cultivation systems (Figure 1B). The “field cultivation” method is the most advanced technique that fits the required nutrient distribution system necessary for ascomata formation. The region already colonized by the mycelial network in the soil is a nutrient “poor” area. The addition of “rich” exogenous nutrient bags allows efficient nutrient transfer from the exogenous nutrient bags to the mycelial network in the soil to achieve successful ascomata formation (Figure 1C). The “Ower’s indoor method” separates the sclerotia cultivation process (energy conversion process) from the ascomata stimulation, while the “Yunnan´s stump wood outdoor” and “field cultivation” methods integrate both stages at the right timing (Figure 1).

Currently, morel field cultivation is conducted directly on field soil as substrate, and ditching, sowing, and ridging are usually carried out in areas where the ambient temperature is lower than 20 °C (usually in autumn). Then, the exogenous nutrition bags containing wheat as the main component are sterilized, punched, and located over the mycelial beds, acting as a nutrient supplier for the mycelium network already established in the soil. After the temperature rises in the spring of the next year, mycelial growth is promoted and abundant ascomata production occurs, completing the whole cultivation cycle

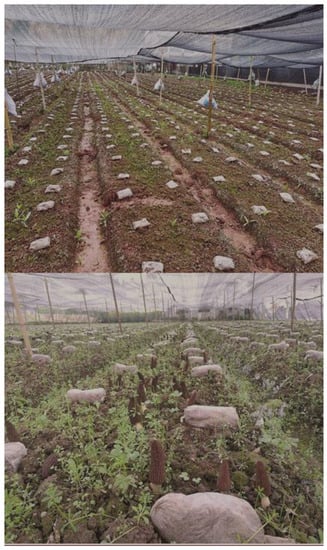

[1,26][6][8]. Using this technology, taking into account the local climate characteristics in different regions of China, simple flat shed sunshades (

Figure 2) and a variety of basic (

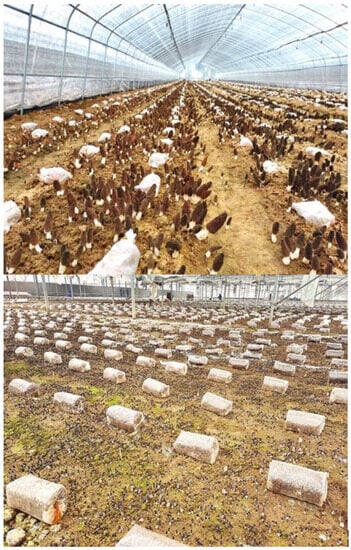

Figure 3) and high-tech greenhouses (

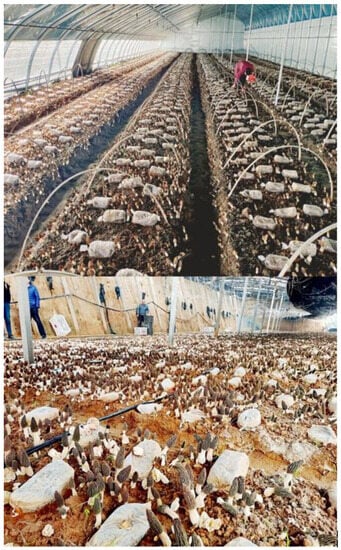

Figure 4) are currently in use for the successful artificial cultivation of morels. The average yield and cultivation stability have been significantly improved by using high-quality facilities and controlled environments. A number of Chinese farms have had yields higher than 1500 g/m

2 (

Figure 3 and

Figure 4).

Figure 2. Morel cultivation facilities with small financial investment using flat-shed modules, which are usual in Southwest China and only help with low control of environmental natural weather outdoor conditions. These basic facilities might have no production (above) or low yields, for example, for M. importuna (below). Usually, these elementary facilities are mostly used in areas where weather conditions are not extreme.

Figure 3. Morchella sextelata cultivated in facilities with moderate financial investment using conventional vegetable greenhouses with plastic (above) or glass (below) sheeting, which allows control of temperate outdoor weather fluctuations. Plastic vegetable greenhouses are the most commonly used, and high yields are clearly observed when using these types of greenhouses.

Figure 4. Morchella sextelata cultivated in facilities with high investment using automated temperature and humidity control greenhouses. Very high yields are clearly observed in both greenhouses (above and below). These facilities are appropriate for any kind of weather condition, including areas with harsh or changing outdoor climate conditions. Cotton felt was added to the plastic greenhouse sheeting for better temperature control (above); and the same material plus removal of 1 m-deep soil was used in order to increase the insulation and temperature control (below).

2. Key Inventions of Successful Cultivation in China

Although Ower conducted interesting seminal technical innovations for morel indoor cultivation in the 1980s, his method was not successfully implemented worldwide. However, the field cultivation of morel in China has gradually taken shape through the efforts of many groups of scientists who currently lead this industry worldwide, mainly based on two facts.

Firstly, the discovery and application of exogenous nutrition bags. In terms of nutrient assimilation, absorption, and transportation, morel cultivation is very different compared to other cultivated edible mushrooms because it needs to create contrasting “rich” and “poor” nutrient environments through its life cycle. In fact, it was impossible to achieve these “nutrient-contrasting conditions” by using substitute materials or base materials traditionally used to stimulate other cultivated edible mushrooms. In his patent, Ower mainly focused on the method of promoting sclerotia formation and directly inducing ascomata formation from them. Despite the fact that the theory of “rich and poor nutrient contrasting conditions” was already implicit in the original indoor method of cultivation

[16[11][12][13][14],

17,18,19], Mr. Ower’s premature death meant that the notion of “exogenous nutrition” was obliterated for a long time

[20,21,22][2][3][4]. The effect of exogenous nutrition bags was discovered accidentally by Chinese researchers in their long-term exploration and matured gradually through the systematic improvement of nutrition metabolism, the application of a specific methodology, and careful observation of the whole production technology

[1][6]. This was one of the main reasons for the rapid development of the morel industry in China in the last decade.

Secondly, the discovery of cultivable and easy-fruiting species.

Morchella is a genus with enormous diversity around the world. Globally, there are more than 300 recognized species, plus 78 phylogenetic species determined by multi-gene phylogenetic analysis

[38][17]. At least 30 phylogenetic species are distributed in China, from which the cultivable varieties are limited to 3 to 7 species, mainly

M. importuna,

M. sextelata, and

M. eximia [46][18]. The different cultivation potentials of morel species may be due to their differential nutritional requirements. The early failure of morel domestication may be explained in terms of an inaccurate selection of species. According to the current feeding cultivation technology, it is still impossible to achieve fruiting in all morel species, particularly in the Esculenta clade. This is a factor of paramount importance in the success of Chinese morel cultivation, which, along with an accurate and careful feeding technology, constitutes a basic element for the improving promotion of morel cultivation in China.

An additional factor that has influenced the rapid development of morel cultivation in China is its whole sociocultural agricultural system and the presence of a number of areas with favorable climate and environmental conditions. Before 2016, the cultivation areas of Morchella started spreading mainly in Southwest China (most conspicuously in Yunnan, Guizhou, and Sichuan provinces). The climate type in these provinces is warm and humid in the spring, and currently, it constitutes the region in which wild morels have the highest natural production. The warm and humid environmental conditions ensure the appropriate natural temperature conditions and water demand for morels to be developed from primordia to mature ascomata. In these areas, with simple shading facilities, it is possible to ensure a certain amount of morel production (Figure 2). Even in some natural mountain forests, ascomata can grow naturally after minor technological intervention. In these areas, the early morel industry in China was initially promoted, and gradually it expanded to other provinces, where different adaptations and technological enhancements boosted the industry. After 2016, China’s morel cultivation gradually spread throughout the country, especially in the Yellow River basin and the north of the country. The construction of greenhouses with higher technology in these areas, with strict regulation of temperature and humidity, allowed for the control of optimal environmental conditions, which, as a consequence, dramatically increased yields per unit area. This situation originated with the rapid development of the morel industry in Northern China in recent years (Figure 3 and Figure 4).

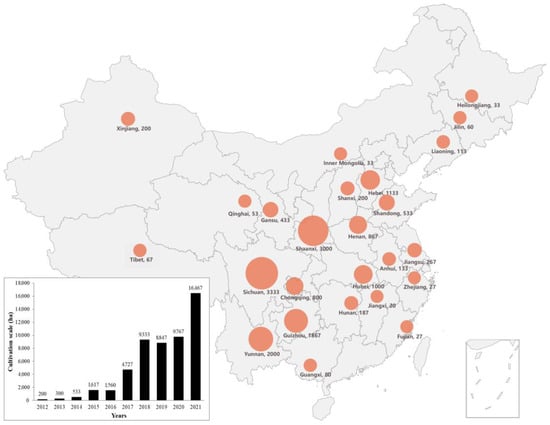

3. Cultivation Scale and Area in China

Since the commercialization of morel cultivation in China in 2012, the cultivation scale has increased from the initial 200 hectares to 16,466 hectares in 2021–2022. This is an awesome increase of more than 80 times during only one decade, and the cultivation area has also spread all over the country (Figure 5). The rapid growth of cultivation scale occurred in 2014–2015 and 2016–2017, with a year-on-year growth rate higher than 200%. The second boost occurred from 2017–2018, with a conspicuous increase of 97%. In addition to the evident increase in cultivation scale initiated by the morel’s cultural charm in China, and all over the world, as an edible and medicinal mushroom, there were also, in some areas, large marketing campaigns, which contributed to the success of the quick growth of this industry. However, along with this increasing growth, some challenges emerged, including, for example: (i) unstable, steady production; and (ii) great price fluctuations due to irregular production and, in some cases, insufficient market development.

Figure 5. Growth and distribution of morel industry in China. The graph shows the annual change trend of morel cultivated area in China from 2012 to 2021, and the map shows the current areas in the country’s provinces from 2021 to 2022, expressed in hectares after the province names and correlated with the size of the salmon-colored circles for each province.

The appropriate natural climate conditions in the early cultivation originated in the fact that the morel cultivation was mainly concentrated in three Chinese provinces: Sichuan, Yunnan, and Guizhou, which at the beginning of commercial production concentrated more than 75% of the total cultivated area of the country. Sichuan Province is the main cultivation area, particularly in the Chengdu Plain and nearby areas. However, after 2018, due to the cultivation failure of large areas during two consecutive years caused by the low quality of spawn, continuous harvesting without proper scientific supervision, lack of appropriate cultivation facilities, climate change, and additional unknown factors, the total cultivation area in Sichuan began to decline, with a year-on-year decrease of about 30% from 2019–2020. This large-scale failure phenomenon also occurred in Yunnan Province, and the potential explanation for these decreases might be similar to those mentioned for Sichuan Province. Outside the southwestern area, Shaanxi was the province with the fastest growth, particularly from 2021–2022. The main reason for this growth is that the warm and humid climate of Hanzhong City in Shaanxi Province is similar to that of Sichuan Province, and the low-temperature period in winter has also increased the stability of cultivation. At the same time, the disastrous failure of Chengdu Plain for two consecutive years led morel farmers to move northward. Similarly, Henan, Hebei, Shandong, and Shanxi provinces in the Yellow River basin and the North China Plain have shown a steady growth trend in recent years (Figure 5). Regional government financial support and technical guidance by enterprises are the main reasons for the conspicuous increase in cultivation areas in these provinces.

4. Challenges of Cultivation in China

Commercial morel cultivation has been maintained in China for the last 10 years. Although the cultivation scale and cultivated area continue to expand and the regional maximum yield record continued to increase, the overall steady profitability has occurred in only around 30% of the farmers, which means that around 70% of the growers have had unstable productions (with harvests per unit area lower than 150 g/m2), and even a proportion of these farmers have had absolute deficits. First, the appropriate scientific advice and the popularization of proper cultivation technology have not had the same expansion as morel cultivation itself. Although the cultivation technology of Morchella in China has been developed for more than ten years, the number of growers or technicians who have been seriously and permanently engaged for that long is less than 20% of the total. Most of them have given up after having a quick low or non-profit in their involvement in this industry. However, every year a large number of new “gold diggers” appear. As a consequence, there is a shortage of well-trained technical personnel or growers in terms of the proper selection of infrastructure conditions, understanding the relevance and management of different soil physical and chemical properties, coping with strategies to mitigate the changing climate, high-quality mycelial culture management, primordium induction technology, management and protection during the growth and development of ascomata, prevention and control of pests and diseases, and harvesting and processing technology. Secondly, with immature and non-standard spawn technology, a number of technical factors and steps must be taken to maintain high-quality standards, including, for example, the spawn quality evaluation, the standardization of proper protocols in its production, high-yield strain selection, and the management of the rapid degradation and aging of some strains. These factors have paramount importance for long-term development and steady yield in the morel cultivation technology. Additionally, a deeper understanding of some basic biological aspects, such as life cycle, mating type, asexual spore formation, sclerotia, and nutrient metabolism, will also play an important role in improving the current cultivation technology of Morchella.

5. Economic Impact Analysis

Moving the morel cultivation process from small production to a commercial scale entails important economic issues. The main inputs involved in large-scale commercial cultivation of morels are the costs included in: (i) Production materials, which comprise spawn and exogenous nutrient bags, including wheat, sawdust, lime, gypsum, sterilization and bags production, spawn cultivation, and technical costs; with an approximate cost of USD 9500 per hectare per year; (ii) facilities, which include two options, (a) simple shading modules, including bamboo or wood to support the cultivation structures, shading nets, construction costs, and land rent; with an approximate cost of USD 3000 per hectare per year, or (b) high-tech greenhouses, including shed and sprinkler facilities (which would help to control the temperature); and land rent, with an approximate cost of USD 12,500 per hectare per year; and (iii) labor and miscellaneous expenses, including land plowing, sowing, placement of nutrient bags, daily management, and ascomata harvesting; with an approximate cost of USD 3000 per hectare per year. Therefore, the approximate costs of commercial morel production would be in the range of USD 16,000 to USD 25,000 for simple or high-tech facilities per hectare per year, correspondingly. In recent years, based on previous experiences that have shown that high-quality facilities (Figure 3 and Figure 4) produce higher profits than those in simple shading modules (Figure 2), there has been an increased trend among farmers to invest in the former. Despite successful field cultivation in China, the total production of cultivated morels is far from reaching the limits of international consumption; therefore, this factor has not yet affected international market prices. However, the two main factors that currently influence morel prices are the ascomata production instability and the harsh environmental changes, due to the fact that they may dramatically decrease morel field yields. Currently, morel production in China is very variable, ranging from 0 to 3000 g per square meter, depending on different factors, including mainly environmental conditions and economic investment in facilities.