Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is a comparison between Version 2 by Peter Tang and Version 1 by Noah Yakah.

A World Bank report estimated that 2.01 billion tonnes of municipal solid waste (MSW) is generated worldwide annually, and this is expected to increase to about 3.4 billion tonnes by the year 2050. Waste incineration with energy recovery is a waste-to-energy (WtE) technology which has been established to be an appropriate method of dealing with MSW worldwide.

- municipal solid waste

- waste to energy

- waste incineration

- disposal

- management

- thermal power plant

- fossil fuels

- primary sources of energy

1. Overview of Waste

There are numerous definitions offered by dictionaries on the term “waste”. An important but simple definition of this term from the Merriam-Webster Dictionary includes, “refuse from places of human or animal habitation, damaged, defective, or superfluous material produced by a manufacturing process”, etc. Waste is also defined as anything which does not have any use for the holder. This definition of waste does not, however, include sewage effluent, radioactive waste, and emissions into the atmosphere. The issue of waste disposal and its management is one that has plagued nations worldwide, regardless of their socio-economic standing or reputation.

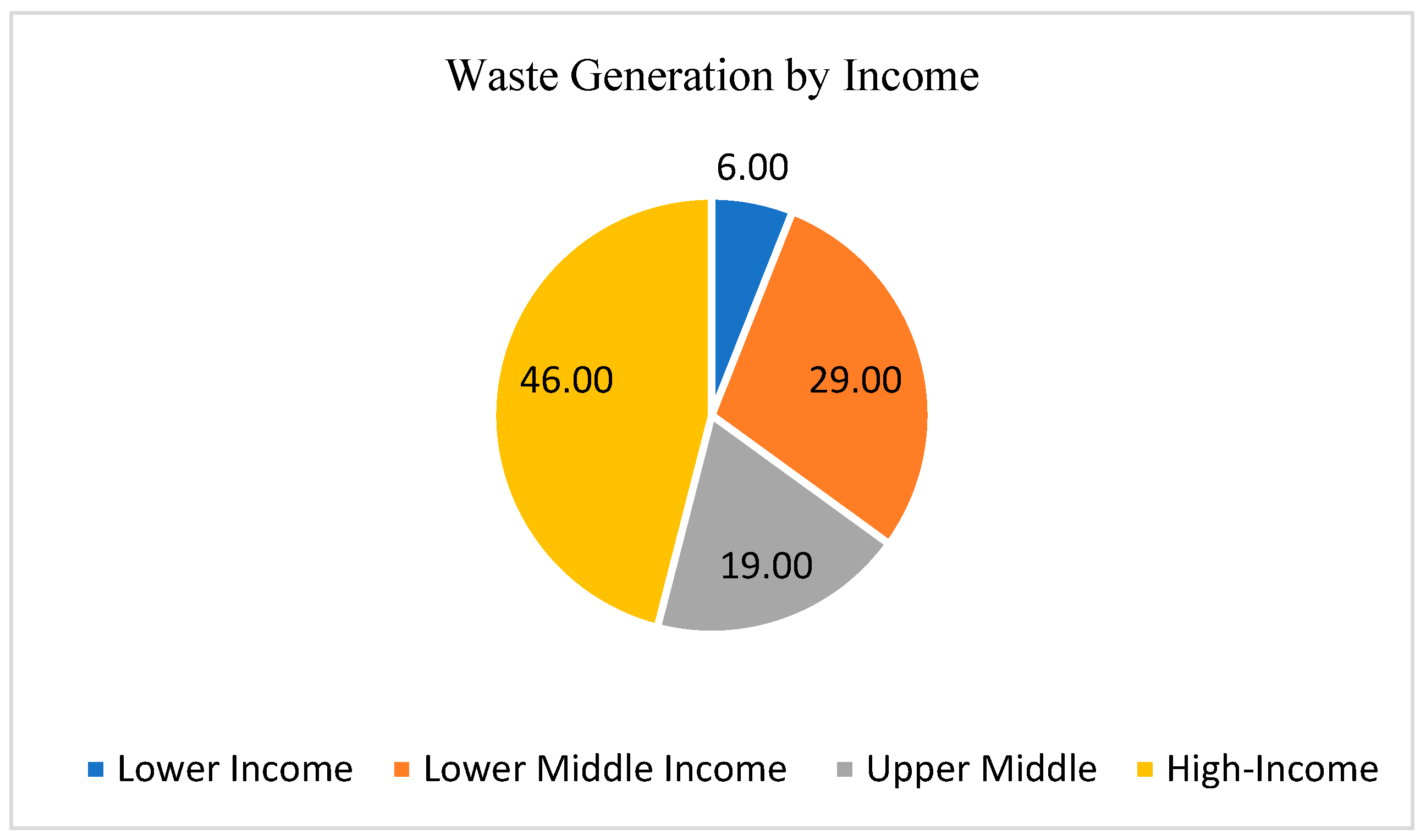

According to the World Bank [1], although there are significant variations in waste generation by region, waste generation can be viewed as a function of wealth. A report estimated that in 2018, global waste generation stood at 2.01 billion tonnes per year. However, this is expected to increase to 3.4 billion tonnes per annum by the year 2025. Generally, it can also be observed that areas with higher rates of urbanisation and economic development tend to have a greater amount of solid waste generation compared to areas with lower rates of economic development. Factors such as local climate and public habits also influence waste generation rates [25][2]. This trend can clearly be observed in Figure 1, which illustrates the percentage of waste generated by lower, lower middle, upper middle, and high-income countries in the world. Tchobanglous G. et al. [26][3] identified seven key issues that need to be considered in discussing solid waste management.

Waste can broadly be categorized into two groups, organic and inorganic. Organic waste is biodegradable waste, and this is waste that basically comes from plants, animals, or food. Inorganic wastes, on the other hand, are non-biodegradable wastes, and these include plastics, glass, papers, and metals [27][4]. Waste can also be classified either as biodegradable or non-biodegradable. Biodegradable waste (also referred to as putrescible waste) is waste that is generated from sources like plants or animal sources and is degradable or can be broken down by organisms; examples are food leftovers, faecal matter, trimmings from lawn mowing, etc. Non-biodegradable waste (also referred to as imputrescible waste), is waste that is usually from materials that are not broken down naturally by organisms; examples include metals, leather, plastics, papers, etc. [28][5]. Waste can also be classified as either being combustible or non-combustible waste when considering the incineration of the waste. Combustible wastes are usually organic wastes, and some other inorganic wastes that are burnable; examples include papers, textiles, plastics, etc., whereas non-combustible wastes include glass, metals, ceramics, etc., and this waste cannot burn [29,30][6][7].

The definition of municipal solid waste (MSW) varies from one literature to the other. However, one of the best definitions is that given by the United States National Research Council [31][8]; MSW is defined as the “solid portion of waste (not classified as hazardous or toxic) generated by households, commercial establishments, public and private institutions, government agencies and other sources”. This stream of waste consists of food and yard waste and a plethora of durable and non-durable products, as well as packaging. MSW is also defined as non-homogeneous materials that are generated through anthropogenic activities by households as well as in commercial places within a municipality. This comprises waste like plastic, leather, metals, glass, as well as waste that is generated from food industries (like hotels, restaurant, hostels, and households), and others which are inorganic [32][9]. MSW, however, excludes waste such as automobile bodies, municipal sludges, non-hazardous industrial process waste, combustion ashes, construction, and demolition waste. The amount of MSW generated can be viewed as the sum of waste collected and disposed of on behalf of the municipal authorities.

Waste composition is considered paramount in the identification of the best practice to be adopted for its disposal and management.

Sources of MSW may differ from one area to another depending on the category of waste and the definition for the scope of waste that the municipal authorities oversee. However, a study [25][2] identified six main sources of MSW. These sources are as follows:

-

Residential—The report identified single and multifamily dwellings as typical waste generators and identified food waste, e-waste, paper, plastics, household hazardous waste, leather, glass, etc.

-

Commercial—Another source of MSW identified by the report is the solid waste from commercial sources. Under this category, markets, stores, hotels, restaurants, and office buildings are typical waste generators. Some of the types of solid waste identified include paper, cardboard, food waste, e-waste, etc.

-

Institutional—Schools, government buildings, airports, prisons, and hospitals (non-medical wastes) were identified as typical waste generators. The same types of solid waste listed under commercial sources were also identified for institutional sources.

-

Industrial—Typical waste generators under this source of MSW include construction sites, fabrication, chemical plants, light and heavy manufacturing, and power plants. Some types of solid waste given under this section include hazardous wastes, packaging, food wastes, housekeeping wastes, etc.

-

Construction and demolition—Solid waste from construction and demolition sources including that from new building sites, road maintenance, renovation sites, and the pulling down of buildings are identified as typical construction and demolition waste generators. Some types of solid waste under this section include bricks, tiles, wood, steel, concrete, and dirt.

-

Municipal services—Under this category of MSW source, street cleaning, landscaping, recreational zones, water, and effluent treatment plants were identified as typical waste generators, while landscape and tree trimmings, street sweepings, general waste from recreational areas, and sludge were identified as other types of solid waste.

Commercial, institutional, and industrial sources are oftentimes grouped and constitute more than 50% of MSW. However, if the municipal authorities oversee the collection and disposal of the following types of waste, then they can also be classified as a source of MSW [25][2]:

-

Process—Refineries, power plants, chemical plants, processing and mineral extraction, and processing constitute some typical waste generators, while materials such as slag, tailings, industrial process waste, and scrap materials are some examples of typical processed solid waste.

-

Medical waste—Under this category of MSW source, hospitals, nursing homes, and clinics were identified as typical waste generators, while pharmaceutical waste, infectious waste such as hand gloves, bandages, cultures, and hazardous waste, i.e., chemicals and sharp objects, were identified as typical solid waste.

-

Agricultural—Typical waste generators identified under this category include crops, dairies, orchards, feedlots, and farms, while spoiled food waste and hazardous waste such as pesticides were identified as typical agricultural solid waste.

As a part of programmes to combat waste, many countries have developed strategies to mitigate against escalating rates of MSW generation. In some literature, the disposal and management of waste is usually presented as integrated waste management (IWM), and according to Tchobanoglous G. et al. [26][3], IWM is defined as “the selection and application of suitable techniques, technologies, and management programmes to achieve specific waste management objectives and goals”. There are basically four IWM strategies that are adopted by the United States Environmental Protection Agency [36][10].

Source reduction: This strategy of MSW management is focused on reducing either the volume or harmfulness of the waste generated and can be adopted by all and sundry. A more pragmatic approach to this strategy of waste management is to switch to reusing products and packaging (a typical example of such is the use of returnable bottles). Consumers are usually encouraged to partake in source reduction through buying as few products as possible or through using products expeditiously [26][3]. According to a study [37][11], while low-income countries have no structured programmes for source reduction, the situation, nevertheless, is different from high-income countries, where a great deal of educational programmes are organized which emphasize the necessity to reuse, reduce, and recycle waste (what has been nicknamed the three Rs of waste). A study [38][12] described source reduction as an immediate aid to the current environmental crisis. The study also stated that not only does source reduction addresses the core issues of waste problems but also takes into consideration the likelihood of environmental consequences as a result of population growth, with accompanying consumption and scarce resources that cannot satisfy the needs of mankind. Additionally, Tchobanoglous G. et al. [26][3] considered source reduction as the best practice at the process design phase of the production of any product. Johnson B. [38][12] listed three practices that can be implemented to reduce waste. These are listed below:

-

Evaluate past consumption—This can be achieved through assessing the true use and need of everything, after which ones which are deemed unnecessary are pared down.

-

To limit present and future consumption in terms of amount and size—This can be achieved through minimising shopping activities to conserve valuable resources which are used to make new things and through making used items available to others. Areas that can be considered include home sizes, reducing packaging, personal effects, etc.

-

Decreasing activities that may support or lead to consumption.

2. WtE Technologies

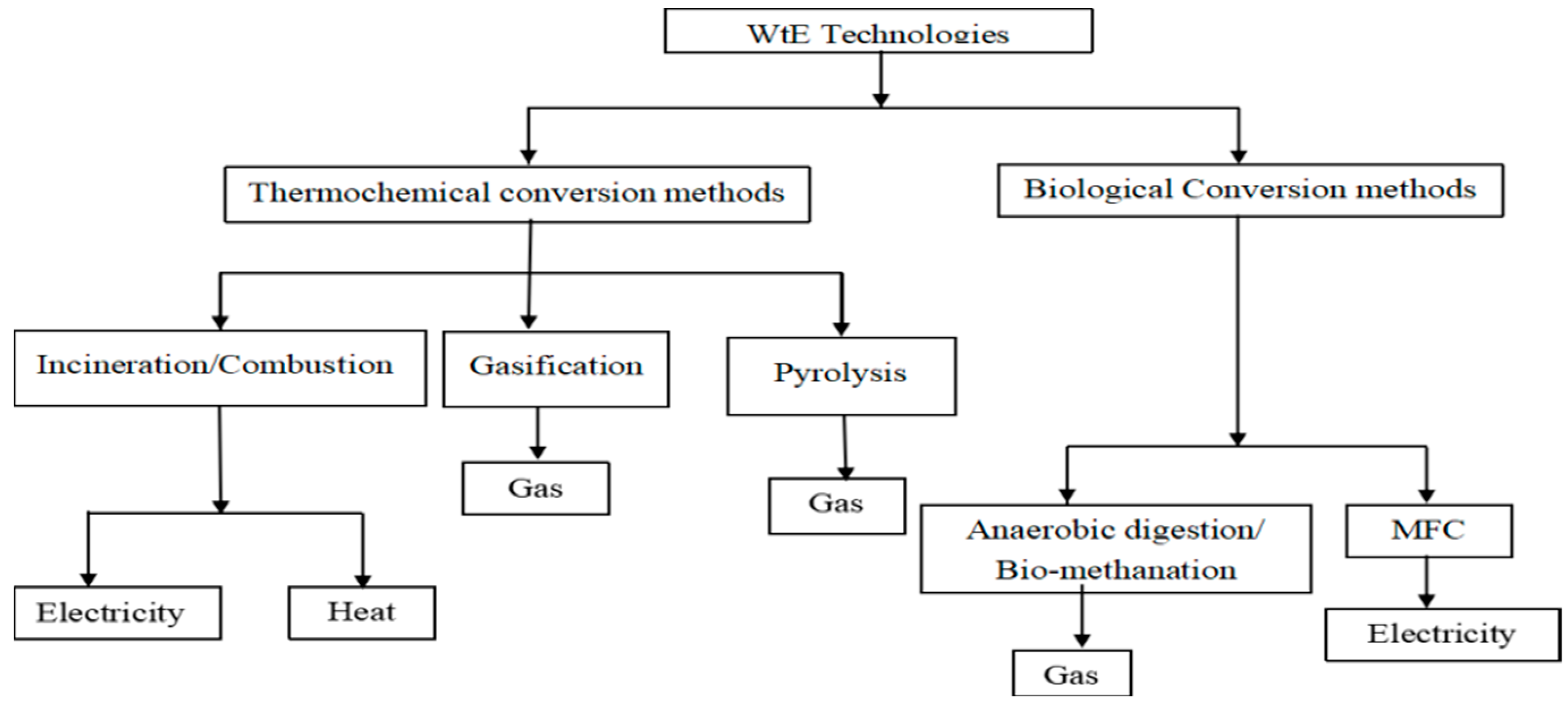

WtE technologies can broadly be classified into two types, namely, thermochemical and biological conversion methods. Figure 2 is a flowchart of the various methods of WtE technologies including the useful energy that can be derived from each technology.

2.1. Thermochemical Conversion Methods

The thermal conversion method of waste-to-energy technology is the application of heat and/or air (or oxygen) in treating MSW to generate electricity and heat. Thermal conversion methods of the WtE technology process can be either exothermic or endothermic. Thermochemical conversion methods, relative to biological conversion methods, have been estimated to be more efficient due to their faster reaction rates and larger reduction in the mass and volumes of the MSW [46][14]. The thermal conversion method of WtE technology can be divided into waste combustion (also referred to as waste incineration), gasification, and pyrolysis. The distinction between the various types of thermal conversion WtE technology depends on the degree of temperature and the amount of air (or oxygen) concentration.

Waste incineration/combustion is a type of WtE technology where, usually, mixed MSW is burned in the presence of excess air or oxygen at temperatures between 800 °C and 1200 °C. Unlike earlier waste incineration facilities which had the sole aim of reducing the mass and volume of MSW that will be sent to landfill sites, recent waste incineration facilities have systems incorporated for the production of steam and, subsequently, for electricity generation. Waste incineration facilities with energy recovery are, in principle, similar to a power plant that is fired by fossil fuels. A typical waste incineration facility with energy recovery consists basically of a waste storage, a boiler or incinerator, a steam turbine, and a flue gas treatment system.

Gasification is a partial oxidation process through which carbonaceous materials (e.g., MSW) are converted into a gaseous form referred to as a synthetic gas (syngas). Most of the carbon and hydrogen in the waste are converted into syngas comprising mainly carbon monoxide (CO), CH4, and hydrogen (H2), leaving behind a solid residue of inert ash and char. In gasification, an external heat source is needed to maintain its operating temperatures at optimum levels. The process of gasification is largely exothermic, although some amount of heat may be required to initiate the process and sustain it. The processed syngas can be used for a variety of applications (after cleaning). The syngas derived from the process of gasification is usually combusted in internal combustion engines to produce heat and electricity. The syngas produced during gasification may also be used to manufacture high-quality oils, additives, or synthetic natural gas (SNG) after it has been treated [47][15].

Pyrolysis is the thermal decomposition of carbon-based materials at higher temperatures in the absence of oxygen. This process involves the change of the chemical composition of the feedstock (MSW in this case). The pyrolysis of organic compounds produces volatile materials referred to as synthetic gas (syngas), a carbon-rich solid residue known in general as bio-char, and an oil also known as bio-oil [48][16]. The amounts of valuable products from the pyrolysis process (CO, H2, CH4, and other hydrocarbons) and their proportion depend exclusively on the pyrolysis temperature and the rate of heating. Bio-char is usually produced at temperatures below 450 °C, while syngas is produced at temperatures above 800 °C; however, bio-oil is produced at relatively intermediate temperatures. In the processes of combustion and gasification, pyrolysis is considered as the first step [48][16]. An external heat source is required to maintain the temperature throughout the process of pyrolysis, and as such, pyrolysis is an entirely endothermic process. A study estimated the net calorific value of syngas produced during the process of pyrolysis to be between 13 and 20 MJ/Nm3 [49][17]. The produced syngas can be combusted in internal combustion engines for the generation of heat and electricity. However, the syngas is cleaned prior to being combusted in the internal combustion engines. It has also been reported that the pyrolysis of plastic materials can produce liquid hydrocarbons, which can be distilled such that they have properties similar to petroleum-based fuels (e.g., diesel and petrol) [49][17]. Advantages of pyrolysis relative to incineration and gasification include the production of multiple valuable products (which can either be solid, liquid, or gas). Additionally, pyrolysis has the least economic concern as well as minimal environmental effects [50,51][18][19]. The major setback of this technology, however, is that to achieve optimum results, solid waste must be segregated, and suitable components must be shredded prior to pyrolysis [50][18]. Additionally, pyrolysis cannot be used in the management of all solid waste.

2.2. Biological Conversion Methods

The biological conversion methods of WtE technology use micro-organisms in carefully controlled conditions to convert MSW into biogas, consisting mainly of methane and carbon dioxide and a stabilised residue known as digestate. Anaerobic digestion/bio-methanation and microbial fuel cells (MFCs) are all biological conversion methods of WtE technology.

Anaerobic digestion (AD): AD is a mechanism in which organic matter is broken down by microorganisms in the absence of oxygen, resulting in biogas, a methane-rich gas used as a fuel, and digestate, which is a nutrient-rich fertiliser. The operating time per cycle, or how long it takes for an anaerobic digestion plant to process organic waste, is usually 15 to 30 days [52][20]. With a combined heat and power unit, the biogas, generated naturally in sealed tanks, is used to generate renewable energy in the form of electricity or heat. The bio-fertiliser is pasteurised, which can eliminate pathogens and can be applied twice a year to farmland, effectively replacing fossil-fuel-based fertilisers. This technology is commonly used in the treatment of wastewater but can also be employed in the treatment of organic waste ranging from household and industrial food wastes to manures and biofuel crops. The steps involved in the anaerobic digestion process are hydrolysis (where hydrolytic enzymes break down complex polymers into basic amino acids, sugars, and fatty acids), acidogenesis (breakdown of simple monomers into volatile fatty acids), acetogenesis (products of acidogenesis are broken down into acetic acid), and finally, methanogenesis (methane and carbon dioxide are produced) [53][21]. These steps usually take place in reactors which are enclosed systems (referred to as digesters). Elango D. et al. [54][22] estimates that 100 m3 of biogas can be generated from a tonne of MSW.

Microbial fuel cell (MFC): The MFC is a system that utilises micro-organisms to transform chemical energy into electrical energy [55][23]. A bio-cathode and/or a bio-anode are used to create these electrochemical cells, and a membrane divides the anode (where oxidation takes place) and the cathode compartments in most MFCs (where reduction takes place). In MFCs, the electrons which are produced during oxidation are directly transferred to an electrode or a redox mediator species. The electron flux is transferred from the anode to the cathode. Most MFCs oxidize an organic electron donor to produce CO2, protons, and electrons. Other electron donors, such as hydrogen or sulphur compounds, have been identified [55][23]. The cathode reaction employs several electron acceptors, the most common of which is oxygen (O2). It can be applied in power generation, biosensors, and wastewater treatment.

Waste incineration with energy recovery is reported to be the most matured WtE technologies employed worldwide [9][24]. Waste incineration with energy recovery is reported to be the most successful WtE technology employed in the EU, with Germany, France, Italy, France, the United Kingdom, and Sweden having the biggest investment in this technology [56][25]. A study indicates that in 2017 alone, a total of about 96 million tonnes of solid waste were combusted in the over 492 WtE plants [57][26] operating in the EU. Sweden is considered one of the most successful countries worldwide in terms of disposing and managing its MSW using waste incineration with energy recover. It is estimated that there are about 34 waste incineration facilities in Sweden which generates electricity to power about 250 000 homes [57,58][26][27]. It is also estimated that Sweden has been able to reduce the amount of solid waste that is sent to landfills to about 0.5%, where over 50% of the MSW generated in various households in 2017 were treated at the various waste incineration facilities operating in the country [57][26]. Another study also indicates that in 2017, the capacities of the waste incineration facilities operating in Sweden were higher than the amount of combustible MSW generated in the country [59][28]. Additionally, in the EU, it is also reported that Germany leads in the use of the waste incineration technology with regard to the electricity generation capacity from waste incineration (with a generation capacity of 1925 MW), followed by the UK and Sweden with electricity generation capacities of 925 MW and 876 MW, respectively [60][29].

Tan et al. [12][30] estimates that Japan has the highest number of waste incineration facilities in operation worldwide, with about 1900 waste incineration facilities operating in the country. These waste incineration facilities are used in the disposal and management of over 80% of the MSW generated in the country. The total power generation capacity of the various waste incineration plants in Japan is estimated to be 10,153 GWh [61][31].

In order to minimize the use of land for landfilling in China, a number of guidelines were introduced, and these guidelines encouraged the use of various WtE facilities, including waste incineration, in the disposal and management of MSW in China [62,63][32][33]. Studies [64,65][34][35] estimate that in 2019, a total of about 121.7 million tonnes of waste were combusted in various waste incineration facilities in China, generating a total of about 60.7 billion kWh of electricity, which makes China the biggest marketplace with regard to installed capacity and electricity generation for WtE technology worldwide. The use of waste incineration is reported to be also gaining popularity in most inhabited developing countries such as Brazil, Indonesia, Pakistan, Bangladesh, and Nigeria, where huge volumes of MSW are generated, and which incidentally have high energy needs [66,67,68][36][37][38].

References

- Kaza, S.; Yao, L.; Bhada-Tata, P.; Van Woerden, F. What a Waste 2.0: A Global Snapshot of Solid Waste Management to 2050; Urban Development; World Bank: Washington, DC, USA, 2018; Available online: https://openknowledge.worldbank.org/handle/10986/30317 (accessed on 3 December 2022).

- Hoornweg, D.; Bhada-Tata, P. What a Waste: A Global Review of Solid Waste Management; Urban Development Series; Knowledge Papers No. 15. World Bank: Washington, DC, USA, 2012. Available online: https://openknowledge.worldbank.org/entities/publication/1a464650-9d7a-58bb-b0ea-33ac4cd1f73c (accessed on 2 March 2022).

- Tchobanoglous, G.; Kreith, F. Handbook of Solid Waste Management, 2nd ed.; McGraw Hill Handbook; The McGraw-Hill Companies, Inc.: New York, NY, USA, 2002.

- Pérez-Gimeno, A.; Navarro-Pedreño, J.; Almendro-Candel, M.B.; Gómez, I.; Zorpas, A.A. The use of wastes (organic and inorganic) in land restoration in relation to their characteristics and cost. Waste Manag. Res. 2019, 37, 502–507.

- Geevarghese, R.; Sajjadi, S.S.; Hudecki, A.; Sajjadi, S.; Jalal, N.R.; Madrakian, T.; Ahmadi, M.; Włodarczyk-Biegun, M.K.; Ghavami, S.; Likus, W.; et al. Biodegradable and Non-Biodegradable Biomaterials and Their Effect on Cell Differentiation. Int. J. Mol. Sci. 2022, 23, 16185.

- Available online: https://www.epa.sa.gov.au/files/8437_food_waste.pdf) (accessed on 20 March 2023).

- Available online: https://www.lawinsider.com/dictionary/combustible-waste (accessed on 30 March 2023).

- National Research Council. Waste Incineration and Public Health; The National Academies Press: Washington, DC, USA, 2000.

- Daura, L.A. Electricity Generation Potential of Municipal Solid Waste in Kano Metropolis. J. Sci. Eng. Res. 2016, 3, 157–161.

- Best Practices for Solid Waste Management: A Guide for Decision-Makers in Developing Countries 2020. Available online: https://www.epa.gov/sites/default/files/2020-10/documents/master_swmg_10-20-20_0.pdf (accessed on 20 December 2020).

- Hezri, A.A. Toward 3R-Based Waste Management: Policy Change in Japan, Malaysia and the Philippines. In 3R Policies for Southeast and East Asia. ERIA Research Project Report 2009–2010; Kojima, M., Ed.; ERIA: Jakarta, Indonesia, 2010; pp. 274–290.

- Johnson, B. Zero Waste Home: The Ultimate Guide to Simplifying Your Life by Reducing Your Waste; Scribner: New York, NY, USA, 2013.

- Executive Summary, Solid Waste Conversion/Waste to Energy Technology Options June 2020, Pre-Feasibility Study Technology Assessment Waste to Energy Options. Available online: https://www.muni.org/Departments/Assembly/Documents/WTE%20Executive%20Summary%20Technology%20Assesmment%20Version%203.pdf (accessed on 21 March 2022).

- Rosen, M.A.; Dincer, I. On exergy and environmental impact. Int. J. Energy Res. 1997, 21, 643–654.

- Sikarwar, V.S.; Zhao, M.; Clough, P.; Yao, J.; Zhong, X.; Memon, M.Z.; Shah, N.; Anthony, E.J.; Fennell, P.S. An overview of advances in biomass gasification. Energy Env. Sci. 2016, 9, 2939–2977.

- Vuppaladadiyam, A.K.; Vuppaladadiyam, S.S.V.; Sahoo, A.; Murugavelh, S.; Anthony, E.; Bhaskar, T.; Zheng, Y.; Zhao, M.; Duan, H.; Zhao, Y.; et al. Bio-oil and biochar from the pyrolytic conversion of biomass: A current and future perspective on the trade-off between economic, environmental, and technical indicators. Sci. Total Environ. 2023, 857, 159155.

- Velghe, I.; Carleer, R.; Yperman, J.; Schreurs, S. Study of the pyrolysis of municipal solid waste for the production of valuable products. J. Anal. Appl. Pyrolysis 2011, 92, 366–375.

- Mohan, D.; Pittman, C.U., Jr.; Steele, P.H. Pyrolysis of wood/biomass for bio-oil: A critical review. Energy Fuels 2006, 20, 848–889.

- Katyal, S. Effect of carbonization temperature on combustion reactivity of bagasse char. Energy Sources Part A 2007, 29, 1477–1485.

- Final Report 2003, an Introduction to Anaerobic Digestion of Organic Wastes. Available online: http://report4_final.doc (accessed on 20 November 2022).

- Vázquez-Fernández, A.; Suárez-Ojeda, M.E.; Carrera, J. Review about bioproduction of Volatile Fatty Acids from wastes and wastewaters: Influence of operating conditions and organic composition of the substrate. J. Environ. Chem. Eng. 2022, 10, 107917.

- Elango, D.; Pulikesi, M.; Baskaralingam, P.; Ramamurthi, V.; Sivanesan, S. Production of biogas from municipal solid waste with domestic sewage. J. Hazard. Mater. 2007, 141, 301–304.

- Beylier, M.R.; Balaguer, M.D.; Colprim, J.; Pellicer-Nàcher, C.; Ni, B.J.; Smets, B.F.; Sun, S.P.; Wang, R.C. 6.22—Biological Nitrogen Removal from Domestic Wastewater. In Comprehensive Biotechnology, 3rd ed.; Moo-Young, M., Ed.; Elsevier: Pergamon, Turkey, 2011; pp. 285–296. ISBN 9780444640475.

- Dong, J.; Tang, Y.; Nzihou, A.; Chi, Y.; Weiss-Hortala, E.; Ni, M.; Zhou, Z. Comparison of waste-to-energy technologies of gasifification and incineration using life cycle assessment: Case studies in Finland, France and China. J. Clean. Prod. 2018, 203, 287–300.

- Hu, Y.; Cheng, H.; Tao, S. The growing importance of waste-to-energy (WTE) incineration in China’s anthropogenic mercury emissions: Emission inventories and reduction strategies. Renew. Sustain. Energy Rev. 2018, 97, 119–137.

- Waste-to-Energy Plants in Europe in 2017. Available online: https://www.cewep.eu/waste-to-energy-plants-in-europe-in-2017/ (accessed on 20 July 2022).

- Available online: https://www.bbva.com/en/sustainability/5-best-recycling-practices-from-around-the-world/ (accessed on 10 March 2023).

- European Commission. Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions: The Role of Waste-to-Energy in the Circular Economy. 2017. Available online: https://ec.europa.eu/docsroom/documents/27321/attachments/1/translations/en/renditions/native (accessed on 30 March 2022).

- Michaels, T.; Krishnan, K.; Energy Recovery Council. Directory of Waste to Energy Facilities 2019. Available online: http://energyrecoverycouncil.org/wp-content/uploads/2019/01/ERC-2018-directory.pdf (accessed on 22 January 2023).

- Tan, S.T.; Ho, W.S.; Hashim, H.; Lee, C.T.; Taib, M.R.; Ho, C.S. Energy, economic and environmental (3E) analysis of waste-to-energy (WTE) strategies for municipal solid waste (MSW) management in Malaysia. Energy Convers. Manag. 2015, 102, 111–120.

- Available online: https://www.statista.com/statistics/689771/japan-power-density-generated-by-waste-incineration/#statisticContainer (accessed on 11 February 2023).

- Han, Z.; Ma, H.; Shi, G.; He, L.; Wei, L.; Shi, Q. A review of groundwater contamination near municipal solid waste landfill sites in China. Sci. Total Environ. 2016, 569, 1255–1264.

- Ji, L.; Lu, S.; Yang, J.; Du, C.; Chen, Z.; Buekens, A.; Yan, J. Municipal solid waste incineration in China and the issue of acidification: A review. Waste Manag. Res. 2016, 34, 280–297.

- China Electricity Council (2019) China Annual Statistic Report on Electricity. Available online: https://cec.org.cn/detail/index.html?3-292822 (accessed on 11 January 2023).

- National Bureau of Statistics of China (2020) China Statistical Yearbook. 2020. Available online: http://www.stats.gov.cn/tjsj/ndsj/2020/indexch.htm (accessed on 3 April 2023).

- Lino, F.A.M.; Ismail, K.A.R. Evaluation of the treatment of municipal solid waste as renewable energy resource in Campinas, Brazil. Sustain. Energy Technol. Assess. 2018, 29, 19–25.

- Mia, S.; Uddin, M.E.; Kader, M.A.; Ahsan, A.; Mannan, M.A.; Hossain, M.M.; Solaiman, Z.M. Pyrolysis and co-composting of municipal organic waste in Bangladesh: A quantitative estimate of recyclable nutrients, greenhouse gas emissions, and economic benefits. Waste Manag. 2018, 75, 503–513.

- Starostina, V.; Damgaard, A.; Eriksen, M.K.; Christensen, T.H. Waste management in the Irkutsk region, Siberia, Russia: An environmental assessment of alternative development scenarios. Waste Manag. Res. 2018, 36, 373–385.

More