Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is a comparison between Version 1 by Gali Madhavi Latha Latha and Version 2 by Sirius Huang.

Geocells, which are polymeric interconnected cells filled with soil, provide excellent support to loads through all-round confinement and a beam effect; hence, they are extensively used in various geotechnical applications such as embankments, foundations, pavements, slopes, railways, and reinforced earth (RE) walls.

- geocells

- geometry

- reinforcing parameters

- pavements

1. Introduction

Since the 1970s, geocells are being widely used in various applications of geotechnical engineering. The idea of a cellular confinement system was originally developed by US army corps of engineers for the ease of transport of military vehicles over weak subgrades [1]. The first cellular confinement systems were made of paper, which were later replaced by aluminum and wooden cells [2][3][2,3].

The modern form of geocells came into existence since 1980s. Unlike planar textiles and grids, geocells, which are three-dimensional networks of cells filled with a choice of soil, provide added benefits such as all-round confinement through hoop stresses developed in the cells and a beam effect resulting from their stiff-mat configuration. Geocells, by virtue of their shape and depth, provide greater load-bearing capacity and reduce lateral deformations in soils confined by them under static and cyclic loading scenarios [4][5][6][7][4,5,6,7]. The inclusion of geocells in various structures has additional benefits such as stability improvement, climate resilience, higher resistance to cyclic loads, erosion control, basal support, and savings in time and cost [4][8][4,8]. Because of these merits, geocells are extensively used in pavements, slopes, foundations, embankments, and reinforced earth (RE) walls. Recently, geocells have also found application in heavy-duty highways and high-speed trains [5][6][5,6].

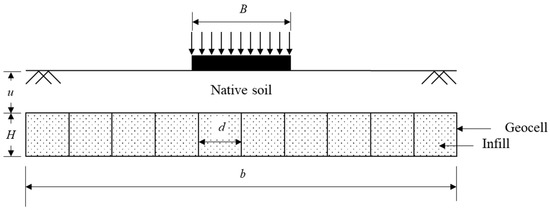

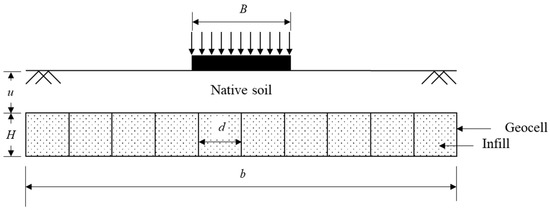

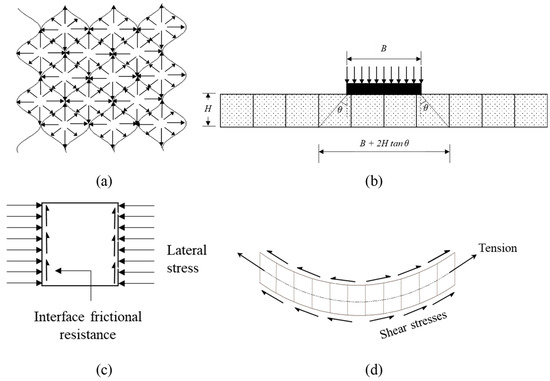

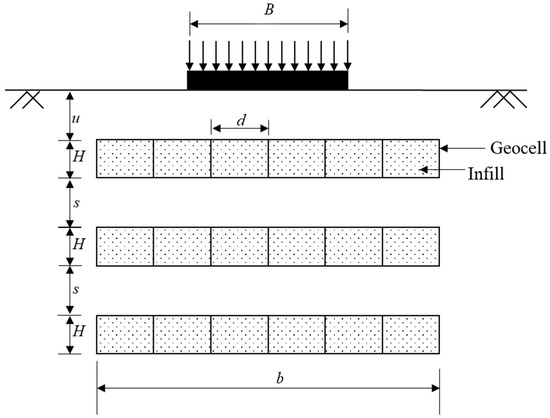

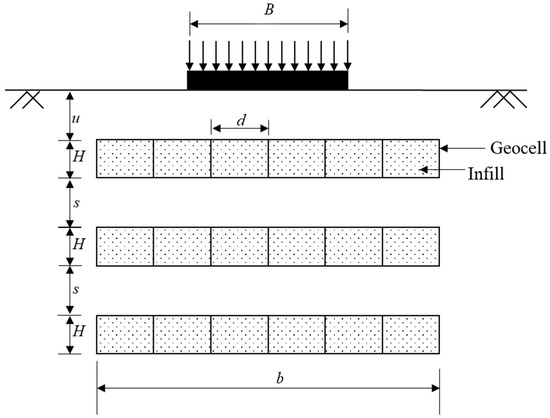

The mechanism of geocell reinforcement has been investigated by many researchers through experimental, numerical, and analytical studies. In a network of geocells, each cell is surrounded by several neighboring cells, and all the cells are filled with soil. With the application of external load, the soil inside the geocell pushes the cell wall, resulting in the development of an additional confining stress along the wall [4][8][9][10][4,8,9,10]. The additional confinement is translated into apparent cohesion, thereby increasing the shear strength of the soil, and preventing its lateral spread [11]. Furthermore, the extension of cell walls is opposed by the lateral stresses from the neighboring cells, causing the interconnected network of geocells to act as a cushion or stiffened mattress with higher strength and stiffness. This beam action redistributes the externally applied loads over a wider area and, thus, reduces the magnitude of stresses acting on the underlying soil [12]. This stiffened soil–geocell composite also hinders the propagation of the failure surface into the underlying soil [13]. Furthermore, at large displacements, the geocell layer acts as a tensioned membrane, providing sufficient upward resistance to the applied loads and, thus, reducing the stresses on the underlying soil [12][14][12,14]. A schematic representation of a geocell-reinforced soil bed is shown in Figure 1. In this figure, B represents the width of the foundation, u represents the depth of the geocell layer from the ground surface, and H, d, and b represent the height, pocket size, and width of the geocell layer, respectively. Various mechanisms responsible for the reinforcing action of geocells are presented in Figure 2. In this figure, θ represents the angle of load dispersion.

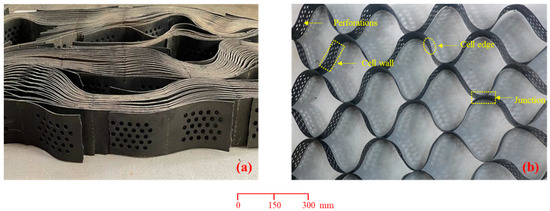

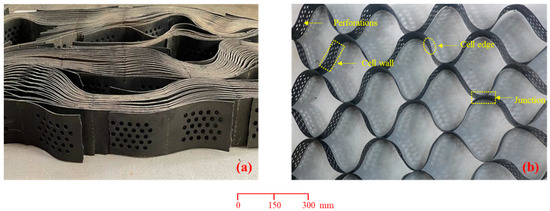

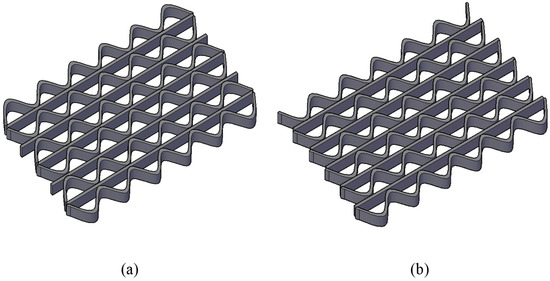

Figure 3 shows a photograph of the latest form of commercially available honeycomb-shaped geocells available at the Indian Institute of Science, Bangalore. Figure 3a shows the collapsed form of geocells, which helps in stacking large volumes of geocells in a compact form. In Figure 3b, an expanded form of a geocell layer is shown, and the cell wall, junctions, and perforations are marked. Geocells took almost five decades to evolve geometrically to their current versatile configuration. Historically, geocell layers were fabricated onsite using planar geosynthetics such as geotextiles and geogrids by strategically connecting the cells and filling them with granular soils [15]. Initially, resins and additives were used to connect the cells, which were chronologically replaced by bodkin joints, photo lamination, and ultrasonic welding in the most recent form of commercial geocells. Similarly, the geometric shape of the geocells has also undergone several transformations from square, circular, rectangular, diamond, and hexagonal to honeycomb. Furthermore, the cell material also evolved from paper, aluminum, and wood to polymer [3]. Currently, solid or perforated high-density polyethylene (HDPE) and novel polymeric alloy (NPA) are the commonly used polymers to manufacture geocells. However, the latter is more popular due to its greater flexibility, thermo-plasticity, and surface texture [16].

Figure 3 shows a photograph of the latest form of commercially available honeycomb-shaped geocells available at the Indian Institute of Science, Bangalore. Figure 3a shows the collapsed form of geocells, which helps in stacking large volumes of geocells in a compact form. In Figure 3b, an expanded form of a geocell layer is shown, and the cell wall, junctions, and perforations are marked. Geocells took almost five decades to evolve geometrically to their current versatile configuration. Historically, geocell layers were fabricated onsite using planar geosynthetics such as geotextiles and geogrids by strategically connecting the cells and filling them with granular soils [15]. Initially, resins and additives were used to connect the cells, which were chronologically replaced by bodkin joints, photo lamination, and ultrasonic welding in the most recent form of commercial geocells. Similarly, the geometric shape of the geocells has also undergone several transformations from square, circular, rectangular, diamond, and hexagonal to honeycomb. Furthermore, the cell material also evolved from paper, aluminum, and wood to polymer [3]. Currently, solid or perforated high-density polyethylene (HDPE) and novel polymeric alloy (NPA) are the commonly used polymers to manufacture geocells. However, the latter is more popular due to its greater flexibility, thermo-plasticity, and surface texture [16].

The present-day configuration of honeycomb geocells enables them to enclose maximum infill with a minimum perimeter of cells [8]. While manufacturing geocells, surface texture is imparted to the geocells, as shown in Figure 3, to enable them to mobilize greater interfacial shear strength when they are in contact with soils [17]. The postmortem analysis of geocells from various model tests showed that the junctions of the geocells remained intact even when local straining and buckling were observed in geocell walls [18][19][18,19]. Furthermore, the perforations present on the geocell walls (refer to Figure 3) facilitate easy drainage to dissipate pore pressures that develop inside the cells. These perforations also provide adequate interlocking between infill soils of adjacent geocells so that the geocell-reinforced soil behaves like a stiffened composite mass [20]. The perforations on cell walls also facilitate root growth within the cells, which is beneficial when vegetation is grown on geocell walls and slopes. The total pore area of the perforations is typically 6–22% of the unit area of the geocell wall. Table 1 presents the typical range of geometric and mechanical properties of commercial geocells reported by earlier studies [8][16][8,16] and geocell manufacturing companies.

The present-day configuration of honeycomb geocells enables them to enclose maximum infill with a minimum perimeter of cells [8]. While manufacturing geocells, surface texture is imparted to the geocells, as shown in Figure 3, to enable them to mobilize greater interfacial shear strength when they are in contact with soils [17]. The postmortem analysis of geocells from various model tests showed that the junctions of the geocells remained intact even when local straining and buckling were observed in geocell walls [18][19][18,19]. Furthermore, the perforations present on the geocell walls (refer to Figure 3) facilitate easy drainage to dissipate pore pressures that develop inside the cells. These perforations also provide adequate interlocking between infill soils of adjacent geocells so that the geocell-reinforced soil behaves like a stiffened composite mass [20]. The perforations on cell walls also facilitate root growth within the cells, which is beneficial when vegetation is grown on geocell walls and slopes. The total pore area of the perforations is typically 6–22% of the unit area of the geocell wall. Table 1 presents the typical range of geometric and mechanical properties of commercial geocells reported by earlier studies [8][16][8,16] and geocell manufacturing companies.

Figure 1.

Schematic representation of geocell reinforced foundation bed.

Figure 2. Mechanisms of geocell reinforcement: (a) confinement effect (plan view); (b) stress dispersion effect (sectional elevation); (c) lateral resistance effect on a single geocell (front view); (d) membrane effect (sectional elevation).

Figure 3.

Commercially available geocells: (

a

) collapsed form; (

b

) expanded form.

Table 1.

Typical properties of commercial geocells.

| Property | Value |

|---|---|

| Density | 0.932–0.95 g/cm3 |

| Strip width | 50–300 mm |

| Strip thickness | 1.53 mm (±10%) |

| Percentage of perforations to cell wall area | 6–22% |

| Ultimate tensile strength | 16–25 kN/m |

| Junction peel strength | 7–10 kN/m |

| Elongation at maximum load | 20% (±15%) |

| Dynamic modulus at service temperature (−60 °C to 60 °C) | 650–800 MPa |

| Resistance to UV degradation | 250–400 min |

| Cumulative permanent deformation (creep resistance) | 2.7–3.5% |

2. Geocell Configuration

The reinforcement efficiency of geocells is mainly governed by the geocell configuration, geocell material properties, and soil properties. This section presents a detailed discussion on the evolution of geocells with variations in the parameters grouped under these three categories. Various studies that dealt with the variation in geocell geometry and configuration are reviewed, and the individual and combined effects of these parameters are discussed in light of the published papers. The geocell configuration mainly pertains to the shape, size, quantity, and location of geocells. The various factors that define the configuration are the height (H), overall width (b), pocket shape, and pocket opening size (d), which is the diameter of the equivalent circle, the pattern of arrangement in the case of geocells made of geogrids, embedment depth (u), and the number of geocell layers, as depicted in Figure 2. Since geocells improve strength through friction and interlocking, their height, width, and pocket size play a pivotal role in their reinforcing action. The number of geocell layers (N) becomes an important parameter only at higher levels of external loads applied on weak soils.

2.1. Height of the Geocells (H)

Several studies are available in the literature on the influence of the height of geocells on their performance. In all these studies, the performance of the geocell-reinforced structures improved with an increase in the height of the geocells up to an optimum value; thereafter, it either stabilized or declined. As height increases, the surface area of geocells increases, and the frictional resistance also increases, which helps in arresting the downward movement of the soil [16][21][16,21]. Furthermore, the increase in the height of the geocells enables the geocell-reinforced soil to act as a composite body, providing anchorage, as shown in Figure 2. It also increases the bending and shear rigidity of geocell-reinforced structures due to an increase in the moment of inertia, which redistributes the overlying load to a larger area, resulting in enhanced load-carrying capacity and reduced settlements in the underlying soil [17][22][23][24][25][17,22,23,24,25]. The increased rigidity offered by the geocell-reinforced soil composite from the increased height of the geocells provides adequate confinement to the infill soil, which prevents lateral displacements [23][24][26][27][23,24,26,27]. Moreover, the interlocking resistance at the soil–geocell interface increases with the height of the geocells, which effectively resists the downward drag developed during the application of external loads [18][24][18,24]. However, after a certain height, local buckling and straining of geocell walls immobilize the increment in flexural and shear rigidity of the geocells; thus, the loads are not effectively transferred through the geocell layer, leading to a deterioration in performance [23][24][25][28][29][30][23,24,25,28,29,30]. Furthermore, the height of geocells beyond the pressure bulb below the foundation can be considered dormant [31]. The optimum depth of geocells is always less than twice the width of the footing, as validated in most of the available studies [17][18][24][27][32][33][17,18,24,27,32,33]. Additionally, the increasing height of geocells poses problems related to compaction in the field, reducing the density of the infill soil [27][31][27,31].

Studies showed that geocells with smaller heights usually behave as flexural members, and that, with an increase in height, they exhibit deep beam behavior [13][34][13,34]. The tensile strength mobilized through the membrane action of geocells also adds to the improvement in performance with an increase in the height of geocells [28]. For a relatively smaller height of the geocells, linear variation of strains was observed along the depth of the geocells, resulting in maximum strain at the bottom. However, for larger heights, the maximum strain was observed at the top and decreased toward the bottom of the geocell mattress, as observed by Dash et al. [13] in plate load tests. This behavior is analogous to the variation of flexural strains along the depth of shallow and deep beams. A geocell layer of smaller height behaved as a centrally loaded thin beam under loads with compressive strains at the top and tensile strains at the bottom [35]. However, with an increase in depth, the tensile strains increase and propagate throughout the depth of the geocells. Thus, the frictional and passive resistance derived from the deep beam behavior of taller geocells was sufficient enough to hold them against the downward drag of the load and, hence, reduced the magnitude of stresses transmitted to the underlying soil [35]. These observations agree with the studies of Cheung and Chan [36] on concrete beams with different span-to-depth ratios.

The observations on the performance of geocells with varying heights are also applicable to cyclic loading. Studies on geocell-reinforced pavements showed that the cumulative permanent deformations (CPD) decreased with an increase in the height of the geocells. For shorter geocells, the flexural stiffness was relatively smaller, resulting in greater CPDs, whereas taller geocells provided enough structural support to restrain the CPDs. This also enhanced the resilient characteristics of the geocells, resulting in greater traffic benefit ratio [37].

2.2. Pocket Size or Aperture Opening Size (d)

Since the pocket size of the geocells is inversely proportional to the confining stresses developed in the infill soil, the decrease in the pocket size of geocells increases the additional confining stresses offered by the cells per unit volume of the soil, increasing the apparent cohesion [8][27][35][38][8,27,35,38]. Thus, the infill soil gets restrained within the geocell pockets due to increased confining stress, leading to controlled settlements and heaves in geocell-reinforced structures [7][22][27][7,22,27]. While it is intuitive to think that a decrease in pocket size results in an overall improvement in the performance of geocells due to a higher reinforcement effect, the literature shows that these correlations are not always true. The performance of geocell-reinforced structures improves with the decrease in the pocket size of geocells up to a certain optimum value and then stabilizes or declines thereafter. Furthermore, the decrease in the pocket size of geocells increases their surface area, which increases the active lateral pressure developed within the geocell wall, thereby enhancing the overall rigidity offered by the geocell reinforced soil composite [28][39][28,39]. However, beyond a certain value, the improvement in performance is negligible. A decrease in the pocket size develops a large amount of counteracting membrane stresses along the geocell walls, resulting in their local buckling and straining, which in turn reduces the flexural and shear rigidity offered by the geocells [13]. Additionally, decreasing the pocket size of geocells poses practical problems for compaction in the field.

2.3. Aspect Ratio of Geocells (H/d)

The aspect ratio of geocells is defined as the height ratio of the geocells to their pocket size. Since the aspect ratio of geocells can be varied by altering either the height of the geocells or their pocket size, the effects of the height and pocket size of geocells described in previous sections can also be viewed through the lens of a change in aspect ratio. Even though many studies are available on the effects of height and pocket size of geocells on their performance, studies specific to aspect ratio are rare [22][40][22,40].

The performance of a geocell-reinforced bed, in general, improves with an increase in the height or a decrease in the pocket size of geocells, as discussed earlier. However, this does not imply that increasing the aspect ratio continuously improves the performance of geocells. The literature presents strikingly contrasting observations regarding the optimum value of aspect ratio. While plate load tests on foundations carried out by Dash et al. [22] suggested that the optimum aspect ratio of geocells is 1.67, results from embankment model studies of Krishnaswamy et al. [40] showed that the optimum aspect ratio is close to unity. The optimum aspect ratio is seen to be a function of geocell configuration, geocell type, foundation properties, and loading [22].

2.4. Width of Geocell Layer (b)

Stresses in soils due to imposed loads on the ground are not just vertically below the load; they follow specific distribution that extends beyond the loaded area. Hence, the reinforcement provided in the soil must at least cover the stressed soil zone and ideally project a little beyond the stressed zone to have adequate anchorage and bonding. Geocell reinforcement layers are usually provided to widths (b) extending beyond the loaded area. The literature suggests that the performance of geocell-reinforced structures increases with the increase in the width of the geocell layer until a certain optimum value, beyond which the effects are negligible. The increase in the width of the geocells increases the rigidity offered by the geocells through the end bearing resistance derived from the enhanced confinement of geocell infill soil composite. Hence, the load is distributed over a larger area of the underlying soil [18][23][39][18,23,39]. This is one of the much-valued benefits of geocell reinforcement because the zone of influence of the load gets truncated slightly below the geocell layer, unlike in the case of the unreinforced soil, where it extends to about twice the width of the loaded area. Furthermore, wider geocell layers have higher quantities of cells contributing to the reinforcement effect, which is another reason for the improved performance [32]. Wider geocells result in less propagation of the failure wedge into the underlying soil and, hence, less surface heaving [22][23][28][39][22,23,28,39]. However, large widths induce local buckling and straining of geocell walls, which dampen the effects of flexural and shear rigidity of the geocells [23]. Analysis of the exhumed geocells after load tests showed higher strains and buckling-type deformations predominantly in the regions under and around the loaded area [23], while the portions of geocell mattress that are far from the load remained intact [13]. Extending geocells beyond the influence zone of footings is beneficial to derive secondary anchorage via frictional and passive resistance at the soil–geocell interface [22][25][39][22,25,39].

In a geocell mattress below a foundation, the maximum tensile strain developed at the center of the footing, and the strains in the geocells reduce rapidly with the increase in the radial distance from the center of the footing. Furthermore, compressive strains were observed to develop at both edges if the width of the geocell mattress was relatively large compared to the width of the footing [13]. When the width was lower, the geocell mattress behaved like a slender column in which the load transfer mechanism was similar to that of a pile. With an increase in the width, it behaved like a composite beam, redistributing the footing load over a larger area [7]. As observed from several studies, the optimum width ratio, which is defined as the ratio of the width of the geocell layer (b) to the width of the footing (B), must be between 4 and 5 to derive maximum improvement in load-bearing performance. This range seems to be logical, considering that the zone of influence of a footing can extend up to twice its width on either side of its central line. Providing layer widths beyond 5B is not beneficial, as asserted by several researchers [7][22][25][28][30][39][40][7,22,25,28,30,39,40].

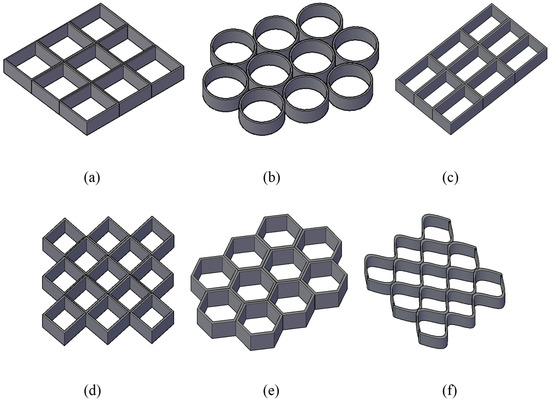

2.5. Pocket Shape of the Geocells

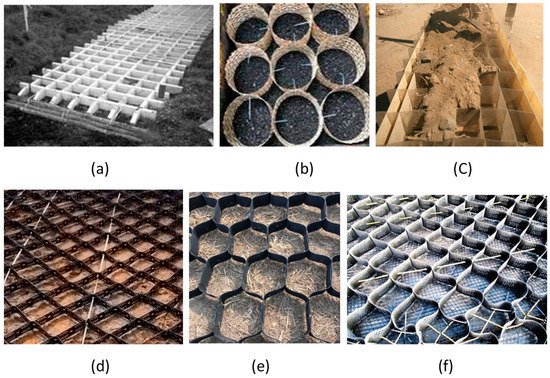

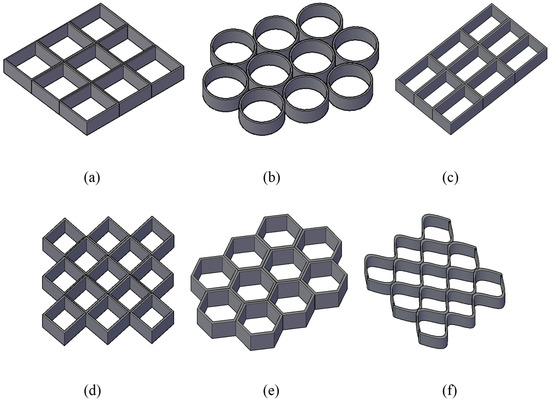

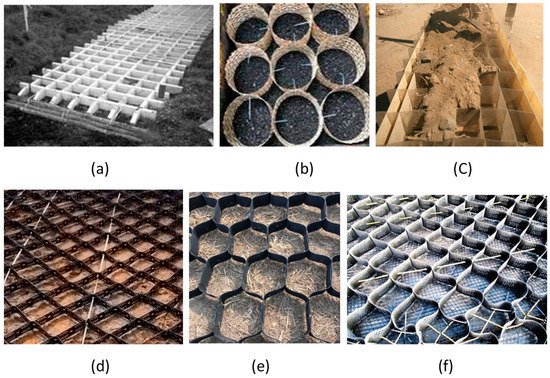

The geometric shape of the geocells has also undergone several transformations from square, circular, rectangular, diamond, and hexagonal to honeycomb. A schematic representation of different pocket shapes of geocells used in some of the earlier studies is shown in Figure 45. Photographs of geocells with different pocket shapes are shown in Figure 56.

The earliest studies on geocells used circular or square-shaped geocells [3][41][3,41]. Studies suggest that the square-shaped and circular geocells made up of the same material provide similar improvement if the quantity of material used is the same [27]. The shape of the geocells evolved into the current shape of honeycomb to enclose maximum infill material with minimum perimeter of cells [17]. Moreover, the honeycomb shape facilitates the easy collapse of cells to store greater volumes of geocells in smaller spaces and helps in easy handling and transport. Most of the commercially available geocells today are honeycomb-shaped. Other advantages of the honeycomb shape are its ability to stay intact under vertical loads and its effectiveness in controlling the vertical and horizontal deformations of geocells, even when the cells are filled with marginal soils [45].

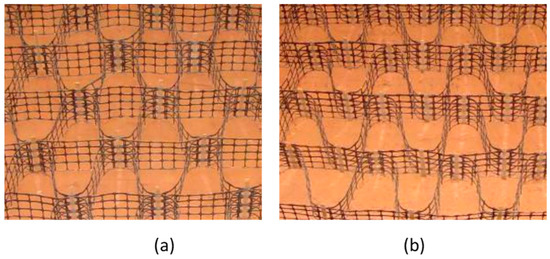

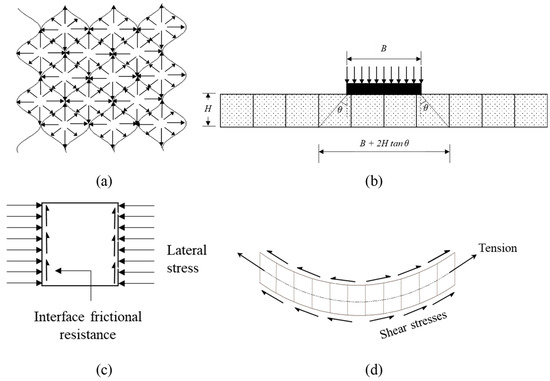

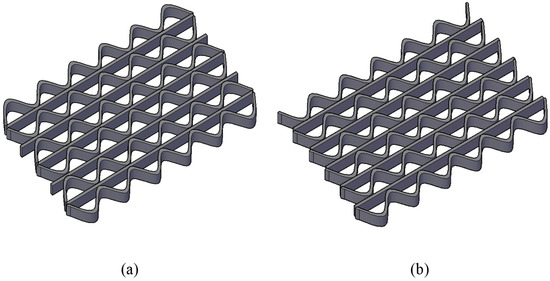

2.6. Pattern of Arrangement

The pattern of arrangement is relevant to geocells fabricated onsite using geogrids. This fabrication can be established in two different patterns, namely, diamond and chevron patterns, as schematically shown in Figure 67. Photographs of geocells fabricated in these two patterns are shown in Figure 78. In both these patterns of arrangement, geogrid strips are vertically erected in the transverse direction first, and diagonal strips are then inserted between the transverse grids using bodkin joints [22][40][22,40]. The chevron pattern is better compared to the diamond pattern because it has more joints; thus, failure of some joints may not lead to the failure of the entire mattress. Since the number of joints is more in a chevron pattern, it offers greater rigidity for the same plan area of the geocells. Moreover, the joints in the chevron pattern are easier to form than diamond pattern as the former involves the connection of only two vertical surfaces, whereas the latter has connections involving three grids [40]. Furthermore, studies show that the chevron pattern offers more flexural rigidity than the diamond pattern in geocell-reinforced foundations, especially at higher settlements. When the soil fails in shear at large settlements, the soil surrounding the geocells starts to deform and move upward to surface heave, thus lowering the density of the geocell infill. Under these conditions, a major proportion of the applied load is taken by the geocell walls. Thus, the chevron pattern with higher flexural rigidity offers greater support to loads than the diamond pattern at large settlements [22].

Figure 67.

Schematics of different patterns of geocells fabricated using geogrids: (

a

) diamond; (

b

) chevron.

2.7. Embedment Depth of Geocells (u)

The value of optimum embedment depth of geocells cannot be generalized as it is a function of the applied load, height of the geocell layer, geocell pocket size, type of soil, and number of geocell layers [47]. However, the significance of embedment depth is well recognized. If the geocell layer is placed just below the footing, localized stresses of higher magnitudes accumulate in the geocell walls, leading to buckling failure [27]. Moreover, shallow placement restricts the mobilization of adequate confinement within the geocells and interface friction at the top and bottom of the geocell layer because of the reduction in normal stress due to overburden [26][42][48][49][26,42,48,49].

The soil cushion between the footing and the geocell layer and in between two geocell layers enables the development of effective friction at geocell–soil interfaces. The soil cushion, along with the geocell-reinforced soil composite, behaves as a rigid system, which enables the distribution of the load over a wider area of the underlying soil [13][24][26][27][28][29][50][13,24,26,27,28,29,50]. The load dispersion mechanism offered by the sand cushion is evident from the measured strains along the height of the geocell wall. The horizontal strains were observed to decrease from a maximum value at the top to a minimum value at the bottom, when the geocell layer was placed at the optimum depth [13]. The soil cushion not only guards the geocell layer from the direct application of loads but also facilitates drainage during the consolidation of the underlying soft soil [23][25][23,25]. The soil cushion was found to be effective even under cyclic loading conditions [44]. However, at embedment depths lower than the optimum, the depth of the soil cushion was not sufficient for the mobilization of frictional resistance against shearing; thus, the particles in the cushion squeezed out, resulting in the poor performance of geocell reinforcement [24][27][24,27]. At embedment depths greater than the optimum, the composite beam-like behavior of geocells vanishes, and the top cushion and the geocell-reinforced soil behave as two separate entities, leading to the shearing of the topsoil cushion. Thus, the soil lying between the footing and the geocell-reinforced soil composite squeezes out laterally, leading to their poor performance. Moreover, the overlying load also has a direct effect on to the underlying geocell reinforced soil composite [13][22][27][13,22,27]. Furthermore, at greater embedment depths, a major portion of the geocell-reinforced soil composite lies outside the zone of influence of the applied loading. Thus, the reinforcing effect is completely nullified, and the geocell-reinforced soil starts to behave as an unreinforced soil [24][25][26][47][49][24,25,26,47,49]. This behavior is observed when the embedment depths are generally greater than the width of the applied loading. Studies with soil cushions made of cohesive soils suggest that it is beneficial to place the footing load directly on the geocell mattress without any soft soil cushion so that the lateral squeezing of the cohesive soil can be avoided [23].

2.8. Number of Geocell Layers (N)

Figure 89 shows a schematic diagram of a foundation reinforced with multiple geocell layers. An increase in the number of geocell layers results in improved performance because of increased soil–geocell contact area, which can contribute to significantly higher frictional resistance, enhanced confinement effect, and its homogeneous stress distribution below the foundation [49][50][49,50]. Furthermore, with more geocell layers, the volume of soil under the reinforcement effect increases, resulting in an overall increase in stiffness [16][19][16,19]. With multiple geocell layers below the loaded area, the entire pressure bulb within the ground can be encased within the geocell reinforcement, thus completely arresting the lateral and vertical deformations [31][50][31,50].

Figure 89.

Soil beds reinforced with multiple geocell layers.

However, the installation of multiple geocell layers requires deeper excavation and filling, which significantly increases the cost of the project. Since geocell reinforcement is provided for shallow foundations and pavements, such deeper excavations are not feasible most of the time. Hence, it is very important to strike a balance between the number of geocell layers and the cost while designing the geocell reinforcement. Furthermore, the literature suggests that the beneficial effects of geocell reinforcement do not linearly increase with the increase in the number of geocell layers beyond a limit [51]. The geocell layers provided below the zone of influence of the load are not subjected to any significant stresses due to the applied load; hence, their contributions to the overall strength and stiffness improvement are minimal [31]. Studies suggest that the geocell layers must be placed in a way that they lie within the influence zone of the applied loads [52].

The resilient characteristics of geocells such as accumulated plastic strains and total settlement of the reinforced bed were reported to improve with the number of geocell layers. Similar to static loading conditions, their improvement became maximum at a particular optimum number; thereafter, their influence was minimal with a further increase in geocell layers. As the number of geocell layer increases, the energy absorbance characteristics offered by them under cyclic loading increase, thus reducing the magnitude of stresses and shocks transferred to the underlying soil [47]. However, unlike static loading conditions where the rate of improvement was higher at higher settlement levels, it became insignificant at higher number of load cycles for heavily reinforced systems during cyclic loading conditions [26][42][48][50][53][26,42,48,50,53].

Multiple layers of geocell are usually placed at a vertical spacing between them so that the interactions with the soil are maximum. However, Kargar and Hoessini [39] studied the influence of two- and four-layered geocells without any spacing between them and found that the increase in the number of geocell layers decreased the strength and stiffness characteristics of geocell-reinforced soil beds. In reinforced foundation beds with two geocell layers, tensile strains developed at the lower portion of the geocells broke the continuity of these cells and separated them into individual cells. Due to this discontinuity, the relative sliding between the layers hampered their integrated performance; thus, stresses could not be effectively transferred to greater depths of the underlying soil [52]. Similarly, in the case of reinforced beds with four geocell layers, it was found that the tensile strains in the geocells were not completely mobilized, resulting in a lower improvement in their strength and deformation characteristics. These observations contradict the observations made by earlier researchers with multiple geocell layers separated by a layer of soil.

Mehdipour et al. [49] studied the influence of number of geocell layers in a slope on the factor of safety (FOS) through numerical simulations. It was observed that the FOS of geocell-reinforced slope increased with an increase in the number of geocell layers by increasing the rigidity, which helped in pushing the slip surface away from the slope. While the first geocell layer was found to develop more resistance against the bending and shear deformations of the slope, the remaining layers mainly contributed to the resistance against lateral deformations [49].