Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is a comparison between Version 1 by Kaushik Rajashekara and Version 2 by Camila Xu.

Subsea oil and gas (O&G) exploration demands significantly high power to supply the electrical loads for extraction and pumping of the oil and gas. The energy demand is usually met by fossil fuel combustion-based platform generation, which releases a substantial volume of greenhouse gases including carbon dioxide (CO2) and methane into the atmosphere.

- offshore

- O&G

- emission

- renewable

- direct electric heating

1. Introduction

The growing trend of energy demand has increased the drilling and exploration of remote offshore oil and gas (O&G) fields. Globally, nearly 1500 oil and gas rigs are located offshore, the largest share of which are in the North Sea and the Gulf of Mexico. Offshore oil and gas deposits are typically much larger than those found on the land. Offshore deep-water O&G production systems need to incorporate high-capacity electric submersible pumps and compressor motors at the seabed, which demand considerable electrical power. Power requirements can be of the order of several hundreds of MW depending on the number of subsea loads. The recent trend in the O&G industry is to install subsea processing loads on the seabed to reduce the required space on the platform or even remove the platform. There are several advantages to installing power converters and equipment close to the loads.

The installation and operation of subsea electrical systems on the seabed have various challenges [1]. The pressure increases by 10 bars (about 145 PSI) for every 100 m depth in the ocean. If all the systems including power electronics and motors need to be located at a water depth of about 3000 m, they have to withstand 300 bars of pressure. Hence, all electrical systems have to be designed and qualified to withstand high pressure. As seawater acts like a conductor and is corrosive, proper isolation between the electrical equipment and seawater must be provided. Also, as the equipment is located at depths of about 3000 m, post-fault maintenance and repair will be challenging and will not be possible without bringing the equipment to the surface. However, relocation of the equipment to the surface is expensive and results in long production outages. The technology for locating all the electrical equipment including the power electronics is still in the early stages of development by organizations like SINTEF in Norway. Hence, only the subsea pumps, gas compression, boosting, and water injection are generally located on the sea floor, and the power is supplied from a topside platform, including that for the downhole electric submersible pump (ESP) [2].

2. Efficiency Improvement of Platform Power Generation

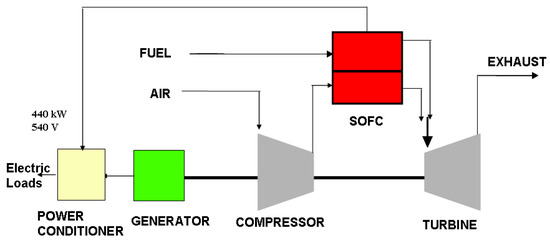

Gas turbine-based efficiency can be improved by capturing and using the waste heat from the gas turbine using a bottoming steam Rankine cycle [3][13]. Power generation using this combined cycle approach can be increased by 30%, and the overall plant efficiency can be as high as 50%. However, the energy loss is still significantly large in a combined-cycle gas turbine-based system, and the processing integration can be challenging, resulting in a sub-optimal emission reduction solution. The average CO2 emissions from a natural gas-fired, combined-cycle power plant are approximately 0.46 metric tons of CO2 per MWh of electricity generated. The integration of carbon capture and storage units in subsea processing systems has been investigated, with an incremental improvement in the exergy index [4][14]. Emission reduction in platform power generation with the use of renewable energy sources can be achieved using hybrid fuel cell power generation systems. This could be incorporated by combining a high-temperature solid oxide fuel cell (SOFC) with the gas turbine, which would increase the overall cycle efficiency while reducing per-kilowatt emissions. The combined system has far greater efficiency than could be provided by either system operating alone. Combining higher efficiencies combined with low emissions, hybrid systems are a good choice for reducing platform-based emissions due to power generation. A high-level architecture of a SOFC/gas turbine hybrid system is shown in Figure 12. In this hybrid power system, a compressor and heat exchanger are included with the turbine. The ambient air is compressed and supplied to the cathode of the SOFC, and the anode is supplied from the fuel, which is reformed to hydrogen. The exhaust of the SOFC, at a high temperature of about 800 °C to 1000 °C, is supplied to the turbine, which causes the desired heat and pressure difference suitable to drive the turbine. The turbine-driven generator output can be combined with the fuel cell output to supply power to subsea loads. This type of hybrid generation can achieve much higher efficiency, of the order of 65% to 70%, compared to the gas turbine or SOFC operating alone. Also, the emission per kW is reduced significantly. A hybrid fuel cell-gas turbine-based approach has also been explored for CO2 capture in platform generation [5][6][15,16]. If SOFC is used, the fuel cell can directly use the locally generated natural gas with external or internal reforming to generate power. As per the need, the same SOFC can be combined with a gas turbine to increase the overall efficiency as shown in Figure 12. However, a polymer electrolyte membrane (PEM) fuel cell can also be used if the green hydrogen is generated with excess wind power using electrolysis. The reformed hydrogen can also be used for the PEM fuel cell after further purification.

3. Integration of Offshore Renewable Energy Sources to Power Offshore Loads

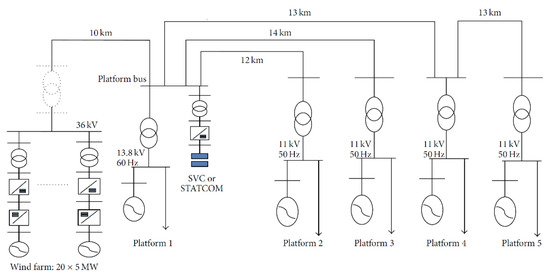

Offshore energy resources can be mainly categorized as offshore wind and ocean renewable energy. Ocean renewable energy (ORE) is broadly defined as all the feasible energy sources harvested from ocean waters. The main categories of ORE are tidal energy, wave energy, and ocean thermal energy conversion (OTEC) [7][17]. Offshore wind power is potentially the most feasible option for subsea electrification and subsequent emission reduction. Offshore wind farms have the largest generation potential among all renewable sources. The synergy between offshore wind and offshore O&G is already underway in Europe, where multiple oil, gas, and marine companies are engaged in wind energy development [8][9][18,19]. According to the International Energy Agency (IEA), total offshore wind capacity is forecast to be more than triple by 2026, reaching close to 120 GW. Major energy companies are looking to boost offshore wind development for electrification of offshore oil and gas platforms along with green hydrogen production. Equinor is studying possible options for building a floating 1 GW offshore wind farm in the Troll area with a predicted annual production of ~4.3 TWh by 2027. This could provide much of the electricity needed to run the Troll-A offshore fields [10][20]. Shell has announced a plan to start building Europe’s largest renewable hydrogen plant in the port of Rotterdam. This hydrogen will use renewable power for the electrolyzer from the offshore wind farm Hollandse Kust (noord), partly owned by Shell [11][21]. The 1.32 GW Hornsea 2 (UK) is the largest operating offshore wind farm in the world. It is 462 km2 (178 square miles) in size and can power more than 1.3 million homes. China’s MingYang Smart Energy has announced an offshore wind turbine even bigger than GE’s Haliade-X. The MySE 16.0-242 is a 16-megawatt, 242-m-tall (794 ft) behemoth capable of powering 20,000 homes per unit over a 25-year service life. Commercial production is slated to begin in the first half of 2024 [12][22]. A case study based on using offshore wind power for powering the platforms located at different places and providing surplus power to an onshore grid is presented in [13][7]. In this study, three scenarios were considered: (1) a 20 MW small offshore wind farm with a stand-alone electrical grid on the offshore oil and gas platform; (2) a 100 MW wind farm is connected to five nearby oil and gas platforms by subsea power cables, as shown in Figure 23; (3) a 1000 MW wind farm for supplying wind power both to oil and gas platforms and to an onshore electrical grid. Based on the simulation study, it was observed that these systems can significantly reduce CO2 emissions. Also, multiple subsea fields can be electrically interconnected as a large microgrid, which then connects to a large offshore wind farm. This technology enables better electrical stability of the offshore grid and reduces the carbon footprint of the entire system.

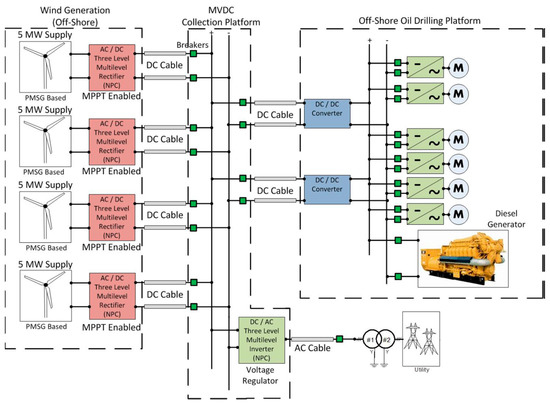

Figure 34. Offshore wind power combined with diesel generator supplying power to offshore oil drilling platform [24].

Offshore wind power combined with diesel generator supplying power to offshore oil drilling platform [8].