You're using an outdated browser. Please upgrade to a modern browser for the best experience.

Please note this is a comparison between Version 2 by Alfred Zheng and Version 1 by PRITI PAL.

In rural areas, where access to conventional energy sources is limited, alternative energy options such as biogas production offer tremendous potential. The sustainable utilization of biowaste resources for biogas production is a promising solution for meeting rural bioenergy requirements. Biowaste, such as agricultural residues, food waste, and animal manure, represents a significant source of organic material that can be converted into biogas through anaerobic digestion.

- waste biomass

- methane

- biofuel

- organic

1. Introduction

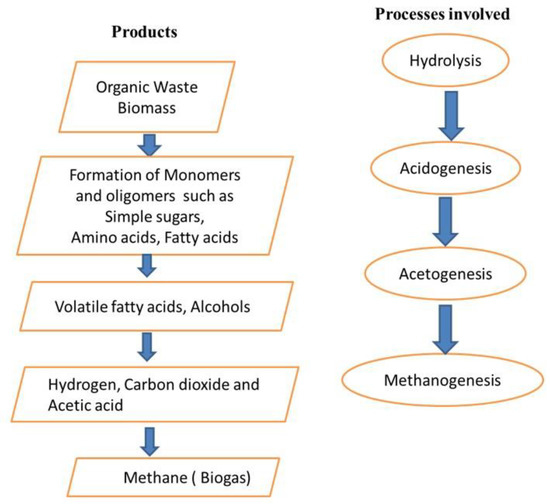

As the world grapples with the challenges of climate change and energy security, sustainable solutions for meeting energy demands are of paramount importance. Many researchers have reported that fossil fuel sources throughout the world will last up to 25 years, and thus, there is a need for alternative sources such as renewable energy [1]. In rural areas, where access to conventional energy sources is limited, alternative energy options such as biogas production offer tremendous potential. The sustainable utilization of biowaste resources for biogas production is a promising solution for meeting rural bioenergy requirements. Biowaste, such as agricultural residues, food waste, and animal manure, represents a significant source of organic material that can be converted into biogas through anaerobic digestion [2]. The fundamental steps in the conversion of biomass to biogas using a biodigester or anaerobic digester are shown in Figure 1. This process involves the decomposition of organic matter by microorganisms in the absence of oxygen, resulting in the production of biogas, primarily composed of methane (CH4) and carbon dioxide (CO2).

Figure 1.

Different steps in biomethanation for biogas formation.

Rural areas often face challenges in accessing reliable energy sources, leading to heavy dependence on traditional fuels such as firewood and fossil fuels. These energy sources are not only environmentally unsustainable but also contribute to deforestation, air pollution, and greenhouse gas emissions [3]. Biogas production from biowaste offers a viable alternative by utilizing locally available organic resources, reducing waste disposal issues, and providing a decentralized energy solution for rural communities. While the utilization of biowaste resources for biogas production offers numerous benefits, there are challenges to overcome. These include the need for proper waste collection and segregation systems, technological know-how, financing options, and policy support. It is crucial to raise awareness among rural communities about the benefits of biogas and provide training and capacity-building programs to enable the adoption of biogas technologies [4].

To promote sustainable utilization of biowaste resources for biogas production, collaboration between various stakeholders is essential. Governments, non-governmental organizations, researchers, and private entities should work together to develop supportive policies, provide financial incentives, and facilitate the dissemination of knowledge and best practices. Additionally, research and development efforts should focus on improving biogas production efficiency, developing cost-effective technologies, and exploring innovative uses for biogas, such as decentralized power generation, cooking fuel, and transportation fuel [5]. Biogas, a renewable energy source, can be derived from the sustainable utilization of biowaste resources.

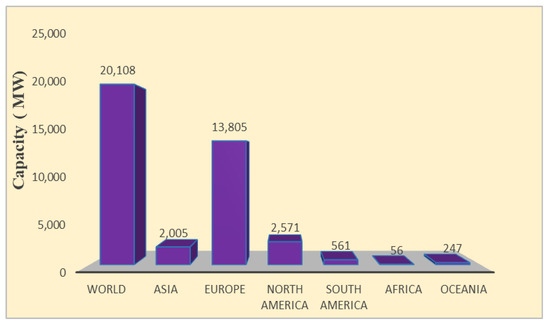

2. Applications of Biogas

The escalating environmental challenges and rapid depletion of conventional energy sources necessitate the exploration of sustainable alternatives. Biogas, as a clean and renewable energy option, emerges as a promising substitute. Unlike traditional energy sources that contribute to ecological and environmental problems, biogas offers a sustainable solution while mitigating adverse ecological impacts. Its renewable nature ensures a continuous supply, reducing dependence on finite resources that are rapidly depleting. By harnessing the potential of biogas, people can address the urgent need for a cleaner and more sustainable energy paradigm. The global biogas production capacity is shown in Figure 2.

Figure 2.

Biogas production capacity around the world.

Biogas production using the anaerobic digestion process offers a versatile solution for converting a wide array of solid or liquid waste materials into a valuable energy resource. Under anaerobic conditions, diverse organic substances undergo degradation by microorganisms, culminating in the generation of energy-dense biogas. This biogas holds significant potential for diverse applications, including the production of vehicle fuel, electric power, and heat. Furthermore, the organic material utilized in the anaerobic digestion process retains essential plant nutrients within the resulting digestion residue, known as digestate, thereby serving as a valuable plant fertilizer. Despite its inherent advantages as a renewable energy source, the widespread adoption of biogas encounters formidable challenges due to the persistent competition posed by readily available conventional energy sources, which often appear to be more economically viable in the short term. To establish biogas as a dominant renewable energy option, it is imperative to address the existing barriers and highlight the long-term benefits and sustainability it offers [87][6].

Biogas, as an environmentally friendly fuel, holds promising potential for future vehicle applications, thereby reducing reliance on conventional fuel imports. However, the existing biogas generation technologies often yield limited amounts of gas over prolonged periods with a high percentage of impurities. Undesirable incombustible gases such as CO2, H2S, and water vapor diminish the calorific value of biogas, rendering transportation and compression challenging. To obtain biogas with a methane content exceeding 90%, various processes such as adsorption, absorption, cryogenic techniques, and membrane separation can be used. Notably, purified biogas and base compressed natural gas (CNG) exhibit equivalent carbon emissions. Biogas can be safely blended with CNG for use as an engine fuel, offering satisfactory engine performance and reduced emissions. The conversion kit required for CNG enables vehicles to run smoothly on biogas without significant modifications. While raw biogas possesses a lower calorific value compared to existing fuels, its quality can be enhanced using purification methods and blending with CNG. Within the realm of biogas generation, anaerobic digestion stands out as a less energy-intensive process, renowned for its effectiveness in converting organic materials into biogas [88][7].

In the realm of green and renewable energy solutions, biogas emerges as a highly promising option for power generation in diverse settings, including rural areas, households, and industrial sectors. Its utilization entails relatively lower capital investment and production costs, making it economically feasible. By harnessing agricultural crop residues and other domestic biomass sources as raw materials, biogas can be effectively generated for various applications, such as driving engines for generators and pump sets. However, it is important to note that the composition of biogas is subject to variations based on the specific raw materials used. One particular challenge arises from the higher concentration of carbon dioxide present in biogas, which can lead to combustion variations that may impact engine durability and performance. Hence, careful attention must be given to optimizing the biogas composition to ensure efficient and reliable utilization in power generation systems [89][8]. A comparison between the properties of various fuel sources and biogas is shown in Table 1.

Table 1.

A comparison between the properties of common biofuels and biogas.

| Methods of Pretreatment |

Biomass | Biogas Yield | Parameters | Reference | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Thermal | Kitchen waste | 2540 mL·L | −1 | 60 °C, 84 h | [26] | [9] | ||||||

| Waste activated sludge | 378 mL·g | −1 | ODS | 90 °C, 60 min, 20 days | [27] | [10] | ||||||

| Sludge | 383 mL·g | −1 | VS | 70 °C, 30 min | [28] | [11] | ||||||

| Food waste | 783 mL·g | −1 | VS | 100 °C, 10 min, 45 days | [29] | [12] | ||||||

| Food waste | 383 mL·g | −1 | VS | 100 °C, 30 min | [30] | [13] | ||||||

| Sewage sludge | 210 mL·g | −1 | VS | 134 °C, 30 min | [31] | [14] | ||||||

| Sludge | 295 mL·g | −1 | VS | 90 °C, 36 h | [32] | [15] | ||||||

| Physiochemical | Agave tequilana | bagasse | 0.26 L CH | 4 | g | −1 | COD | 32 °C, pH 5 | [33] | [16] | ||

| Corn stover | 217.5 mL CH | 4 | g | −1 | vs. 243 mL CH | 4 | g | −1 | VS | 37 °C for 28 days | [34] | [17] |

| Wheat straw | 305.5 mL CH | 4 | g | −1 | VS | 35 °C, 120 rpm | [35] | [18] | ||||

| Biological | Corn stover silage | 265.1 mLCH4 g | −1 | VS | 37 °C, 30 days | [24] | [19] | |||||

| Corn stover | 238.4 mL CH | 4 | 30 °C, 6 h | [36] | [20] | |||||||

| Agropyron elongatum | 169.2 mL CH | 4 | g | −1 | V | 28 °C, 28 days | [37] | [21] |

The integration of a direct-biogas solid oxide fuel cell (SOFC) with a micro-gas turbine (MGT) system presents a promising avenue for the development of a decentralized combined heat and power (CHP) system with significant environmental benefits. To assess the feasibility of utilizing biogas as the primary energy source for a direct-biogas SOFC-MGT hybrid CHP system, a sensitivity analysis was performed under various operating conditions. The objective was to examine the impact of key operating parameters on the performance of the hybrid CHP system while also considering operational constraints. Using this analysis, the researchers aimed to understand the intricate interplay between different factors and their influence on the overall system performance. Factors such as fuel composition, operating temperature, and electrical and thermal loads were carefully evaluated to assess their effects on system efficiency and reliability [90][22]. By conducting this sensitivity analysis, valuable insights were gained regarding the optimal configuration and operating conditions for the direct-biogas SOFC-MGT hybrid CHP system. The findings from this cited study will contribute to the advancement and effective deployment of environmentally friendly and sustainable energy systems, paving the way for greener decentralized CHP solutions [90][22].

A novel integrated energy recovery system was devised to facilitate the manipulation of feedstock and the regulation of digester operating parameters, ensuring sustainable biogas production in continuously fed digesters. This advanced system encompasses a range of meticulously designed components that have been seamlessly integrated into a cutting-edge energy recovery system. The system has undergone prototyping and subsequent deployment in a real working environment to conduct pilot studies. Notably, the configuration of the system enables the precise measurement of feedstock moisture content. Based on this measurement, the system calculates the optimal amount of water required to be added to the feedstock, subsequently displaying this information to the operator. This innovative approach ensures that the substrate quality is optimized, enhancing the overall efficiency and effectiveness of the biogas production process [91][23].

3. Biogas as Energy in Rural Sector and Significance

Biogas is increasingly being recognized as a valuable energy source in the rural sector. In rural areas, where access to traditional energy sources may be limited, biogas provides an efficient and sustainable alternative. It is produced by the breakdown of organic matter, such as animal manure, crop residues, and kitchen waste, through a process called anaerobic digestion. This decentralized energy solution has several advantages for rural communities. Firstly, biogas can be used for cooking, heating, and lighting, addressing the energy needs of households and reducing reliance on firewood or fossil fuels. This improves indoor air quality, reduces deforestation, and decreases greenhouse gas emissions. Secondly, biogas production helps in managing organic waste effectively [92][24]. By converting waste into biogas, it prevents the release of harmful methane gas into the atmosphere, mitigating climate change. Additionally, the by-product of the biogas production process, known as digestate, is a nutrient-rich organic fertilizer that can enhance soil fertility and agricultural productivity. Biogas plants can also create job opportunities and support local economies in rural areas. Overall, biogas holds great potential to promote sustainable development, improve energy access, and contribute to environmental stewardship in the rural sector [93][25].

Biogas is an excellent source of renewable energy in the rural sector. It is produced through the anaerobic digestion of organic materials such as agricultural waste, livestock manure, and food scraps. Biogas is primarily composed of methane (CH4) and carbon dioxide (CO2), with small amounts of other gases. When biogas is captured and stored, it can be used as fuel for cooking, heating, and electricity generation. The methane content makes it a valuable energy source. Biogas production offers a sustainable solution for managing organic waste generated in rural areas. Agricultural residues, livestock manure, and food waste can be diverted from landfills and instead used as feedstock for biogas production. This helps in reducing greenhouse gas emissions, controlling odors, and minimizing the environmental impact of waste disposal. In many rural areas, traditional cooking methods rely on biomass fuels like wood and charcoal, which can have adverse health and environmental effects [94][26]. Biogas can replace these traditional fuels, providing a cleaner and more efficient cooking solution. It reduces indoor air pollution, minimizes deforestation, and saves time and effort in fuel collection. Biogas can be used for decentralized electricity generation in rural areas. Small-scale biogas plants can produce electricity that powers rural households, schools, and healthcare centers. This helps to bridge the energy access gap and improve the quality of life in rural communities. Biogas production generates a nutrient-rich by-product called digestate [44][27]. This digestate can be used as an organic fertilizer, replacing chemical fertilizers in agricultural practices. It helps improve soil health, enhance crop yields, and reduce dependence on synthetic fertilizers, thereby promoting sustainable agriculture. Biogas production in rural areas can create economic opportunities by generating income and employment. Farmers and rural communities can benefit from selling excess biogas to the grid, providing maintenance and operational services for biogas plants, and producing and marketing digestate as a valuable organic fertilizer. Overall, biogas offers a sustainable energy solution for rural areas by providing clean cooking fuel, decentralized electricity, waste management, and agricultural benefits. Its utilization can contribute to rural development, environmental sustainability, and energy access for rural populations [95][28]. Biowaste materials act as sustainable sources for various bioenergy purposes [96,97,98,99,100][29][30][31][32][33]. Various technological interventions and studies were conducted on waste biomass utilization for bioenergy production [101,102,103][34][35][36]. Anaerobic digestion systems offer significant advantages to developing nations due to their cost-effectiveness relative to alternative technologies, simplicity, low maintenance requirements, and inherent safety. These systems not only provide a reliable source of fuel but also contribute to improved public health and sanitation. Additionally, they alleviate the labor-intensive task of collecting substantial amounts of firewood, thereby enabling individuals to engage in other productive activities. Consequently, biomass-based energy systems play a pivotal role in facilitating rural development.

The implementation of biogas in rural areas also yields environmental benefits. By replacing wood fires, biogas helps curb deforestation rates and mitigates the associated emissions. Furthermore, biogas serves as a clean and renewable energy source, diminishing reliance on fossil fuels. From a chemical perspective, biogas shares similarities with natural gas; however, it differentiates itself as a renewable fuel, whereas natural gas is derived from fossilized sources. If organic waste is left untreated, the methane it contains would be released into the atmosphere through natural processes, whereas the greenhouse gases in natural gas would remain trapped underground. By utilizing biogas as a fuel source, the amount of methane emitted from open decomposition processes is significantly reduced. The utilization of biogas not only addresses energy requirements but also tackles sanitation challenges. The establishment of a biogas system in rural households is considerably less complex compared to other alternatives. This approach presents a viable solution to both energy and sanitation issues, offering a straightforward and practical method for rural communities.

References

- Bhatia, L.; Sarangi, P.K.; Nanda, S. Current advancements in microbial fuel cell technologies. In Biorefinery of Alternative Resources: Targeting Green Fuels and Platform Chemicals; Nanda, S., Vo, D.V.N., Sarangi, P.K., Eds.; Springer Nature: Singapore, 2020; pp. 477–494.

- Kumar, J.A.; Sathish, S.; Prabu, D.; Renita, A.A.; Saravanan, A.; Deivayanai, V.; Anish, M.; Jayaprabakar, J.; Baigenzhenov, O.; Hosseini-Bandegharaei, A. Agricultural waste biomass for sustainable bioenergy production: Feedstock, characterization and pre-treatment methodologies. Chemosphere 2023, 331, 138680.

- Kasinath, A.; Fudala-Ksiazek, S.; Szopinska, M.; Bylinski, H.; Artichowicz, W.; Remiszewska-Skwarek, A.; Luczkiewicz, A. Biomass in biogas production: Pretreatment and codigestion. Renew. Sustain. Energy Rev. 2021, 150, 111509.

- Chodkowska-Miszczuk, J.; Martinat, S.; Van Der Horst, D. Changes in feedstocks of rural anaerobic digestion plants: External drivers towards a circular bioeconomy. Renew. Sustain. Energy Rev. 2021, 148, 111344.

- Jain, A.; Sarsaiya, S.; Awasthi, M.K.; Singh, R.; Rajput, R.; Mishra, U.C.; Chen, J.; Shi, J. Bioenergy and bio-products from bio-waste and its associated modern circular economy: Current research trends, challenges, and future outlooks. Fuel 2022, 307, 121859.

- Deepanraj, B.; Sivasubramanian, V.; Jayaraj, S. Effect of substrate pretreatment on biogas production through anaerobic digestion of food waste. Int. J. Hydrog. Energy 2017, 42, 26522–26528.

- Singh, H.; Padhi, T.; Kashyap, A.; Taneja, S. Recent advances in biogas production using various bio-waste’s and its potential application: An overview. Mater. Today Proc. 2023.

- Gupta, P.; Kurien, C.; Mittal, M. Biogas (a promising bioenergy source): A critical review on the potential of biogas as a sustainable energy source for gaseous fuelled spark ignition engines. Int. J. Hydrog. Energy 2023, 48, 7747–7769.

- Kuo, W.; Cheng, K. Use of Respirometer in Evaluation of Process and Toxicity of Thermophilic Anaerobic Digestion for Treating Kitchen Waste. Bioresour. Technol. 2007, 98, 1805–1811.

- Appels, L.; Degrève, J.; Van der Bruggen, B.; Van Impe, J.; Dewil, R. Influence of Low Temperature Thermal Pre-Treatment on Sludge Solubilisation, Heavy Metal Release and Anaerobic Digestion. Bioresour. Technol. 2010, 101, 5743–5748.

- Liao, X.; Li, H.; Zhang, Y.; Liu, C.; Chen, Q. Accelerated High-Solids Anaerobic Digestion of Sewage Sludge Using Low-Temperature Thermal Pretreatment. Int. Biodeterior. Biodegrad. 2016, 106, 141–149.

- Gandhi, P.; Paritosh, K.; Pareek, N.; Mathur, S.; Lizasoain, J.; Gronauer, A.; Bauer, A.; Vivekanand, V. Multicriteria Decision Model and Thermal Pretreatment of Hotel Food Waste for Robust Output to Biogas: Case Study from City of Jaipur, India. BioMed Res. Int. 2018, 2018, 9416249.

- Gnaoui, Y.E.; Karouach, F.; Bakraoui, M.; Barz, M.; Bari, H.E. Mesophilic Anaerobic Digestion of Food Waste: Effect of Thermal Pretreatment on Improvement of Anaerobic Digestion Process. Energy Rep. 2020, 6, 417–422.

- Chen, H.; Yi, H.; Li, H.; Guo, X.; Xiao, B. Effects of Thermal and Thermal-Alkaline Pretreatments on Continuous Anaerobic Sludge Digestion: Performance, Energy Balance and, Enhancement Mechanism. Renew. Energy 2020, 147, 2409–2416.

- Liu, T.; Wu, C.; Wang, Y.; Xue, G.; Zhang, M.; Liu, C.; Zheng, Y. Enhanced Deep Utilization of Low-Organic Content Sludge by Processing Time-Extended Low-Temperature Thermal Pretreatment. ACS Omega 2021, 6, 28946–28954.

- Arreola-Vargas, J.; Ojeda-Castillo, V.; Snell-Castro, R.; Corona-González, R.I.; Alatriste-Mondragón, F.; Méndez-Acosta, H.O. Methane production from acid hydrolysates of Agave tequilana bagasse: Evaluation of hydrolysis conditions and methane yield. Biore-Sour. Technol. 2015, 181, 191–199.

- Siddhu, M.A.H.; Li, J.; Zhang, J.; Huang, Y.; Wang, W.; Chen, C.; Liu, G. Improve the anaerobic biodegradability by copretreatment of thermal alkali and steam explosion of lignocellulosic waste. BioMed. Res. Int. 2016, 2016, 2786598.

- Yao, Y.; Bergeron, A.D.; Davaritouchaee, M. Methane recov- ery from anaerobic digestion of urea-pretreated wheat straw. Renew. Energy 2018, 115, 39–148.

- Liu, S.; Li, X.; Wu, S.; He, J.; Pang, C.; Deng, Y.; Dong, R. Fungal pretreatment by Phanerochaete chrysosporium for enhancement of biogas production from corn stover silage. Appl. Biochem. Biotechnol. 2014, 174, 1907–1918.

- Schroyen, M.; Vervaeren, H.; Vandepitte, H.; Van Hulle, S.W.; Raes, K. Effect of enzymatic pretreatment of various lignocel- lulosic substrates on production of phenolic compounds and biomethane potential. Bioresour. Technol. 2015, 192, 696–702.

- Lalak, J.; Kasprzycka, A.; Martyniak, D.; Tys, J. Effect of biological pretreatment of Agropyron elongatum ‘BAMAR’ on biogas pro- duction by anaerobic digestion. Bioresour. Technol. 2016, 200, 194–200.

- Wongchanapai, S.; Iwai, H.; Saito, M.; Yoshida, H. Performance evaluation of a direct-biogas solid oxide fuel cell-micro gas turbine (SOFC-MGT) hybrid combined heat and power (CHP) system. J. Power Sources 2013, 223, 9–17.

- Tumusiime, E.; Kirabira, J.B.; Musinguzi, W.B. An integrated energy recovery system for productive biogas applications: Continuous mode operation and assessment. Energy Rep. 2023, 9, 4532–4546.

- Siddiki, S.Y.A.; Uddin, M.N.; Mofijur, M.; Fattah, I.M.R.; Ong, H.C.; Lam, S.S.; Kumar, P.S.; Ahmed, S.F. Theoretical calculation of biogas production and greenhouse gas emission reduction potential of livestock, poultry and slaughterhouse waste in Bangladesh. J. Environ. Chem. Eng. 2021, 9, 105204.

- Sawyerr, N.; Trois, C.; Workneh, T.; Okudoh, V. An overview of biogas production: Fundamentals, applications and future research. Int. J. Energy Econ. Policy 2019, 9, 105.

- Shaibur, M.R.; Husain, H.; Arpon, S.H. Utilization of cow dung residues of biogas plant for sustainable development of a rural community. Curr. Res. Environ. Sustain. 2021, 3, 100026.

- Honcharuk, I.; Tokarchuk, D.; Gontaruk, Y.; Hreshchuk, H. Bioenergy recycling of household solid waste as a direction for ensuring sustainable development of rural areas. Polityka Energetyczna-Energy Policy J. 2023, 23–42.

- Wang, Q.; Xia, C.; Alagumalai, K.; Le, T.T.N.; Yuan, Y.; Khademi, T.; Berkani, M.; Lu, H. Biogas generation from biomass as a cleaner alternative towards a circular bioeconomy: Artificial intelligence, challenges, and future insights. Fuel 2023, 333, 126456.

- Mahjoub, B.; Domscheit, E. Chances and challenges of an organic waste–based bioeconomy. Curr. Opin. Green Sustain. Chem. 2020, 25, 100388.

- Mishra, S.; Singh, P.K.; Mohanty, P.; Adhya, T.K.; Sarangi, P.K.; Srivastava, R.K.; Jena, J.; Das, T.; Hota, P.K. Green synthesis of biomethanol—Managing food waste for carbon footprint and bioeconomy. Biomass Convers. Biorefin. 2022, 12, 1889–1909.

- Sarangi, P.K.; Nanda, S. Biohydrogen production through dark fermentation. Chem. Eng. Technol. 2020, 43, 601–612.

- Sarangi, P.K.; Nayak, M.M. Agro-waste for Second Generation Biofuels. In Liquid Biofuels: Fundamentals, Characterization, and Applications; Shadangi, K.P., Ed.; Wiley-Scrivener, Scrivener Publishing LLC: Beverly, MA, USA, 2021; pp. 697–706.

- Sarangi, P.K.; Nanda, S.; Vo, D.V.N. Technological Advancements in the Production and Application of Biomethanol. In Biorefinery of Alternative Resources: Targeting Green Fuels and Platform Chemicals; Nanda, S., Vo, D.V.N., Sarangi, P.K., Eds.; Springer Nature: Boston, MA, USA, 2020; pp. 127–140.

- Sarangi, P.K.; Nanda, S. Recent advances in consolidated bioprocessing for microbe-assisted biofuel production. In Fuel Processing and Energy Utilization; Nanda, S., Sarangi, P.K., Vo, D.V.N., Eds.; CRC Press: Boca Raton, FL, USA, 2019; pp. 141–157.

- Yadav, S.; Singh, D.; Mohanty, P.; Sarangi, P.K. Biochemical and Thermochemical Routes of H2 Production from Food Waste:A Comparative Review. Chem. Eng. Technol. 2021, 46, 191–203.

- Sarangi, P.K.; Subudhi, S.; Bhatia, L.; Saha, K.; Mudgil, D.; Prasad, K.; Shadangi, K.P.; Srivastava, R.K.; Pattnaik, B.; Arya, R.K. Utilization of agricultural waste biomass and recycling toward circular bioeconomy. Environ. Sci. Pollut. Res. 2022, 30, 8526–8539.

More