Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is a comparison between Version 2 by Camila Xu and Version 1 by Peng Du.

Baijiu is a traditional fermented Chinese beverage with a history of hundreds of years. The notable characteristics of Baijiu include diverse raw materials, complex technology, and the co-fermentation of multiple strains.

- Baijiu

- trace components

- health benefits

- fermentation

1. Introduction

Chinese Baijiu (referred to as Baijiu) is a transparent, strong alcoholic beverage, which is highly consumed worldwide [1]. Baijiu appeared in China during the second century BC. During the Yuan Dynasty, the Chinese invented solid-state fermentation and distillation processes, which were recorded in the traditional Chinese medical book Compendium of Materia Medica [2]. Baijiu is a distilled alcoholic beverage primarily produced from grains [3]. The fermentation process of Baijiu is unique and more complex than the fermentation of whisky and brandy. During natural fermentation, saccharification occurs quietly [4]. “Jiuqu” (a mixture of wheat and many microorganisms) is the fermentation starter, and sorghum, wheat, corn, rice, glutinous rice, and rice husks are the raw materials [1]. The entire Baijiu brewing process can be divided into jiuqu production, raw material saccharification, fermentation, solid distillation, aging, and blending [4]. Each process impacts the quality of Baijiu and the content and types of its trace components.

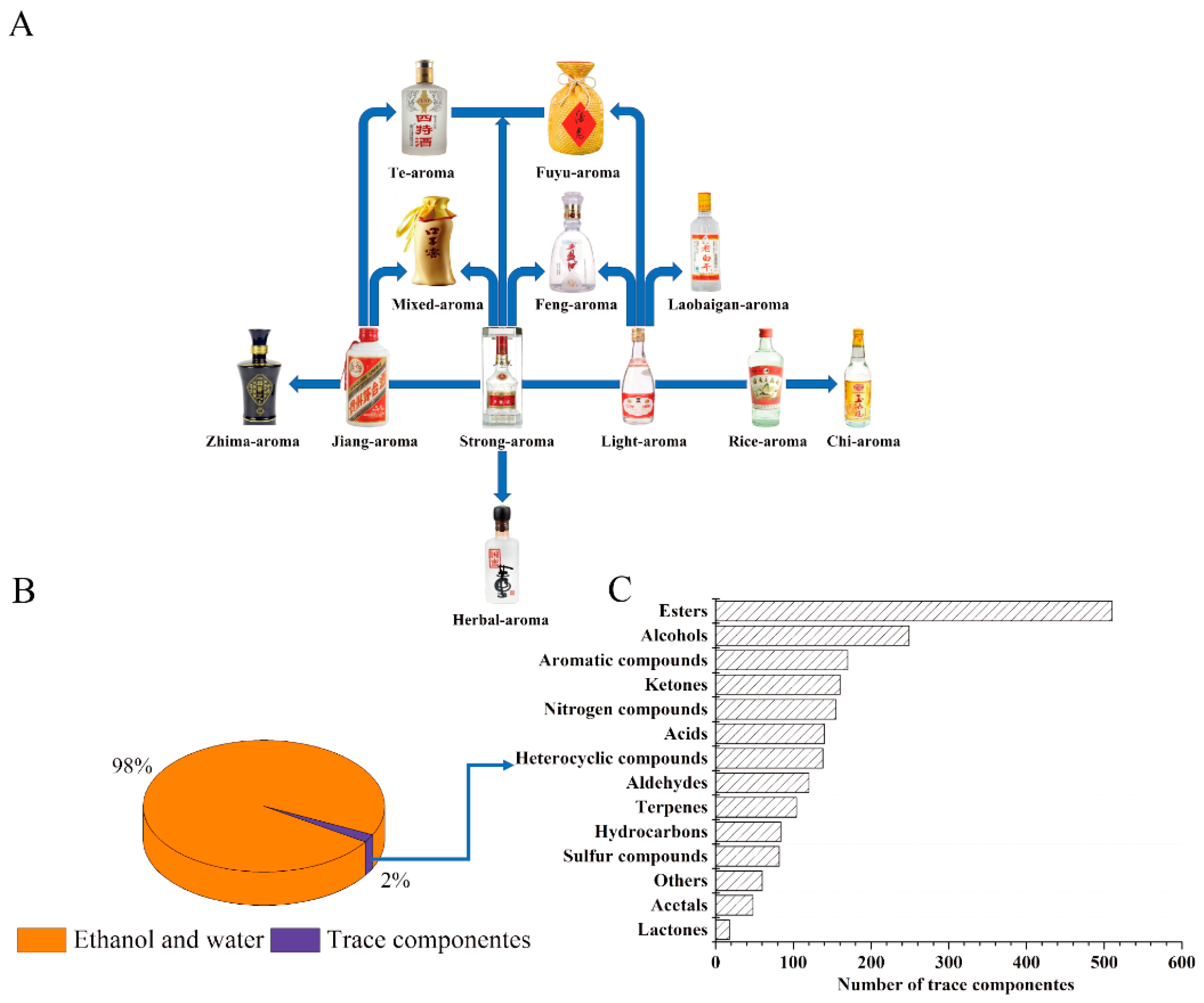

Temperature, air humidity, and microbial composition differ among brewing regions. Baijiu aroma differs according to the brewing technology and “jiaochi” (the container for solid Baijiu fermentation) in different regions and according to the brewing materials and proportions [5]. Originally, Baijiu aroma was classified into 12 different types: Strong, jiang, light, rice, zhima, fuyu, laobaigan, chi, herbal (dong aroma baijiu), te, mixed, and feng [6]. These aromas are related and interdependent. Strong-, jiang-, light-, and rice-aromas are the four primary aroma types and are the bases for the development and evolution of the remaining eight (Figure 1A) [7]. Technological innovations have alleviated the Baijiu constraints associated with the aroma types, causing the evolution of more aromas [8]. For example, the “Hexiang aroma” (produced by adding lotus leaves during fermentation and aging) has attracted many consumers; however, the 12 Baijiu aromas dominate the market.

Figure 1.

(

A

) Development relationship among 12 Baijiu aroma types; (

B

) types of trace components in Baijiu; and (

C

) quantity.

Complex brewing processes create different Baijiu aromas and endow the beverage with complex trace components. Approximately 98% of the Baijiu components are ethanol and water, and approximately 2% are trace components (Figure 1B). Although sparsely present, these components are crucial for Baijiu aromas [6]. Baijiu aromas classified based on their characteristics are determined by trace component composition. In Baiju, 2020 trace ingredients, including 510 esters, 249 alcohols, 140 acids, 18 lactones, 102 aldehydes, 160 ketones, 48 acetals, 82 sulfur compounds, 155 nitrogen compounds, 138 heterocycles, 170 aromatics, 84 hydrocarbons, 104 terpenes, and 60 others have been reported (Figure 1C) [6]. These trace components can be divided into volatile and non-volatile components. Volatile components determine the aroma of Baijiu, whereas the non-volatile affect its taste. Several sources of Baijiu aroma have been identified; the aroma of grain in raw materials is an example. The rice hull in “jiupei” contains more pentosan and furfural and is a “zaoxiang” source in Baijiu. Similarly, jiuqu is a significant source of Baijiu aroma. Another factor is the container jiaochi, which provides a stable environment for microbial metabolism to generate various aroma components [9]. The production of volatile components is primarily influenced by microorganisms. Alcohols are the precursors for other volatile compounds, which are primarily derived through microbial decomposition and metabolism of sugars and amino acids in raw materials [3]. Metabolic pathways, such as alcohol oxidation, keto-acid decarboxylation, amino acid deamination, and amino acid decarboxylation are the primary sources of volatile aldehydes and ketones [3,10][3][10]. Volatile esters have two sources: The metabolic production of yeast and the esterification reaction between acids and alcohols at a specific temperature [3]. Acids are essential components of Baijiu aromas. They can balance the aroma and primarily originate from the metabolic processes of acetic and lactic acid bacteria [6]. In a study of jiang-aroma Baijiu, benzaldehyde and 4-ethyl guaiacol were found as essential aromatic compounds [11]. Pyrazine is a common nitrogen-containing compound. Nuts and roasted aromas are typical aroma characteristics of pyrazine, significantly contributing to the zhima-aroma Baijiu [12]. Apart from the volatile components, non-volatile components are crucial to determining whether Baijiu is mellow. Appropriate amounts of glycerol, 2,3-butanediol, and mannitol are used as Baijiu buffers, making it sweet and mellow [9].

With living standard improvements, requirements beyond aroma, such as the health attributes have been sought for. Due to the many chemical components present in it, Baijiu is not considered an ethanol solution [13]. Alcohol consumption is a double-edged sword, whose abuse harms human health and can cause adverse health outcomes [14]. It is considered the primary cause of hepatitis and neurocognitive impairment [15,16,17][15][16][17] and a contributing factor to certain cancers [18]. In contrast, moderate alcohol consumption has many positive effects. Baijiu trace components are believed to be vital for its health attributes [6,7][6][7]. In ancient China, Baijiu was a drug rather than an alcoholic drink. For example, it is recorded in the Compendium of Materia Medica that: Baijiu can dispel cold and wet phlegm in the skeleton, stop stagnation, and treat cholera, malaria, asphyxia, and heartache [6]. Modern medical research has shown that proper Baijiu consumption can reduce serum uric acid concentration [19] and the risk of Alzheimer’s disease [20]. The trace components in Baijiu can improve blood lipid levels and reduce the risk of cardiovascular diseases [2]. A recent study showed that moderate consumption of strong-aroma Baijiu reduced liver injury [21,22][21][22]. Therefore, moderate drinking without excess consumption is encouraged.

Alcohols and esters are the most abundant and essential trace components in determining Baijiu aromas [23]. Esters account for over 60% of the total trace components [24], while alcohols account for approximately 12% of the total trace components [9]. Similarly, the acidic compound content of Baijiu is high [7]. Alcohols, esters, and acids constitute the aromatic skeleton of Baijiu. Nitrogenous compounds are substances that significantly affect the aroma compounds of Baijiu. For example, pyrazine (a nitrogenous compound in Baijiu) has significant health effects [25]. Sulfur compounds are substances with low aroma thresholds, small amounts, and unique aroma characteristics; however, their contribution to the taste and aroma of Baijiu is notable [26,27][26][27]. These five trace components are essential in the aroma of Baijiu and positively affect health [7,8,25,28,29][7][8][25][28][29].

2. Sources of Baijiu Trace Components

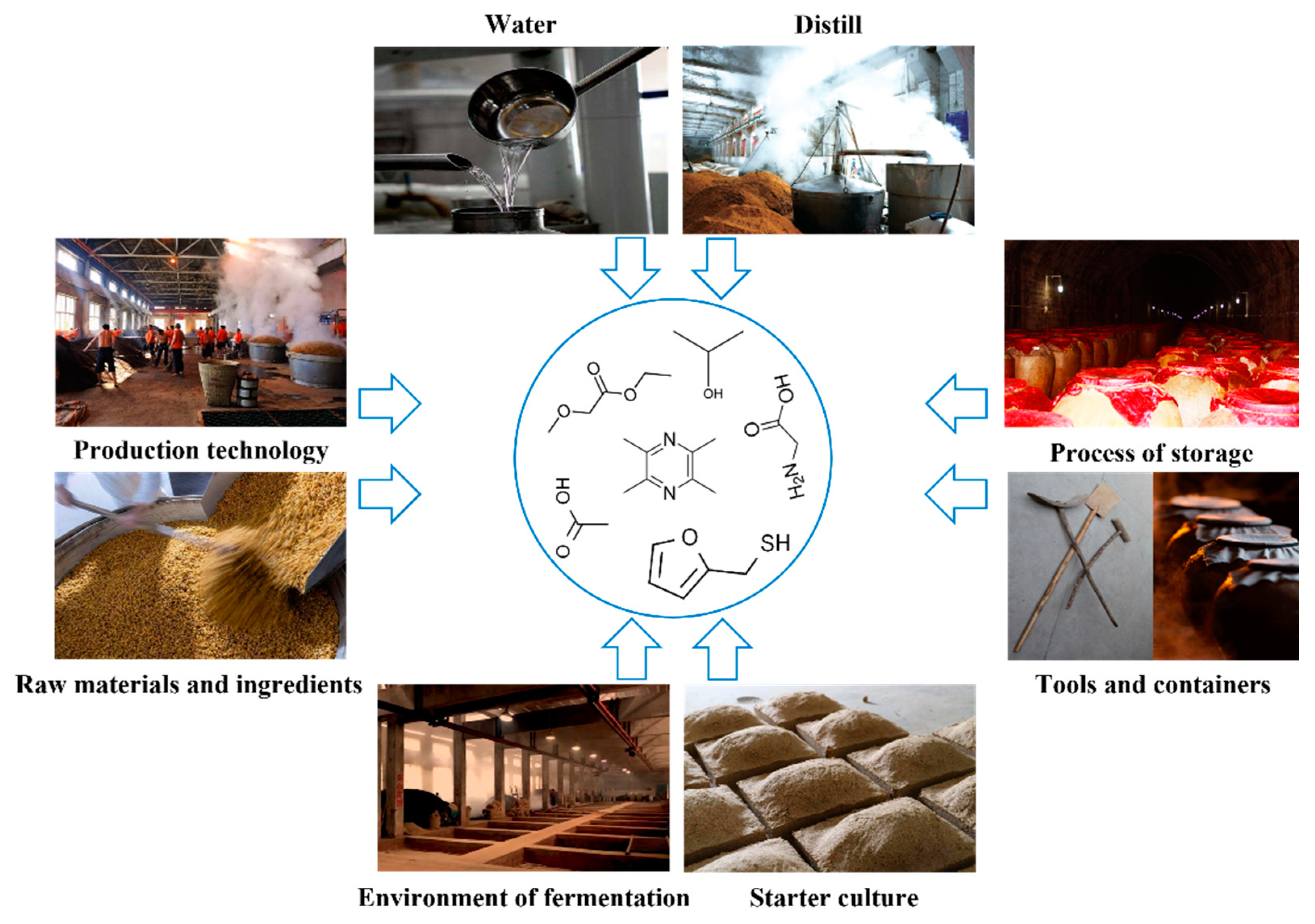

Baijiu is characterized by complex raw materials, special processes, co-fermentation of multiple strains, and a complex product composition [3]. The aroma characteristics and Baijiu quality are determined by the trace components, which account for only 2% of the total. Research shows that Chinese Maotai (a type of jiang-aroma Baijiu) does not harm the liver since its trace components are balanced [30]. Therefore, the control and balance of trace components are worth studying, and understanding their sources is the foundation of this research. The sources of the trace components in Baijiu are shown in Figure 2.

Figure 2.

Source of trace components in Baijiu.

2.1. Production Technology

Different production processes produce different aromatic components. The 12 aroma types are processed differently; therefore, the aroma components of the produced Baijiu differ and are a feature of Baijiu technology [10]. Baijiu production is a complex process involving many microorganisms. The metabolic activity of microorganisms is influenced by many factors. For example, during the production of jiang-aroma Baijiu, the high temperature generated by stacking fermentation destroys many microorganisms; however, their metabolic activities adapt to high temperatures [31]. Many physical and chemical reactions are also associated with microorganism metabolites. For example, some pyrazines are products of the Maillard reaction, which utilizes metabolites, such as reducing sugars and amino acids produced by microorganisms as their precursors [32]. Therefore, the differences in each step may cause differences in the trace components. The production process includes the factors described below [9].2.2. Raw Materials and Ingredients

Different raw materials produce various trace components during fermentation. Some trace components in the raw materials are introduced into Baijiu, some are transformed by microorganisms as precursors of other substances, and some diffuse into the air and disappear [3]. Sorghum has high amylopectin and phosphorus contents, suitable tannin content, and induces a mellow taste after fermentation. Wheat has a high protein content and is the primary “Chenxiang” flavor source. Corn fermentation can produce higher alcohols, which eases Baijiu drinking [33]. Amongst excipients, rice husk is the most suitable; others produce an unpleasant odor to Baijiu. The primary purpose of rice husks in the fermentation process is to form a properly sized spatial structure around the raw materials, which helps in regulating the temperature and facilitating oxygen flow [34]. Phenolic compounds released by microbial corrosion of rice husks are essential trace components [35]. Different qualities of rice husks affect Baijiu differently. Rice husks with high freshness, low impurity, low moisture content, and large particles are the best choices [9].2.3. Environment of Fermentation

The fermentation environment usually includes the fermentation container, surrounding temperature, air humidity, and the number and abundance of microbial populations within a certain spatial range. Many types of fermentation containers are available for Baijiu, including cellars, stone cellars, brick cellars, and wooden barrels. Different fermentation containers significantly affect the growth, reproduction, and metabolites of microorganisms [2]. The trace components contained in the container penetrate the jiupei. The brewing of strong Baijiu aroma has always been associated with the saying “A thousand year old jiaochi and a thousand year old distiller’s grains”. This indicates that old cellars and long-term aging distiller grains are indispensable for brewing high-quality strong-aroma Baijiu [36]. Similarly, this phrase illustrates the significance of microorganisms in fermentation environments. Porcelain jars and stone cellars are used for fermenting light- and jiang-aroma Baijiu, respectively. Different fermentation container materials produce different Baijiu types [9].2.4. Starter Culture

The fermentation starter significantly influences the formation of trace components in Baijiu [2,8][2][8]. The raw materials used in the fermentation starter, its microorganisms and esterifying enzymes, and its production process affect the trace components in Baijiu. This fermentation starter is known as jiuqu. Wheat and barley are commonly used raw materials in fermentation starters. Notably, Chinese herbal medicine is added to the fermentation starter used in fermenting the herbal Baijiu aroma, and some researchers believe that terpenes are introduced in this process [8,37][8][37]. The significance of fermentation starters is not negligible. The application of cell immobilization technology (including immobilized enzymes and bacteria) enables direct altering of the trace component content [9].2.5. Tools and Containers

In traditional Baijiu production, the used tools and utensils comprise iron, copper, tin, aluminum, wood, bamboo, slate, brick, and yellow mud. The most commonly used are wood and bamboo, which gradually enter the jiupei after continuous wear, tear, and fermentation. Through the corrosion of acids and alcohols and their interaction with microbial metabolites, these materials release aroma components indispensable for high-quality Baijiu and may be a source of its phenolic compounds. In addition, the wear of tools comprising iron, slate, or other materials during use enters the Baijiu fermentation system directly or indirectly, and thus affects its trace components [2]. Fermentation and storage containers are used for fermenting Baijiu. Tile jars, pottery jars, and “jiuhai” (a large Baijiu container), made of rattan, pig blood, lime, and other materials, are the common storage containers. Modern storage containers, such as aluminum barrels and stainless-steel cans have emerged. According to the traditional concept, a long Baijiu storage in tile jars, pottery jars, and jiuhai produces a better aroma. These containers have microporous and breathable structures, and the participation of oxygen induces slow chemical reactions in Baijiu, generating more trace components. Trace metal elements in tile and pottery jars, rattan, pig blood, lime, and other components in jiuhai infiltrate into Baijiu and increase its trace components [2,9][2][9].2.6. Process of Storage

The trace components in Baijiu undergo physical and chemical reactions and produce new trace components during storage. Therefore, storage is essential for determining the source and changes in trace components in Baijiu. The storage time, conditions, and methods affect the storage process. Practical experience indicates that quality of Baijiu increases with longer duration of storage. Jiang- and light-aroma Baijiu have a storage period of over 3 years [38], and that of strong-aroma has a storage period of over 1 year [36]. This period is known as the Baijiu maturation period. Similarly, storage conditions and methods promote the formation of trace components in Baijiu. Storing in a constant temperature and humidity environment, such as basements and natural caves, modifies the quality slowly, and the loss is minor. However, when stored indoors at room temperature, its quality changes rapidly, and the loss is enormous. Addition of tiles and pottery chips to the storage process have been found to accelerate the ripening of Baijiu, with a positive effect. X-rays, magnetic fields, ultrasonics, and other technologies have also been used to accelerate Baijiu maturation [9].2.7. Distillation

Distillation is the primary method for extracting ethanol and trace components from jiupei. During fermentation, many beneficial and a few harmful components are generated. The primary purpose of distillation is to substantially extract beneficial components [2]. It is conducted at high temperatures, and the acids and alcohols in jiupei undergo spontaneous esterification to generate esters. The glycoside precursors on wheat skin and the tannins on sorghum skin decompose and are converted into phenolic compounds, which enter Baijiu with alcohol vapor, increasing the trace aroma components in Baijiu. The amino acids in Baijiu are supposed to be originating primarily from distillation, and controlling the temperature and time during the process is key to ensuring the amino acid content [39]. It is believed that the “zhaijiu” (technology for removing the Baijiu flowing out at the beginning and the end of distillation while retaining only that in the middle) can affect the trace components in Baijiu. Due to their different boiling points, the trace components in jiupei flow out sequentially, with low-boiling-point alcohol-soluble components appearing first. Similarly, low-boiling-point olefins and aldehydes were distilled, followed by high-boiling-point trace components. A high component retention by zhaijiu produces rich trace components in Baijiu [9].2.8. Water

The water mentioned in this section refers to fermentation and blending water. The trace components contained in the water used for fermentation can be directly introduced into Baijiu and may affect microbial metabolism. The jiang-aroma Baijiu originated from the Maotai town. The water for fermenting the traditional jiang-aroma Baijiu is obtained from the Chishui river. The water is rich in iron ions [40] and can affect the biological activity of many enzymes [41], possibly a secret of the jiang-aroma Baijiu fermentation. Water accounts for more than half of the Baijiu, and blending water is the primary source of trace components in Baijiu. Purified water is the common blending water and is the basis of the clean Baijiu taste [9].References

- Fan, W.L.; Qian, M.C. Characterization of aroma compounds of Chinese “Wuliangye” and “Jiannanchun” liquors by aroma extract dilution analysis. J. Agric. Food Chem. 2006, 54, 2695–2704.

- Zheng, X.-W.; Han, B.-Z. Baijiu (白酒), Chinese liquor: History, classification and manufacture. J. Ethn. Foods 2016, 3, 19–25.

- Hong, J.; Zhao, D.; Sun, B. Research Progress on the Profile of Trace Components in Baijiu. Food Rev. Int. 2021, 39, 1666–1693.

- Jin, G.; Zhu, Y.; Xu, Y. Mystery behind Chinese liquor fermentation. Trends Food Sci. Technol. 2017, 63, 18–28.

- Wei, Y.; Zou, W.; Shen, C.H.; Yang, J.G. Basic flavor types and component characteristics of Chinese traditional liquors: A review. J. Food Sci. 2020, 85, 4096–4107.

- Hong, J.; Tian, W.; Zhao, D. Research progress of trace components in sesame-aroma type of baijiu. Food Res. Int. 2020, 137, 109695.

- Wu, Y.S.; Hou, Y.X.; Chen, H.; Wang, J.S.; Zhang, C.S.; Zhao, Z.G.; Ao, R.; Huang, H.; Hong, J.X.; Zhao, D.R.; et al. “Key Factor” for Baijiu Quality: Research Progress on Acid Substances in Baijiu. Foods 2022, 11, 2959.

- Xu, Y.; Zhao, J.; Liu, X.; Zhang, C.; Zhao, Z.; Li, X.; Sun, B. Flavor mystery of Chinese traditional fermented baijiu: The great contribution of ester compounds. Food Chem. 2022, 369, 130920.

- Wang, R.M. Liquor Blending Technology; Chemical Industry Press: Beijing, China, 2007.

- Liu, H.; Sun, B. Effect of Fermentation Processing on the Flavor of Baijiu. J. Agric. Food Chem. 2018, 66, 5425–5432.

- Wang, X.; Fan, W.; Xu, Y. Comparison on aroma compounds in Chinese soy sauce and strong aroma type liquors by gas chromatography–olfactometry, chemical quantitative and odor activity values analysis. Eur. Food Res. Technol. 2014, 239, 813–825.

- Zhang, W.; Li, J.; Rao, Z.; Si, G.; Zhang, X.; Gao, C.; Ye, M.; Zhou, P. Sesame flavour baijiu: A review. J. Inst. Brew. 2020, 126, 224–232.

- Fang, C.; Du, H.; Jia, W.; Xu, Y. Compositional Differences and Similarities between Typical Chinese Baijiu and Western Liquor as Revealed by Mass Spectrometry-Based Metabolomics. Metabolites 2019, 9, 2.

- Roerecke, M.; Rehm, J. Alcohol consumption, drinking patterns, and ischemic heart disease: A narrative review of meta-analyses and a systematic review and meta-analysis of the impact of heavy drinking occasions on risk for moderate drinkers. BMC Med. 2014, 12, 182.

- Roerecke, M.; Rehm, J. Cause-specific mortality risk in alcohol use disorder treatment patients: A systematic review and meta-analysis. Int. J. Epidemiol. 2014, 43, 906–919.

- Ceni, E.; Mello, T.; Galli, A. Pathogenesis of alcoholic liver disease: Role of oxidative metabolism. World J. Gastroenterol. 2014, 20, 17756–17772.

- Jacobus, J.; Tapert, S.F. Neurotoxic effects of alcohol in adolescence. Annu. Rev. Clin. Psychol. 2013, 9, 703–721.

- Smith-Warner, S.A.; Spiegelman, D.; Yaun, S.S.; van den Brandt, P.A.; Folsom, A.R.; Goldbohm, R.A.; Graham, S.; Holmberg, L.; Howe, G.R.; Marshall, J.R.; et al. Alcohol and breast cancer in women: A pooled analysis of cohort studies. JAMA 1998, 279, 535–540.

- Hendriks, H.F.J. Alcohol and Human Health: What Is the Evidence? Annu. Rev. Food Sci. Technol. 2020, 11, 1–21.

- Djousse, L.; Arnett, D.K.; Eckfeldt, J.H.; Province, M.A.; Singer, M.R.; Ellison, R.C. Alcohol consumption and metabolic syndrome: Does the type of beverage matter? Obes. Res. 2004, 12, 1375–1385.

- Wu, C.; Xing, X.; Liu, G.; Su, D.; Li, A.; Gui, S.; Lu, W.; Liang, J. Effects of Nongxiangxing baijiu (Chinese liquor) on mild alcoholic liver injury revealed by non-target metabolomics using ultra-performance liquid chromatography quadrupole-time-of-flight mass spectrometry. J. Biosci. Bioeng. 2022, 134, 62–69.

- Fang, C.; Du, H.; Xiaojiao, Z.; Zhao, A.; Jia, W.; Xu, Y. Flavor compounds in fermented Chinese alcoholic beverage alter gut microbiota and attenuate ethanol-induced liver damages. bioRxiv 2018.

- Fan, W.L.; Xu, Y.; Qian, M. Current Practice and Future Trends of Aroma and Flavor Research in Chinese Baijiu. Acs Sym. Ser. 2019, 1321, 145–175.

- Qian, Y.L.; An, Y.; Chen, S.; Qian, M.C. Characterization of Qingke Liquor Aroma from Tibet. J. Agric. Food Chem. 2019, 67, 13870–13881.

- Shi, X.; Zhao, S.; Chen, S.; Han, X.; Yang, Q.; Zhang, L.; Xia, X.; Tu, J.; Hu, Y. Tetramethylpyrazine in Chinese baijiu: Presence, analysis, formation, and regulation. Front. Nutr. 2022, 9, 1004435.

- Herderich, M.J.; Fedrizzi, B.; Ugliano, M.; Siebert, T.; Jeffery, D.W. The good, the bad, and the unknown: Analysis and formation of key sulfur aroma compounds in wine. Abstr. Pap. Am. Chem. Soc. 2009, 238, 167.

- Song, X.B.; Zhu, L.; Jing, S.; Li, Q.; Ji, J.; Zheng, F.P.; Zhao, Q.Z.; Sun, J.Y.; Chen, F.; Zhao, M.M.; et al. Insights into the Role of 2-Methyl-3-furanthiol and 2-Furfurylthiol as Markers for the Differentiation of Chinese Light, Strong, and Soy Sauce Aroma Types of Baijiu. J. Agric. Food Chem. 2020, 68, 7946–7954.

- Sun, H.; Ni, B.; Yang, J.; Qin, Y. Nitrogenous compounds and Chinese baijiu: A review. J. Inst. Brew. 2022, 128, 5–14.

- Sun, J.; Wang, Z.; Sun, B. Low Quantity but Critical Contribution to Flavor: Review of The Current Understanding of Volatile Sulfur-containing Compounds in Baijiu. J. Food Compos. Anal. 2021, 103, 104079.

- Cheng, M.; Wu, J.; Wang, H.; Xue, L.; Tan, Y.; Ping, L.; Li, C.; Huang, N.; Yao, Y.; Ren, L.; et al. Effect of Maotai liquor in inducing metallothioneins and on hepatic stellate cells. World J. Gastroenterol. 2002, 8, 520–523.

- Wang, H.; Narsing Rao, M.P.; Cheng, M.; Xian, M.; Zhou, Y.; Zhou, L.; Cao, H.; Li, W.-J.; Sibirny, A.; Wang, F.; et al. Regulatory effect of moderate Jiang-flavour baijiu (Chinese liquor) dosage on organ function and gut microbiota in mice. J. Biosci. Bioeng. 2023, 135, 298–305.

- Wu, J.; Cheng, M.L.; Zhang, G.H.; Zhai, R.W.; Huang, N.H.; Li, C.X.; Luo, T.Y.; Lu, S.; Yu, Z.Q.; Yao, Y.M.; et al. Epidemiological and histopathological study of relevance of Guizhou Maotai liquor and liver diseases. World J. Gastroenterol. 2002, 8, 571–574.

- Ye, H.; Wang, J.; Shi, J.; Du, J.; Zhou, Y.; Huang, M.; Sun, B. Automatic and Intelligent Technologies of Solid-State Fermentation Process of Baijiu Production: Applications, Challenges, and Prospects. Foods 2021, 10, 680.

- Fan, B.; Xiang, L.; Yu, Y.; Chen, X.; Wu, Q.; Zhao, K.; Yang, Z.; Xiong, X.; Huang, X.; Zheng, Q. Solid-state fermentation with pretreated rice husk: Green technology for the distilled spirit (Baijiu) production. Environ. Technol. Innov. 2020, 20, 101049.

- Du, P.; Zhou, J.; Zhang, L.; Zhang, J.; Li, N.; Zhao, C.; Tu, L.; Zheng, Y.; Xia, T.; Luo, J.; et al. GC × GC-MS analysis and hypolipidemic effects of polyphenol extracts from Shanxi-aged vinegar in rats under a high fat diet. Food Funct. 2020, 11, 7468–7480.

- Wang, J.; Chen, H.; Wu, Y.; Zhao, D. Uncover the flavor code of strong-aroma baijiu: Research progress on the revelation of aroma compounds in strong-aroma baijiu by means of modern separation technology and molecular sensory evaluation. J. Food Compos. Anal. 2022, 109, 104499.

- He, X.; Yangming, H.; Gorska-Horczyczak, E.; Wierzbicka, A.; Jelen, H.H. Rapid analysis of Baijiu volatile compounds fingerprint for their aroma and regional origin authenticity assessment. Food Chem. 2021, 337, 128002.

- Wang, L. Research trends in Jiang-flavor baijiu fermentation: From fermentation microecology to environmental ecology. J. Food Sci. 2022, 87, 1362–1374.

- Li, Y.; Yuan, S.; Yong, X.; Zhao, T.; Liu, J. Research progress on small peptides in Chinese Baijiu. J. Funct. Foods 2020, 72, 104081.

- Ge, X.; Wu, Q.; Wang, Z.; Gao, S.; Wang, T. Sulfur Isotope and Stoichiometry–Based Source Identification of Major Ions and Risk Assessment in Chishui River Basin, Southwest China. Water 2021, 13, 1231.

- Andreini, C.; Bertini, I.; Cavallaro, G.; Holliday, G.L.; Thornton, J.M. Metal ions in biological catalysis: From enzyme databases to general principles. J. Biol. Inorg. Chem. 2008, 13, 1205–1218.

More