Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is a comparison between Version 1 by Giacomo Di Ruocco and Version 2 by Camila Xu.

The issue of environmental sustainability is increasingly topical, and one of the most impactful sectors is the construction industry. As stated in the GlobalABC reports, the building sector is the main sector responsible for GHG emissions, generating about 37% of global CO2e emissions.

- life cycle assessment

- GHG emissions

- timber buildings

1. Introduction

The current awareness of environmental issues’ importance, linked to the scarcity of the planet’s resources and the negative consequences of greenhouse gas emissions, has imposed the need to adopt alternative approaches to construction. Today’s building industry is more concerned with material selection and every phase of the structure’s life cycle. This new way of designing has the parameters of the so-called circular economy, an alternative model to the traditional linear type, where waste is no longer something to be disposed of in landfills but a resource to be reused and recycled. To pursue sustainable development, the European Commission’s 2030 Climate Target Plan [1] proposes to increase the EU’s ambition to reduce greenhouse gas emissions to at least 55% below 1990 levels by 2030 and achieve climate neutrality by 2050. The new proposal maintains the commitment made in the Communication on the European Green Deal and aligns with the Paris Agreement [2], which aims to keep the global temperature rise below 2 °C [3]. Global efforts are currently focused on achieving the UN’s 2030 Agenda for Sustainable Development goals [4], signed in 2015 by 193 countries, which provides an integrated vision of the three dimensions of sustainable development: economic, social, and environmental sustainability. The seventeen goals set by the Agenda, to be achieved by 2030, are interconnected and embrace the most important issues for sustainability, such as the fight against poverty, the elimination of hunger in the world, the reduction of inequalities, and the fight against climate change.

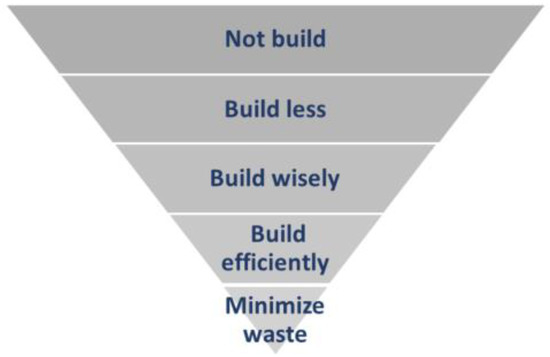

Environmental policies contributed to a decline in greenhouse gas emissions for construction operations between 2019 (9.6 Gt) and 2020 (8.7 Gt). Despite the slight reduction, however, the global account of CO2e emissions (directly and indirectly related to heating, cooling, lighting, etc.) from the construction sector, compared to the total, remains high at 37% [5]. The construction industry requires the extraction of large quantities of raw materials, with the consequent consumption of energy resources and release of pollutant emissions into the atmosphere. The pyramid in Figure 1 highlights the hierarchy of policy strategies to mitigate CO2e emissions from the construction sector; in the perspective of complete decarbonization, the best approach would be not to build at all, an unattainable goal that points toward a construction model based on flexible design and removable and reusable structures. When not building is not feasible, we should build less, make better use of existing structures, repurpose waste materials, use low-carbon products, and create a construction design that minimizes waste through prefabrication, reuse, and recycling. It is possible to reach an efficient design and optimize structural solutions with effort.

Figure 1.

Approaches to a decarbonization-oriented design (© Di Ruocco, Gaita).

2. Life Cycle Assessment from Cradle-to-Handover Approach to Greenhouse Gas Emissions Mitigation

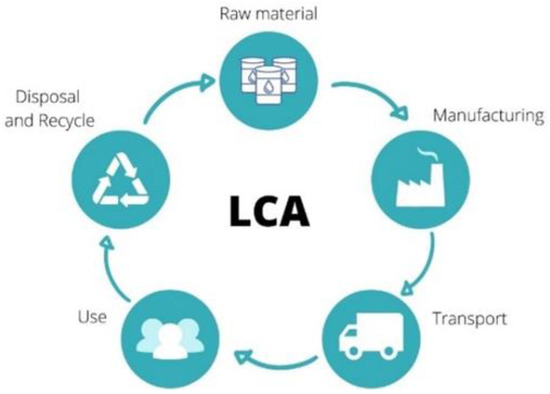

The LCA (life cycle assessment) method makes it possible to assess the environmental impact associated with a product or activity and to guide design choices to improve environmental quality. LCA analysis quantifies factors contributing to CO2e emissions at all stages of the life cycle, from the acquisition of raw materials to the benefits of their recovery/reuse/recycling (Figure 2).

Figure 2.

Life cycle assessment phases (© Di Ruocco, Gaita).

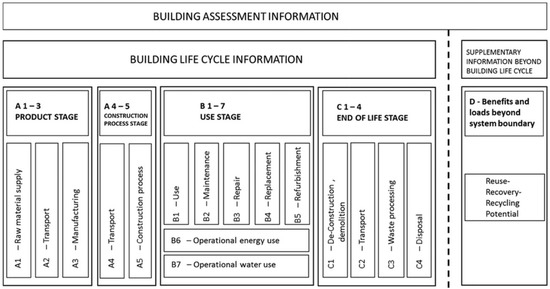

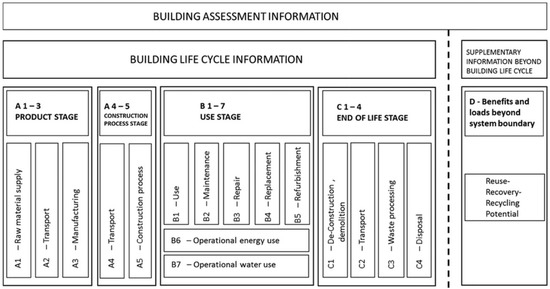

The LCA method makes it possible to identify steps with significant greenhouse gas emissions and intensive resource consumption. Therefore, careful LCA analysis can help preserve natural resources, mitigate climate change, improve air and water quality, and promote sustainable development. Adopting green approaches in product design provides economic benefits, meets the demand of environmentally conscious consumers, and complies with environmental regulations [6][7][8][6,7,8]. Life Cycle Thinking is applicable to all types of products. Fargnoli et al. [9] stressed the importance of integrating environmental aspects into product design, demonstrating the positive impact of reconditioning operations using life cycle simulation and product-service systems (PSS). The study on household dishwashers highlighted the benefits of the PSS approach on environmental performance, customer satisfaction, and company profitability. The LCA approach is recommended by several European policies, including the Integrated Product Policy [10]. This study uses two environmental indicators to quantify the impact, over the life cycle, of each case study: Operating Energy (OE) and Embodied Energy (EE). Embodied energy is that which materials need during their life cycle. Operational energy is the amount of energy needed in the utilization phase of the building. Embodied and operational energy factors correspond to CO2e emission factors: Embodied Carbon (EC) and Operational Carbon (OC) [11][12][11,12]. Open access databases containing information on embodied carbon and energy for various raw materials are critical to helping develop sustainability analysis tools based on energy use and emissions [13]. The European standard BS EN 15978:2011 [14] develops the life-cycle analysis methodology for assessing the environmental performance of buildings, outlining five key blocks: Production, Construction, Use, End of Life, and Benefits and Loads (Figure 3) (Table 1).

Figure 3.

Building assessment information (Source: [14]).

Table 1.

Carbon emission factors in relation to the engine of the machinery.

| Engine | Carbon Emission Factor [Kg C/kW h] |

Carbon Emission Factor [Kg CO2/kW h] |

|---|---|---|

| Coal | 0.0817 | 0.3 |

| Coke | 0.101 | 0.37 |

| Petroliferous Coke | 0.0927 | 0.34 |

| Gas/Diesel | 0.068 | 0.25 |

The F.G. Banfill et al. [15] study provides an overview of LCA studies in the building sector, identifying challenges and suggesting further research. They highlight complexities, lack of standardization, and the need for an internationally accepted framework and conversion tools. Despite limitations, the study concludes that LCA is a powerful tool for evaluating the environmental impact of buildings and supporting sustainable development. Even for wood, which has gained popularity in construction due to its sustainability and low environmental impact compared to traditional building materials, it is important to conduct a thorough Life Cycle Assessment (LCA) that considers the entire life cycle of the material, from production to disposal, to ensure that it is a truly sustainable option.

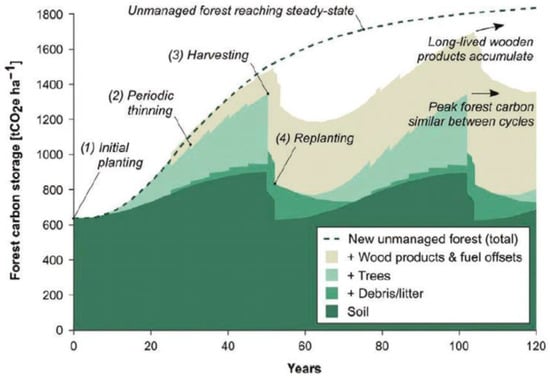

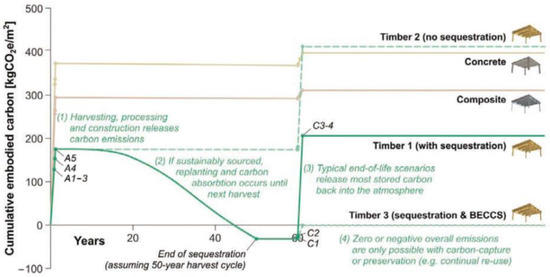

Cultivating trees and using wooden buildings as carbon sinks is a potentially significant strategy, but it raises questions about the environmental impact of timber and forest growth. Hawkins’ [16] comparison of a commercially managed Sitka spruce forest with an unmanaged forest reveals that carbon absorption in newly planted trees begins slowly but increases over time (Figure 4). Unlike unmanaged forests, which reach a peak and stabilize, managed forests continuously accumulate carbon, although with shorter harvesting cycles. Moreover, storing carbon in wood products significantly contributes to overall carbon sequestration, surpassing the levels found in unmanaged forests [17].

Figure 4. Carbon stored in trees and soil for a typical Sitka spruce plantation with a periodic rotation of 50 years, compared to an unmanaged forest (Source: [16]).

In Italy, the importance of sourcing wood from responsibly managed forests is emphasized by CAM Edilizia [18][19][20][18,19,20] regulations, which require sustainable and legal wood sourcing for construction materials. This includes using recycled wood or a combination of recycled and responsibly sourced wood.

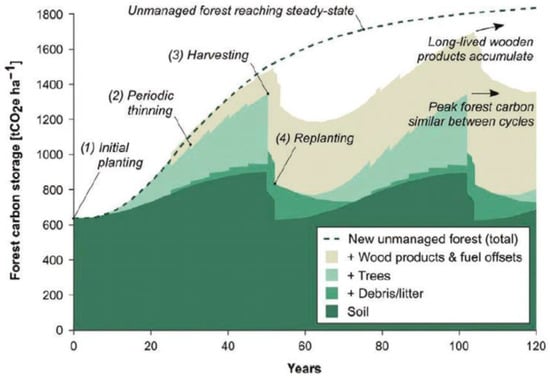

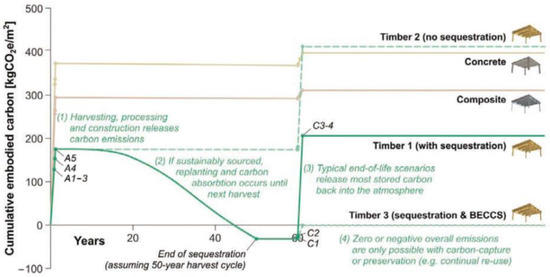

Hawkins [16] also conducted a study comparing the environmental impact of different materials for a multi-story structure, following the life-cycle phases outlined in the European standard BS EN 15978:2011. The report shows that the concrete structure solution is the most impacting on the environment, followed by steel and wood. Production emissions for timber products from harvesting, drying, and sawdust are significant and cannot be avoided; in fact, it is better not to build at all than to build a wooden building. In phase B (BS EN 15978:2011), it is possible to appreciate the advantage of the use of wood due to the compensatory carbon credit. Carbon storage is possible because the tree, during its growth, absorbs carbon dioxide, transforms it into carbon, and releases oxygen into the environment. Carbon remains trapped in the tree until it rots or is incinerated and then returns to the atmosphere. Building in wood, therefore, means creating a real carbon warehouse, which would otherwise have ended up in the atmosphere once the life of the tree had ended. For the concrete and steel structures, analyzing the phases of use (B) and end of life (C), there are very small changes in the amount of Embodied Carbon, while for the wood solution, the change is remarkable. Despite the large emissions, total carbon is still lower for the wooden building than for concrete and steel ones (Figure 5).

Figure 5.

Comparison of cumulative emissions of embodied carbon for different types of construction (Source: [16]).

In fact, despite being among the first materials to be used in construction, wood is among the best solutions for biocompatible buildings. In recent years, research has been interested in these innovative systems and the advantages of building dry rather than wet in terms of Embodied Energy and Embodied Carbon. Studies conducted by Di Ruocco et al. [21][22][23][24][21,22,23,24] explored different building systems, including reinforced concrete, steel, and wood, to determine their environmental impact in terms of embodied energy (EE) and embodied carbon (EC). The results indicate that the wood building system has the lowest EE and EC values.