Bio-based composites are reinforced polymeric materials in which one of the matrix and reinforcement components or both are from bio-based origins. The biocomposite industry has recently drawn great attention for diverse applications, from household articles to automobiles. This is owing to their low cost, biodegradability, being lightweight, availability, and environmental concerns over synthetic and nonrenewable materials derived from limited resources like fossil fuel. The focus has slowly shifted from traditional biocomposite systems, including thermoplastic polymers reinforced with natural fibers, to more advanced systems called hybrid biocomposites. Hybridization of bio-based fibers/matrices and synthetic ones offers a new strategy to overcome the shortcomings of purely natural fibers or matrices. By incorporating two or more reinforcement types into a single composite, it is possible to not only maintain the advantages of both types but also alleviate some disadvantages of one type of reinforcement by another one.

- biocomposites

- green polymers

- hybrid composites

- natural fibers

- mechanical properties

Please note: Below is an entry draft based on your previous paper, which is wrirren tightly around the entry title. Since it may not be very comprehensive, we kindly invite you to modify it (both title and content can be replaced) according to your extensive expertise. We believe this entry would be beneficial to generate more views for your work. In addition, no worry about the entry format, we will correct it and add references after the entry is online (you can also send a word file to us, and we will help you with submitting).

1. Introduction

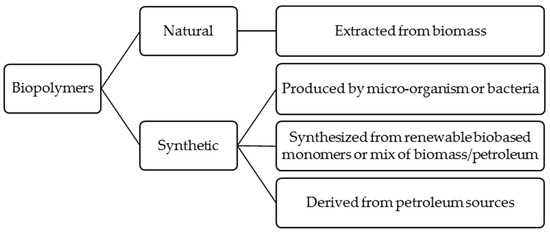

Nowadays, global environmental safety, ecological concerns, recyclability, eco-efficiency, and economic factors are fundamental driving forces to increase the employment of bio-based materials [1][2][1,2]. The EU Bioeconomy Strategy [3] is one of the developed plans or policies to accelerate the UN Sustainable Development Goals (SDGs). This strategy focuses not only on shifting from fossil resources to renewable raw materials but also on recycling renewable bio-based raw materials and innovating in the production and consumption of materials [3]. In this regard, biocomposites are among the potential sectors for the bioeconomy. Renewable and sustainable biomaterials as an alternative for petroleum-based materials prevent generating carbon dioxide causing global warming. They would be a solution to alleviating the petroleum supplies'’ uncertainty, which are about to decline shortly [4][5][4,5]. Within recent years, biopolymers or green polymers have received tremendous interest among biomaterials. The term biopolymer is a polymer of monomeric molecules derived from natural resources, including biological systems or living organisms. Moreover, biopolymers can be found in nature and daily life, such as natural rubber, starch, cotton, leather, wool, etc. [6][7][8][6,7,8]. Biopolymers are renewable, environmentally friendly, or/and biodegradable materials, which can be divided into two broad groups of natural and synthetic (Figure 1) with the following origins [9][10][11][12][13][9,10,11,12,13]:

Figure 1. Origins of biopolymer materials [©MB, JA, MAM_UC3M2020].

-

Natural biopolymers extracted from biomass (e.g., polysaccharides, proteins)

-

Synthetic biopolymers produced by a micro-organism or bacteria (e.g., bacterial cellulose, polyhydroxyvalerate, polyhydroxybutyrate)

-

Synthetic biopolymers synthesized from renewable bio-based monomers or mixed sources of biomass and petroleum (e.g., polylactic acid, aliphatic polyester, aliphatic-aromatic copolyesters)

-

Biodegradable polymers that are derived from nonrenewable resources (petroleum sources) (e.g., polycaprolactone)

Despite the advantages of biopolymer materials, they have some limitations compared to petroleum-based materials, such as relatively low stiffness, tensile strength, permeability, and thermal stability [8][9][8,9]. Therefore, to modify biopolymers'’ properties and commercial importance, "“biopolymer composites"” are tremendously explored by adding reinforcement materials within the micro or nanoscale [14][15][16][17][18][14,15,16,17,18]. These composites have a large assortment of applications in construction, medicine, electronics, packaging, and automotive sectors [19][20][21][22][23][24][19,20,21,22,23,24].

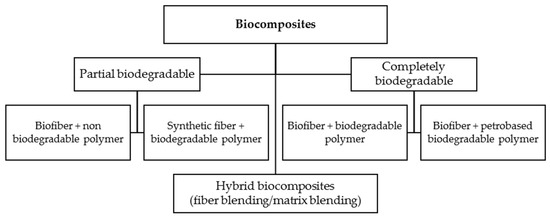

Composite materials systems are made from one or more discontinuous reinforcing phases embedded in a continuous matrix phase. Biopolymer composites or biocomposites are referred to as composites in which at least one constituent is bio-based or biodegradable [25]. The focus of this review will be on the fibrous composites rather than laminate and particulate composites. Fibrous composites can be made of natural/biofiber and synthetic fiber. Biocomposite systems can be classified into partial biodegradable and complete biodegradable biocomposites on the basis of the matrix and fibers (Figure 2) [2][5][26][2,5,26]. In the complete biodegradable biocomposites, bio-fibers are employed with the matrices are made of biodegradable polymers such as renewable biopolymer matrices (e.g., cellulosic plastic, soy plastic, starch plastic) or petro-based biodegradable polymer matrices (e.g., aliphatic co-polyester, polyesteramides). However, in the partial biodegradable biocomposites, bio-based matrices are reinforced with synthetic fibers, or non-biodegradable polymers matrices such as traditional thermoplastic polymers (e.g., polypropylene, polyethylene) and thermoset polymers (e.g., epoxy, polyester) are reinforced with bio-fibers [5][26][5,26]. It is worth noting this classification of biocomposites does not estimate time or amount of degradation, which depends on many parameters, such as environment, temperature, and micro-organisms and can be defined by standard degradation tests. This classification emphasizes that if both fibers and matrix be 100% biodegradable materials, a composite will decompose at the end of its life and completely go back into the natural environment. Otherwise, if one of them be non-biodegradable, the composite doesn'’t show full biodegradability properties. Recently, the blending of two or more polymers reinforced with one or more fibers that produce hybrid composites materials has become an effective way to manipulate biocomposites properties and maintain the balance among ecology-economy-technology.

Figure 2. Classification of biocomposites. Adapted from [5].

2. Hybridization

The concept of hybridization can be found in various fields, such as mechanics, polymer and chemistry, metallurgy, physics, science and technology, and energy fuels. Regardless of the research area, this process'’s main objective is to combine three or more materials to achieve improved performance or properties compared to each substance for a proposed application [27]. In the field of composite materials, by incorporating two or more filler/fiber into a matrix material, the disadvantages of one type of reinforcement can be reduced by another one [28]. For example, by hybridization of natural fibers with any synthetic fibers, although the main benefits of natural fiber composites such as biodegradability, easy handling and processing, and natural resources are being reduced, hybridization can decrease the cost, weight, and environmental concerns produced by the synthetic fiber composites effectively. Several publications scientifically prove that hybridization techniques can enhance the composites'’ mechanical, thermal, and dynamic characteristics, such as minimizing water absorption and increasing flame retardancy [29][30][31][29,30,31]. The main parameters, which significantly affect the properties of the manufactured hybrid composite products, are as follows [27]:

-

Materials selection (matrix and fiber), which depend mostly on the proposed application;

-

Preparation technique, which depends on the fiber, matrix, and working conditions (viz. outdoors or indoors);

-

Interaction between the fibers and matrix, which can be controlled by fiber treatment or the use of coupling agents.

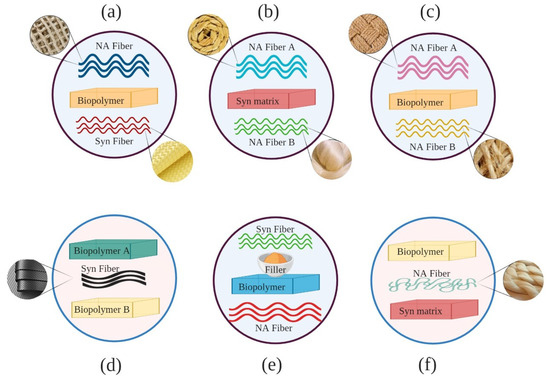

Considering the mentioned parameters is significantly essential, since they could cause unexpected effects in the results. Many studies have reported adverse effects of hybridization due to the inappropriate selection of materials, processing techniques, a sequence of layers in a hybrid structure, and the loading arrangement. For instance, Sreekala et al. [32] reported a negative effect of oil palm empty fruit bunch (OPEFB) fiber hybridization on the tensile strength and tensile modulus at very low and high fiber volume fractions. Zweben [33] predicted that high elongation fibers might behave like crack arrestors on a micromechanical level when introduced in low elongation fiber composites. This behavior increases the strain level needed for fiber break propagation. Hariharan and Abdul Khalil [34], who hybridized oil palm fibers with glass fibers, also stated an undesired hybrid effect on the strength properties. Marom et al. [35] investigated positive or negative hybrid effects in hybrid composites as a positive or negative deviation of a specific mechanical property according to the rule-of-mixtures behavior. It is based on the weighted average of the characteristic properties of the distinct composites [36]. Based on biocomposites classification (Figure 2) and the concept of hybridization, different configurations of hybrid fiber-reinforced biocomposites could be manufactured as some of them are depicted in Figure 3.

Figure 3. Some configurations of hybrid biocomposites (NA: natural, Syn: synthetic): (a) hybridization of natural and synthetic fibers with biopolymer matrix; (b) hybridization of two or more natural fibers with synthetic matrix; (c) hybridization of two or more natural fibers with biopolymer matrix; (d) hybridization of two or more biopolymer matrices with synthetic fiber; (e) hybridization of natural and synthetic fibers with fillers with biopolymer matrix (f) hybridization of biopolymer and synthetic matrices with natural fiber. [©MB, JA, MAM_UC3M2020].

3. Materials Selection

3.1. Fiber Selection

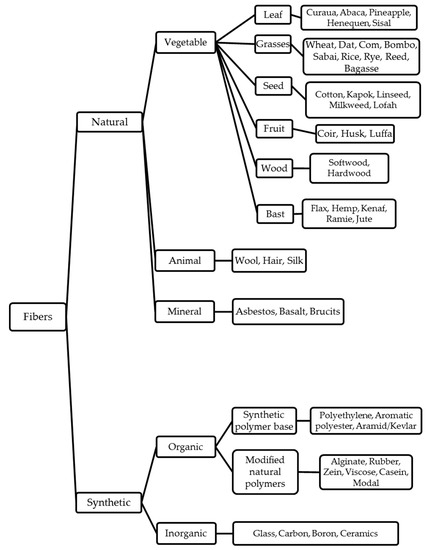

Fibers'’ function as a discontinuous reinforcement phase in fiber-reinforced composites is modifying properties to obtain desired enhancement in the composite structure'’s strength or/and stiffness. They can be subdivided into synthetic or natural fibers according to their origin, as illustrated in Figure 4 [37][38][37,38].

Figure 4. Classification of natural and synthetic fibers. Adapted from [38].

3.2. Matrix Selection

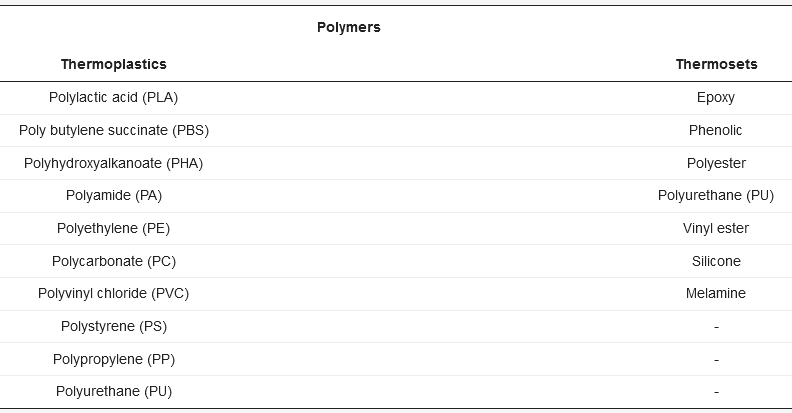

A matrix in the composites provides the overall durability, including surface appearance, shape, and environmental tolerance. Another function of the matrix is to efficiently bind the fibers to transfer load between them [39][74]. These matrices depending on the processing technique and type of bonding present in them can be classified into thermoplastic and thermosets. Major polymers used as a matrix for composites are presented in Table 4.

Table 4.

Major polymers used as a matrix for composites.

Both thermoplastics and thermosets polymers have certain advantages and disadvantages as matrix materials in polymer matrix composites (PMC). The primary difference between thermoset and thermoplastic polymers is their behavior in exposure to heat. Thermoplastics can be reheated, remolded, and reprocessed into a new shape without any chemical changes, while thermosets that strengthen after heating cannot be remolded or dissolved in a solvent [39][40][74,75]. This behavior is attributed to the polymer chains'’ interaction with each other. This interaction in thermosets is strong covalent bonds and chains have a highly cross-linked structure [41][76]. Therefore, thermoset resins such as epoxy, polyester, and polyamide have excellent dimensional stability and resistance against high temperatures without losing their structural integrity. Moreover, they have limited water absorption, high modulus, high strength, and good chemical resistance. The major drawback of thermosets is that recycling and reprocessing are virtually impossible after the initial forming [42][43][77,78]. On the other hand, thermoplastics that also have non-covalent bonds (i.e., relatively weak Van der Waals forces between long-chain molecules) are often chosen over thermosets due to their reversible changes, recyclability, moldability into various shapes, relatively low processing costs, and easy manufacturing with high volume and precision [44][79].

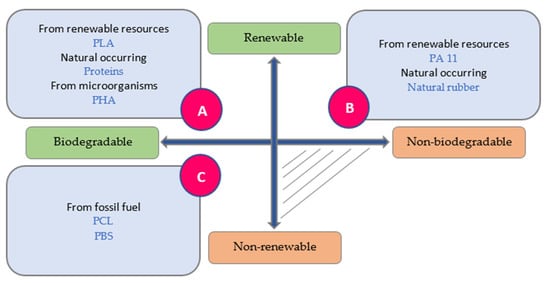

Resins or matrices in the concept of biopolymer can be defined by two criteria (Figure 5): (1) biodegradability of the polymer, (2) source of raw materials [45][80]. The first group (A) of resins are biodegradable biopolymers made from renewable raw materials (bio-based). The second group (B) of resins are non-biodegradable biopolymers made from renewable raw materials (bio-based). The last group (C) of resins are biodegradable biopolymers made from fossil fuels. The biodegradable bio-based resins (type A) are divided into three groups: (1) synthetic polymers from renewable resources, e.g., PLA; (2) biopolymers generated by micro-organisms, e.g., PHA; (3) natural occurring biopolymers, e.g., starch or proteins. The non-biodegradable bio-based resins (type B) that can be produced from biomass or renewable resources are divided into two groups: (1) synthetic polymers from renewable resources such as specific PAs from castor oil (PA 11); (2) natural occurring biopolymers, e.g., natural rubber or amber. The biodegradable resins of type C, such as polybutylene succinate (PBS) and polycaprolactone (PCL), are produced from fossil fuel such as synthetic aliphatic polyesters made from crude oil or natural gas [45][46][47][59,80,81]. Accordingly, not all the bio-based polymers are biodegradable, and not all the biodegradable polymers are bio-based, while some belong to both, such as PHA. Based on the above categories, the biopolyethylene derived from sugarcane, namely "“green polyethylene,"” developed recently, is classified in type B of novel biopolymers [48][82].

Figure 5. Biopolymer matrices classifications [©MB, JA, MAM_UC3M2020].

4. Mechanical Properties of Hybrid Biocomposites

Mechanical properties of hybrid biocomposites may depend on various features such as reinforcements and matrix mechanical properties, reinforcements dispersion and distribution, reinforcements volume fractions and aspect ratio, interfacial adhesion between polymer and reinforcements, loading and test conditions, fibers dimension and orientation, as well as surface modification [16][49][50][51][52][53].

Mechanical properties of hybrid biocomposites may depend on various features such as reinforcements and matrix mechanical properties, reinforcements dispersion and distribution, reinforcements volume fractions and aspect ratio, interfacial adhesion between polymer and reinforcements, loading and test conditions, fibers dimension and orientation, as well as surface modification [16,152,153,154,155,156].

5. Conclusions

Here, hybrid biocomposites have been reviewed, especially in mechanical properties, including tensile, flexural, and impact strength, water absorption, and flammability. In this regard, hybrid composites comprising natural-synthetic fibers, natural-natural fibers, and natural fiber hybrid with nanoparticles or fillers were investigated. Using multiple fibers and developing hybrid composites have received popularity due to the enhanced performance of manufactured products and the possibility of overwhelming the drawbacks of purely natural or synthetic fibers reinforced composites. The focus of this concept is to develop multifunctional materials and structures for advanced applications with improved properties. Researchers have applied various strategies in order to improve the mechanical properties of hybrid biocomposites. Adding a second filler in either micro or nano-size, change the weight percentage of natural and synthetic fibers, addition of fire retardants, change in layering stacking sequence, chemical or physical modification, and changing production techniques are some of the critical strategies. Despite significant challenges with the compatibility and processing of hybrid materials, the aforementioned applied techniques showed remarkable improvements in strength, water absorption resistance, and flame retardancy.

To sum up, in the investigated studies in this review, hybridizations of natural and synthetic fibers with polymeric matrices as well as employing the optimized amount of substances, such as nanoclays, CNTs, silica, cement, and iron oxide particles, alumina, aluminum hydroxide, and graphite nanoplatelets effectively enhanced mechanical properties (e.g., flexural, tensile, and impact strength, flame, and water absorption resistance). High-performance glass and carbon fibers are still the most applicable synthetic fibers for hybridizing the natural fiber composites in recent years. Moreover, chemical treatments or modifications of fibers generally resulted in better mechanical properties, fire, and water resistance than untreated composites due to the improved fiber-matrix bonding after treatments. Among the processing methods, compression molding and hand lay-up are the most often used techniques for hybrid composites with polymeric matrix materials.

Undoubtedly, due to the rising environmental, economic, and application concerns, hybrid biocomposites are gaining significant attention in the future and provide a competitive market for numerous industrial applications. Consequently, this concept is still open, and further research on the possible ways to improve hybrid biocomposites' properties has to be done. Modeling and simulation would be desirable facilities for optimizing these materials properties and addressing the key required changes in production processes.

Undoubtedly, due to the rising environmental, economic, and application concerns, hybrid biocomposites are gaining significant attention in the future and provide a competitive market for numerous industrial applications. Consequently, this concept is still open, and further research on the possible ways to improve hybrid biocomposites’ properties has to be done. Modeling and simulation would be desirable facilities for optimizing these materials properties and addressing the key required changes in production processes.