Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is a comparison between Version 3 by Dean Liu and Version 2 by Dean Liu.

By incorporating halal bioactive materials into the packaging system, it becomes possible to interact with the contents and surrounding environment of halal food products, helping preserve them for longer periods. One particularly promising avenue of research is the use of natural colourants as halal bioactive materials.

- active materials

- food packaging

- bioactive compound

- intelligent indicator

- halal

- food safety and security

1. Introduction

The food crisis has led to a strong desire to preserve food integrity and safety. According to the World Health Organisation [1], food safety must address the risks of climate change and the outbreak of pests and diseases, such as COVID-19, where 600 million people, or one in every ten, have been affected by food-borne diseases caused by contaminated food. In addition, the persistent weakness in handling and storage infrastructure has led to serious food waste and loss because foodstuffs, especially fresh foods, can be easily exposed to food-borne diseases caused by bacterial, viral, parasitic, fungal, and prion infections due to improper handling and processing. This issue has impacted 10% of the world’s population and results in 420,000 deaths each year [2]. Subsequently, this situation has led to an increase in world hunger and severe food insecurity. Thus, the development of intelligent food packaging incorporating halal bioactive materials is a great solution to the challenges of food safety concerns.

Food packaging was first used in the eighteenth century, and it has been developed and improved since the twentieth century [3] into various types of packaging technologies, including intelligent food packaging technology [4]. Intelligent food packaging technology is an extension and improvement of traditional food packaging, adding sensors and other technologies to extend the shelf life of packaged goods. Intelligent packaging technology is becoming more relevant in response to dynamic shifts in global consumer demand and food industry trends. This alternative offers the potential for preserving food integrity because it supports sustainability as well as food safety and security. Intelligent packaging is intended to be an indicator of environmental conditions in order to detect changes in food conditions such as time–temperature, gas leakage, and level of freshness, which is in line with the current food crisis. Two major components must be considered in the production of good and successful intelligent packaging: packaging material and additives [2][4].

Bio-based packaging refers to biodegradable materials used as food-contact materials. For instance, poly (lactic acid) (PLA) is a green polymer from renewable resources manufactured by the polymerization of lactic acid monomers derived from the fermentation of starch feedstock, which is biodegradable and compostable [5]. PLA has emerged as a substitute for petrochemical-based polymers, which are hazardous to the environment, owing to its easy availability, good biodegradability, and outstanding mechanical qualities. Additionally, biodegradable polymers have a well-grounded role in tackling the waste problem [6]. This polymer also aids in reducing food loss and environmental contamination caused by the excessive dumping of non-biodegradable garbage [3][7].

Bioactive ingredients such as anthocyanin, betalain, carotenoid, and chlorophyll, with superior antioxidant and antimicrobial properties, can be used as additives in food packaging. However, these safe, natural pigments have demonstrated several issues, including low bioavailability and instability under a variety of environmental conditions, including exposure to moisture, oxygen, and light. Encapsulation, including nanoencapsulation and microencapsulation, is an effective method to protect these plant pigments from potentially harmful environmental conditions while allowing targeted and controlled release [8]. For example, these compounds can be encapsulated in the PLA matrix to improve their properties while maintaining nutritional quality by preventing pathogenic spoilage and oxidative deterioration of food products [9][10].

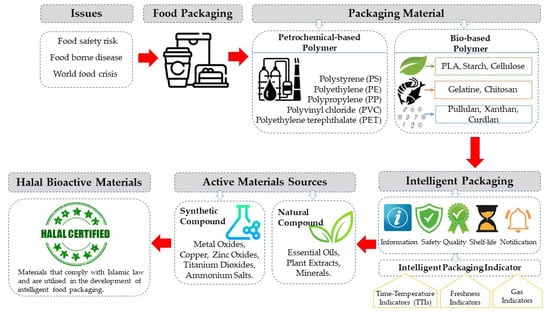

Halal bioactive materials for intelligent food packaging indicators are materials that adhere to Islamic laws and are used in the development of intelligent food packaging. The use of halal bioactive materials in food packaging helps to provide Muslim consumers with peace of mind when purchasing food products. As halal goes beyond religious reasons to include ethical production, responsible consumption, and environmental protection, it supports the development of sustainable and environmentally friendly packaging solutions that enhance the safety and quality of food products. Figure 1 illustrates the integration of bioactive compounds into the packaging system, highlighting their role in enhancing food safety and mitigating potential risks.

Figure 1. Schematic representation of halal bioactive materials for intelligent packaging indicators addressing food safety concerns.

2. Intelligent Packaging

Intelligent packaging is defined as a technology that can communicate and facilitate decision-making to deliver information, enhance safety, assure quality, expand shelf-life, and provide notification of any complication by monitoring alterations in the external and internal environment of packages [11][12]. It aims to observe the product and convey information to consumers, such as the content of a package, the manufacturing date, and storage conditions. The indicator for this intelligent packaging is generally a small item placed either inside or attached to the outside of the package [4]. This information can be used to improve supply chain management, prevent food waste, and enhance the consumer experience.Intelligent Packaging Indicator

The function of indicators is to measure and provide a signal for any reaction. Intelligent packaging indicators regulate the presence and absence of any constituent within the range of their concentration and reaction towards foodstuffs. The indicator is projected by visual changes, such as the modification of colour intensities [4]. Three main indicators are used: time–temperature indicators (TTIs), freshness indicators, and gas indicators. Temperature is one of the factors affecting the shelf life of foodstuffs. The alteration in temperature over time can lead to the growth of microorganisms, which may eventually cause the food to deteriorate and become unsafe for consumption. TTIs may also notify of changes in foodstuffs caused by enzymes, mechanical, chemical, or electrochemical factors. Thus, in the use of TTIs, the temperature of food products must be maintained during handling and transportation before being received by the end consumers [4]. Following that, the freshness indicator performs a similar function to TTIs, but it aids in directly notifying the quality of food products. The freshness indicator will react when metabolites are formed by the growth of microbes in the foodstuff. It will show irreparable visual changes upon the increase in bacteria in the products. Given that this indicator is dependent on metabolites, factors such as the nature of packed foodstuff, flora spoilage, and packaging variety must be considered because they are related to the establishment of metabolites [13]. Gas indicators also ensure food safety and quality. Foodstuff, especially fresh food, starts to decay or is spoiled by microbial fermentation after being packed because of the production and multiplication of carbon dioxide in the packaging. The gas changes with storage time and temperature, which is determined by the type of food, respiratory characteristics, packaging material, and product headspace. Thus, gas indicators may help in tracking the gas level in the headspace of packages to determine the quality of foodstuff [14]. Some intelligent packaging also incorporates active packaging features, such as indicators that can detect the presence of microorganisms or changes in the chemical composition of the food product. Additionally, packaging that incorporates colour changes of active materials indicates the status of the food product, such as changes in temperature, humidity, or other environmental factors, and provides information about the quality and safety of the food product [15][16]. These colour-changing active packaging systems can be considered intelligent packaging because they have the added capability of providing information to the consumer in addition to their functional benefits. The accuracy of intelligent packaging indicators can vary depending on several factors, including the technology used, the type of information being monitored, and the environment in which the system is used [17]. It is also important to realise that, while this technology can indicate food quality, it is not a guarantee of food safety and should be used in conjunction with other food safety measures, such as proper handling, storage, and preparation [7][18].3. Active Materials for Intelligent Food Packaging Indicator

Active materials play a role in controlling the environment inside the package, increasing the shelf life, and preserving the quality and visual appearance of packed foods. Interestingly, reviews on food packaging with these active materials as additives are abundant [19][20]. Two groups of sources are used as additives: synthetic and natural active compounds. Synthetic compounds, such as metal ions, metal oxides, copper, zinc oxides, titanium dioxides, ammonium salts, and ethylenediaminetetraacetic acid, have been widely used as additives for thousands of years. When used in low concentrations, they have been shown to be the most effective in terms of function and to have the least systemic toxicity to humans. Regardless, controversies and contradictory findings regarding the long-term safety of these synthetic additives to human health must be addressed [20][21]. Natural or bioactive compounds with specific functional properties, such as essential oils, plant extracts, and minerals, have all been studied for use in active packaging [22][23]. The appropriate bioactive compound is chosen based on a variety of factors, including its efficacy, compatibility with the food product, and intended end-use application. Therefore, bioactive compounds, especially those from plant sources, are being introduced as alternatives, given that plants consist of pigments, such as chlorophyll, carotenoid, anthocyanin, and betalain. These natural pigments can also be derived from fruits and vegetable wastes and by-products, such as seeds, peels, skins, and leaves [9]. These natural pigments contain a variety of bioactive compounds with physiological effects, such as antioxidants and antimicrobials, and can protect tissues and cells from free radicals and singlet oxygen damage; they can also extend the shelf life of fresh or processed food [10][24][25]. Table 1 exhibits the synthetic and natural active compounds that are currently being used as additives for intelligent food packaging indicators.Table 1. Synthetic and natural active food packaging materials.

| Compound | Food | Function | References |

|---|---|---|---|

| Roses | Shrimp | Freshness indicator | [26] |

| Sodium bicarbonate and citric acid | Chicken | Gas indicator | [27] |

| Red beet | Fish/shrimp | Freshness indicator | [28] |

| Betalain | Meat | Freshness indicator | [29] |

| Dragon fruit | Fish | Freshness indicator | [30] |

| Zinc oxides | Apple | Microbial indicator | [31] |

| Thyme herb | Bread | Freshness indicator | [32] |

| Nisin | Ham | Microbial indicator | [33] |

| Purple sweet potato | Meat | Time–temperature indicator | [34] |

| Pomegranate | Orange fruit | Microbial indicator | [35] |

| Roselle | Pork | Freshness indicator | [36] |

| Red cabbage | Pasteurised Milk | Time–temperature indicator | [37] |

| Eggplant | Milk | Freshness indicator | [38] |

| Clove essential oil and zinc oxide | Shrimp | Microbial indicator | [39] |

| Red cabbage | Milk | Freshness indicator | [40] |

| Jambolan fruit | Shrimp | Time–temperature indicator | [41] |

| Lactoferrin | Fresh sausages | Microbial indicator | [42] |

| Black rice bran | Pomfret/shrimp | Freshness indicator | [43] |

Halal Bioactive Materials for Intelligent Packaging

Polymers are typically made from petroleum-based raw materials. Because of the global problem of pollution, alternative eco-friendly and biodegradable polymers are in high demand. Biopolymers are classified into three types based on their origin and method of production: directly extracted from biomass, synthesised bioderived monomers, and microorganisms [47]. Animal-based and plant-based materials are both viable options for producing edible films and intelligent packaging. The use of either type of material depends on factors such as the intended application, the desired properties of the packaging, and the sustainability and ethical considerations of the material [48]. The primary concern for Halal consumers is the use of additives derived from indefinite sources in the manufacture of polymer resins. For Muslim consumers, the use of biopolymer materials or additives derived from non-halal sources such as animal blood and protein such as collagen, gelatine, and keratin from the non-halal animal is prohibited. According to MS 2565:2014 Halal Packaging–General Guidelines published by the Department of Islamic Development Malaysia (JAKIM), “halal packaging” refers to packaging materials and containers that comply with Islamic law, which includes not only the ingredients used in the packaging but also the manufacturing process and handling procedures [49]. The guidelines provide a set of criteria that must be met for packaging to be considered halal, such as ensuring that the materials used are from permissible sources and that there is no contamination from non-halal substances during the production process. Bioplastics derived from starch, cellulose-based materials, chitosan derived from shrimp and crab shells, and bamboo fibres are some examples of halal biomaterials for food packaging. These materials are renewable, biodegradable, and compostable, making them eco-friendly and sustainable packaging options for food. In addition to meeting the requirements of Islamic law, packaging made from halal biomaterials is an environmentally responsible solution for the packaging industry. In the current Malaysian market, NLYTech Biotech located in Simpang Ampat, Pulau Pinang, and ADA Biotech based in Butterworth, Pulau Pinang are prominent manufacturers specializing in the production of halal-certified biomaterials for packaging applications. These manufacturers use a variety of halal-certified biomaterials, such as broken rice flour, tapioca starch, bamboo, natural food-grade colouring, and even used coffee grounds, to create environmentally friendly and halal-compliant packaging solutions. Their commitment to using permissible sources under Islamic law and meeting the stringent requirements for halal certification exemplifies the industry’s commitment to meeting the needs of Muslim consumers who seek environmentally friendly and ethical products. Meanwhile, halal bioactive materials for intelligent food packaging refer to materials that comply with Islamic law and are utilised in the development of intelligent food packaging. These materials interact with the food product and provide information about the food’s freshness or safety, thereby preventing food spoilage and food waste caused by spoilage. Ultimately, the primary distinction between halal and non-halal intelligent packaging materials is that halal materials must be derived from Islamic law-compliant sources [50]. Another distinction is the manufacturing process. Halal bioactive materials must be produced in a halal-compliant manner, such as by avoiding cross-contamination with prohibited substances or by using equipment that has not been exposed to prohibited substances. There is no discernible difference in terms of performance between halal and non-halal bioactive materials. Both can significantly improve the preservation and shelf life of food products. Examples of halal bioactive materials for intelligent food packaging indicators include pH indicators that change colour in response to changes in the acidity of the food product, oxygen indicators that change colour in response to changes in the oxygen levels inside the package, and microbial indicators that change colour in response to the growth of bacteria and other microorganisms in food products. Due to consumers’ growing concerns about the use of synthetic additives in food products, the food industry has increasingly turned to natural colourants as an alternative to synthetic colourants [51]. In the market of food colouring, natural pigments such as carmine, annatto, and curcumin are prevalent. The excellent tinctorial qualities of cochineal carmine, a dye produced by Dactylopius coccus insects, are highly prized. It is a high-demand functional dye due to its superior antioxidant activity, which is comparable to that of well-known antioxidants such as quercetin, ascorbic acid, and Trolox [52]. According to Islamic law, cochineal carmine is halal because the insects used to produce it are not killed or harmed during extraction, and an insect whose blood does not flow is deemed pure. The Malaysian Fatwa Committee and the Malaysian Food Regulations have permitted the use of cochineal dye because it is manufactured in accordance with Good Manufacturing Practises and does not pose a health risk [53]. There have been previous attempts to improve the mechanical and gas barrier properties of polyvinyl alcohol (PVA) films using a carminic acid-containing edible gel [54]. It should be emphasised that while the current halal certification of packaging materials available in the market is not specifically aimed at the development of bioactive materials for intelligent food packaging, it is still a critical step towards creating an industry-wide halal intelligent food packaging. This initiative demonstrates a strong commitment to advancing sustainable and halal-friendly practices in the packaging industry, and it sets the stage for future research and development of packaging materials that incorporate halal bioactive components for enhanced food safety and quality. By embracing these innovative solutions, the industry can continue to evolve and meet the growing demand for environmentally friendly and ethically sourced packaging solutions.References

- World Health Organization. Available online: https://www.who.int/publications/m/item/the-state-of-food-security-and-nutrition-in-the-world-2022. (accessed on 10 September 2022).

- Halonen, N.; Pálvölgyi, P.S.; Bassani, A.; Fiorentini, C.; Nair, R.; Spigno, G.; Kordas, K. Bio-Based Smart Materials for Food Packaging and Sensors–A Review. Front. Mater. 2020, 7, 82.

- Mtolo, M.; Ruzengwe, F.; Ijabadeniyi, O.A. 14 Food packaging and packaging innovations. Food Science and Technology: Trends and Future. Prospects 2020, 1, 2.

- Müller, P.; Schmid, M. Intelligent Packaging in the Food Sector: A Brief Overview. Foods 2019, 8, 16.

- Nogueira, G.F.; Oliveira, R.A.; Velasco, J.I.; Fakhouri, F.M. Methods of incorporating plant-derived bioactive compounds into films made with agro-based polymers for application as food packaging: A brief review. Polymers 2020, 12, 2518.

- Balla, E.; Daniilidis, V.; Karlioti, G.; Kalamas, T.; Stefanidou, M.; Bikiaris, N.D.; Vlachopoulos, A.; Koumentakou, I.; Bikiaris, D.N. Poly(lactic Acid): A Versatile Biobased Polymer for the Future with Multifunctional Properties—From Monomer Synthesis, Polymerization Techniques and Molecular Weight Increase to PLA Applications. Polymers 2021, 13, 1822.

- Vågsholm, I.; Arzoomand, N.S.; Boqvist, S. Food Security, Safety, and Sustainability—Getting the Trade-Offs Right. Front. Sustain. Food Syst. 2020, 4, 16.

- Ghosh, S.; Sarkar, T.; Das, A.; Chakraborty, R. Natural colorants from plant pigments and their encapsulation: An emerging window for the food industry. LWT 2022, 153, 112527.

- Sharma, M.; Usmani, Z.; Gupta, V.K.; Bhat, R. Valorization of fruits and vegetable wastes and by-products to produce natural pigments. Crit. Rev. Biotechnol. 2021, 41, 535–563.

- Tanna, B.; Choudhary, B.; Mishra, A.; Yadav, S.; Chauhan, O.; Elansary, H.O.; Shokralla, S.; El-Abedin, T.K.Z.; Mahmoud, E.A. Biochemical and Anti-proliferative activities of seven abundant tropical red seaweeds confirm nutraceutical potential of Grateloupia indica. Arab. J. Chem. 2022, 15, 103868.

- Drago, E.; Campardelli, R.; Pettinato, M.; Perego, P. Innovations in Smart Packaging Concepts for Food: An Extensive Review. Foods 2020, 9, 1628.

- Chia, M.-R.; Ahmad, I.; Phang, S.-W. Starch/Polyaniline Biopolymer Film as Potential Intelligent Food Packaging with Colourimetric Ammonia Sensor. Polymers 2022, 14, 1122.

- Smolander, M. Freshness indicators for food packaging. In Smart Packaging Technologies for Fast Moving Consumer Goods; Kerry, J., Butler, P., Eds.; John Wiley & Sons: West Sussex, UK, 2008; pp. 111–127.

- Jung, J.; Puligundla, P.; Ko, S. Proof-of-concept study of chitosan-based carbon dioxide indicator for food packaging applications. Food Chem. 2012, 135, 2170–2174.

- Kerry, J.; O’grady, M.; Hogan, S. Past, current and potential utilisation of active and intelligent packaging systems for meat and muscle-based products: A review. Meat Sci. 2006, 74, 113–130.

- Kuswandi, B.; Wicaksono, Y.; Jayus, J.; Abdullah, A.; Heng, L.Y.; Ahmad, M. Smart packaging: Sensors for monitoring of food quality and safety. Sens. Instrum. Food Qual. Saf. 2011, 5, 137–146.

- Mohebi, E.; Marquez, L. Intelligent packaging in meat industry: An overview of existing solutions. J. Food Sci. Technol. 2014, 52, 3947–3964.

- Uçar, A.; Yilmaz, M.V.; Çakiroglu, F.P. Food Safety–Problems and Solutions. In Significance, Prevention and Control of Food Related Diseases; IntechOpen: London, UK, 2016.

- Flórez, M.; Guerra-Rodríguez, E.; Cazón, P.; Vázquez, M. Chitosan for food packaging: Recent advances in active and intelligent films. Food Hydrocoll. 2022, 124, 107328.

- Vilela, C.; Kurek, M.; Hayouka, Z.; Röcker, B.; Yildirim, S.; Antunes, M.D.C.; Nilsen-Nygaard, J.; Pettersen, M.K.; Freire, C.S.R. A concise guide to active agents for active food packaging. Trends Food Sci. Technol. 2018, 80, 212–222.

- Carocho, M.; Barreiro, M.F.; Morales, P.; Ferreira, I.C. Adding Molecules to Food, Pros and Cons: A Review on Synthetic and Natural Food Additives. Compr. Rev. Food Sci. Food Saf. 2014, 13, 377–399.

- Salgado, P.R.; Di Giorgio, L.; Musso, Y.S.; Mauri, A.N. Recent Developments in Smart Food Packaging Focused on Biobased and Biodegradable Polymers. Front. Sustain. Food Syst. 2021, 5, 630393.

- Carpena, M.; Nuñez-Estevez, B.; Soria-Lopez, A.; Garcia-Oliveira, P.; Prieto, M.A. Essential Oils and Their Application on Active Packaging Systems: A Review. Resources 2021, 10, 7.

- Mohd-Husni, N.; Amer, N.M.; Sofian-Seng, N.S.; Kasim, K.F. Development and characterization of antimicrobial film from Clinacanthus nutans and Polyvinyl Alcohol (PVA) mixture for food packaging. Malays. J. Microsc. 2020, 16, 1.

- Okafor, S.N.; Obonga, W.; Ezeokonkwo, M.A.; Nurudeen, J.; Orovwigho, U.; Ahiabuike, J. Assessment of the Health implications of Synthetic and Natural Food Colourants–A Critical Review. Pharm. Biosci. J. 2016, 4, 01–11.

- Yang, Y.; Yu, X.; Zhu, Y.; Zeng, Y.; Fang, C.; Liu, Y.; Hu, S.; Ge, Y.; Jiang, W. Preparation and application of a colorimetric film based on sodium alginate/sodium carboxymethyl cellulose incorporated with rose anthocyanins. Food Chem. 2022, 393, 133342.

- Holck, A.L.; Pettersen, M.K.; Moen, M.H.; Sørheim, O. Prolonged Shelf Life and Reduced Drip Loss of Chicken Filets by the Use of Carbon Dioxide Emitters and Modified Atmosphere Packaging. J. Food Prot. 2014, 77, 1133–1141.

- Filho, J.G.D.O.; Bertolo, M.R.V.; Rodrigues, M.V.; Silva, G.D.C.; de Mendonça, G.M.N.; Junior, S.B.; Ferreira, M.D.; Egea, M.B. Recent advances in the development of smart, active, and bioactive biodegradable biopolymer-based films containing betalains. Food Chem. 2022, 390, 133149.

- Amjadi, S.; Nazari, M.; Alizadeh, S.A.; Hamishehkar, H. Multifunctional betanin nanoliposomes-incorporated gelatin/chitosan nanofiber/ZnO nanoparticles nanocomposite film for fresh beef preservation. Meat Sci. 2020, 167, 108161.

- Ardiyansyah; Apriliyanti, M.W.; Wahyono, A.; Fatoni, M.; Poerwanto, B.; Suryaningsih, W. The Potency of betacyanins extract from a peel of dragon fruits as a source of colourimetric indicator to develop intelligent packaging for fish freshness monitoring. IOP Conf. Series Earth Environ. Sci. 2018, 207, 012038.

- Li, W.; Li, L.; Cao, Y.; Lan, T.; Chen, H.; Qin, Y. Effects of PLA Film Incorporated with ZnO Nanoparticle on the Quality Attributes of Fresh-Cut Apple. Nanomaterials 2017, 7, 207.

- Suwanamornlert, P.; Kerddonfag, N.; Sane, A.; Chinsirikul, W.; Zhou, W.; Chonhenchob, V. Poly(lactic acid)/poly(butylene-succinate-co-adipate) (PLA/PBSA) blend films containing thymol as alternative to synthetic preservatives for active packaging of bread. Food Packag. Shelf Life 2020, 25, 100515.

- Correa, J.P.; Molina, V.; Sanchez, M.; Kainz, C.; Eisenberg, P.; Massani, M.B. Improving ham shelf life with a polyhydroxybutyrate/polycaprolactone biodegradable film activated with nisin. Food Packag. Shelf Life 2017, 11, 31–39.

- Capello, C.; Trevisol, T.C.; Pelicioli, J.; Terrazas, M.B.; Monteiro, A.R.; Valencia, G.A. Preparation and Characterization of Colorimetric Indicator Films Based on Chitosan/Polyvinyl Alcohol and Anthocyanins from Agri-Food Wastes. J. Polym. Environ. 2020, 29, 1616–1629.

- Kharchoufi, S.; Parafati, L.; Licciardello, F.; Muratore, G.; Hamdi, M.; Cirvilleri, G.; Restuccia, C. Edible coatings incorporating pomegranate peel extract and biocontrol yeast to reduce Penicillium digitatum postharvest decay of oranges. Food Microbiol. 2018, 74, 107–112.

- Zhang, J.; Zou, X.; Zhai, X.D.; Huang, X.W.; Jiang, C.P.; Holmes, M. Preparation of an intelligent pH film based on biodegradable polymers and roselle anthocyanins for monitoring pork freshness. Food Chem. 2019, 272, 306–312.

- Pereira, V.A.; de Arruda, I.N.Q.; Stefani, R. Active chitosan/PVA films with anthocyanins from Brassica oleraceae (Red Cabbage) as Time–Temperature Indicators for application in intelligent food packaging. Food Hydrocoll. 2015, 43, 180–188.

- Yong, H.; Wang, X.; Zhang, X.; Liu, Y.; Qin, Y.; Liu, J. Effects of anthocyanin-rich purple and black eggplant extracts on the physical, antioxidant and pH-sensitive properties of chitosan film. Food Hydrocoll. 2019, 94, 93–104.

- Ejaz, M.; Arfat, Y.A.; Mulla, M.; Ahmed, J. Zinc oxide nanorods/clove essential oil incorporated Type B gelatin composite films and its applicability for shrimp packaging. Food Packag. Shelf Life 2018, 15, 113–121.

- Vo, T.-V.; Dang, T.-H.; Chen, B.-H. Synthesis of Intelligent pH Indicative Films from Chitosan/Poly(vinyl alcohol)/Anthocyanin Extracted from Red Cabbage. Polymers 2019, 11, 1088.

- Merz, B.; Capello, C.; Leandro, G.C.; Moritz, D.E.; Monteiro, A.R.; Valencia, G.A. A novel colorimetric indicator film based on chitosan, polyvinyl alcohol and anthocyanins from jambolan (Syzygium cumini) fruit for monitoring shrimp freshness. Int. J. Biol. Macromol. 2020, 153, 625–632.

- Padrão, J.; Gonçalves, S.; Silva, J.P.; Sencadas, V.; Lanceros-Méndez, S.; Pinheiro, A.C.; Vicente, A.A.; Rodrigues, L.R.; Dourado, F. Bacterial cellulose-lactoferrin as an antimicrobial edible packaging. Food Hydrocoll. 2016, 58, 126–140.

- Wu, C.; Sun, J.; Zheng, P.; Kang, X.; Chen, M.; Li, Y.; Ge, Y.; Hu, Y.; Pang, J. Preparation of an intelligent film based on chitosan/oxidized chitin nanocrystals incorporating black rice bran anthocyanins for seafood spoilage monitoring. Carbohydr. Polym. 2019, 222, 115006.

- Abedi-Firoozjah, R.; Yousefi, S.; Heydari, M.; Seyedfatehi, F.; Jafarzadeh, S.; Mohammadi, R.; Garavand, F. Application of red cabbage anthocyanins as pH-sensitive pigments in smart food packaging and sensors. Polymers 2022, 14, 1629.

- Dhall, R.K. Advances in Edible Coatings for Fresh Fruits and Vegetables: A Review. Crit. Rev. Food Sci. Nutr. 2013, 53, 435–450.

- Martins, C.; Vilarinho, F.; Silva, A.S.; Andrade, M.; Machado, A.V.; Castilho, M.C.; Sá, A.; Cunha, A.; Vaz, M.F.; Ramos, F. Active polylactic acid film incorporated with green tea extract: Development, characterization and effectiveness. Ind. Crop. Prod. 2018, 123, 100–110.

- Lisitsyn, A.; Semenova, A.; Nasonova, V.; Polishchuk, E.; Revutskaya, N.; Kozyrev, I.; Kotenkova, E. Approaches in animal proteins and natural polysaccharides application for food packaging: Edible film production and quality estimation. Polymers 2021, 13, 1592.

- Khodaei, D.; Álvarez, C.; Mullen, A.M. Biodegradable packaging materials from animal processing co-products and wastes: An overview. Polymers 2021, 13, 2561.

- MS 2565:2014; Halal Packaging-General Guidelines. Department of Standards Malaysia: Selangor, Malaysia, 2014.

- Mohamed Syazwan, A.T.; Mohd Remie, M.J. Issues in Halal Packaging: A Conceptual Paper. Int. Bus. Manag. 2012, 5, 94–98.

- Evangelho, J.A.D.; Dannenberg, G.D.S.; Biduski, B.; el Halal, S.L.M.; Kringel, D.H.; Gularte, M.A.; Fiorentini, A.M.; Zavareze, E.D.R. Antibacterial activity, optical, mechanical, and barrier properties of corn starch films containing orange essential oil. Carbohydr. Polym. 2019, 222, 114981.

- González, E.A.; García, E.M.; Nazareno, M.A. Free radical scavenging capacity and antioxidant activity of cochineal (Dactylopius coccus C.) extracts. Food Chem. 2010, 119, 358–362.

- Al Kafi li al-Fatawi #505: Pewarna Merah Gincu Bibir Yang Diperbuat Daripada Cochineal. Adakah halal? Mufti of Federal Territory’s Office. Available online: https://muftiwp.gov.my/en/artikel/al-kafi-li-al-fatawi/2085-al-kafi-505-pewarna-merah-gincu-bibir-yag-diperbuat-daripada-cochineal-adakah-halal (accessed on 24 March 2023).

- Bayer, G.; Shayganpour, A.; Zia, J.; Bayer, I.S. Polyvinyl alcohol-based films plasticized with an edible sweetened gel enriched with antioxidant carminic acid. J. Food Eng. 2022, 323, 111000.

More