Power plants related to distributed generation can be classified according to the type of primary energy: fossil fuel, nuclear or renewable energy, or waste heat. Combustion-based plants, depending on the type of fossil fuel, can be divided into those using natural gas, coal, peat, wood, oil, diesel, gasoline, etc. The most common fuels for 1–100 MW plants are natural gas, diesel and coal, as they have a significant heat value, are low-cost and are available in large quantities. In the case of natural gas or diesel, electricity can be generated using open cycles such as the Brayton, Otto and Diesel cycles. They can be implemented in gas turbine plants (GTPs), gas piston plants (GPPs) and diesel generator power (DGP) complexes. When using any organic fuel, a closed energy cycle implemented in steam turbine power plants (STPs) can be used. Closed power cycles on water or organic coolants can also be used to generate electricity from industrial waste heat.

1. Small Thermal and Renewable Power Plants

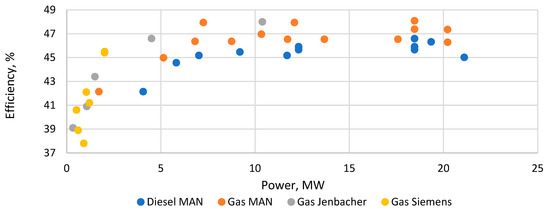

At the moment, thermal power plants are the most common among distributed generation facilities. Small-capacity power plants (up to 50 MW) use piston internal combustion engines fueled by natural gas or liquid fuels. This is due to the unit output limitation of the most efficient four-stroke engines at 20 MW. At the same time, the efficiency of piston engines grows from 37.8 to 48% (

Figure 1)

[1][2][3][13,14,15], with diminishing returns as the unit output grows from 1 to 20 MW.

Figure 1.

The ICE efficiency dependence on power.

Micro-GTUs from Capstone, Bladon Jets, Kawasaki and Ansaldo have a similar capacity level. However, their efficiency and service life are lower than those of internal combustion engines, and the capital cost is higher, which is the reason for their little use.

For power plant capacities of more than 50 MW, it is possible to use gas turbine and combined-cycle plants, which are mainly manufactured by GE, Siemens and Mitsubishi. In addition, it is possible to use steam turbine power units burning coal, natural gas and other fuels.

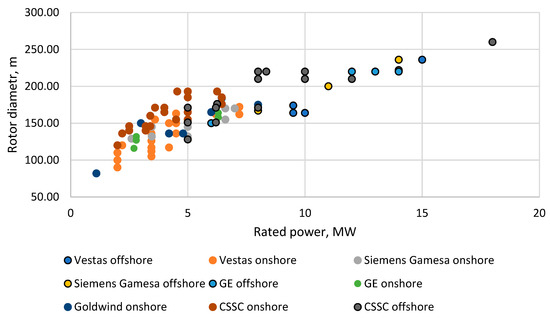

Wind power plants (WPPs) have similar installed capacities and can scale up to hundreds of megawatts by increasing the number of installations. Currently, Vestas, Goldwind, and GE

[4][12] account for about 40% of the total wind turbine market. The main way to reduce the cost of electricity from WPPs is to increase the unit output of the plant, which is achieved by increasing the sweep area and hence the length of the blade and the diameter of the rotor (

Figure 2)

[5][6][7][8][9][16,17,18,19,20]. The unit output of a wind turbine also differs significantly depending on the area of use (onshore and offshore). Onshore installations have a lower capacity, which averages 2.5–3 MW and can reach 7 MW, while coastal installations have an average capacity of 3.6 MW and can reach 18 MW

[10][21]. Higher capacity with similar rotor diameter dimensions is primarily associated with higher wind speed over the sea surface and a corresponding increase in IEC Wind Class to I

[11][22].

Figure 2.

Rotor diameter dependence on efficiency for different wind turbines.

For solar power plants, the most important indicators are efficiency and unit cost. There are two main types of solar power plants: those based on a thermodynamic cycle, in which the radiation energy is concentrated on a thermal energy storage device to increase the temperature of the working fluid, and those based on direct conversion, in which photon energy is converted into electrical energy using semiconductor materials. At the moment, photovoltaic solar panels are the cheapest and most common

[12][23]. There are solar cells based on silicon, perovskite, selenide, copper, indium, gallium, cadmium, telluride, their organic compounds and other materials. From a technology point of view, solar cells are single-crystal, in the form of a thin film, multi-crystal, multi-junction and others. In 2021, more than 95% of all new PV panels were silicon-based, of which 85% were made from single crystals

[13][24]. The average efficiency of the most common single-crystal silicon panels is 20–22%. At the same time, the laboratory samples of cells can reach higher efficiency: silicon single-crystal without a concentrator—26.1%; multi-crystal without a concentrator—24.4%; in the form of a thin film—23.35%; using perovskite—32.5%. The most efficient are multi-junction PVs, which allow the use of solar radiation in a wider frequency range and achieve an efficiency above 40%; for example, four-junction cell 4-J,665x made by Fraunhofer Institute for Solar Energy Systems in Germany has reached 47.6%

[14][25].

When conducting a comparative analysis of the technical and economic characteristics of the most common distributed energy facilities, it is advisable to choose the completed installations, the operation of which does not imply the provision of special conditions. Such installations include piston internal combustion engines, gas turbine plants, steam turbine plants, onshore wind power plants and solar power plants using single-crystal silicon cells.

2. Small Nuclear Power Plants

The use of SNPPs is especially important for the power supply in remote regions. The main advantages of SNPPs compared to fossil fuel plants are the absence of harmful emissions and the small volumes of fuel consumed, which must be delivered to the site and stored. Moreover, compared to renewable energy sources, SNPPs can have a constant and controlled source of electrical and thermal energy that is almost independent of external conditions, which is important when operating in an isolated power system with a small number of generating units.

Depending on the technology, small-capacity reactors are subdivided into water-cooled land-based and sea-based reactors, high-temperature gas-cooled reactors, and fast-neutron liquid-metal reactors using molten salts. At the moment, SNPP projects already exist and are being developed around the world. In China, the 210 MW HTR-PM reached its full capacity in 2022, and work began on the construction of the 125 MW ACP100 reactor. In Argentina, the 25 MW CAREM reactor is under construction. In the USA, NuScale is going to build six reactors with a capacity of 50 MW each, and the British company Rolls-Royce SMR plans to build plants for the production of equipment for SNPPs. Russia has already built a floating nuclear thermal power plant with a capacity of 70 MW with two KLT-40S reactors and nuclear icebreakers with 53 MW RITM-200 reactors. Moreover, it is planned to create ABV-6, Shelf-M and SVBR-100 reactors with capacities of 6–9, 10 and 100 MW. The distribution of existing and most developed SNPP reactor designs in comparison with alternative power generation technologies depending on power is given in

Table 1 [15][26]. Most of the installations are based on thermal neutron reactors, which use a water coolant and operate under pressure.

.

Table 2 shows the characteristics of Russia’s most developed projects or small-size nuclear reactors already in operation

[15][18][19][26,29,30]. The presented models cover a wide range of electrical and thermal capacities. A distinctive feature of SNPPs is a higher degree of fuel enrichment compared to standard NPPs, which are limited to 20% due to IAEA requirements, and a lower burn-up fraction.

To develop the far north of Russia, independent small-capacity power supply sources with minimal emissions of harmful substances are needed

[16][27], so SNPPs are one of the promising ways to develop the sea route and explore the Arctic

[17][28]The results of a comparison of the main technical and economic characteristics of most of the known distributed power generation installations are presented in

Table 3 [4][20][21][12,31,32]. For small-capacity plants, capacity strongly affects the unit cost of plants (this is characteristic primarily for plants where the number of equipment units is almost independent of the installed capacity of the power unit), which leads to a wide range of changes in capital costs. At low capacities, the cheapest are piston internal combustion engines. For higher installed capacities, gas turbine plants have the lowest capital cost, followed by internal combustion engines and solar power plants. This is followed by steam turbine plants and wind power plants. The cost of NPP installed capacity is the highest and several times higher than the cost of alternative technologies; however, NPP service life is also much longer, which reduces the share of capital costs in the cost of electricity. It is also worth noting that plants with the same installed capacity will produce different amounts of electricity per year due to the need for repairs, changes in external weather conditions and other factors, which are reflected in the capacity factor and will significantly affect the cost of electricity.

Internal combustion engines have the highest efficiency at low capacities, followed by gas turbine and steam turbine plants with similar efficiency. This is followed by wind, nuclear and solar power plants. Since renewable power plants do not consume fuel but use only available energy sources, the efficiency parameter is irrelevant to them. Therefore, in the case of RES, the efficiency and potential of renewable sources are reflected in the CF (capacity factor), and the cost of electricity produced is most affected by the unit capital cost of the plant.

Carbon dioxide emissions from power generation depend primarily on the type of fossil fuel used and, secondarily, on the efficiency of the plant. The most environmentally friendly fossil fuel is natural gas, followed by diesel and coal, which lead to significantly more harmful emissions. Therefore, the lowest carbon dioxide emissions are achieved when using an internal combustion engine running on natural gas, followed by an internal combustion engine running on diesel, STP and GTP on natural gas and STP on coal.

Thus, the resviearch w made it possible to conclude that the main characteristics of distributed generation plants, including energy efficiency and cost, differ significantly. Therefore, the feasibility of introducing a specific electricity generation technology will largely depend on specific scenario conditions, first of all, the cost of fuel. To identify the influence of the mentioned factor on the economic attractiveness of various distributed generation plants, a technical and economic analysis was carried out.