Given the immense amount of battery data produced over its operational life, the scientific community is increasingly turning to cloud computing for data storage and analysis. This cloud-based digital solution presents a more flexible and efficient alternative to traditional methods that often require significant hardware investments. The integration of machine learning is becoming an essential tool for extracting patterns and insights from vast amounts of observational data. As a result, the future points towards the development of a cloud-based artificial intelligence (AI)-enhanced battery management system (BMS). This will notably improve the predictive and modeling capacity for long-range connections across various timescales, by combining the strength of physical process models with the versatility of machine learning techniques.

1. Introduction

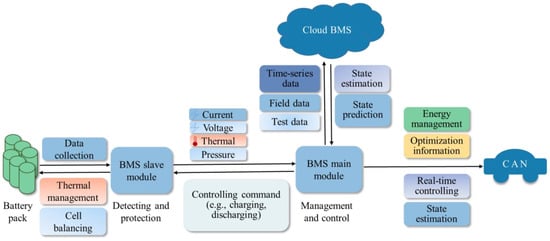

Machine learning has emerged as a powerful instrument; however, it necessitates substantial quantities of high-quality and pertinent observational samples. The computational complexity associated with this requirement surpasses the capabilities of onboard Battery Management Systems (BMS). Cloud-based BMS (Figure 1) provides a brand-new digital solution, as it can process and analyze data in a more efficient and flexible manner. Sensor measurements can be uploaded to the cloud, enabling machine learning to continually learn from these data points while harnessing the vast wealth of information present in the samples. A cloud BMS enables remote monitoring, diagnostics, and even predictive maintenance, improving overall battery management and reducing the need for manual inspections or on-site intervention. The cloud BMS can also facilitate fleet management by aggregating data from multiple vehicles or energy storage systems, allowing operators to optimize energy consumption and plan maintenance schedules more efficiently. Additionally, a Cloud BMS can enable over-the-air (OTA) updates to the onboard BMS firmware and algorithms, further enhancing battery performance and extending its lifespan.

Figure 1.

Cloud-based framework for battery management in EV applications.

2. IoT-Devices

Given the extensive embrace of Internet of Things (IoT) technology

[1][45], end-use devices have gained the ability to collect and analyze vast amounts of data across various spatial and temporal scales. Equipped with electronics and network connectivity, these devices hold a key position in monitoring and management. As the number of sensors is expected to reach trillions in the near future, integrating data streams with diverse levels of fidelity into real-world applications and battery models becomes increasingly feasible.

The physical, chemical, and electrochemical performance of batteries can exhibit significant variations due to dynamic loading conditions such as current rate, operating voltage, temperature, and more. Consequently, continuous monitoring throughout the operational lifetime is of paramount importance

[2][46]. The onboard Battery Management System (BMS) enables the transfer of sensor measurements from the battery cells to the IoT component, employing the Controller Area Network (CAN) protocol for communication. To optimize resource utilization while efficiently transmitting a substantial volume of sequential data generated by both private and fleet vehicles, the message queuing telemetry transport (MQTT) protocol

[3][47] enables bidirectional communication between the device and the cloud. The infrastructure can effortlessly support millions of IoT devices, seamlessly accommodating their operations. Moreover, the data stored in the onboard memory can be efficiently transmitted to the cloud system using TCP/IP protocols, ensuring smooth and reliable upload processes. Modern cities’ IoT systems provide infrastructure for remote data transmission through the use of IoT actuators and on-board sensors. For a more detailed explanation of the next-generation IoT, please refer to

[4][48].

3. Cloud Server-Farm

A cloud server farm is a large-scale data center infrastructure that offers remote data storage and analysis capabilities, including real-time monitoring, early warning systems, and intelligent diagnosis over the internet. This beckons scientists as data sets continue to expand

[5][49]. Cloud storage and computing has been widely recognized and acknowledged as a highly effective and flexible solution for remote monitoring, especially in the context of large-scale EV applications

[6][50]. In this context, developers have the flexibility to seamlessly tailor their cloud to meet their specific needs and demands, thereby achieving maximum efficiency and convenience. The cloud based BMS has the capability to learn and analyze the continuous flow of the charging and discharging data of battery systems, enabling the generation of health information.

The cloud BMS can learn and analyze the continuous stream of time-series battery data and generate electronic health records, which provide insightful information about the battery’s performance and health status. Java and Go are among the most commonly used programming languages for cloud development, providing developers with robust and efficient tools to create sophisticated and reliable cloud applications. Additionally, PHP offers a flexible and effective solution for web developers to design interactive interfaces and engage with the vast amount of data generated by the system

[7][51].

In order to implement the battery-cloud system efficiently, it is essential for users to have some basic computing skills, but more importantly, it requires a deep understanding and knowledge of the learning task at hand, particularly in the context of complex, nonlinear multiphysics battery systems that exhibit gappy and noisy boundary conditions. Moreover, modeling of battery systems for field applications, such as prognostics and predictive health management (PHM), is often prohibitively expensive and requires complex formulations, new algorithms, and elaborate computer codes.

4. Machine Learning

In spite of the progress achieved in forecasting the dynamics of battery systems utilizing fundamental principles, atomic-level analysis, or methods rooted in physics, a notable obstacle persists due to the lack of all-encompassing prognostic models capable of establishing robust connections between cell properties, underlying mechanisms, and the states of the cell. The prognostication and modeling of battery systems’ multi-dimensional behavior, influenced by various spatio-temporal factors, emphasize the necessity for a revolutionary approach. Deep learning has exhibited extraordinary advancements in addressing enduring quandaries faced by the artificial intelligence community

[8][52]. The widespread availability of open-source software and the automation capabilities of material tools have seamlessly integrated machine learning into computational frameworks. Prominent software libraries like TensorFlow

[9][10][53,54], PyTorch

[11][12][55,56], and JAX

[13][57] contribute significantly to the analysis of cell performance by harnessing diverse data modalities encompassing time series data, spectral data, laboratory tests, field data, and more.

In the realm of predictive modeling of battery systems, there has been a recent push towards synergistically integrating machine learning tools with cloud computing. In this context, researchers and engineers can access real-time data streams and perform real-time analysis and predictions of battery performance, which is pivotal when it comes to the design and optimization of battery systems. The integration of machine learning algorithms, cloud computing, and big data analysis has created a powerful ecosystem for the representation of multiscale and multiphysics battery systems. By incorporating actual sensor data to calibrate the models, a battery-powered digital twin strives to emulate the dynamics of the physical entity in a digital environment. Physics-informed learning is poised to emerge as a driving force in the transformative era of digital twins, thanks to its innate ability to seamlessly integrate physical models and data.

A recent illustration of this innovative learning approach is Physics-Informed Neural Networks (PINNs). The integration of data from measurements and partial differential equations (PDEs) is flawlessly accomplished by PINNs through the incorporation of these PDEs into the neural networks. This approach exhibits exceptional adaptability, allowing it to effectively handle a wide range of PDE types, including integer-order PDEs, fractional PDEs, and stochastic PDEs. To illustrate its effectiveness, the PINN model can be successfully employed to solve forward problems utilizing the viscous Burgers’ equation, which can be represented as:

The physics-uninformed networks act as a surrogate for the PDE solution u(x, t), whereas the physics-informed networks characterize the PDE residual. The loss function encompasses both a supervised loss, incorporating data measurements of u obtained from initial and boundary conditions, and an unsupervised loss, which captures the PDE discrepancy:

where

The two sets of points,

and

, correspond to samples taken from initial and boundary locations and the complete domain, respectively. To effectively balance the relationship between the two loss terms, weight,

and

are utilized. The neural network undergoes training using gradient-based optimizers like Adam to minimize the loss until it is below a predefined threshold ε. For a detailed discussion and introduction of PINN, one can refer to a comprehensive review

[14][58].