Extensive studies have been conducted on utilising natural fibres as reinforcement in composite production. All-polymer composites have attracted much attention because of their high strength, enhanced interfacial bonding and recyclability. Silks, as a group of natural animal fibres, possess superior properties, including biocompatibility, tunability and biodegradability. This makes them promising candidates for application as a new composite material. Understanding both the applications and fundamental behaviours of silk fibroin is essential. This can be achieved with techniques like time-temperature superposition to understand the effects of dissolution on raw silk fibres.

- silk-based composites

- time–temperature superposition

- biomaterials

1. Introduction

2. Silk Structure and Silk-Based Composites Properties

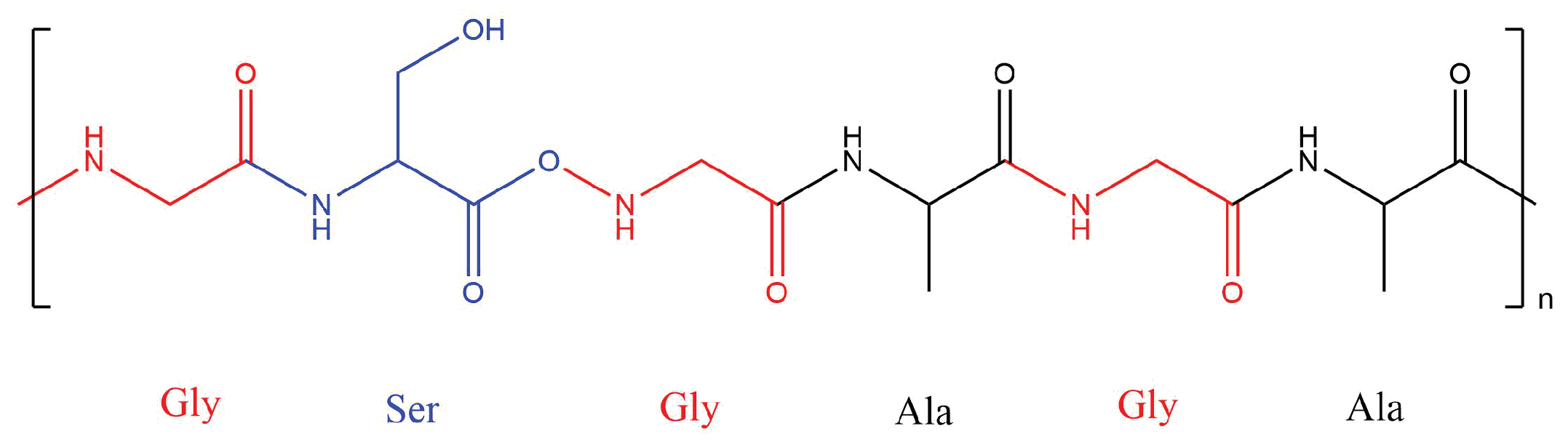

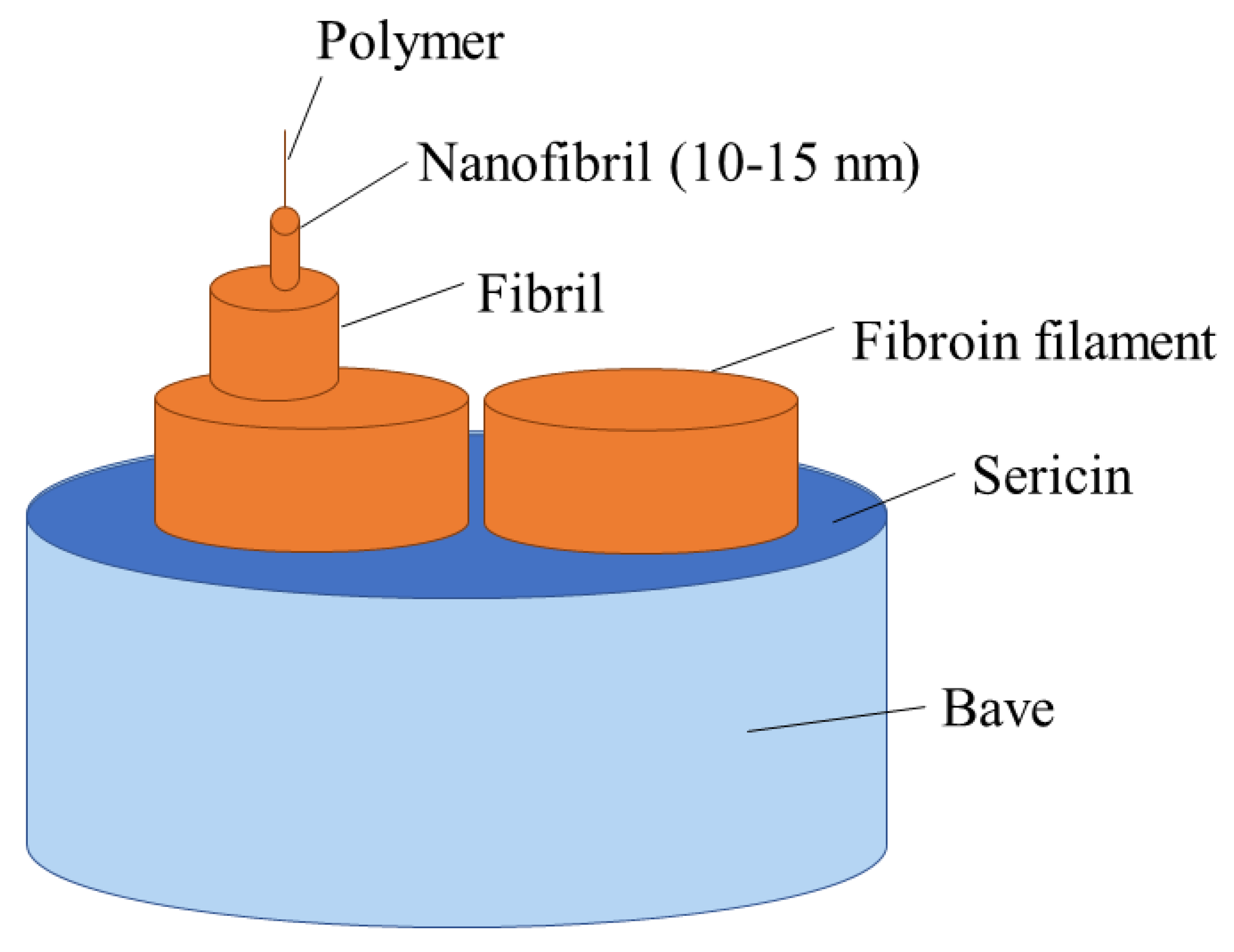

Silk is a common biological protein formed of a complex hierarchical structure with variable chemical compositions. The most common of these are the silk sericin and silk fibroin (SF) proteins. SF typically has a hexapeptide primary sequence dominated by glycine amino acid units, as seen in Figure 1 [34]. Raw fibre sheets of these biomaterials have inherent flaws compared to composites. Existing voids act as water channels to allow degradation by wetting, and hydrogen bonds can be broken by water molecules, which allows solvation and plasticisation [35]. This and other issues can be overcome by their inclusion in composites, which can improve material properties.

3. Published Methods of Tailoring Mechanical Properties of Silk Composites

Mechanical properties of NFRPCs are one of the most important characteristics for their use in engineering and biomedical fields, and it is essential for composite materials to provide adequate mechanical behaviour (tensile, flexural, impact and hardness) based on their desired applications [44][45]. The mechanical properties of NFRPCs depend on various parameters, such as fibre alignment, fibre length, fibre orientation, volume fraction of fibres, aspect ratio of fibres and fibre–matrix adhesion [46][47][48][49][50]. Studies investigating mechanical performance of NFRPCs have focused on two major aspects: (i) influences of various treatments of fibres (physical, chemical and biological), fibre content, fabrication process and external coupling agents on mechanical properties; and (ii) incorporating experimental data and well-established models to predict mechanical behaviour [51][52][53][54][55][56][57][58][59][60]. Natural silk fibres from Bombyx mori have relatively high mechanical properties: 300–740 MPa (ultimate strength), 4–26% (breaking strain), 10–17 GPa (Young’s modulus) and 70–78 MJm−3(toughness). These properties often exceed those of synthetic fibres such as nylon, Kevlar and polypropylene [61][62][63][64][65][66][67]. The variation in mechanical properties of Bombyx mori silk fibres comes from several factors, such as the food, rearing conditions and health of silkworms [68], differences in the spinning process (natural spinning, forced spinning at a controlled drawing rate and modulated spinning in an electric field) [61][69][70] and genetic modification of the silk sequence [71][72]. For the purpose of broadening silk-based applications, silk fibres generally undergo the process of degumming, dissolution and regeneration and subsequently form the formats of sponges, hydrogels, films, mats and composites for versatile applications. Research suggests that these SF materials show good biocompatibility with a series of cell types and also promote the characteristics of adhesion, proliferation, growth and functionality [73]. In particular, research on tailoring the mechanical properties of silk-based composites also follows the two major aspects addressed earlier: (i) applying experimental treatments to tune the mechanical properties in order to achieve the desired structure–property–application relationship; and (ii) using analytical models to predict mechanical performance for further facilitation of composite material design and optimisation.4. Applications of Silk Composites

Although the fundamental research of silk composites is interesting due to the inherent complexity of the natural system and preparation conditions, they are often researched with intended applications in mind. Hence, research can either be approached as bottom-up, fundamental, blue-sky research or challenge-driven top-down research [74]. Silks have been primarily used for biomedical applications as they are perceived to be biocompatible, biodegradable and non-toxic [75]. It is of note that biocompatibility is not universal and must be specific to tissue and wound to encourage the correct immune response during healing [74]. Current uses of silk include sutures, surgical meshes and medical fabrics. Coating silk fibres with regenerated SF for use as sutures is one of the first examples of ASC use in medicine. Some future applications still being developed include tissue engineering and wound healing [74]. Microneedles also offer an exciting new development in transdermal vaccine delivery. SF microneedles offer a solution for controlled-release drug delivery with minimally invasive techniques [76][77]. As shown in works by Tsioris et al. and Stinson et al., SF microneedles provide favourable mechanical properties, biocompatibility, biodegradability, benign processing conditions and the ability to maintain the activity of biological compounds in its matrix [76][77]. This biomaterial could offer a new application for engineered biocomposites of SF in which the techniques mentioned above may confer improved toughness over simpler SF microneedle arrays. Scaffolds of biomimetic materials are common forms of biosynergistic composites and function as host environments for cell and tissue growth and proliferation [78]. In order to be biomimetic, these engineered tissues must regulate healing phases by imitation of immunoresponse signals [79]. When preparing a composite for tissue engineering, it must provide [80][81][82][83]:- [84];Appropriate permeability and absorption [81];

-

Native femoral artery—≈9.0 MPa [84];Correct release behaviour [81];

- ][83];

-

Structural stability [80];

-

Human medial meniscus—≈1.0 MPa [84];Porosity [80Thermal stability [

-

Fixation plates—≈700 MPa [85];

-

Articular cartilage—0.4–1.6 MPa

- Cancellous bone—0.05–5 GPa

- [

- 86].

5. Conclusion

With recent awareness of global environmental challenges, it has become of increasing importance to utilise sustainable biomaterials to replace non-renewable alternatives. In this role, silk possesses unique qualities of strength and biocompatibility that highlight it as a key contributor to future developments in NFRPCs. Through this rentry, the researchers view, we discussed the behaviours and uses of silk-based composites and reported on the enhancement of mechanical properties of silk-based composites. The researchersWe separated enhancements into experimental (chemical and/or physical) treatments to achieve desired properties and the use of analytical models to predict the mechanical properties for further design and optimisation of the structure and properties. As an example of this, the researchers rewe reported on the modelling of the fabrication of ASCs using time–temperature superposition. This can be used to manipulate the mechanical properties and morphology of composites via changes to the dissolution time and temperature that alter the volume fraction of the matrix. This gives rise to clearly defined trends of material properties as a function of time, temperature or matrix fraction. ASCs can therefore be manipulated for desired purposes with good interfacial bonding between the fibre and the matrix due to chemical homogeneity. Finally, the researchers we discussed the applications of silk composites. This entryreview focused on biomedical uses, with other examples in water sanitation, aeronautical engineering and decorative functional materials. This shows a future of applications in many industries with challenges highlighted in upscaling as well as achieving true sustainability with widespread use of these new materials.

References

- Corbin, A.C.; Soulat, D.; Ferreira, M.; Labanieh, A.R.; Gabrion, X.; Malécot, P.; Placet, V. Towards hemp fabrics for high-performance composites: Influence of weave pattern and features. Compos. Part B Eng. 2020, 181, 107582.

- Suddell, B.C.; Evans, W.J. Natural fiber composites in automotive applications. In Natural Fibers, Biopolymers, and Biocomposites; CRC Press: Boca Raton, FL, USA, 2005; pp. 253–282.

- Mohanty, A.K.; Misra, M.; Drzal, L.T. Natural Fibers, Biopolymers, and Biocomposites; CRC Press: Boca Raton, FL, USA, 2005.

- Koronis, G.; Silva, A.; Fontul, M. Green composites: A review of adequate materials for automotive applications. Compos. Part B Eng. 2013, 44, 120–127.

- Ahmad, F.; Choi, H.S.; Park, M.K. A review: Natural fiber composites selection in view of mechanical, light weight, and economic properties. Macromol. Mater. Eng. 2015, 300, 10–24.

- Fantuzzi, N.; Bacciocchi, M.; Benedetti, D.; Agnelli, J. The use of sustainable composites for the manufacturing of electric cars. Compos. Part C Open Access 2021, 4, 100096.

- Naik, V.; Kumar, M. A review on natural fiber composite material in automotive applications. Eng. Sci. 2021, 18, 1–10.

- Cheung, H.Y.; Ho, M.P.; Lau, K.T.; Cardona, F.; Hui, D. Natural fibre-reinforced composites for bioengineering and environmental engineering applications. Compos. Part B Eng. 2009, 40, 655–663.

- Xie, Y.; Hill, C.A.; Xiao, Z.; Militz, H.; Mai, C. Silane coupling agents used for natural fiber/polymer composites: A review. Compos. Part A Appl. Sci. Manuf. 2010, 41, 806–819.

- Zhao, X.; Copenhaver, K.; Wang, L.; Korey, M.; Gardner, D.J.; Li, K.; Lamm, M.E.; Kishore, V.; Bhagia, S.; Tajvidi, M.; et al. Recycling of natural fiber composites: Challenges and opportunities. Resour. Conserv. Recycl. 2022, 177, 105962.

- Gao, C.; Yu, L.; Liu, H.; Chen, L. Development of self-reinforced polymer composites. Prog. Polym. Sci. 2012, 37, 767–780.

- Capiati, N.J.; Porter, R.S. The concept of one polymer composites modelled with high density polyethylene. J. Mater. Sci. 1975, 10, 1671–1677.

- Barkoula, N.M.; Peijs, T.; Schimanski, T.; Loos, J. Processing of single polymer composites using the concept of constrained fibers. Polym. Compos. 2005, 26, 114–120.

- Ward, I.; Hine, P. Novel composites by hot compaction of fibers. Polym. Eng. Sci. 1997, 37, 1809–1814.

- Ward, I.; Hine, P. The science and technology of hot compaction. Polymer 2004, 45, 1413–1427.

- Ward, I. Developments in oriented polymers, 1970–2004. Plast. Rubber Compos. 2004, 33, 189–194.

- Rasburn, J.; Hine, P.; Ward, I.; Olley, R.; Bassett, D.; Kabeel, M. The hot compaction of polyethylene terephthalate. J. Mater. Sci. 1995, 30, 615–622.

- Yu, L.; Liu, H.; Dean, K.; Chen, L. Cold crystallization and postmelting crystallization of PLA plasticized by compressed carbon dioxide. J. Polym. Sci. Part Polym. Phys. 2008, 46, 2630–2636.

- Ward, I.M.; Coates, P.D.; Dumoulin, M.M. Solid Phase Processing of Polymers; Hanser Publishers: Munich, Germany, 2000.

- Nishino, T.; Matsuda, I.; Hirao, K. All-cellulose composite. Macromolecules 2004, 37, 7683–7687.

- Gindl, W.; Keckes, J. All-cellulose nanocomposite. Polymer 2005, 46, 10221–10225.

- Nishino, T.; Arimoto, N. All-cellulose composite prepared by selective dissolving of fiber surface. Biomacromolecules 2007, 8, 2712–2716.

- Soykeabkaew, N.; Nishino, T.; Peijs, T. All-cellulose composites of regenerated cellulose fibres by surface selective dissolution. Compos. Part A Appl. Sci. Manuf. 2009, 40, 321–328.

- Qin, C.; Soykeabkaew, N.; Xiuyuan, N.; Peijs, T. The effect of fibre volume fraction and mercerization on the properties of all-cellulose composites. Carbohydr. Polym. 2008, 71, 458–467.

- Arévalo, R.; Picot, O.T.; Wilson, R.M.; Soykeabkaew, N.; Peijs, T. All-cellulose composites by partial dissolution of cotton fibres. J. Biobased Mater. Bioenergy 2010, 4, 129–138.

- Liang, Y.; Hawkins, J.E.; Ries, M.E.; Hine, P.J. Dissolution of cotton by 1-ethyl-3-methylimidazolium acetate studied with time–temperature superposition for three different fibre arrangements. Cellulose 2021, 28, 715–727.

- Shibata, M.; Teramoto, N.; Nakamura, T.; Saitoh, Y. All-cellulose and all-wood composites by partial dissolution of cotton fabric and wood in ionic liquid. Carbohydr. Polym. 2013, 98, 1532–1539.

- Ouajai, S.; Shanks, R.A. Preparation, structure and mechanical properties of all-hemp cellulose biocomposites. Compos. Sci. Technol. 2009, 69, 2119–2126.

- Chen, K.; Xu, W.; Ding, Y.; Xue, P.; Sheng, P.; Qiao, H.; He, J. Hemp-based all-cellulose composites through ionic liquid promoted controllable dissolution and structural control. Carbohydr. Polym. 2020, 235, 116027.

- Hawkins, J.E.; Liang, Y.; Ries, M.E.; Hine, P.J. Time temperature superposition of the dissolution of cellulose fibres by the ionic liquid 1-ethyl-3-methylimidazolium acetate with cosolvent dimethyl sulfoxide. Carbohydr. Polym. Technol. Appl. 2021, 2, 100021.

- Abbott, A.; Bismarck, A. Self-reinforced cellulose nanocomposites. Cellulose 2010, 17, 779–791.

- Adak, B.; Mukhopadhyay, S. A comparative study on lyocell-fabric based all-cellulose composite laminates produced by different processes. Cellulose 2017, 24, 835–849.

- Gindl-Altmutter, W.; Keckes, J.; Plackner, J.; Liebner, F.; Englund, K.; Laborie, M.P. All-cellulose composites prepared from flax and lyocell fibres compared to epoxy–matrix composites. Compos. Sci. Technol. 2012, 72, 1304–1309.

- Love, S.A.; Hu, X.; Salas-de la Cruz, D. Controlling the structure and properties of semi-crystalline cellulose/silk-fibroin biocomposites by ionic liquid type and hydrogen peroxide concentration. Carbohydr. Polym. Technol. Appl. 2022, 3, 100193.

- Bai, F.; Dong, T.; Chen, W.; Wang, J.; Li, X. Nanocellulose hybrid lignin complex reinforces cellulose to form a strong, water-stable lignin–cellulose composite usable as a plastic replacement. Nanomaterials 2021, 11, 3426.

- Kostag, M.; Jedvert, K.; El Seoud, O.A. Engineering of sustainable biomaterial composites from cellulose and silk fibroin: Fundamentals and applications. Int. J. Biol. Macromol. 2021, 167, 687–718.

- Susanin, A.I.; Sashina, E.S.; Novoselov, N.P.; Zakharov, V.V. Change of Silk Fibroin Molecular Mass During Dissolution in Ionic Liquids. Fibre Chem. 2020, 52, 208–213.

- Cianci, C.; Chelazzi, D.; Poggi, G.; Modi, F.; Giorgi, R.; Laurati, M. Hybrid fibroin-nanocellulose composites for the consolidation of aged and historical silk. Colloids Surfaces Physicochem. Eng. Asp. 2022, 634, 127944.

- Sashina, E.S.; Bochek, A.M.; Novoselov, N.P.; Kirichenko, D.A. Structure and solubility of natural silk fibroin. Russ. J. Appl. Chem. 2006, 79, 869–876.

- Meirovitch, S.; Shtein, Z.; Ben-Shalom, T.; Lapidot, S.; Tamburu, C.; Hu, X.; Kluge, J.A.; Raviv, U.; Kaplan, D.L.; Shoseyov, O. Spider silk-CBD-cellulose nanocrystal composites: Mechanism of assembly. Int. J. Mol. Sci. 2016, 17, 1573.

- Zhou, W.; He, J.; Du, S.; Cui, S.; Gao, W. Electrospun Silk Fibroin/Cellulose Acetate Blend Nanofibres: Structure and Properties. Iran. Polym. J. 2011, 20, 389–397.

- Sashina, E.S.; Golubikhin, Y.A.; Novoselov, N.P. Thermochemical study on the dissolution and regeneration of fibroin from solutions in imidazole-based ionic liquids. Russ. J. Gen. Chem. 2012, 82, 1440–1443.

- Zhao, M.; Qi, Z.; Tao, X.; Newkirk, C.; Hu, X.; Lu, S. Chemical, Thermal, Time, and Enzymatic Stability of Silk Materials with Silk I Structure. Int. J. Mol. Sci. 2021, 22, 4136.

- Salernitano, E.; Migliaresi, C. Composite materials for biomedical applications: A review. J. Appl. Biomater. Biomech. 2003, 1, 3–18.

- Namvar, F.; Jawaid, M.; Tanir, P.M.; Mohamad, R.; Azizi, S.; Khodavandi, A.; Rahman, H.S.; Nayeri, M.D. Potential use of plant fibres and their composites for biomedical applications. BioResources 2014, 9, 5688–5706.

- Elanchezhian, C.; Ramnath, B.V.; Ramakrishnan, G.; Rajendrakumar, M.; Naveenkumar, V.; Saravanakumar, M. Review on mechanical properties of natural fiber composites. Mater. Today Proc. 2018, 5, 1785–1790.

- Sanjay, M.; Madhu, P.; Jawaid, M.; Senthamaraikannan, P.; Senthil, S.; Pradeep, S. Characterization and properties of natural fiber polymer composites: A comprehensive review. J. Clean. Prod. 2018, 172, 566–581.

- Saheb, D.N.; Jog, J.P. Natural fiber polymer composites: A review. Adv. Polym. Technol. J. Polym. Process. Inst. 1999, 18, 351–363.

- Khan, M.Z.; Srivastava, S.K.; Gupta, M. Tensile and flexural properties of natural fiber reinforced polymer composites: A review. J. Reinf. Plast. Compos. 2018, 37, 1435–1455.

- Shah, D.U.; Porter, D.; Vollrath, F. Opportunities for silk textiles in reinforced biocomposites: Studying through-thickness compaction behaviour. Compos. Part A Appl. Sci. Manuf. 2014, 62, 1–10.

- Rong, M.Z.; Zhang, M.Q.; Liu, Y.; Yang, G.C.; Zeng, H.M. The effect of fiber treatment on the mechanical properties of unidirectional sisal-reinforced epoxy composites. Compos. Sci. Technol. 2001, 61, 1437–1447.

- Bledzki, A.; Mamun, A.; Lucka-Gabor, M.; Gutowski, V. The effects of acetylation on properties of flax fibre and its polypropylene composites. Express Polym. Lett. 2008, 2, 413–422.

- Sawpan, M.A.; Pickering, K.L.; Fernyhough, A. Improvement of mechanical performance of industrial hemp fibre reinforced polylactide biocomposites. Compos. Part A Appl. Sci. Manuf. 2011, 42, 310–319.

- Boey, J.Y.; Lee, C.K.; Tay, G.S. Factors Affecting Mechanical Properties of Reinforced Bioplastics: A Review. Polymers 2022, 14, 3737.

- Bahrami, M.; Abenojar, J.; Martínez, M.Á. Recent progress in hybrid biocomposites: Mechanical properties, water absorption, and flame retardancy. Materials 2020, 13, 5145.

- Chanda, A.; Sinha, S.K.; Datla, N.V. The influence of fiber alignment, structure and concentration on mechanical behavior of carbon nanofiber/epoxy composites: Experimental and numerical study. Polymer Compos. 2021, 42, 1155–1173.

- Garcia-Zetina, F.; Martinez, E.; Alvarez-Castillo, A.; Castano, V. Numerical analysis of the experimental mechanical properties in polyester resins reinforced with natural fibers. J. Reinf. Plast. Compos. 1995, 14, 641–649.

- Tan, P.; Tong, L.; Steven, G. Modelling for predicting the mechanical properties of textile composites—A review. Compos. Part A Appl. Sci. Manuf. 1997, 28, 903–922.

- Pathan, M.; Ponnusami, S.; Pathan, J.; Pitisongsawat, R.; Erice, B.; Petrinic, N.; Tagarielli, V. Predictions of the mechanical properties of unidirectional fibre composites by supervised machine learning. Sci. Rep. 2019, 9, 13964.

- Mulenga, T.K.; Ude, A.U.; Vivekanandhan, C. Techniques for modelling and optimizing the mechanical properties of natural fiber composites: A review. Fibers 2021, 9, 6.

- Shao, Z.; Vollrath, F. Surprising strength of silkworm silk. Nature 2002, 418, 741.

- Koh, L.D.; Cheng, Y.; Teng, C.P.; Khin, Y.W.; Loh, X.J.; Tee, S.Y.; Low, M.; Ye, E.; Yu, H.D.; Zhang, Y.W.; et al. Structures, mechanical properties and applications of silk fibroin materials. Prog. Polym. Sci. 2015, 46, 86–110.

- Vepari, C.; Kaplan, D.L. Silk as a biomaterial. Prog. Polym. Sci. 2007, 32, 991–1007.

- Sirichaisit, J.; Brookes, V.L.; Young, R.J.; Vollrath, F. Analysis of structure/property relationships in silkworm (Bombyx mori) and spider dragline (Nephila edulis) silks using Raman spectroscopy. Biomacromolecules 2003, 4, 387–394.

- Cunniff, P.M.; Fossey, S.A.; Auerbach, M.A.; Song, J.W.; Kaplan, D.L.; Adams, W.W.; Eby, R.K.; Mahoney, D.; Vezie, D.L. Mechanical and thermal properties of dragline silk from the spider Nephila clavipes. Polym. Adv. Technol. 1994, 5, 401–410.

- Gosline, J.M.; Guerette, P.; Ortlepp, C.; Savage, K. The mechanical design of spider silks: From fibroin sequence to mechanical function. J. Exp. Biol. 1999, 202, 3295–3303.

- Kumar, S.; Doshi, H.; Srinivasarao, M.; Park, J.O.; Schiraldi, D.A. Fibers from polypropylene/nano carbon fiber composites. Polymer 2002, 43, 1701–1703.

- Rahmathulla, V. Management of climatic factors for successful silkworm (Bombyx mori L.) crop and higher silk production: A review. Psyche J. Entomol. 2012, 2012, 121234.

- Jin, H.J.; Kaplan, D.L. Mechanism of silk processing in insects and spiders. Nature 2003, 424, 1057–1061.

- Servoli, E.; Maniglio, D.; Motta, A.; Migliaresi, C. Folding and assembly of fibroin driven by an AC electric field: Effects on film properties. Macromol. Biosci. 2008, 8, 827–835.

- Wen, H.; Lan, X.; Zhang, Y.; Zhao, T.; Wang, Y.; Kajiura, Z.; Nakagaki, M. Transgenic silkworms (Bombyx mori) produce recombinant spider dragline silk in cocoons. Mol. Biol. Rep. 2010, 37, 1815–1821.

- Teulé, F.; Miao, Y.G.; Sohn, B.H.; Kim, Y.S.; Hull, J.J.; Fraser, M.J., Jr.; Lewis, R.V.; Jarvis, D.L. Silkworms transformed with chimeric silkworm/spider silk genes spin composite silk fibers with improved mechanical properties. Proc. Natl. Acad. Sci. USA 2012, 109, 923–928.

- Hakimi, O.; Knight, D.P.; Vollrath, F.; Vadgama, P. Spider and mulberry silkworm silks as compatible biomaterials. Compos. Part B Eng. 2007, 38, 324–337.

- Holland, C.; Numata, K.; Rnjak-Kovacina, J.; Seib, F.P. The Biomedical Use of Silk: Past, Present, Future. Adv. Healthc. Mater. 2019, 8, 1800465.

- El Seoud, O.A.; Jedvert, K.; Kostag, M.; Possidonio, S. Cellulose, chitin and silk: The cornerstones of green composites. Emergent Mater. 2021, 5, 785–810.

- Tsioris, K.; Raja, W.K.; Pritchard, E.M.; Panilaitis, B.; Kaplan, D.L.; Omenetto, F.G. Fabrication of silk microneedles for controlled-release drug delivery. Adv. Funct. Mater. 2012, 22, 330–335.

- Stinson, J.A.; Raja, W.K.; Lee, S.; Kim, H.B.; Diwan, I.; Tutunjian, S.; Panilaitis, B.; Omenetto, F.G.; Tzipori, S.; Kaplan, D.L. Silk Fibroin Microneedles for Transdermal Vaccine Delivery. ACS Biomater. Sci. Eng. 2017, 3, 360–369.

- Pramanik, R.; Arockiarajan, A. Mechanical and morphological characterization of a novel silk/cellulose-based soft composite. Mater. Lett. 2022, 314, 131871.

- Tandon, S.; Kandasubramanian, B.; Ibrahim, S.M. Silk-Based Composite Scaffolds for Tissue Engineering Applications. Ind. Eng. Chem. Res. 2020, 59, 17593–17611.

- Chen, Z.J.; Zhang, Y.; Zheng, L.; Zhang, H.; Shi, H.H.; Zhang, X.C.; Liu, B. Mineralized self-assembled silk fibroin/cellulose interpenetrating network aerogel for bone tissue engineering. Mater. Sci. Eng. C 2021, 134, 112549.

- Ang-atikarnkul, P.; Watthanaphanit, A.; Rujiravanit, R. Fabrication of cellulose nanofiber/chitin whisker/silk sericin bionanocomposite sponges and characterizations of their physical and biological properties. Compos. Sci. Technol. 2014, 96, 88–96.

- Singh, B.N.; Pramanik, K. Generation of bioactive nano-composite scaffold of nanobioglass/silk fibroin/carboxymethyl cellulose for bone tissue engineering. J. Biomater. Sci. Polym. Ed. 2018, 29, 2011–2034.

- Narayanan, V.; Sumathi, S. Preparation, characterization and in vitro biological study of silk fiber/methylcellulose composite for bone tissue engineering applications. Polym. Bull. 2019, 76, 2777–2800.

- Dorishetty, P.; Balu, R.; Athukoralalage, S.S.; Greaves, T.L.; Mata, J.; de Campo, L.; Saha, N.; Zannettino, A.C.W.; Dutta, N.K.; Choudhury, N.R. Tunable Biomimetic Hydrogels from Silk Fibroin and Nanocellulose. ACS Sustain. Chem. Eng. 2020, 8, 2375–2389.

- Lee, J.M.; Kim, J.H.; Lee, O.J.; Park, C.H. The fixation effect of a silk fibroin-bacterial cellulose composite plate in segmental defects of the zygomatic arch: An experimental study. JAMA Otolaryngol. Head Neck Surg. 2013, 139, 629–635.

- Chen, J.; Zhuang, A.; Shao, H.; Hu, X.; Zhang, Y. Robust silk fibroin/bacterial cellulose nanoribbon composite scaffolds with radial lamellae and intercalation structure for bone regeneration. J. Mater. Chem. B 2017, 5, 3640–3650.

- Eivazzadeh-Keihan, R.; Khalili, F.; Khosropour, N.; Aliabadi, H.A.M.; Radinekiyan, F.; Sukhtezari, S.; Maleki, A.; Madanchi, H.; Hamblin, M.R.; Mahdavi, M.; et al. Hybrid Bionanocomposite Containing Magnesium Hydroxide Nanoparticles Embedded in a Carboxymethyl Cellulose Hydrogel plus Silk Fibroin as a Scaffold for Wound Dressing Applications. ACS Appl. Mater. Interfaces 2021, 13, 33840–33849.

- Valencia–Lazcano, A.A.; Román–Doval, R.; De La Cruz–Burelo, E.; Millán–Casarrubias, E.J.; Rodríguez–Ortega, A. Enhancing surface properties of breast implants by using electrospun silk fibroin. J. Biomed. Mater. Res. Part B Appl. Biomater. 2018, 106, 1655–1661.

- Carrasco-Torres, G.; Valdés-Madrigal, M.A.; Vásquez-Garzón, V.R.; Baltiérrez-Hoyos, R.; la Cruz-Burelo, E.D.D.; Román-Doval, R.; Valencia-Lazcano, A.A. Effect of Silk Fibroin on cell viability in electrospun scaffolds of polyethylene oxide. Polymers 2019, 11, 451.

- Lan, D.; Liu, Z.; Zhou, J.; Xu, M.; Li, Z.; Dai, F. Preparation and characterization of silk fibroin/polyethylene oxide nanofiber membranes with antibacterial activity. J. Biomed. Mater. Res. Part A 2022, 110, 287–297.

- Feng, Y.; Li, X.; Li, M.; Ye, D.; Zhang, Q.; You, R.; Xu, W. Facile Preparation of Biocompatible Silk Fibroin/Cellulose Nanocomposite Films with High Mechanical Performance. ACS Sustain. Chem. Eng. 2017, 5, 6227–6236.

- Park, C.H.; Jeong, L.; Cho, D.; Kwon, O.H.; Park, W.H. Effect of methylcellulose on the formation and drug release behavior of silk fibroin hydrogel. Carbohydr. Polym. 2013, 98, 1179–1185.

- Lujerdean, C.; Baci, G.M.; Cucu, A.A.; Dezmirean, D.S. The Contribution of Silk Fibroin in Biomedical Engineering. Insects 2022, 13, 286.

- Wahab, N.; Saeed, M.; Ibrahim, M.; Munir, A.; Saleem, M.; Zahra, M.; Waseem, A. Synthesis, Characterization, and Applications of Silk/Bentonite Clay Composite for Heavy Metal Removal From Aqueous Solution. Front. Chem. 2019, 7, 654.

- Mayank; Bardenhagen, A.; Sethi, V.; Gudwani, H. Spider-silk composite material for aerospace application. Acta Astronaut. 2022, 193, 704–709.

- Victoria, A.; Ries, M.E.; Hine, P.J. Use of interleaved films to enhance the properties of all-cellulose composites. Compos. Part A Appl. Sci. Manuf. 2022, 160, 107062.

- Hadadi, A.; Whittaker, J.W.; Verrill, D.E.; Hu, X.; Larini, L.; Cruz, D.S.D.L. A Hierarchical Model to Understand the Processing of Polysaccharides/Protein-Based Films in Ionic Liquids. Biomacromolecules 2018, 19, 3970–3982.

- Kimura, T.; Aoki, S. Application of silk composite to decorative laminate. Adv. Compos. Mater. Off. J. Jpn. Soc. Compos. Mater. 2007, 16, 349–360.