In this entry, several battery equalizer circuits are reviewed and simulated. In addition, a table is presented where the main characteristics of the equalizers are summarized. These characteristics are used to assign a score to each circuit with respect to how many characteristics are similar to the ideal equalizer. Finally, a methodology is presented to compare these equalizers, taking into account the results obtained from the table.

In this entry, several battery equalizer circuits are reviewed and simulated. In addition, a table is presented where the main characteristics of the equalizers are summarized. These characteristics are used to assign a score to each circuit with respect to how many characteristics are similar to the ideal equalizer. Finally, a methodology is presented to compare these equalizers, taking into account the results obtained from the table.

- battery management systems

- battery equalizer circuits

- electric vehicles

Please note: Below is an entry draft based on your previous paper, which is wrirren tightly around the entry title. Since it may not be very comprehensive, we kindly invite you to modify it (both title and content can be replaced) according to your extensive expertise. We believe this entry would be beneficial to generate more views for your work. In addition, no worry about the entry format, we will correct it and add references after the entry is online (you can also send a word file to us, and we will help you with submitting).

Definition

Electric vehicles (EVs) are an alternative to internal combustion engine (ICE) cars, as they can reduce the environmental impact of transportation. The bottleneck for EVs is the high-voltage battery pack, which utilizes most of the space and increases the weight of the vehicle. Currently, the main challenge for the electronics industry is the cell equalization of the battery pack.

1. Introduction

Global warming is one of the biggest challenges today for humankind. The increase in temperature has caused the disappearance of animal and plant species, defrosting of glaciers, sea level rise, extreme weather events and many other phenomena that threaten life on our planet as we know it. The main cause of this change is the emission of greenhouse gases into the atmosphere. These gases allow the light coming from the sun to pass through them and reach Earth. However, they keep part of the radiation that is bounced back from the surface of the Earth [1,2,3,4][1][2][3][4].

Some of the leading sources of these greenhouse gases are electricity generation, transportation, industry, agriculture, and the commercial and residential sectors. The transportation sector is one of the most significant contributors, representing 23.96% of total emissions of CO2

worldwide [5]. Moreover, it is responsible for the higher growth in emissions today due to the growth of tourism, the globalized economy and the increase in living standards [5,6][5][6].

A viable alternative to reduce emissions in this sector is the use of EVs, which practically behave like zero-emission cars. Despite the recent interest in these automobiles, their invention dates back to the nineteenth century. William Morrison built the first successful electric car in the United States of America (USA) in 1891. By 1914, the sales of these cars began an irreversible and inevitable decline due to competition with ICE automobiles. They never disappeared completely, but were limited to light-duty vehicles [7,8][7][8].

Most reasons why these cars never had extensive use remain today. One of the main obstacles is the autonomy of the car since it depends on the battery. In addition, the charging time makes it unattractive, they have a high selling price, and there is not a large number of charging stations. However, currently, they present a comparable performance to ICE-based vehicles [9,10][9][10].

Despite the above mentioned limitations, benefits have been provided in the USA to encourage the purchase of these cars due to their positive environmental impact. Some examples are credits for purchase, access to shared travel lanes, exemption from inspections, and reduction of registration fees, among others [11,12][11][12]. These and other factors have caused the growth of sales of these vehicles by seven times from 2010 to 2015 [13,14,15][13][14][15].

New challenges have emerged in the electronic industry for EVs application with the accelerated increase in sales of these automobiles. In [16[16][17][18],17,18], the main standout trends of the research applied to these cars are described as follows: improving and decreasing the size of the battery chargers from the grid, creation of DC–DC converters for the interface of the sources with a DC bus and the creation of new inverter topologies for the traction system. The main issue related to the battery identified in these papers is the cell equalization.

Typically, an EV battery pack consists of a cluster of cells, where each Li-ion cell is not exactly equal to the others in terms of capacity, internal resistance and self-discharge rate because of normal dispersion during manufacturing. These characteristics cause a different charge/discharge time for each cell, which can lead to the undercharge, overcharge or over-discharge on some cells if the battery pack is operated without protection [16,19][16][19]. In these states, the cell loses capacity and can explode; consequently, avoiding them is desirable. The most viable solution for this problem is not found by modifying the chemistry of the battery, but it is found in the electronic industry. Hence, the battery pack is equipped with cell equalizers to avoid the states mentioned above [19,20,21][19][20][21].

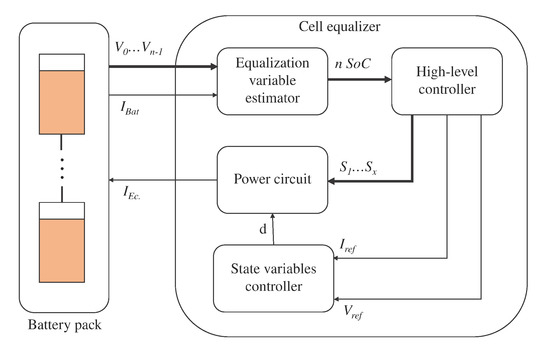

A BEC is essentially a power electronic controller, which takes active measures to equalize the voltage or the state of charge (SOC) in each cell [22,23,24][22][23][24]. As a result, each of the cells has the same SOC during charging and discharging, even in conditions of high dispersion in capacity and internal resistance. If all the cells have the same SOC utilization, they degrade equally at the average degradation of the pack. If this condition is accomplished, then all cells have the same capacity during the whole lifetime of the battery pack, avoiding premature end of life due to the end of life of only one cell [25,26,27][25][26][27]. A diagram of these devices is presented in Figure 1.

General diagram of a cell equalizer.

There are several variables used to decide the homogeneity of the battery pack. The operating voltage of the cell is widely used because it is pretty straightforward to understand and the tension is directly measured. However, this variable does not reflect the internal state of the cell and it is affected by many internal parameters that yield in fluctuations of the voltage and the activation of the equalization process [28,29,30,31][28][29][30][31]. If the operating voltage were used, the equalization variable estimator is not used. When the equalization variable is the SOC or the capacity of the cell, these variables are not measured directly and require a state estimator. Compared with the operating voltage, these methods reflect the internal state of the battery more accurately and present a lower equalization time. Moreover, it is not affected by the aging process and makes full use of the power of the battery pack. Nevertheless, the main drawback of this variable is its complexity to be obtained accurately. Therefore, the design time is increased and it requires a powerful hardware to be implemented [32,33,34,35][32][33][34][35]. It is well known that batteries are indeed the main hurdle to driving EVs and, as stated above, the main issue for the electronics industry is the cell equalization [16,36][16][36]. There are several papers in the literature that present a review of BEC and make a qualitative analysis of these devices [37,38,39,40][37][38][39][40].

2. Discussion

Battery equalizers are a crucial component to ensure a safety operation in a battery bank. The balancing efficiency is an essential parameter in equalizers since the less power it consumes, the more energy transferred into the cell. In this aspect, passive methods present a poor performance when compared to active ones. Moreover, switched capacitor–inductor network equalizers and capacitor-based equalizers suppress the switching losses; hence, these equalizers offer good efficiency. The other active equalizers present switching and conduction losses; therefore, they present a lower efficiency [71][41].

Reference [31] discusses other factors that impact in the efficiency. The equalization variable used is crucial since the operating voltage leads to an inefficient process. This behavior is explained because the variable does not reflect the internal state of the cell. Thereupon, the equalization process will be over-activated. Moreover, the equalization strategy can also lead to repeated equalization, e.g., rationalize the equalization variable to a threshold, minimize the equalization time and maximize the battery capacity. A recommended strategy to avoid an inefficient process is to minimize energy consumption. However, it is difficult to obtain the proper data and increases the cost of the hardware needed [31,72][31][42].

Battery equalizers are a crucial part of the storage system of EVs. They take active measures to keep all cells within an allowed range of the equalization variable, even when they present a high dispersion in capacity and internal resistance [16,39,40][16][39][40]. In this way, the batteries are protected, which is the most expensive element in EVs. Further investigations in this area are needed to overcome the shortcomings of the reviewed topologies. Advancements need to be made to improve one or more of the critical parameters highlighted as the component count, power losses, equalization time, controller and implementation complexity, current and voltage stress in the switches, size and cost. The advantages and limitations of the topologies present in the literature were highlighted in this work. We think that this paper serves as a guideline for future research and investigations regarding the issues and challenges of this topic.

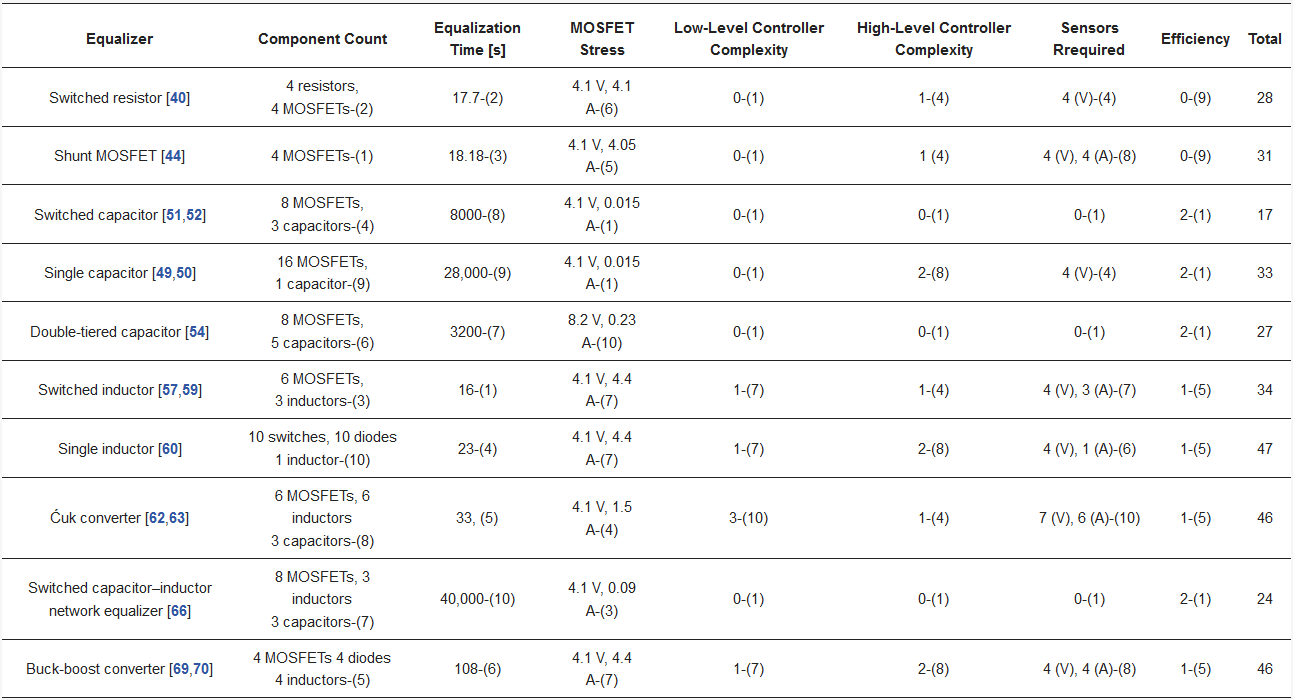

Table 1 summarizes the results obtained in the simulations of this work. The complexity of the low-level controller indicates the number of variables that are required to regulate. For example, in the Ćuk converter, it is necessary to control 3 variables, the current in both inductors and the voltage in the internal capacitor. The complexity in the high-level controller indicates if it only decides the stop condition (1) or if it also decides the cells for power transfer (2). Finally, for efficiency, a score of 0 was given to passive schemes, 1 to those that present switching and conduction losses and 2 to equalizers that only present conduction losses.

Comparative analysis of the reviewed equalizers for a four-cell battery bank.

| Equalizer | Component Count | Equalization Time [s] | MOSFET Stress | Low-Level Controller Complexity | High-Level Controller Complexity | Sensors Rrequired | Efficiency | Total |

|---|---|---|---|---|---|---|---|---|

|

Switched resistor [40] |

4 resistors, 4 MOSFETs-(2) |

17.7-(2) |

4.1 V, 4.1 A-(6) |

0-(1) |

1-(4) |

4 (V)-(4) |

0-(9) |

28 |

|

Shunt MOSFET [43] |

4 MOSFETs-(1) |

18.18-(3) |

4.1 V, 4.05 A-(5) |

0-(1) |

1 (4) |

4 (V), 4 (A)-(8) |

0-(9) |

31 |

|

8 MOSFETs, 3 capacitors-(4) |

8000-(8) |

4.1 V, 0.015 A-(1) |

0-(1) |

0-(1) |

0-(1) |

2-(1) |

17 |

|

|

16 MOSFETs, 1 capacitor-(9) |

28,000-(9) |

4.1 V, 0.015 A-(1) |

0-(1) |

2-(8) |

4 (V)-(4) |

2-(1) |

33 |

|

|

Double-tiered capacitor [48] |

8 MOSFETs, 5 capacitors-(6) |

3200-(7) |

8.2 V, 0.23 A-(10) |

0-(1) |

0-(1) |

0-(1) |

2-(1) |

27 |

|

6 MOSFETs, 3 inductors-(3) |

16-(1) |

4.1 V, 4.4 A-(7) |

1-(7) |

1-(4) |

4 (V), 3 (A)-(7) |

1-(5) |

34 |

|

|

Single inductor [51] |

10 switches, 10 diodes 1 inductor-(10) |

23-(4) |

4.1 V, 4.4 A-(7) |

1-(7) |

2-(8) |

4 (V), 1 (A)-(6) |

1-(5) |

47 |

|

6 MOSFETs, 6 inductors 3 capacitors-(8) |

33, (5) |

4.1 V, 1.5 A-(4) |

3-(10) |

1-(4) |

7 (V), 6 (A)-(10) |

1-(5) |

46 |

|

|

Switched capacitor–inductor network equalizer [54] |

8 MOSFETs, 3 inductors 3 capacitors-(7) |

40,000-(10) |

4.1 V, 0.09 A-(3) |

0-(1) |

0-(1) |

0-(1) |

2-(1) |

24 |

|

4 MOSFETs 4 diodes 4 inductors-(5) |

108-(6) |

4.1 V, 4.4 A-(7) |

1-(7) |

2-(8) |

4 (V), 4 (A)-(8) |

1-(5) |

46 |

Metrics from Table 1 were used to compare the reviewed equlizaers with an idea equalizer. An ideal equalizer has few devices, low equalization time, low switch stress, low controller complexity and high efficiency. According to their approximation to the ideal equalizer, we assign them a number where 1 is the most desirable equalizer. For example, the shunt MOSFET equalizer is 1 in component count because it is the equalizer with the fewest components. All the places assigned in the previous step for a converter are added to take into account all the parameters. The last column of Table 1 shows the accumulated places for each converter. Finally they are ordered from lowest to highest, where the converter with the lowest score is the one with the most desirable characteristics. The best equalizer using this methodology is the switched capacitor. However, this procedure is quite simple and has many points that can be improved. For example, weighted coeficients can be used to highlight parameters of interest. In this way, using this table a designer can reach important conclusions to select an equalizer suitable for his application.

2.1. Future Trends

Several topics offer promising opportunities to improve existing BECs. In recent years, reconfigurable battery systems were proposed to achieve battery equalization. Reconfigurable batteries define their connections between cells by software. The battery reconfiguration allows the connection of cells/modules to be flexible and adapt the battery pack to the charging/discharging requirements. In cell equalization, this feature is used to send the larger current to the lower SOC batteries. Commonly,two to six switches are used per cell to obtain a flexible battery pack [73,74][57][58]. A drawback of this method is that the reconfiguration must be offline to prevent dangerous situations. If this strategy is combined with the equalizers reviewed, the balance performance could be improved and even optimized [73][57].

Moreover, current equalizers present a fixed volume of equalization depending on the battery pack. The component count of the BEC relies on the number of cells of the battery pack and the architecture selected. Sometimes, it is desirable to design a circuit with the components to use before-hand. In BECs, that challenge has not been widely studied [75,76][59][60].

There is also interest in the integration of the BECs with the charger of the vehicle. In general, the trend in the power converters applied to EVs is the integration to achieve more functions with fewer electronics. It is possible to use one circuit to realize both functions, the charging process and the equalization [9]. However, this technique can only be applied in level 1 or 2 of charging since the fast charging is with an off-board converter. This method is a challenge for future investigations and has the opportunity to create a cost-effective converter when compared to dedicated converters for each function [40,77][40][61].

The high-level controller is another subsystem that offers promising research opportunities. In contrast with the BECs the investigation on control strategies is further behind. The SOC and capacity estimators need to be more stable and accurate without requiring powerful real-time implementation hardware. Moreover, the stability and accuracy of estimators through the whole lifecycle of the cells is a major challenge. The equalization objectives need to be designed in a multi-objective perspective instead of using a singular objective approach. However, all technical indexes are difficult to meet; therefore, to set the proper constraints for the indexes remains unsolved. Finally, any classic, intelligent or data-driven controller requires a model for the battery pack and, since the cells are complex nonlinear time-varying systems, this area needs further investigations [31,78,79][31][62][63].

Another trend in EVs that can play a significant role in battery equalizers is the wireless power transfer. This technology does not require heavy cables, connectors, etc. Therefore, it can be achieved a low cost and light-weight system with great flexibility and reliability. Moreover, it can make obsolete the high-level controller since the cells will have the possibility to communicate and make decisions. This groundbreaking technology will have a huge impact on battery equalization, charge and other applications offering a promising field of study in the coming years [80,81][64][65].

3. Conclusions

The main parameters to select in an EV are its range, charging time, and acceleration. All these elements are related to the battery of the vehicle. Moreover, this device represents the most expensive, heaviest and bulkiest component in the system. Therefore, it is imperative to protect this element against dangerous situations. The main challenge in a battery pack used in EVs is to keep all cells within an allowable range of SOC or voltage operation. The array of cells connected in series to form a battery pack are charged/discharged at a different rate. This behavior is due to the dispersion in internal capacity, resistance, self-discharge rate and uneven distribution of the temperature in the battery pack. If the battery pack is operated without a battery equalizer, it decreases the service life of the cells and can even explode. BECs prevent these situations by taking active measures to keep all the cells within the same SOC.

The equalizers are classified, taking into account the main component in its architecture and energy dissipation. Passive equalizers present a low efficiency because they burn the excess of energy through a resistor. For this reason, it is not widely used for high-power applications. In contrast, active equalizers are preferred since the cell/string of cells with the highest SOC transfer the excess of energy to other cells/string of cells with lower SOC. The capacitor-based equalizers are simple to control and inexpensive, but present surge currents that can damage the cells. In the inductor-based equalizers, the current is controlled and they have a short equalization time. However, they present magnetization losses, saturation problems, are expensive and are bulky. The equalizers based on converters control the current extracted from the cell and the current delivered. Nevertheless, they are complex to control and expensive. The equalizer selection depends on the application, the budget and the critical parameter to consider for the designer. In this work we used a methodology to compare the main topologies based in quantitative simulation data. According to the results, the best active equalizers are the switched capacitor and the switched capacitor–inductor network.

Promising research opportunities were highlighted to move forward in this topic of investigation. Combining the existent equalizers with reconfigurable batteries could improve the equalization process. However, there are more questions than answers in the reconfiguration of the battery online. Although Tesla, Microsoft and several top tier universities accepted the software-defined batteries as a promising technology for EVs we consider that this technology will not reach its full potential in the near future. Moreover, another research opportunity is to design the volume of the equalization circuit to operate the battery pack. We think that this research trend can play a major role in the near future, due to the flexibility in the design process. Since the number of components can be accommodated to the application, it can be designed to optimize several parameters such as the cost, equalization time, number of components, etc. Finally, another identified trend is the integration of the battery equalizer and the charger, to achieve a multi-purpose converter instead of two dedicated converters. This approach has proved to be cost-effective in other applications. In general, the batteries need in-depth research since it is well known that it is the main hurdle for the widespread use of EVs.

References

- Anderson, T.R.; Hawkins, E.; Jones, P.D. CO2, The greenhouse effect and global warming: From the pioneering work of Arrhenius and Callendar to today’s Earth System Models. Endeavour 2016, 40, 178–187.

- Papalexiou, S.M.; Montanari, A. Global and regional increase of precipitation extremes under global warming. Water Resour. Res. 2019, 55, 4901–4914.

- He, Q.; Zhou, G.; Lü, X.; Zhou, M. Climatic suitability and spatial distribution for summer maize cultivation in China at 1.5 and 2.0 °C global warming. Sci. Bull. 2019, 64, 690–697.

- Silva, P.S.; Bastos, A.; Libonati, R.; Rodrigues, J.A.; DaCamara, C.C. Impacts of the 1.5 °C global warming target on future burned area in the Brazilian Cerrado. For. Ecol. Manag. 2019, 446, 193–203.

- Solaymani, S. CO2 emissions patterns in 7 top carbon emitter economies: The case of transport sector. Energy 2019, 168, 989–1001.

- Santos, G. Road transport and CO2 emissions: What are the challenges? Transp. Policy 2017, 59, 71–74.

- Sulzberger, C. An early road warrior: Electric vehicles in the early years of the automobile. IEEE Power Energy Mag. 2004, 2, 66–71.

- Sulzberger, C. Early road warrior, part 2-competing electric and gasoline vehicles. IEEE Power Energy Mag. 2004, 2, 83–88.

- Alvarez-Diazcomas, A.; López, H.; Carrillo-Serrano, R.V.; Rodríguez-Reséndiz, J.; Vázquez, N.; Herrera-Ruiz, G. A novel integrated topology to interface electric vehicles and renewable energies with the grid. Energies 2019, 12, 4091.

- Estévez-Bén, A.A.; López Tapia, H.J.C.; Carrillo-Serrano, R.V.; Rodríguez-Reséndiz, J.; Vázquez Nava, N. A new predictive control strategy for multilevel current-source inverter grid-connected. Electronics 2019, 8, 902.

- Jenn, A.; Springel, K.; Gopal, A.R. Effectiveness of electric vehicle incentives in the United States. Energy Policy 2018, 119, 349–356.

- Wang, N.; Tang, L.; Pan, H. A global comparison and assessment of incentive policy on electric vehicle promotion. Sustain. Cities Soc. 2019, 44, 597–603.

- Zhang, X.; Bai, X.; Shang, J. Is subsidized electric vehicles adoption sustainable: Consumers’ perceptions and motivation toward incentive policies, environmental benefits, and risks. J. Clean. Prod. 2018, 192, 71–79.

- Vallés, M.; Reneses, J.; Cossent, R.; Frías, P. Regulatory and market barriers to the realization of demand response in electricity distribution networks: A European perspective. Electr. Power Syst. Res. 2016, 140, 689–698.

- Estévez-Bén, A.A.; Alvarez-Diazcomas, A.; Rodríguez-Reséndiz, J. Transformerless multilevel voltage-source inverter topology comparative study for PV systems. Energies 2020, 13, 3261.

- Williamson, S.S.; Rathore, A.K.; Musavi, F. Industrial electronics for electric transportation: Current state-of-the-art and future challenges. IEEE Trans. Ind. Electron. 2015, 62, 3021–3032.

- Tan, D. Transportation electrification: Challenges and opportunities. IEEE Power Electrons. Mag. 2016, 3, 50–52.

- Khaligh, A.; D’Antonio, M. Global trends in high-power on-board chargers for electric vehicles. IEEE Trans. Veh. Technol. 2019, 68, 3306–3324.

- Li, W.; Chen, S.; Peng, X.; Xiao, M.; Gao, L.; Garg, A.; Bao, N. A comprehensive approach for the clustering of similar-performance cells for the design of a lithium-ion battery module for electric vehicles. Engineering 2019, 5, 795–802.

- Yun, L.; Sandoval, J.; Zhang, J.; Gao, L.; Garg, A.; Wang, C.T. Lithium-ion battery packs formation with improved electrochemical performance for electric vehicles: Experimental and clustering analysis. J. Electrochem. Energy Convers. Storage 2019, 16.

- Reddy, K.R.; Meikandasivam, S.; Vijayakumar, D. A novel strategy for maximization of plug-In electric vehicle’s storage utilization for grid support with consideration of customer flexibility. Electr. Power Syst. Res. 2019, 170, 158–175.

- Rui, L.; Lizhi, W.; Xueli, H.; Qiang, D.; Jie, Z. A review of equalization topologies for lithium-ion battery packs. In Proceedings of the 2015 34th Chinese Control Conference (CCC), Hangzhou, China, 28–30 July 2015; pp. 7922–7927.

- Kelkar, A.; Dasari, Y.; Williamson, S.S. A Comprehensive Review of Power Electronics Enabled Active Battery Cell Balancing for Smart Energy Management. In Proceedings of the 2020 IEEE International Conference on Power Electronics, Smart Grid and Renewable Energy (PESGRE2020), Cochin, India, 2–4 January 2020; pp. 1–6.

- Zhou, Z.; Shang, Y.; Duan, B.; Zhang, C. An any-cell (s)-to-any-cell (s) equalizer based on bidirectional inductor converters for series connected battery string. In Proceedings of the 2016 IEEE 11th Conference on Industrial Electronics and Applications (ICIEA), Hefei, China, 5–7 June 2016; pp. 2511–2515.

- Ali, M.U.; Zafar, A.; Nengroo, S.H.; Hussain, S.; Junaid Alvi, M.; Kim, H.J. Towards a smarter battery management system for electric vehicle applications: A critical review of lithium-ion battery state of charge estimation. Energies 2019, 12, 446.

- Xiong, R.; Cao, J.; Yu, Q.; He, H.; Sun, F. Critical review on the battery state of charge estimation methods for electric vehicles. IEEE Access 2017, 6, 1832–1843.

- Tie, S.F.; Tan, C.W. A review of energy sources and energy management system in electric vehicles. Renew. Sustain. Energy Rev. 2013, 20, 82–102.

- Liu, X.; Zou, Y. The proportional current control strategy for equalization circuits of series battery packs. In Proceedings of the 2018 21st Int. Conference on Elect. Machines and Systems (ICEMS), Jeju, Korea, 7–10 October 2018; pp. 846–849.

- Song, D.; Shi, F.; Liu, W. Review of lithium battery equalization control methods. Phys. Conf. Ser. 2020, 1449, 12–87.

- Einhorn, M.; Conte, F.V.; Fleig, J. Improving of active cell balancing by equalizing the cell energy instead of the cell voltage. World Electr. Veh. 2010, 4, 400–404.

- Feng, F.; Hu, X.; Liu, J.; Lin, X.; Liu, B. A review of equalization strategies for series battery packs: Variables, objectives, and algorithms. Renew. Sustain. Energy Rev. 2019, 116, 109464.

- Zhang, S.; Qiang, J.; Yang, L.; Zhao, X. Prior-knowledge-independent equalization to improve battery uniformity with energy efficiency and time efficiency for lithium-ion battery. Energy 2016, 94, 1–12.

- Zhang, R.; Xia, B.; Li, B.; Cao, L.; Lai, Y.; Zheng, W.; Wang, H.; Wang, W. State of the art of lithium-ion battery SOC estimation for electrical vehicles. Energies 2018, 11, 1820.

- How, D.N.; Hannan, M.; Lipu, M.H.; Ker, P.J. State of charge estimation for lithium-ion batteries using model-based and data-driven methods: A review. IEEE Access 2019, 7, 136116–136136.

- Diao, W.; Xue, N.; Bhattacharjee, V.; Jiang, J.; Karabasoglu, O.; Pecht, M. Active battery cell equalization based on residual available energy maximization. Appl. Energy 2018, 210, 690–698.

- May, G.J.; Davidson, A.; Monahov, B. Lead batteries for utility energy storage: A review. J. Energy Storage 2018, 15, 145–157.

- Caspar, M.; Eiler, T.; Hohmann, S. Systematic comparison of active balancing: A model-based quantitative analysis. IEEE Trans. Veh. Technol. 2016, 67, 920–934.

- Mohamed, D.; Noshin, O.; Peter, V.; Joeri, V. A review of passive and active battery balancing based on Matlab/Simulink. Int. Rev. Electr. Eng 2011, 6, 2974–2989.

- Hoque, M.; Hannan, M.; Mohamed, A.; Ayob, A. Battery charge equalization controller in electric vehicle applications: A review. Renew. Sustain. Energy Rev. 2017, 75, 1363–1385.

- Carter, J.; Fan, Z.; Cao, J. Cell equalisation circuits: A review. J. Power Sources 2020, 448, 227489.

- Peng, F.; Wang, H.; Yu, L. Analysis and design considerations of efficiency enhanced hierarchical battery equalizer based on bipolar CCM buck–boost units. IEEE Trans. Ind. Appl. 2019, 55, 4053–4063.

- Arani, A.K.; Gharehpetian, G.; Abedi, M. Review on energy storage systems control methods in microgrids. Int. Electr. Power Energy Syst. 2019, 107, 745–757.

- Koseoglou, M.; Tsioumas, E.; Jabbour, N.; Mademlis, C. Highly Effective Cell Equalization in a Lithium-Ion Battery Management System. IEEE Trans. Power Electron. 2019, 35, 2088–2099.

- Goodarzi, S.; Beiranvand, R.; Mousavi, S.M.; Mohamadian, M. A new algorithm for increasing balancing speed of switched-capacitor lithium-ion battery cell equalizers. In Proceedings of the 6th Power Electronics, Drive Systems & Technologies Conference (PEDSTC2015), Tehran, Iran, 3–4 February 2015; pp. 292–297.

- Kim, M.Y.; Kim, J.W.; Kim, C.H.; Cho, S.Y.; Moon, G.W. Automatic charge equalization circuit based on regulated voltage source for series connected lithium-ion batteries. In Proceedings of the 8th International Conference on Power Electronics-ECCE Asia, Jeju, Korea, 30 May–3 June 2011; pp. 2248–2255.

- Uno, M.; Tanaka, K. Single-switch multioutput charger using voltage multiplier for series-connected lithium-ion battery/supercapacitor equalization. IEEE Trans. Ind. Electron. 2012, 60, 3227–3239.

- Daowd, M.; Antoine, M.; Omar, N.; Van den Bossche, P.; Van Mierlo, J. Single switched capacitor battery balancing system enhancements. Energies 2013, 6, 2149–2174.

- Baughman, A.C.; Ferdowsi, M. Double-tiered switched-capacitor battery charge equalization technique. IEEE Trans. Ind. Electron. 2008, 55, 2277–2285.

- Moo, C.; Hsieh, Y.; Tsai, I.; Cheng, J. Dynamic charge equalisation for series-connected batteries. IEEE Proc. Electr. Power Appl. 2003, 150, 501–505.

- Phung, T.H.; Crebier, J.C.; Chureau, A.; Collet, A.; Nguyen, V. Optimized structure for next-to-next balancing of series-connected lithium-ion cells. In Proceedings of the 2011 Twenty-Sixth Annual IEEE Applied Power Electronics Conference and Exposition (APEC), Daegu, Korea, 22–26 October 2011; pp. 1374–1381.

- Park, S.H.; Kim, T.S.; Park, J.S.; Moon, G.W.; Yoon, M.J. A new battery equalizer based on buck-boost topology. In Proceedings of the 2007 7th Internatonal Conference on Power Electronics, Daegu, Korea, 22–26 October 2007; pp. 962–965.

- Lee, Y.S.; Duh, C.Y.; Chen, G.T.; Yang, S.C. Battery equalization using bi-directional cuk converter in DCVM operation. In Proceedings of the 2005 IEEE 36th Power Electronics Specialists Conference, Recife, Brazil, 16 June 2005; pp. 765–771.

- Moghaddam, A.F.; Van den Bossche, A. A battery equalization technique based on Ćuk converter balancing for lithium ion batteries. In Proceedings of the 2019 8th International Conference on Modern Circuits and Systems Technologies (MOCAST), Thessaloniki, Greece, 13–15 May 2019; pp. 1–4.

- Shang, Y.; Zhang, Q.; Cui, N.; Zhang, C. A cell-to-cell equalizer based on three-resonant-state switched-capacitor converters for series-connected battery strings. Energies 2017, 10, 206.

- Hsieh, Y.C.; Moo, C.S.; Tsai, I.; Cheng, J.C. Dynamic charge equalization for series-connected batteries. In Proceedings of the 2002 IEEE International Conference on Industrial Technology, 2002. IEEE ICIT ’02, Bankok, Thailand, 11–14 December 2002; Volume 1, pp. 444–449.

- Moo, C.S.; Hsieh, Y.C.; Tsai, I. Charge equalization for series-connected batteries. IEEE Trans. Aerosp. Electron. Syst. 2003, 39, 704–710.

- Han, W.; Zou, C.; Zhang, L.; Ouyang, Q.; Wik, T. Near-fastest battery balancing by cell/module reconfiguration. IEEE Trans. Smart Grid 2019, 10, 6954–6964.

- Ji, F.; Liao, L.; Wu, T.; Chang, C.; Wang, M. Self-reconfiguration batteries with stable voltage during the full cycle without the DC-DC converter. J. Energy Storage 2020, 28, 101213.

- Rahimi-Eichi, H.; Ojha, U.; Baronti, F.; Chow, M.Y. Battery management system: An overview of its application in the smart grid and electric vehicles. IEEE Ind. Electron. Mag. 2013, 7, 4–16.

- Lu, C.; Kang, L.; Luo, X.; Linghu, J.; Lin, H. A novel lithium battery equalization circuit with any number of inductors. Energies 2019, 12, 4764.

- Tashakor, N.; Farjah, E.; Ghanbari, T. A bidirectional battery charger with modular integrated charge equalization circuit. IEEE Trans. Power Electron. 2016, 32, 2133–2145.

- Awadallah, M.A.; Venkatesh, B. Accuracy improvement of SOC estimation in lithium-ion batteries. J. Energy Storage 2016, 6, 95–104.

- Tong, S.; Lacap, J.H.; Park, J.W. Battery state of charge estimation using a load-classifying neural network. J. Energy Storage 2016, 7, 236–243.

- Huang, X.; Sui, X.; Stroe, D.I.; Teodorescu, R. A Review of Management Architectures and Balancing Strategies in Smart Batteries. In Proceedings of the IECON 2019-45th Annual Conference of the IEEE Industrial Electronics Society, Lisbon, Portugal, 14–17 October 2019; Volume 1, pp. 5909–5914.

- Zhang, B.; Carlson, R.B.; Smart, J.G.; Dufek, E.J.; Liaw, B. Challenges of future high power wireless power transfer for light-duty electric vehicles—technology and risk management. eTransportation 2019, 2, 100012.