Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is a comparison between Version 1 by Qi-Jun Sun and Version 2 by Conner Chen.

Pressure sensors show significant potential applications in health monitoring, bio-sensing, electronic skin, and tactile perception. Consequently, tremendous research interest has been devoted to the development of high-performance pressure sensors.

- polymer composites

- pressure sensors

- wearable electronics

1. Introduction

As an electronic device for detecting and transmitting information, the pressure sensor has the ability to perceive pressure signals and transform them into corresponding electrical signals. This enables the sensor to collect, transmit, process, analyze, and display information. Tactile perception [1][2][3][4][1,2,3,4], medical monitoring [5][6][7][8][5,6,7,8], wearable electronic products [9][10][11][12][13][9,10,11,12,13], and human motion detection [14][15][16][14,15,16] have emerged as popular application themes in the area of pressure sensors, especially in the previous few years. The classical pressure sensor ground on Micro-Electro-Mechanical Systems (MEMS) mainly consists of metal, semiconductors, piezoelectric crystals, etc., which are usually rigid materials. The technique of utilizing these materials to fabricate pressure sensors is proven and can precisely achieve remarkable performance in terms of low measurement errors and mass fabrication [17][18][19][20][21][17,18,19,20,21]. However, their shortcomings include the large volume and limited deformation. Others have hindered their application in human motion detection, health monitoring, and other scenes. Therefore, developing flexible pressure sensors that can bend and deform without losing performance is vital for expanding their potential uses in wearable devices and robotic systems.

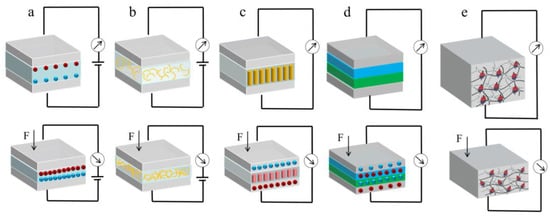

Generally, based on different conduction mechanisms, pressure sensing devices can be basically classified into five types, including capacitive [9][11][22][23][24][25][26][9,11,22,23,24,25,26], piezoresistive [14][27][28][29][30][14,27,28,29,30], piezoelectric [15][31][32][33][34][35][15,31,32,33,34,35], triboelectric [36][37][38][39][40][36,37,38,39,40], and magnetoelastic [41][42][43][41,42,43] pressure sensors (Figure 1). In recent years, researchers have shown great research interest in capacitive and piezoresistive pressure sensors due to their straightforward device configuration and convenient signal processing. Meanwhile, piezoelectric, triboelectric, and magnetoelastic pressure sensors have the advantage of being self-powered, requiring no input external current or voltage to operate. While these sensors exhibit reliable dynamic pressure detection, achieving reliable static pressure detection remains challenging.

Figure 1. Pressure sensors with different working principles: (a) Capacitive; (b) Piezoresistive; (c) Piezoelectric; (d) Triboelectric; (e) Magnetoelastic.

These sensors take on different forms, such as capacitive, piezoresistive, piezoelectric, triboelectric, and magnetoelastic sensors. The sensing principles and representative examples of these sensors are introduced and discussed. Numerous studies have demonstrated the feasibility of wearable sensing devices for health monitoring, electronic skin, and human physiology detection.

In the future, polymer-based pressure sensors are expected to have more advantages over other sensors or sensing technologies, such as high sensitivity, low cost, simple fabrication, and biocompatibility. Some of the potential applications of these sensors include artificial organs, electronic skin, health monitoring, and environmental detection. To achieve these goals, some of the research directions that need to be explored are: (1) Developing novel polymer materials or composites with tunable electrical and mechanical properties. (2) Improving the sensitivity and selectivity to different types of pressure. (3) Integrating polymer-based pressure sensors with other types of sensing devices, such as temperature, humidity, or chemical sensors, to form multifunctional sensing devices. (4) Developing flexible and wearable power supply systems that can provide sufficient and stable energy for the sensors. (5) Optimizing the fabrication methods and scaling up the production of polymer-based pressure sensors for practical applications. (6) Enhancing reliability and durability under various environmental circumstances.

2. Parameters for Pressure Sensors

Pressure sensors with different operating principles have different sensitivity, stability, linear response range, detect limit, response time and output signals for different types of pressure (absolute, gauge, differential, or vacuum pressure). Therefore, when selecting flexible pressure sensors, appropriate pressure types and operating principles should be selected according to specific application scenarios and test objectives.

2.1. Pressure Sensitivity

The sensitivity (S) is expressed as the change in output signal relative to applied pressure, which is defined as S = (ΔE/E0)/ΔP. The initial electrical signal (such as current, capacitance, voltage, etc.) is denoted by E0, the relative variation of the corresponding signal is denoted by ΔE, and the change of the applied pressure is denoted by ΔP. Generally, sensitivity can be enhanced by decreasing the initial electrical signal E0. The relative variation in voltage output (current, capacitance) on the basis of external pressure is usually indicated, with the slope of the curve representing sensitivity.

2.2. Linear Response Range

The linear response range refers to the range where the output is proportional to the input. In order to ensure a certain level of measurement accuracy, it is highly desirable for the relationship between the external stimuli input and relative electrical signal outputs to be linear. Theoretically, flexible pressure sensors have ideal linear models over a wide range of sensing, but in practice, the linear range is often only a part of the full range.

2.3. Detection Limit and Response Speed

The detection limit and response speed are crucial parameters that determine the effectiveness of a sensor. The detection limit refers to the minimum signal or the corresponding physical quantity that the sensor can measure with a certain precision or repeatability and is used to evaluate whether it is suitable for a given application. The response speed is how fast a sensor reacts to pressure changes. Real-time detection of stimuli signals such as heartbeat pulse, subtle human movements, and gas concentration necessitates a high response speed. In addition, when analyzing the parameter of response time, appropriate research methods should be selected according to different application scenarios and test purposes. If you only observe the response of a slow indicator, you do not need to change the pressure frequently. However, if you study the response of a precision tester, you have to consider the speed and accuracy of the testing equipment itself. Therefore, appropriate research methods must be considered when selecting sensors for these applications.

2.4. Reliability

The reliability of a pressure sensor refers to the ability of its components and equipment to maintain the same function and performance within a specified period of time. The higher the reliability of the sensor, the more stable and accurate it can measure pressure, and it can maintain its performance over a long period of use. In the application areas where the demand for sustained stability is not as high, as long as it is within the margin of error. In other high-reliability demanding applications, such as automotive, industrial automation, and aerospace, the reliability of pressure sensors is crucial because any failure can lead to loss or safety issues.