Due to the large number of distribution transformers in the distribution grid, the status of distribution transformers plays an important role in ensuring the safe and reliable operation of the these grids. To evaluate the distribution transformer health, many assessment techniques have been studied and developed. These tools will support the transformer operators in predicting the status of the distribution transformer and responding effectively. A group of authors from University of Hawaii at Manoa and University of Palermo have reviewed the literature in the area, analyzed the latest techniques as well as highlighted the advantages and disadvantages of current methodologies. This gives the other researchers an overview of the development process of distribution transformer condition assessment technologies, thereby continuing to develop new effective evaluation techniques.

- transformer health

- distribution transformer

- real-time assessment

1. Introduction

With the increase in peak demand and the need to improve grid infrastructure for the ease of operation and management with high reliability, the distribution smart grid is one of the most important elements to accelerate the modernization of the currently aging power system. The distribution grid is also the area that is affected significantly by smart technologies

[1]

. Automating and controlling the grid remotely will help reduce operating costs, increase information accuracy as well as quickly fix faulty areas in the electricity power system

[2]

.

The distribution transformer is the last component for voltage transformation in the power grid. It is used to convert the medium voltage to the low voltage level that is used for households or for commercial use. Distribution transformers are thus one of the most important components of the distribution power system

[3]

. Moreover, for each HV/MV primary substation, there are tens of secondary substations. As a result, in a medium-sized city with 40 HV/MV primary stations, there is around one thousand distribution transformers. Many of them are damaged every year due to various reasons. Accelerated degradation and failure of distribution transformers can occur because of several conditions such as oil leakage, overloading, unbalanced loading and harmonics. However, the majority of failures are caused by a combination of these electrical, mechanical and thermal stresses acting upon the power transformer components over time

[4]

. Although the manufacturer generally establishes design and operational limits, the impact on service life is non-binary and multi-dimensional in nature. For example, exceeding a thermal limit to a moderate extent for a short amount of time will not cause immediate failure, but more severe overloading for an extended period will likely cause irreversible damage. If these impacts can be more fully characterized or impending issues can be detected in the field, it could help utilities reduce the rate of failures and degradation, increase the reliability of electric service and reduce the cost of utility operations and maintenance. Therefore, it is important to study and develop effective methods of monitoring the condition and health of distribution transformers.

2. Advanced Technologies for Real-Time Monitoring Transformer Condition in a Smart Distribution Grid

Due to some economic aspects, the online condition monitoring system has not been directly implemented in distribution transformers in past times

. However, with the new generation of the smart distribution grid, the internet of things (IoT), cloud computing, and advanced metering infrastructure are often combined in the electric power systems. This complex system can gather huge data and information, assisted by an array of new approaches, technologies and applications. The real-time data collection, transmission, data access, and rapid analysis of huge amounts of multivariate data are becoming the basis for sustaining the reliable operation of power systems. The development of these advanced technologies aims to optimize the operation of the distribution network, simplify the distribution transformer monitoring process but still ensure high accuracy. While the Internet of Things can help to track, monitor and manage electric equipment through connecting with the internet for information exchange, improve the communication platform of the smart grid. Cloud computing provides a solution to store huge amounts of data and process heavy computational work for transformer monitoring activities of the distribution grid. Many research studies have been implemented to take advantage of this smart management system.

Because distribution transformers are critical assets and the load of a distribution transformer is governed by the end-user, which therefore makes it an uncontrollable load

, further uncertainty comes from PV integration at the distribution level as well as EV recharging facilities. Thus extensive and continuous monitoring is required. Most conventional diagnosis methods for distribution transformers were traditionally carried out off-line when the transformer was taken out of service. With the development of the information technology and smart sensors devices, the reliability of the transformer status assessment system can be carried out on line. The monitoring process is carried out online, in real-time, and thus the accuracy of the condition analysis for the transformer can be greatly improved. Real-time monitoring of transformers can help to find out the potential risks of failure for distribution transformers. For this reason, further analysis can be implemented to identify the development trend of the risks easily and help giving necessary decisions in time in order to avoid unexpected and catastrophic equipment shut-downs. Monitoring data is also stored on the cloud system and analyzed to assist in making decisions on the replacement and maintenance of distribution transformers in the future.

In

[9]

, an online transformer health monitoring system is proposed by using the global mobile service (GSM). A mobile-embedded system including a single-chip microcontroller and sensors is designed to monitor load currents, over-voltage, transformer oil level and oil temperature. If there is any abnormality in the system, the GSM module will send short message service (SMS) messages to designated mobile telephones containing information about the abnormality. After the fault clearing, the total system again starts to monitor the condition of the transformer. As it is a wireless communicating system, there is no need for high-cost large cables. In paper

[10]

, GSM is also used to monitor distribution transformers’ parameters such as current, temperature, oil level, vibration and humidity in every fifteen seconds. The monitoring process is implemented pretty the same with the described system in

[11]

. The microcontroller is the core of RTU that collects data from sensors nearby the transformer and sends data to monitoring nodes via GSM/GPRS module. GPRS has high efficiency, convenience and low cost and provides a good solution to meet the need of distribution transformer monitoring systems.

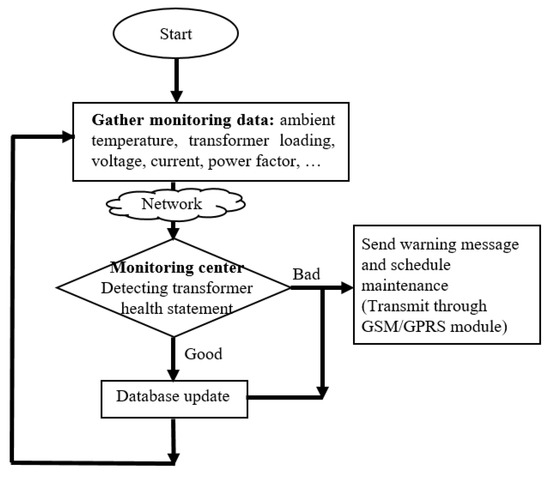

presents the general flowchart of the monitoring systems.

Figure 6. The flowchart of the monitoring systems.

The investment cost of a distribution transformer is much lower than that of a power transformer. In order to get quality evaluation results, high-quality sensors are required. This means that the monitoring system will be very expensive, not consistent with the actual ability of the utilities. Therefore, the corresponding monitoring system for distribution transformers should be designed to be acceptable. To save installation costs, the monitoring parameters are usually voltage, current or ambient temperature that can get easily from electrical measurement systems. These parameters also contribute significantly in identifying the potential risks of transformers in operation, thereby making initial assessments of transformer status before making more thorough inspection decisions. Real-time monitoring transformers using advanced metering infrastructure (AMI) is an effective low-cost solution for managing smart transformers as well as smart grids. In

[12]

, an AMI system is proposed to supervise transformer operation under fire hazards. The main parts of the detection system are sensors, valve systems and the control box. The control box will receive measured data from sensors and send commands to control the system. This smart monitoring system not only provides fast fault detection but also improves the overall health of transformers as well as the distribution system. In

[13]

, the AMI systems are used to collect data in real-time including transformer loading, transformer aging, estimated ambient temperature, computed the hottest temperature from oil-immersed distribution transformers. The gathering information can be used indirectly to determine the priority candidate transformer for replacement before failure. The meter measurements can be utilized to develop temporally high-resolution views of transformer loading indirectly to determine each operational transformer’s aging acceleration. In

, the papers provided a methodology that was used to predict the outage and congestion for distribution transformers. This paper uses the hourly usage data collected from Ameren Illinois’ AMI meters to determine distribution transformer outage, failure, and overload. The proposed methodology not only detects and visualizes outage and congested areas in near real-time but also detects transformers and distribution areas with a long history of outage and congestion.

More recently, portable systems allow diagnosing the dielectric part of many electrical apparatus including oil-insulated transformers

. The portable system uses a sensor which is a special wideband antenna. It allows to detect both partial discharges pulses and the signal of AC supply voltage remotely from the tested component; in this way, the need for direct connection or component turn-off is avoided.

It can be seen that the advanced techniques are good solutions and have the potential to provide a low-cost health assessment system based on existing sensors, energy monitoring meters and the existing communication networks. These solutions can support utilities to monitor distribution transformers continuously and set up suitable transformer management strategies. However, low-cost does not directly translate into a short lifetime or lack of robustness. A good design practice may achieve higher quality and lifetime from lower-cost components (e.g., design for manufacturability, good weatherization, good thermal design, etc.). Point out the distinction between number and cost of power and distribution transformers: power transformers more expensive but fewer of them.

The low-cost health assessment system is also relative to the cost of the considered transformer. The US market for distribution transformers is currently standing at about 650,000–750,000 units per year. The price of a distribution transformer ranges from $700 to $12,000, depending on order quantity and kVA ratings

[19]

. Therefore, health assessment solutions for distribution transformers must be lower cost but sophisticated and precise solutions may not be as important. Because the number of distribution transformers in the electric power system is huge, any reasonably reliable health assessment solution for distribution transformers may be helpful to reduce the cost of maintenance, replacement, and outages—better than “nothing”.

References

- J. R. Agüero, "Applications of smart grid technologies on power distribution systems," in 2012 IEEE PES Innovative Smart Grid Technologies (ISGT), 2012, pp. 1-1

- Z. Du, J. He, R. Fang, and B. Wang, "Diagnosis of smart distribution grid development," in 2014 IEEE PES Asia-Pacific Power and Energy Engineering Conference (APPEEC), 2014, pp. 1-4.

- Transformers: Basics, Maintenance, and Diagnostics. Denver, Colorado, USA: Reclamation Bureau, 2005.

- R. Murugan and R. Ramasamy, "Understanding the power transformer component failures for health index-based maintenance planning in electric utilities," Engineering Failure Analysis, vol. 96, pp. 274-288, 2019/02/01/ 2019.

- A. D. Ashkezari, H. Ma, T. K. Saha, and C. Ekanayake, "Application of fuzzy support vector machine for determining the health index of the insulation system of in-service power transformers," IEEE Transactions on Dielectrics and Electrical Insulation, vol. 20, pp. 965-973, 2013.

- A. Nelson, G. Jaiswal, and M. Ballal, Economical aspects of Remote Conditon Monitoring System for Distribution Transformer, 2014.

- J. A. Jardini, H. P. Schmidt, C. M. V. Tahan, C. C. B. D. Oliveira, and S. U. Ahn, "Distribution transformer loss of life evaluation: a novel approach based on daily load profiles," IEEE Transactions on Power Delivery, vol. 15, pp. 361-366, 2000

- J. K. Pylvanainen, K. Nousiainen, and P. Verho, "Studies to Utilize Loading Guides and ANN for Oil-Immersed Distribution Transformer Condition Monitoring," IEEE Transactions on Power Delivery, vol. 22, pp. 201-207, 2007.

- Y. M. Dileepkumar Reddy, "Real Time Transformer Health Monitoring System Using GSM Technology," International Journal of Research, vol. 7, 2018

- R. R. Pawar and S. B. Deosarkar, "Health condition monitoring system for distribution transformer using Internet of Things (IoT)," in 2017 International Conference on Computing Methodologies and Communication (ICCMC), 2017, pp. 117-122.

- S. Rahman, S. Dey, B. Kumar Bhawmick, and N. Das, "Design and implementation of real time transformer health monitoring system using GSM technology," presented at the 2017 International Conference on Electrical, Computer and Communication Engineering (ECCE), Bangladesh, 2017.

- G. Velhal, A. Pujara, V. Velhal, D. Bakre, and M. Venkat, "Smart Transformer using Advanced Metering Infrastructure (AMI) and Advance Sensor Infrastructure (ASI)," IJIREEICE, vol. 3, pp. 5-8, 08/15 2015

- G. Atkinson and M. Thottan, "Leveraging advanced metering infrastructure for distribution grid asset management," in 2014 IEEE Conference on Computer Communications Workshops (INFOCOM WKSHPS), 2014, pp. 670-675.

- Shil, P.; Anderson, T. Distribution Transformer Health Monitoring and Predictive Asset Maintenance. In Proceedings of the 2019 SAS Global Forum, Dallas, TX, USA, 28 April–1 May 2019; pp. 1–11. [Google Scholar]

- Candela, R.; Di Stefano, A.; Fiscelli, G.; Bononi, S.F.; De Rai, L.; Di Stefano, A. A novel partial discharge detection system based on wireless technology. In Proceedings of the AEIT Annual Conference 2013, Palermo, Italy, 3–5 October 2013; pp. 1–6

- Madonia, A.; Vigni, V.L.; Sanseverino, E.R.; Romano, P.; Viola, F.; Candela, R. Remote voltage synchronization for wireless Partial Discharge diagnostics. In Proceedings of the 2016 IEEE International Conference on Dielectrics (ICD), Montpellier, France, 3–7 July 2016; pp. 947–950

- Chen, N.; Ding, Y.; Sun, Q.; Sun, X.; Liu, L. Threshold decision-based online monitoring system for detection and location partial discharges in power transformers. In Proceedings of the IET International Communication Conference on Wireless Mobile & Computing (CCWMC 2009), Shanghai, China, 7–9 December 2009; pp. 444–447

- Tran, Q.T.T.; Davies, K.; Roose, L.; Doan, B.V.; Nguyen, N.Q. Online distribution service transformer health assessment using real-time grid energy monitor. In Proceedings of the 2020 IEEE Kansas Power and Energy Conference (KPEC), Manhattan, KS, USA, 13–14 July 2020; pp. 1–6.

- U.S. Market for Distribution Transformers Standing at $3 Billion . Newton-Evans Study. Retrieved 2020-11-24