Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is a comparison between Version 1 by zhiqiang niu and Version 2 by Dean Liu.

By considering the intra-echelon connection of facilities within the same layer of echelon, rwesearchers propose a new distribution network design model by reformulating the classical quadratic assignment problem (QAP). To minimize the overall transportation costs, the proposed model jointly optimizes two types of decisions to enable agile distribution with dynamic “shortcuts”

- multi-echelon distribution network

- lateral-transshipment

- quadratic assignment problem

1. Basic Types of City Logistics Distribution Networks

A simple distribution network usually consists of three types of facilities/nodes, i.e., warehouses/plants, DCs, and delivery stations/customers[1]. City logistics, as warehouses and DCs occupy relatively large areas, are usually located in suburban areas. Meanwhile, delivery stations are widely distributed across the city to guarantee the fast delivery of orders.

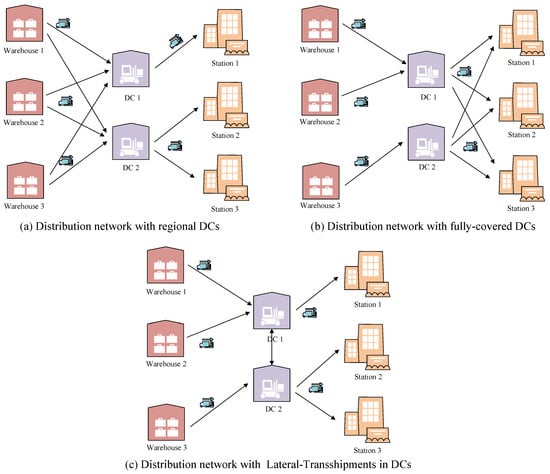

According to the volumes of goods, fulfillment services, and types of goods, different distribution network structures should be designed and continuously improved. Generally, there are three basic types of network structures, as shown in Figure 1. For the distribution network with regional DCs in Figure 1a[2][3], warehouses and DCs are fully connected and each delivery station can only be served by one DC. In the case of the distribution network shown in Figure 1b with fully covered DCs, warehouses are allowed to connect specific DCs, while each DC can connect to all delivery stations. The last type of structure shown in Figure 1c implements the idea of the consolidation of goods to the maximum extent. In this situation, warehouses and DCs do not need to supply all their downstream facilities, but they are required to ensure that demand can always be met by transfer transportation between DCs. It should be noted that there are no extra connections (in comparison to the basic skeleton model) in most analytical studies, while multiple coverages are allowed in practice[4][5][6].

Figure 1. Different types of distribution networks.

2. Distribution Network Design Problem and Related Models

The distribution network design (DND) problem is concerned with the decisions regarding the number of facilities and their optimal locations and facility capacity allocation[7][8][9][10][11][12]. It can also be viewed as a variation of the facility location-allocation or the production-distribution problem, which are reviewed in this subsection.

The coordination of distribution network design and planning has been addressed by some studies, which aim to integrate a number of different layers of supply chain (SC). For example, ref. [13]designed an integrated model considering production and distribution functions in a two-echelon system on a just-in-time (JIT) basis. Focusing on the production process in supply chain, ref. [14]constructed a continuous flexible process network model to maximize the operating profit. Ref. [15] set up a bi-objective model to minimize costs and the delay for the JIT delivery in a three-echelon supply chain. To provide a system-level optimized supply network, [4] attempted to solve the problems jointly in the entire supply network, including network design, production quota assignment, production planning, capacity planning for various facilities, and distribution planning. Ref. [16]investigated the effectiveness of production and distribution integration by a computational study under different logistic environments. In [17], the configuration of a production and distribution network needs to be optimized; there are two types of constraints (namely operational and financial constraints) in the model. Considering process uncertainty and robustness, ref. [18]studied the design and planning of supply chain networks involving multi-echelon, multi-product, and multi-period situations. Ref. [2]presented mathematical models to optimize inventory control and facility locations for a four-echelon supply chain network. With environmental considerations, some studies designed more realistic production-inventory models [19][20]. Ref. [6]developed a nonlinear mixed-integer programming model to optimize multi-echelon sustainable production-distribution supply networks under carbon emission policies. Aiming to increase the total value of a company by configuring and controlling all parts of a supply chain, [21]proposed a three-echelon, multi-commodity, and multi-period model for tactical and strategic decision-making. To ensure a responsive and resilient supply chain network, [22]addresses a multi-period supply chain (SC) network design problem where customer demands depend on the delivery lead-times of the facilities serving them. Interested readers are further referred to a number of excellent review papers on integrating production and distribution in supply chain management [8][23][24][25][26][27].

3. Solution Algorithms

In multi-echelon distribution network design and planning problems, the combined multi-layer decisions could dramatically increase the size of the search space, especially when additional real-world factors (the capacity, costs, uncertainty, etc.) are included. As a result, the design of algorithms for real-life instances has been challenging for practical applications and theoretical research. Given its inherent multi-layer structure, it is beneficial to adopt decomposition methods that can simplify the original problems and solve them efficiently. The Lagrangian relaxation-based method[28] is one of the most frequently used decomposition techniques. For instance, [29] used Lagrangian relaxation to decompose a location-inventory problem and provide a lower bound rule, then the branch-and-bound algorithm was used to obtain feasible solutions. To solve a distribution planning problem, [30]presented a Lagrangian substitution-based solution approach to transform the original nonlinear model into a mixed-integer linear programming model with univariate (solvable) concave models. Ref. [31]also developed a Lagrangian relaxation solution framework to decompose the network design problem into closely related knapsack and time-dependent least cost path problems. Although there are other decomposition-oriented applications in the field of supply chain management[3][4][13][32], theoretically rigorous and computationally reliable decomposition techniques are much needed for different complex scenarios[6]. Comparatively, commonly used heuristic methods aim to find a close-to-optimal solution rapidly in integrated production-distribution problems. To name a few: adapted imperialist competitive algorithm (AICA), variable neighborhood search (VNS) algorithm[7], genetic algorithm (GA)[13][14], and ant colony (AC) algorithm[9]. Ref. [20]utilized the VNS, Tabu Search (TS), Keshtel Algorithm (KA), Water Wave Optimization (WWO), and Particle Swarm Optimization (PSO) to solve a tri-level location-allocation model for forwarding/reverse supply chain systems. Furthermore, different commercial software packages are also developed to solve production-distribution planning problems[33][2][17][34].

Table 1 compares key modeling components in some closely related literature. Most multi-echelon DND models in the existing literature follow a linear structure in which lateral-transshipments within the same echelon is not considered[7][8] or there is no single sourcing strategy[35]. In the work of [2], they used a general linearization technique in quadratic assignment problems to address the quadratic term in the objective function. TheOur proposed approach is developed from the perspective of quadratic assignment problems, with more emphasis on the problem decomposition scheme and branch-and-bound algorithms with domain-specific lower bound rules.

Table 1. Comparison of key modeling components in some closely related literature.

| Publication | Number of Echelons | Model | Problem Decomposition Schemes | Solution Algorithms |

|---|---|---|---|---|

| [13] | 2 | MIP, linear | Lagrangian relaxation | LR |

| [4] | 7 | MIP, linear | Sequential; Lagrangian relaxation | LR; GA |

| [16] | 2 | MIP, linear | Two-phase heuristic | LS |

| [14] | 3 | MIP, linear | - | GA |

| [17] | 3 | MIP, linear | - | CPLEX solver |

| [3] | 3 | 0–1 IP, linear | Lagrangian relaxation | LR |

| [2] | 4 | CQMIP, nonlinear | - | CPLEX solver |

| [7] | 9 | MIP, linear | - | AICA; VNS |

| [18] | 3 | MIP, linear | - | CPLEX solver; Simulation |

| [20] | 4 | MIP, nonlinear | Nested approach | VNS; TS; PSO; KA; WWO |

| [5] | 3 | MIP, nonlinear | Sequential | Heuristic |

| [35] | 4 | MIP, linear | Sequential | Heuristic; GAMS |

| This respapearch | 3 | 0–1 IP, nonlinear | Two-stage decomposition via cost estimation | BB; ALNS |

Model: CQMIP—conic quadratic mixed-integer programming; IP—integer programming; MIP—mixed-integer programming. Solution algorithms: LR—lagrangian relaxation; GA—genetic algorithm; AICA—adapted imperialist competitive algorithm; VNS—variable neighborhood search; LS—local search; TS—tabu search; PSO—particle swarm optimization; KA—keshtel algorithm; WWO—water wave optimization; BB—branch-and-bound.

References

- Ambrosino, D.; Scutella, M.G Distribution network design: New problems and related models. European Journal of Operational Research 2005, 165, 610-624.

- Shahabi, M.; Akbarinasaji, S.; Unnikrishnan, A.; James Integrated inventory control and facility location decisions in a multi-echelon supply chain network with hubs. Networks and Spatial Economics 2013, 13, 497-514.

- 14.18. Shi, J., Zhang, G., & Sha, J A Lagrangian based solution algorithm for a build-to-order supply chain network design problem. Advances in Engineering Software 2012, 49, 21-28.

- Jang, Y. J., Jang, S. Y., Chang, B. M., & Park, J A combined model of network design and production/distribution planning for a supply network. Computers & Industrial Engineering 2002, 43, 263-281.

- Manupati, V. K., Jedidah, S. J., Gupta, S., Bhandari, A., & Ramkumar, M. Optimization of a multi-echelon sustainable production-distribution supply chain system with lead time consideration under carbon emission policies. Computers & Industrial Engineering 2019, 135, 1312-1323.

- Melo, M. T., Nickel, S., & Saldanha-Da-Gama, F Facility location and supply chain management–A review. European journal of operational research 2009, 196, 401-412.

- Devika, K., Jafarian, A., & Nourbakhsh, V Designing a sustainable closed-loop supply chain network based on triple bottom line approach: A comparison of metaheu-ristics hybridization techniques. European Journal of Operational Research 2014, 253, 594-615.

- Eskandarpour, M., Dejax, P., Miemczyk, J., & Péton, O Sustainable supply chain network design: An optimization-oriented review. Omega 2015, 54, 11-32.

- Wang, H. S A two-phase ant colony algorithm for multi-echelon defective supply chain network design. European Journal of Operational Research 2009, 192, 243-252.

- Wang, K. J., Makond, B., & Liu, S. Y Location and allocation decisions in a two-echelon supply chain with stochastic demand–A genetic-algorithm based solution. Expert Systems with Applications 2011, 38, 6125-6131.

- Park, S., Lee, T. E., & Sung, C. S A three-level supply chain network design model with risk-pooling and lead times. Transportation Research Part E: Logistics and Transportation Review 2010, 46, 563-581.

- Mogale, D. G., Kumar, M., Kumar, S. K., & Tiwari, M. K Grain silo location-allocation problem with dwell time for optimization of food grain supply chain network. Transportation Research Part E: Logistics and Transportation Review 2018, 111, 40-69.

- Barbarosoğlu, G., & Özgür, D Hierarchical design of an integrated production and 2-echelon distribution system. European Journal of Operational Research 1999, 118, 464-484.

- Farahani, R. Z., & Elahipanah, M A genetic algorithm to optimize the total cost and service level for just-in-time distribution in a supply chain. International Journal of Production Economics 2008, 111, 229-243.

- Chen, P., & Pinto, J. M Lagrangean-based techniques for the supply chain management of flexible process networks. Computers & Chemical Engineering 2008, 32, 2505-2528.

- Park, Y. B An integrated approach for production and distribution planning in supply chain management. International Journal of Production Research 2005, 43, 1205-1224.

- Tsiakis, P., & Papageorgiou, L. G Optimal production allocation and distribution supply chain networks. International Journal of Production Economics 2008, 111, 468-483.

- Akbari, A. A., & Karimi, B A new robust optimization approach for integrated multi-echelon, multi-product, multi-period supply chain network design under process uncertainty. The International Journal of Advanced Manufacturing Technology 2015, 79, 229-244.

- Fard, A. M. F., & Hajiaghaei-Keshteli, M A bi-objective partial interdiction problem considering different defensive systems with capacity expansion of facilities under imminent attacks. Applied Soft Computing 2018, 68, 343-359.

- Fard, A. M. F., & Hajaghaei-Keshteli, M A tri-level location-allocation model for forward/reverse supply chain. Applied Soft Computing. Applied Soft Computing 2018, 62, 328-346.

- Badri, H., Ghomi, S. F., & Hejazi, T. H A two-stage stochastic programming approach for value-based closed-loop supply chain network design. Transportation Research Part E: Logistics and Transportation Review 2017, 105, 1-17.

- Fattahi, M., Govindan, K., & Keyvanshokooh, E Responsive and resilient supply chain network design under operational and disruption risks with delivery lead-time sensitive customers. Transportation research part E: Logistics and transportation review 2017, 101, 176-200.

- Aikens C.H Facility location models for distribution planning. European Journal of Operational Research 1985, 22, 263-279.

- Vidal, C. J., & Goetschalckx, M Strategic production-distribution models: A critical review with emphasis on global supply chain models. European journal of operational research 1997, 98, 1-18.

- Fahimnia, B., Farahani, R. Z., Marian, R., & Luong, L A review and critique on integrated production–distribution planning models and techniques. Journal of Manufacturing Systems 2013, 32, 1-19.

- Goetschalckx, M., Vidal, C. J., & Dogan, K Modeling and design of global logistics systems: A review of integrated strategic and tactical models and design algorithms. European journal of operational research 2002, 143, 1-18.

- Chen, Z. L Integrated production and outbound distribution scheduling: review and extensions. . Operations research 2010, 58, 130-148.

- Fisher, M. L., Jörnsten, K. O., & Madsen, O. B Vehicle routing with time windows: Two optimization algorithms. Operations research 1997, 45, 488-492.

- Shen, Z. J. M., Coullard, C., & Daskin, M. S A joint location-inventory model. Transportation science 2003, 37, 40-55.

- Pan, F., & Nagi, R Multi-echelon supply chain network design in agile manufacturing. Omega 2013, 41, 969-983.

- Ben Abid, T., Ayadi, O., & Masmoudi, F An integrated production-distribution planning problem under demand and production capacity uncertainties: new formu-lation and case study. Mathematical Problems in Engineering 2020, 19, 1-15.

- Larimi, N Gilani , S. Yaghoubi , and S. M. Hosseini-Motlagh Itemized platelet supply chain with lateral transshipment under uncertainty evaluating inappropriate output in laboratories. Socio-Economic Planning Sciences 2019, 68, 38-121.

- Puga, M. S., Minner, S., & Tancrez, J. S Two-stage supply chain design with safety stock placement decisions. International Journal of Production Economics 2019, 209, 183-193.

- Tsiakis, P., Shah, N., & Pantelides, C. C Design of multi-echelon supply chain networks under demand uncertainty. Industrial & engineering chemistry research 2001, 40, 3585-3604.

- Rabbani, M., Sabbaghnia, A., Mobini, M., & Razmi, J A graph theory-based algorithm for a multi-echelon multi-period responsive supply chain network design with lat-eral-transshipments. Operational Research 2020, 20, 2497-2517.

More