You're using an outdated browser. Please upgrade to a modern browser for the best experience.

Please note this is a comparison between Version 3 by Jessie Wu and Version 2 by Jessie Wu.

Poly-1-vinyl-1,2,4-triazole is a unique polymer with a wide range of valuable, practically significant properties.

- 1,2,4-triazole

- proton conductivity

- proton-conducting membranes

- Poly-1-vinyl-1,2,4-triazole

1. Introduction

There are several types of electrolyte membranes used in the development of fuel cells. The main ones are perfluorinated sulphate-containing electrolyte membranes, such as “Nafion” (E.I. Du Pont de Nemours Co. Inc., Wilmington, Delaware, USA), “Flemion” (Asahi Glass Company, Tokyo, Japan), “Neosepta-F” (Tokuyama Soda Co. Ltd., Tokyo, Japan), and MF-4SK (OAO Plastpolimer, St. Petersburg, Russia), based on copolymers of tetrafluoroethylene with perfluorinated sulfonic monomers [1][2][3][4][5][6][7][8][9][10]. These membranes are characterized by high proton conductivity (up to 10−1 S/cm) at high humidity and temperatures up to 80 °C, as well as good mechanical characteristics; however, the use of such membranes in medium-temperature fuel cells is limited due to their low ionic conductivity at low humidity and elevated temperatures, their tendency toward destruction, and their high cost.

Therefore, intensive research on the development of polymeric proton-conducting membranes for fuel cells with commercial availability and high-performance characteristics (proton conductivity, chemical stability) in a wide temperature range (100–200 °C) continues. Of particular interest are proton-conducting membranes based on polymers with fluorinated and sulfonated styrene fragments [11][12].

To fabricate proton-conducting membranes, heteropoly compounds and various polymers containing active pyridine fragments, SO2, CH3, SO3Na, and OH groups in macromolecules, which provide high proton conductivity (up to 10−1 S/cm) in a wide frequency range, are studied, examining temperature range (90–170 °C), mechanical strength, and chemical stability [13]. However, the strong dependence of the conductivity of these membranes on the relative humidity of the environment limits their use in fuel cells.

A large amount of research is devoted to the development and study of proton-conducting membranes based on polybenzimidazole (PBI) and its derivatives, which are characterized by high proton conductivity [14][15][16][17][18][19][20]. It has been shown that the modification of PBI by sulfonation and phosphorylation leads to a significant improvement in the proton-conducting, mechanical, and thermal characteristics of PBI-based membranes. It was assumed that the use of imidazole in the production of electrolytes would provide intermolecular proton transfer at temperatures above 100 °C and the corresponding performance of new-generation fuel cells. However, the low solubility, high glass transition temperature (300–400 °C), and insufficient electrochemical stability of imidazole, due to the high electron density of the imidazole ring, prevent the widespread use of PBI for the manufacturing of membranes [21][22].

2. Study of Proton-Conducting Membranes Based on 1-Vinyl-1,2,4-tTriazole Homopolymers

A large amount of research is devoted to the development and study of proton-conducting membranes based on 1-vinyl-1,2,4-triazole homopolymers (Table 1).

Table 1. Main characteristics of proton-conducting membranes based on poly-1-vinyl-1,2,4-triazole: maximum proton conductivity in the anhydrous state (σ), ion exchange capacity (IEC), and water uptake (WU).

| Sample Name | T, °C | σ, S/cm | IEC, mmol/g |

WU, % | Reference |

|---|---|---|---|---|---|

| Poly-1-vinyl-1,2,4-triazole and phosphoric acid | 50 | 1.2 × 10−4 | – | – | [23] |

| Poly-1-vinyl-1,2,4-triazole and phosphoric acid | 140 150 |

5.0 × 10−3 4.0 × 10−3 |

– | – | [24] |

| Poly-1-vinyl-1,2,4-triazole and nitrilotri(methyl triphosphonic acid) | 150 | 8.5 × 10−4 | – | – | [25] |

| Poly(1-vinyl-1,2,4-triazole) and nitrilotri (methyl triphosphonic acid) | 150 | 8.5 × 10−4 | – | – | [26] |

| Poly(1-vinyl-1,2,4-triazole) and poly(vinylphosphonic acid) | 180 * 100 |

2.5 × 10−5 * 2.2 × 10−2 |

– | 150–350 | [27] |

| Poly(1-vinyl-1,2,4-triazole) and poly(styrene sulfonic acid) | 120 150 |

3.3 × 10−2 1.5 × 10−2 |

– | – | [28] |

| Poly(1-vinyl-1,2,4-triazole) and toluenesulfonic acid | 110 150 |

1.2 × 10−2 8.0 × 10−4 |

– | – | [29] |

| Poly(1-vinyl-1,2,4-triazole) and trifluoromethanesulfonic (triflic) acid | 80 | 1.2 × 10−2 | – | – | [30] |

| Poly(1-vinyl-1,2,4-triazole) and poly(2-acrylamido2-methyl-1-propanesulfonic acid) | 150 * 100 |

1.1 × 10−6 * 3.0 × 10−1 |

– | 150–240 | [31] |

| Poly(1-vinyl-1,2,4-triazole) and polybenzimidazole (blends) and phosphoric acid | 160 | 1.1 × 10−1 | – | 33–43 | [32] |

| Poly(1-vinyl-1,2,4-triazole) and poly(vinyl alcohol) with sulfosuccinic acid | 150 * 60 |

2.5 × 10−5 * 2.8 × 10−3 |

– | 80–150 | [33] |

| Poly(1-vinyl-1,2,4-triazole) with phenol-2,4-disulfonic acid and poly(vinyl alcohol) cross-linked with oxalic acid | 80 | 6.0 × 10−2 7.3 × 10−3 6.2 × 10−3 |

0.9–3.4 | 50–200 | [34][35] |

| Poly(1-vinyl-1,2,4-triazole) and sulfonated polysulfone and phosphoric acid | 150 | 3.6 × 10−4 | 3.05 | – | [36] |

| Poly(1-vinyl-1,2,4-triazole) and Nafion (blends) | 220 * 25 |

5.3 × 10−4 * 1.0 × 10−3 |

– | 48–140 | [37] |

* After humidification (RH = 50%).

In the studies [23][24][25][26], poly-1-vinyl-1,2,4-triazole (PVT) was produced by free radical polymerization of 1-vinyl-1,2,4-triazole and was doped with phosphoric acid and nitrilotri(methyl-triphosphonic acid) at various molar ratios. The synthesized PVT is thermally stable up to approximately 250 °C. The proton exchange reactions between PVT and H3PO4 (or C3H18NO24P9) was proved with Fourier transform infrared spectroscopy. After doping PVT, the intensities of the bands corresponding to the triazole ring stretching (C–N, C=N) vibrations between 1430 and 1650 cm−1 changed [24]. Additionally, a strong peak at 3100 cm−1 could be associated with N–H absorption in the protonated triazole. A broadening of the band between 3500 and 2000 could be related to a hydrogen bonding network formation. Within the 1800–900 cm−1 region, the peaks near 1100 cm−1 and 979 cm−1 were attributed to characteristic absorptions of the HPO42− and H2PO4− in the blends [24]. The presence of HPO42− and H2PO4− anions implied that phosphoric acid is ionized in the blend system. The proton conductivity of these materials increased with dopant concentration and temperature. In the anhydrous state, the proton conductivity of PVT—H3PO4 was 5.0 × 10−3 S/cm at 150 °C [24] and the conductivity of PVT—C3H18NO24P9 was 8.5 × 10−4 S/cm at 150 °C [25][26].

In the work [27], the results of a study of PVT complexes with poly(vinylphosphonic acid) (PVPA) are discussed. The complexes of various compositions were synthesized and homogeneous plastic materials were formed on their bases. The positive effect of PVT was its ability to prevent the formation of phosphonic acid anhydrides up to 150 °C. The PVT-PVP-based membrane showed a proton conductivity of 2.5 × 10−5 S/cm at 180 °C in the anhydrous state. After humidification (RH = 50%), PVT-PVPA showed a proton conductivity of 0.022 S/cm at 100 °C, which is close to that of Nafion 117 at the same humidity level [27].

Homogeneous proton-conducting membranes, thermally stable up to 250 °C, were synthesized by complexation of PVT with poly(styrene sulfonic acid) [28]. The maximum proton conductivity of the obtained membranes in the anhydrous state was 0.033 S/cm at 120 °C [28].

Membranes obtained based on PVT doped with toluenesulfonic acid at various molar ratios (0.5, 1, 1.5, 2, with respect to the polymer repeating unit) are characterized by thermal stability up to 250 °C, electrochemical stability over 3 V, and proton conductivity of 8.0 × 10−4 S/cm at 150 °C and 0.012 S/cm at 110 °C [29].

Promising membranes were obtained by doping PVT with trifluoromethanesulfonic (triflic) acid (CF3SO3H) at several molar percentages (25, 50, 75, 100, and 150%) with respect to the polymer repeat unit [30]. Due to the strong interaction between of sulfonic acid groups of triflic and the triazole units of PVT, no phase separation occurred during solvent evaporation; hence homogeneous and transparent films formed. The thermal stability of these membranes was 300 °C, depending on the acid content. Maximum proton conductivity of 0.012 S/cm at 80 °C was obtained for PVT doped by triflic acid, which is comparable to that of hydrated Nafion [30].

New proton-conducting materials, such as transparent thin films, were obtained by the complexation of PVT and poly(2-acrylamido2-methyl-1-propanesulfonic acid) at various ratios (from 0.25 to 4) [31]. The maximum values of proton conductivity were obtained for the complexes of PVT and acid with ratio compositions 1:2 and 1:4. In the anhydrous state, the proton conductivities of these complexes at 150 °C were 1.1 × 10−8 S/cm and 1.2 × 10−6 S/cm, respectively. The proton conductivities of these complexes in the hydrated state increased significantly, namely, to 0.3 S/cm and 0.06 S/cm, respectively, at 100 °C [31].

Polymer–polymer blends based on PVT are promising alternative proton-conducting materials. In study [32], a simple and economical method for obtaining new polymeric materials was carried out by mixing two polymers with different physical properties (PVT and polybenzimidazole (PBI)) in order to obtain a material with improved physical and chemical properties, namely high proton conductivity and high thermal and mechanical stability. The authors [32] carefully analyzed the FT-IR spectra of PVT, PBI, and blend films in the range of 1700–1150 cm−1 and found that there was an N–H ··N type of interaction between the two polymers. This confirmed the formation of hydrogen bonds between the two polymers in the mixture. The presence of interactions between the two polymers was also confirmed by the results of solid-state NMR, in which a shift of the characteristic PBI peaks to a higher field in a mixture of polymers was observed, as well as by corresponding changes in the absorption and emission spectra of the fluorescence of the PBI and PVT samples, and that of their mixture [32]. All samples of the mixture in their unalloyed state were thermally stable up to 300 °C. A significant increase in the proton conductivity of the polymer mixture doped with phosphoric acid was found. The maximum values of proton conductivity were observed for a 50:50 mixture of polymers equal to 1.1 × 10−1 S/cm at 160 °C, which is an order of magnitude higher compared to pure PBI. The main reason for the high proton conductivity of mixed membranes is their more porous morphology, which contributes to a higher degree of doping with phosphoric acid, which leads to an increase in proton conductivity.

New types of composite membranes were synthesized by crosslinking poly(vinyl alcohol) (PVA) with sulfosuccinic acid (SSA) and intercalating PVT into the resulting matrix [33]. The resulting hybrid membranes were transparent, flexible, heat-resistant up to 200 °C, and had a proton conductivity of (1.6–7.7) × 10−5 S/cm at 150 °C. After wetting the membranes (RH=100%), the proton conductivity increased to 2.8 × 10−3 S/cm at 60 °C [33]. An increase in the absorption of the solvent (water/methanol) was established with an increase in the content of PVT in the membranes.

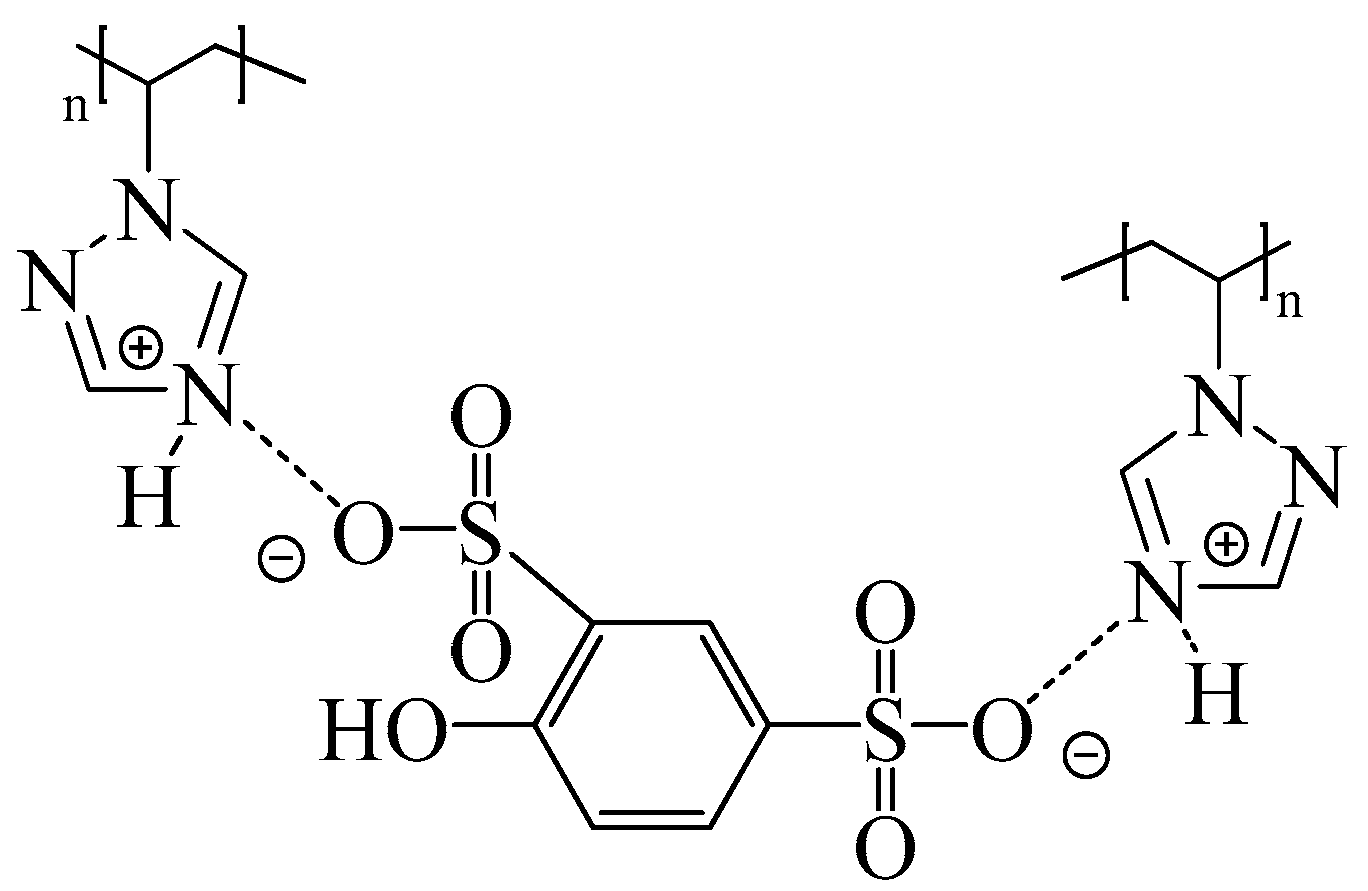

Researchers recently reported on the development of new proton exchange membranes based on PVT and phenol-2,4-disulfonic acid (PDSA) with different ratios, as well as the additional use of polyvinyl alcohol crosslinked with oxalic acid [34][35]. It has been shown that due to the transfer of protons from PDSA to the triazole fragments of PVT, acid–base complexes are formed, which contribute to an increase in the mechanical and thermal stability (up to 245 °C of the resulting membranes) (Figure 1). Furthermore, 15N NMR proves that the PVT triazole rings in the membranes are protonated by PDSA.

Figure 1. Structure of PVT–PDSA acid–base complexes.

The proton conductivity of the membranes and the activation energy of proton transfer increased with an increase in the content of PDSA in their composition and amounted to 6.0 × 10−2, 7.3 × 10−3, and 6.2 × 10−3 S/cm (at a temperature of 80 °C and a humidity of 75%) and 19.5, 21.6, and 38.2 kJ/mol for membranes, containing 36, 24, and 8 mass.% of PDSA, respectively [34][35].

The proton-conducting polymeric membranes were obtained by mixing PVT with sulfonated polysulfone and phosphoric acid [36]. In the course of the reaction, an interaction took place between the triazole fragments and sulfonic acid units, which was confirmed by the data from the Fourier transform infrared spectroscopy. Proton exchange reactions between the polymer and H3PO4 were established. The obtained membranes were thermally stable up to 150 °C and possessed a maximum proton conductivity of 3.63 × 10−4 S/cm at 150 °C [36].

The originality of PVT is evidenced by the results of study [37], which demonstrated that the insertion of PVT into hydrophilic Nafion channels led to the production of electrochemically, thermally, and mechanically stable membranes. The authors of [37] studied a mixture of Nafion with PVT. Due to the strong interaction between the sulfonic acid groups of Nafion and the triazole units of PVT, phase separation did not occur during solvent evaporation, and homogeneous and transparent films were formed. In a mixed system, proton conduction can occur through triazole units, which, when combined, form dynamic hydrogen chains that support long-distance proton transport. The conductivity of the Nafion-PVT-blend membranes was measured to be 5.3 × 10−4 S/cm at 220 °C in an anhydrous state, and increased at least three orders of magnitude upon hydration. At the same time, these Nafion-PVT membranes are characterized by high thermal stability up to 300 °C and low methanol permeability, namely two times lower than that of commercial Nafion 112 [37].

References

- De Almeida, S.H.; Kawano, Y. Thermal behavior of Nafion membranes. J. Therm. Anal. Calorim. 1999, 58, 569–577.

- Li, Q.F.; He, R.H.; Jensen, J.O.; Bjerrum, N.J. Approaches and recent development of polymer electrolyte membranes for fuel cells operating above 100 °C. Chem. Mater. 2003, 15, 4896–4915.

- Lufrano, F.; Staiti, P. Conductivity and capacitance properties of a supercapacitor based on Nafion electrolyte in a njnaqueous system. Electrochem. Solid State Let. 2004, 7, A447–A450.

- Wang, J.; Xu, C.; Taya, M.; Kuga, Y. A Flemion-based actuator with ionic liquid as solvent. Smart Mater. Struct. 2007, 16, S214–S219.

- Saito, M.; Hayamizu, K.; Okada, T. Temperature Dependence of Ion and Water Transport in Perfluorinated Ionomer Membranes for Fuel Cells. J. Phys. Chem. 2005, 109, 3112–3119.

- Souzy, R.; Ameduri, B. Functional fluoropolymers for fuel cell membranes. Prog. Polym. Sci. 2005, 30, 644–687.

- Yaroslavtsev, A.B.; Nikonenko, V.V. Ion-exchange membrane materials: Properties, modification, and practical application. Russ. Nanotechnolog. 2009, 4, 137–159.

- Ivanchev, S.S.; Myakin, S.V. Polymeric membranes for fuel cells: Manufacture, structure, modification, properties. Russ. Chem. Rev. 2010, 79, 101–117.

- Lain, L.; Barragan, V.M. Swelling properties of alkali-metal doped polymeric anion exchange membranes in alcohol media for application in fuel cells. Int. J. Hydrogen Energy 2016, 41, 14160–14170.

- Karimi, M.B.; Hooshyari, K.; Salarizadeh, P.; Beydaghi, H.; Ortiz-Martınez, V.M.; Ortiz, A.; Ortiz Uribe, I.; Mohammadi, F. A comprehensive review on the proton conductivity of proton exchange membranes (PEMs) under anhydrous conditions: Proton conductivity upper bound. Int. J. Hydrogen Energy 2021, 46, 34413–34437.

- Carretta, N.; Tricoli, V.; Picchioni, F. Ionomeric membranes based on partially sulfonated poly(styrene): Synthesis, proton conduction and methanol permeation. J. Membr. Sci. 2000, 166, 189–197.

- Francisco-Vieira, L.; Benavides, R.; Da Silva, L.; Cuara-Diaz, E.; Morales-Acosta, D. Effect of sulfonating agent in the properties of styrene copolymers for PEMFC membranes. Int. J. Hydrogen Energy 2022, 47, 30303–30314.

- Dobrovolsky, Y.A.; Chikin, A.I.; Sanginov, E.A.; Chub, A.V. Proton-exchange membranes based on heteropoly compounds for low temperature fuel cells. Altern. Energy Ecol. (ISJAEE) 2015, 168, 22–45.

- Li, Q.; He, R.; Jensen, J.O.; Bjerrum, N.J. PBI-based polymer membranes for high temperature fuel cells—Preparation, characterization and fuel cell demonstration. Fuel Cells 2004, 4, 147–159.

- Angioni, S.; Villa, D.C.; Dal Barco, S.; Quartarone, E.; Righetti, P.P.; Tomasi, C.; Mustarelli, P. Polysulfonation of BI-based membranes for HT-PEMFCs: A possible way to maintain high proton transport at a low H3PO4 doping level. J. Mater. Chem. A 2014, 2, 663–671.

- Villa, D.C.; Angioni, S.; Dal Barco, S.; Mustarelli, P.; Quartarone, E. Polysulfonated fluoro-oxyPBI membranes for PEMFCs: An efficient strategy to achieve good fuel cell perfomances with low H3PO4 doping levels. Adv. Energy Mater. 2014, 4, 1031949.

- Mack, F.; Aniol, K.; Ellwein, C.; Kerres, J.; Zeis, R. Novel phosphoric acid-doped PBI-blends as membranes for high-temperature PEM fuel cells. J. Mater. Chem. A 2015, 3, 10864–10874.

- Fisher, K.; Qian, G.; Benicewicz, B.C. PBI membranes via the PPA process. In High Temperature Polymer Membrane Fuel Cells; Li, Q., Aili, D., Hjuler, H.A., Jensen, J.O., Eds.; Springer: Berlin/Heidelberg, Germany, 2016; pp. 217–238.

- Melchior, J.-P.; Majer, G.; Kreuer, K.-D. Why do proton conducting polybenzimidazole phosphoric acid membranes perform well in high-temperature PEM fuel cells? Phys. Chem. Chem. Phys. 2017, 19, 601–612.

- Quartarone, E.; Angioni, S.; Mustarelli, P. Polymer and Composite Membranes for Proton-Conducting, High-Temperature Fuel Cells: A Critical Review. Materials 2017, 10, 687.

- Noda, A.; Susan, M.; Abu Bin, H.; Kudo, K.; Mitsushima, S.; Hayamizu, K.; Watanabe, M. Brønsted Acid-Base Ionic Liquids as Proton-Conducting Nonaqueous Electrolytes. J. Phys. Chem. B 2003, 107, 4024–4033.

- Deng, W.; Molinero, V.; Goddard, W.A. Fluorinated Imidazoles as Proton Carriers for Water-Free Fuel Cell Membranes. J. Am. Chem. Soc. 2004, 126, 15644–15645.

- Pu, H.; Ye, S.; Wan, D. Anhydrous proton conductivity of acid doped vinyltriazole-based polymers. Electrochem. Acta 2007, 52, 5879–5883.

- Celik, S.Ü.; Aslan, A.; Bozkurt, A. Phosphoric acid-doped poly(1-vinyl-1,2,4-triazole) as water-free proton conducting polymer electrolytes. Solid State Ion. 2008, 179, 683–688.

- Gustian, I.; Çelik, S.; Suratno, W.; Bozkurt, A. Proton conducting composite membranes based on poly(1-vinyl-1,2,4-triazole) and nitrilotri (methyl triphosphonic acid). J. Phys. Chem. Solids 2011, 72, 1377–1380.

- Gustian, I.; Gelik, S.U.; Bozkurt, A. Synthesis of Poly(1-vinyl-1,2,4-triazole) and Preparation of Proton Conducting Membrane for High Temperature Operation. Adv. Mater. Res. 2013, 789, 294–299.

- Aslan, A.; Bozkurt, A. Development and characterization of polymer electrolyte membranes based on ionical cross-linked poly(1-vinyl-1,2,4 triazole) and poly(vinylphosphonic acid). J. Power Sources 2009, 191, 442–447.

- Aslan, A.; Sen, U.; Bozkurt, A. Preparation, Properties, and Characterization of Polymer Electrolyte Membranes Based on Poly(1-vinyl-1,2,4 triazole) and Poly(styrene sulfonic acid). J. Electrochem. Soc. 2009, 156, B1112–B1116.

- Ozden, S.; Celik, S.; Bozkurt, A. Polymer Electrolyte Membranes Based on p-Toluenesulfonic Acid Doped Poly(1-vinyl-1,2,4-triazole): Synthesis, Thermal and Proton Conductivity Properties. J. Polym. Sci. Part B Polym. Phys. 2010, 48, 1016–1021.

- Aslan, A.; Celik, S.Ü.; Sen, Ün.; Haser, R.; Bozkurt, A. Intrinsically proton-conducting poly(1-vinyl-1,2,4-triazole)/triflic acid blends. Electrochim. Acta 2009, 54, 2957–2961.

- Aslan, A.; Bozkurt, A. Proton conducting properties of ionically cross-linked poly(1-vinyl-1,2,4 triazole) and poly(2-acrylamido2-methyl-1-propanesulfonic acid) electrolytes. Polym. Bull. 2011, 66, 1099–1110.

- Hazarika, M.; Jana, T. Proton exchange membrane developed from novel blends of polybenzimidazole and poly(vinyl-1,2,4-triazole). ACS Appl. Mater. 2012, 4, 5256–5265.

- Boroglu, M.S.; Celik, S.U.; Bozkurt, A.; Ismail Boz, I. Proton-Conducting Blend Membranes of Crosslinked Poly(vinyl alcohol)–Sulfosuccinic Acid Ester and Poly(1-vinyl-1,2,4-triazole) for High Temperature Fuel Cells. Polym. Eng. Sci. 2013, 53, 153–158.

- Lebedeva, O.; Pozhidaev, Y.; Raskulova, T.; Belkovich, A.; Ivanova, A.; Korzhova, S.; Emelyanov, A.; Pozdnyakov, A. Synthesis and characterization of new proton-exchange membranes based on poly-1-vinyl-1,2,4-triazole doped with phenol-2,4-disulfonic acid. Int. J. Energy Res. 2021, 45, 14547–14560.

- Emelyanov, A.I.; Lebedeva, O.V.; Malakhova, E.A.; Raskulova, T.V.; Pozhidaev, Y.N.; Verkhozina, Y.A.; Larina, L.I.; Korzhova, S.A.; Prozorova, G.F.; Pozdnyakov, A.S. Acid–Base Membranes for Solid Polymer Fuel Cells. Membr. Membran. Technol. 2021, 3, 147–154.

- Sevinc, S.; Celik, S.U.; Bozkurt, A. An investigation of proton conductivity of binary matrices sulfonated polysulfone/polyvinyltriazole after doping with inorganic acids. Bull. Mater. Sci. 2015, 38, 573–578.

- Sen, U.; Bozkurt, A.; Ata, I. Nafion/poly(1-vinyl-1,2,4-triazole) blends as proton conducting membranes for polymer electrolyte membrane fuel cells. J. Power Sources 2010, 195, 7720–7726.

More