Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is a comparison between Version 1 by Karl Dearn and Version 2 by Rita Xu.

The condition of a joint in a human being is prone to wear and several pathologies, particularly in the elderly and athletes. Current means towards assessing the overall condition of a joint to assess for a pathology involve using tools such as X-ray and magnetic resonance imaging, to name a couple. These expensive methods are of limited availability in resource-constrained environments and pose the risk of radiation exposure to the patient. The prospect of acoustic emissions (AEs) presents a modality that can monitor the joints’ conditions passively by recording the high-frequency stress waves emitted during their motion.

- AE

- signal processing

- orthopaedics

- joint wear

1. Introduction

1.1. Joint Wear and Its Epidemiology

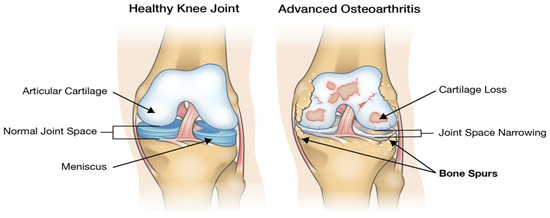

It is estimated that there are around 360 joints in the human body, the majority of which are subject to wear and degradation as human beings age, depending on their professions and lifestyle, where problems such as chronic pain and osteoarthritis occur as a result [1]. Further, it has been noted that the world population is ageing and is projected to rise further by the year 2050. From a joint and structural perspective, the implication is that joint-wear problems can be even more prevalent due to the ageing population [2]. For example, one of the noticeable results of joint wear is osteoarthritis, which manifests itself with erosive behaviour of the joint cartilage due to repeated trauma or considerable injury [3]. During osteoarthritis, metabolic changes occur within the joint due to the continued wear, which forms nano/micro-scale fractures that regenerate to form osteophytes, resulting in the knee producing additional fluid, which causes further pain, discomfort and swelling [1][3][1,3]. The accumulation of the factors above eventually manifests biomechanically as structural instability, misalignments and deformity. A visual comparison of a healthy knee with a worn knee can be seen in Figure 1, from which it can be noted that there is a substantial amount of cartilage loss, joint-space narrowing and the production of bone spurs.

Figure 1. Visual comparison of a healthy and worn knee.

In addition to ageing individuals, athletes involved in high-impact sports, such as basketball and dancers, have been seen to carry a degree of risk of developing joint-based diseases related to overall wear and osteoarthritis later in life [4][5]. The early detection of these joint-wear pathologies can allow for proactive care strategies to be offered to patients, thus negating the need for orthopaedic-based surgeries on the joints [4][5].

1.2. Means of Diagnosing Joint Pathologies, Their Shortcomings and AE

Traditionally, the means for diagnosing and identifying joint pathologies is using X-ray imaging, although this method has been critiqued for mostly projecting a cross-section of the bones in question [5][6]. Computed tomography (CT) is an improvement on traditional X-ray, as it offers a three-dimensional projection of joints and bones, but still exposes the patient to harmful rays during the imaging process and does not give reliable insights into soft tissues, ligaments or muscles [6][7]. The emergence of dynamic measurements such as magnetic resonance imaging (MRI) has offered a means towards producing an image-based diagnosis of both joint and soft-tissue pathologies, but has shortcomings based on portability, power consumption and overall costs. Thus, their acquisition and use are specialised [7][8]. Although ultrasound imaging offers a cheaper alternative to MRI—whilst offering an image-based perspective for both joints and soft tissues—its use is limited in diagnosing joint wear and pathologies due to being prone to noise and unable to detect micro- and hairline fractures [8][9].

Seminal work has been done by researchers who have attempted to track the sound waves—known as biomechanical acoustic emission (AE) waves—that are produced when various joints are flexed, resulting from tissue changes during deformations and movements, and provided signs to suggest that AE can be applied as a means towards assessing the level of degeneration in a joint [9][10][11][12][10,11,12,13]. The conceptual physics is based on the expectation that the AE events generated by a healthy joint would be less than that of one with a considerable degree of wear within it and can serve as a non-invasive means towards condition monitoring of joint wear [9][10][11][12][10,11,12,13].

Contrasting the AE sensing approach to clinical joint diagnosis techniques, it is a passive technique that poses minimal risk of infection and radiation and is affordable, as well as being a non-invasive means towards the acquisition of rich signal information that can be utilised towards the diagnosis and assessment of joint health [13][14]. AE has predominantly seen traditional use in condition monitoring and maintenance of machinery components, in addition to process monitoring, but recent scientific advancements have seen applications of the technique in areas such as biomechanics and orthopaedics, as mentioned [9][10][11][12][13][10,11,12,13,14].

Tribological research work by Olorunlambe et al. [9][10][14][10,11,15] identified the notion that there mainly exists a constrained array of signal processing techniques applied towards ortho-tribological case studies, which they built upon by developing machine learning models that could differentiate between adhesive and abrasive wear conditions. The work by Olorunlambe et al. [9][10][14][10,11,15] showcased how machine learning-based methods could distinguish between these two wear conditions from benchtop-based wear conditions in their running in early and steady-state (continuous) stages of wear. The research presented in this paper aims to build on this by designing pattern recognition-based predictive models that can identify and differentiate between the latent and early stages of joint-wear pathologies, a broad class of common joint-wear conditions that includes abrasive, adhesive, burnishing, burnishing-to-scoring transition, and scoring. These results are the first time AE has been applied to investigate and recognise such a broad class of wear conditions. ResearchersWe aim to investigate this problem by applying and comparing two signal processing methods, including a concatenation of a broad list of manually extracted (handcrafted) and an unsupervised feature extraction method from deep wavelet scattering (DWS). DWS represents a fusion between wavelet transform and deep learning, which can extract multiscale features in an unsupervised manner without requiring expert knowledge for the feature extraction stage [15][16].

2. AE Sensing

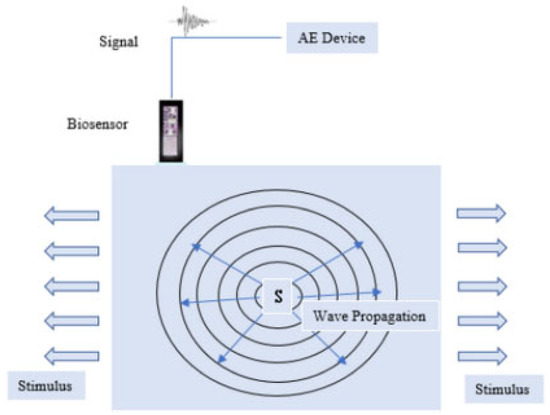

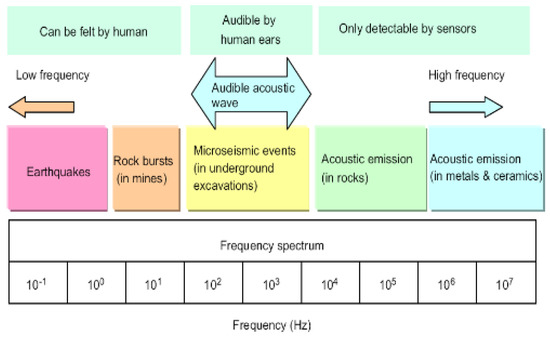

The concept behind AE sensing is based on the use of a passive monitoring technique capable of recording source events that emanate from events of various kinds during energy release [14][15]. The said energy release is known to travel in the form of stress waves in high-frequency regions (unless stated as audible), which are detected and measured by a sensor that converts an equivalent stress magnitude into a corresponding electrical signal [14][15]. A visual illustration is shown in Figure 2, while an illustration of the acoustic spectrum can be seen in Figure 3.

Figure 2. Visual illustration of the propagation of an AE signal.

Figure 3. The acoustic spectrum.

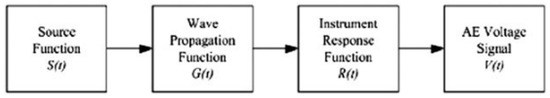

Figure 4. Signal shaping chain.

3. Tribological Surface Mechanics

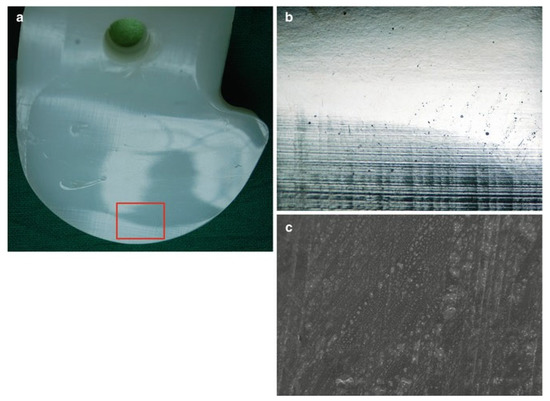

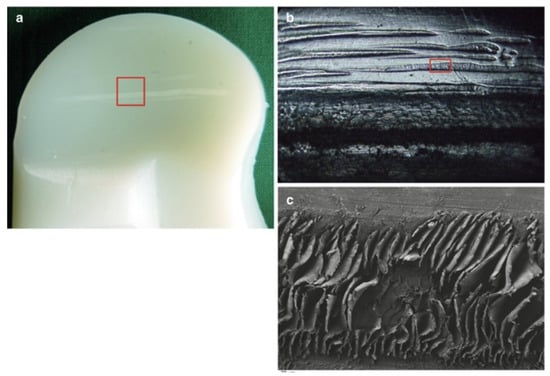

Tribology is the science of surfaces that rub and are in contact with each other, which serves as an equivalent scale-down and theoretical basis towards the study of biotribological and orthopaedic conditions that can occur in the joints of a human being, assuming a set of surfaces that have contact and an apparent interaction that can span nano/macro-scale contact depending on the level and scale of the interaction [16][19]. Di Puccio and Mattei [16][19] described the contact forces, assuming a macro-scale interaction, as ideal bodies that are elastic under loading conditions and that undergo a form of elastic deformation that can be physically governed using the principle of Young’s modulus. For a scenario involving contact with two surfaces assumed to be perfect spheres, an analytical solution can be obtained using Hertz’s theory of contact, which considers the contact pressure and area for two spheres in contact [17][20]. Although Hertz’s proposition is for nonconformal bodies of two spheres, its principles can be extrapolated forward for a scenario involving biological joint contact [17][20]. The friction during the process is a resistance source between the two bodies in contact, which, as per Di Puccio and Mattei [16][19], can either be rolling or sliding. These can coincide where the friction force is likely due to adhesions and surface deformations at contact junctions [16][19]. In order to minimise the effect of friction on contacting bodies in biological joints, a lubrication source (synovial fluid) usually is present to promote a safe and sustainable range of motion [16][19]. This lubrication source is optimally placed between contact bodies to minimise the asperities and frictional force between them [16][19]. TIn this paper, the following five joint pathological conditions are examined and investigated with the aid of AE sensing. (1) Abrasive wear involves the concept of abrasion and refers to the scratching and rubbing motion between a set of contact bodies. (2) Adhesive wear is generated under plastic contact and ultimately leads to a fracture due to the adhesion between the two surfaces. It thus represents a kind of wear that occurs when the atomic force between a set of materials under a loading condition supersedes the apparent properties of the material surface [18][21]. It is common for particles to form a by-product of the wear between two surfaces, typically called ‘wear particles’ [18][21]. (3) Burnishing wear involves the systematic plastic deformation of a surface by another due to prolonged and continuous sliding contact, during which surface smoothening creates a glare-like reflection of the burnished surface. The mechanical principle is based on the induced localised contact stress exceeding the overall yield strength of the material. A series of images illustrating this concept for a candidate tibial polyethylene material can be seen in Figure 5.

Figure 5. Tibial polyethylene with successive higher resolutions. In (a), the highlighted rectangle is zoomed in and can be seen in (b), showing a series of horizontal wear marks at the bottom, while (c) is a scanning electron microscopic image that further shows the machining marks on the surface of the material.

Figure 6. (a) Image of a polyethylene material with a red rectangle, which is zoomed into for (b) with a further magnification of the scratched area, while (c) represents a scanning electron microscopic image in high resolution, further providing a visual illustration of the concept.