Introduction

German high-tech strategic initiative plans for 2020 for the digital revolution in production, as published in 2011, gave birth to Industry 4.0—the fourth industrial revolution. Society’s transition from the first to the fourth industrial revolution (IR4.0) was characterized by production with an inclination toward digitization and the adoption of “smart production” (Lasi et al. 2014; Lee and Lee 2015; Schmidt et al. 2014; Bahrin 2016). Hermann et al. (2016) identified the critical components of IR4.0 as cyber-physical systems (CPS), Internet of things (IoT), Internet of services (IoS), artificial intelligence (AI), big data, and smart production, which are useful for the optimal modus operandi in the construction industry. The essence of IR4.0 is to ascertain intelligent and smart operations during production in which data classification is based on fuzzy clustering/neural networks and scheduling based on a genetic algorithm to revolutionize the management decision-making process (Fengque et al. 2017).

Every industrial company is at the moment at different level of digitalization and adoption of new digital trends. Some of them are more innovating than the others depends on the complexity of company structure where smaller are more flexible to adopt new trends. Schumpeter (1942) asserted the importance of innovation on economic transformation via digitization but not the economic system practiced. Economic transformation (production) depends on labor, land, capital, and the entrepreneur, and land is a key factor of production in the construction industry. With information and communication technology (ICT), optimal sectoral outputs (including construction industry) are ensured given a reduction in the human interface of a production line, which is termed “smart production”.

The challenges that companies face in the engineering and construction (E&C) industry are relatively close to other industries experience with respect to various technology they are based on. Technological innovation is changes so quick so the speed of adoption of new trends and even discussion of their adoption is quite often even earlier than the market is ready to absorb them and to benefit from them. The revolution in the E&C industry was largely catalyzed by innovations and technology with the aid of AutoCAD, BIM, ERP, cloud solutions, analytics, drones, and hand-held tech. Essentially, the E&C industry’s revolution is its version of Industry 4.0, a move toward greater digitization while many new technologies and equipment’s like prefabrication, automation, 3D printing, virtual reality, drones, sensors and mainly robots are used to help the industry understand better the industry process almost in real time. Based on the data from process a historical data are analyzed to support decisions based on the history and predict near and a bit far future of process inside company but mainly business tasks. However, unlike other sectors such as manufacturing, E&C is challenged by the very thing that it is often celebrated for: bespoke projects and one-off designs. The industry does not produce the same tape of equipment’s for dozens of years. Architects design the new buildings to be unique using a specific materials. The future of the industry will be about finding process repetition in the industry to benefit from using of new technologies and techniques.

Increasing digitalization and availability of data coming from industry process a many new job titles rise with focus on digital transformation, such as “Innovation Director” or “Digitization Director”. These roles are shaping the future of digitalization within the industry at the “decision-making level.” Companies are starting to see the opportunities that technology brings to reduce wastage and duplication as well as to control quality, time, and budgets on projects. Companies are observing how this impacts the bottom line as well as their reputations. These factors are critical for success in such a competitive market with such narrow margins.

Consequently, the notion of Construction 4.0 includes not only the narrow concept of the “construction industry” but also the entire construction process from the conditions for the placement of the construction, through the design and investment preparation, the construction itself, and the operation and maintenance of the buildings. Many countries’ governments are supporting Industry 4.0 in the construction industry. Effort is being made to concentrate scattered investment and construction management powers, to complete the recodification of construction legislation, including the standardization of new processes, to enforce the complete electronic form of the construction process—from project preparation, budgeting, building approvals, construction management, and building management—and to the application of these principles of public construction contracts by law to ensure the necessary retraining for this process.

Therefore, the aim of this paper is to map the state of Industry 4.0 in construction not from the point of view of specific technologies but from the point of view of managerial activities, such as investment management, project preparation, and an overall approach to management-related activities.

Literature Review on Management

The Evolution of Management and Theory Underpinning

Management is the art, or science, of achieving goals through people (Olum 2004). History has witnessed how humans used managerial skills to build legacies; for example, the Chinese with their great wall, the Egyptians with their majestic pyramids, and the Romans with their sophisticated cities equipped with roads and waterways (Kwok 2018). A series of records and documents of managerial strategies and their contribution to the management field have been documented in The History of Management Thought (Jackson, 2013), from ancient civilizations to management in medieval times, the industrial revolution and the beginning of modern management. The development of managerial thought is portrayed in some early writing such as The Art of War (Tzu 1910), Arthashastra by Chanakya (third century BC) and The Prince by Machiavelli (1531). These books influenced the management industry with their development of a theory of management and the management of organizations and were reflected in Western military hierarchy and public administration systems(from the essay UK Evolution of Management Theory (2018)).

The industrial revolution brought about drastic changes in basic technology, thus determining the operating and power modes of the items designed, how people feel, the mode and scale of public perception, and the method that people use to cognize knowledge, to the extent that a new living method can be constructed (Wang et al. 2015). We have heard great stories regarding the success of revolution-era industry that created a global reorganization of production, utilization, demographic activities and international relations, with few names of industrialists having been mentioned. What we have seldom heard about is the unreadiness of most people to adopt new technologies and the increasing amount of the population that demand work but whose opportunities have been replaced by machines (Gulzar 2015). The theory of management provided a rational and scientific basis for the management of organizations to create efficient planning, organizing, influence and control of all work activities (Pindur and Rogers 1995) with a managerial educational framework to motivate employees and to improve productivity (Sarker and Khan 2013). This theory is called classical management theory, which stands on two fundamental pillars: scientific management and administrative management.

According to Khorasani and Almasifard (2017), in the late 19th century, scientific management theory was introduced by Taylor. It is based on the strong principle of dividing employees according to their skills, tasks, knowledge, performance and rewards, which improves the efficiency of production. In contrast to scientific management theory, administrative management theory as described by Fayol and Weber focuses on hierarchical and bureaucratic structured organization for effective management. In the 1930s, management theory extended its boundaries to behavioral science in order to address the concept of development goals through aspiration and motivation (Greve and Argote 2015). Drucker (2007) has identified seven more post-war managerial developments that consist of management science theory, decentralization, personnel management, manager development, managerial accounting, marketing and long-range planning. However, according to Drucker (2007), there is a need to have a ‘final’ management paradigm that focuses on results and performance as their first task. Another method is project management. This concept was created in the 1990s as a tool for managing project activities (Crawford 2006). A project consists of a temporary organization of cross-functional members that disband at the end of the project. According to PMI Congress Denver 10′08 Archives (2008), “the project-based organization is an ideal form for managing increasing product complexity, fast changing markets, cross-functional business expertise, customer-focused innovation and markets, and technological uncertainty” (Using Cross Project Learning to Improve Project Management (2010)). It is therefore clear that it is a contextual concept phenomenon of Industry 4.0.

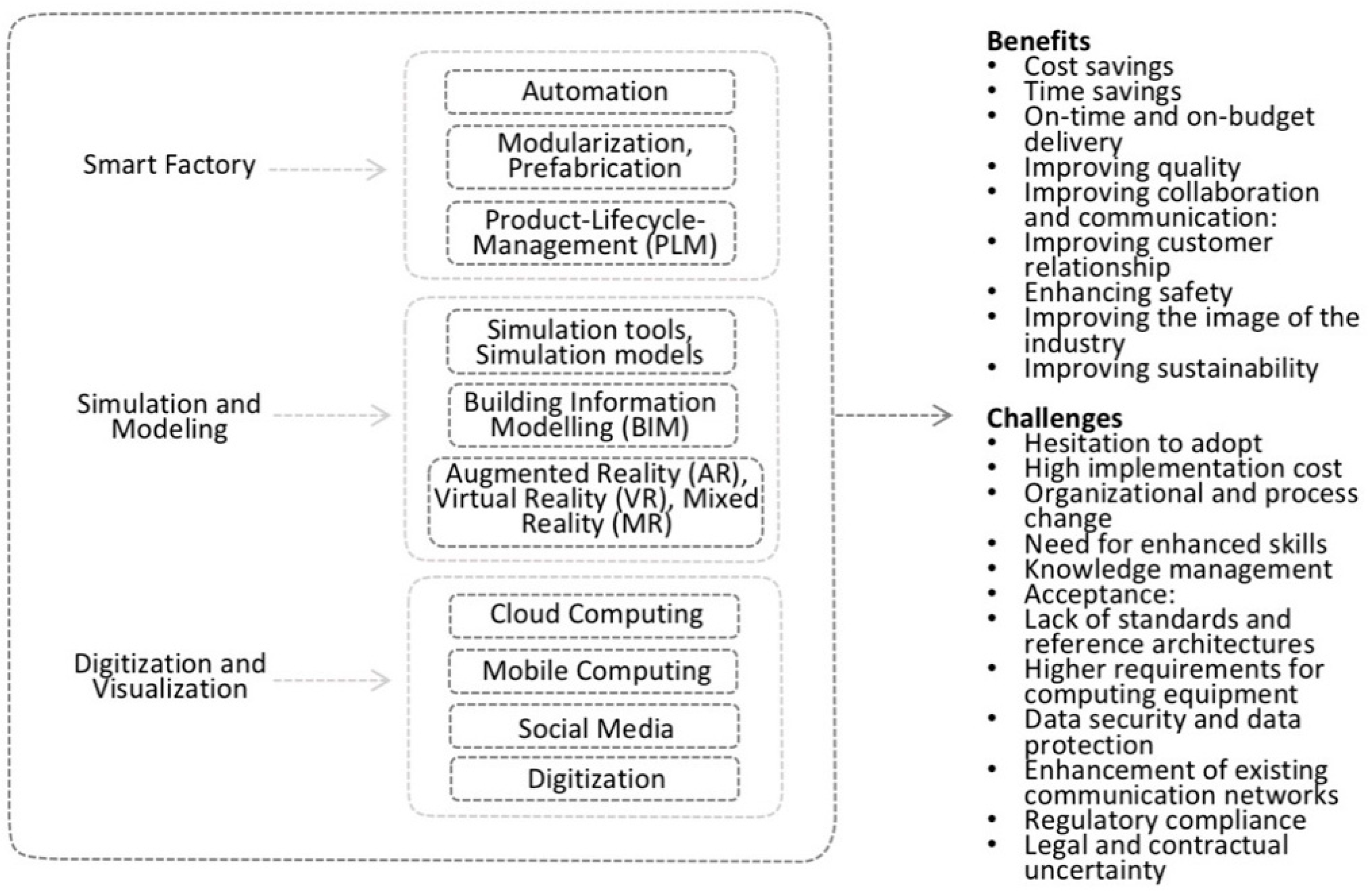

Industry 4.0 has the potential to create the need for a managerial paradigm shift as the industry experiences technological and innovation changes and is replacing all sort of manual business operation with digital computerization. Shamim et al. (2016) stated that the final managerial shift should tackle workforce training skills, the aging society, resource efficiency, clean production and mass customization, and should increase product variability, shorten life cycles, and deal with dynamic value chains, volatile markets and cost reduction pressures. Future study should consider these issues alongside the applicability of technologies. The concept of IR 4.0 for the construction industry, together with the benefits and challenges of IR 4.0 toward the construction industry, is pictured in Figure 1 (Oesterreich and Teuteberg 2016).

Figure 1. Benefits and challenges of adopting Industry 4.0 technology and concept cluster (Oesterreich and Teuteberg 2016).

Management in the Construction Industry

Construction involves many people with diverse interests, talents and backgrounds. The primary triad involves stakeholders—who are the owners—design professionals and contractors, with subcontractors, material suppliers, bankers, insurance and bonding companies, attorneys and public agency officials as the supporting team (Bennett 2014). This overall construction management team will undergo very complex project life cycle processes which are decomposed into several stages: market study, conceptual planning, design, procurement and construction, startup for occupancy, operation and maintenance and disposal (Hendrickson 2012). Activities and tasks in some stages may depend on which country and what authority controls the project. RIBA (2013), from Royal Institute of British Architecture has developed a thorough explanation of the RIBA work plan project stages, with 7 stages in total: strategic definition, preparation and brief, concept design, development design, technical design, construction, handover and close out. The construction industry is known for the heterogeneity of its construction activities (Gálvez-Martos et al. 2018), and all projects need to undergo these stages for the effective management of a project’s schedule, cost, quality, safety, scope, and function.

IR 4.0 has introduced construction digitalization, where building information modeling (BIM) has become the center of the project. BIM is presented as an ideal stage for the development of powerful and innovative applications for the engineering and construction (AEC) industry by providing additional layers of data that are able to interact in real time and collaborate throughout the design stage (Bilal et al. 2015). The innovation of BIM provides a new means of predicting, managing and monitoring the quality and quantity of material to achieve better material handling. Currently, with BIM360 API, existing construction management tools are possible to integrate with BIM to extend its capabilities in the construction ecosystem during the design stage (Autodesk BIM 360 API 2019).

The critical components of IR 4.0, cyber-physical systems (CPS), Internet of things (IoT), Internet of services (IoS), artificial intelligence (AI), big data, and smart production applications (Hermann et al. 2016), can optimize the use of BIM during the construction stage. This increases productivity by improving waste management operations. It extends the capabilities of BIM by monitoring the material handling on site, segregating the waste on site, monitoring the operation of the project and supervising the workers using the BIM model. An example could be the location of the truck and the amount of waste carried by the trucks. This will enhance the operation and data management by the local authorities and government agencies. This paper is expected able to highlight the new route of construction management in the IR 4.0 era.

Methods

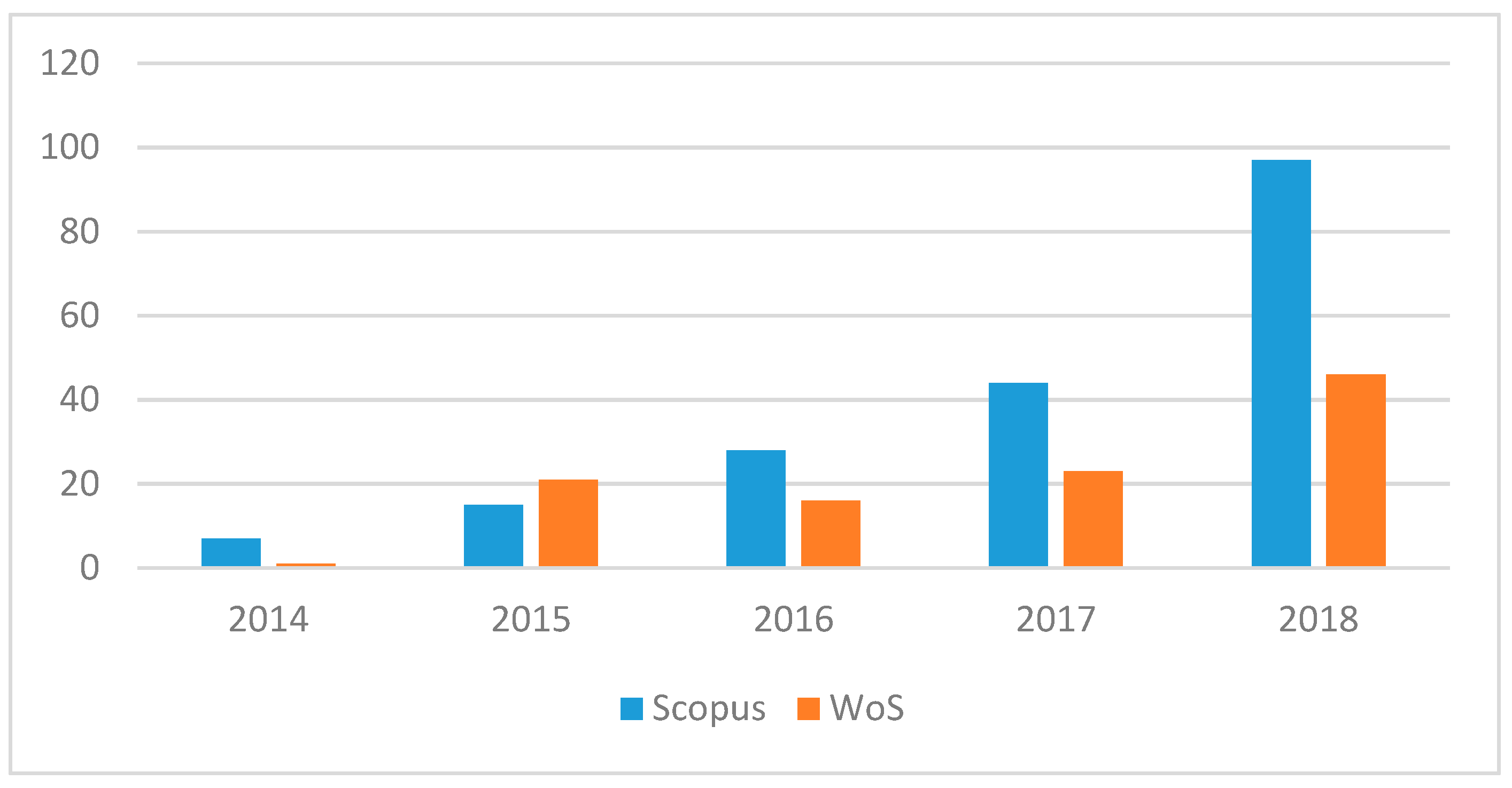

This scoping review is performed to provide an overview and summary of current studies that focus on IR 4.0. To date, although the number of publications covering these topics is limited, the data indicate rapid development, as the number of studies is growing tremendously. For example, in the Scopus database, using the Industry 4.0 search theme, the number of publications has doubled every year. In 2014, 8 papers were recorded, which increased to 36 papers in 2015, 44 papers in 2016, 67 papers in 2017, and 143 in 2018, making a total of 298 papers. However, this study focuses only on the construction industry topic, and so searching for Industry 4.0 and construction industry-related papers is required.

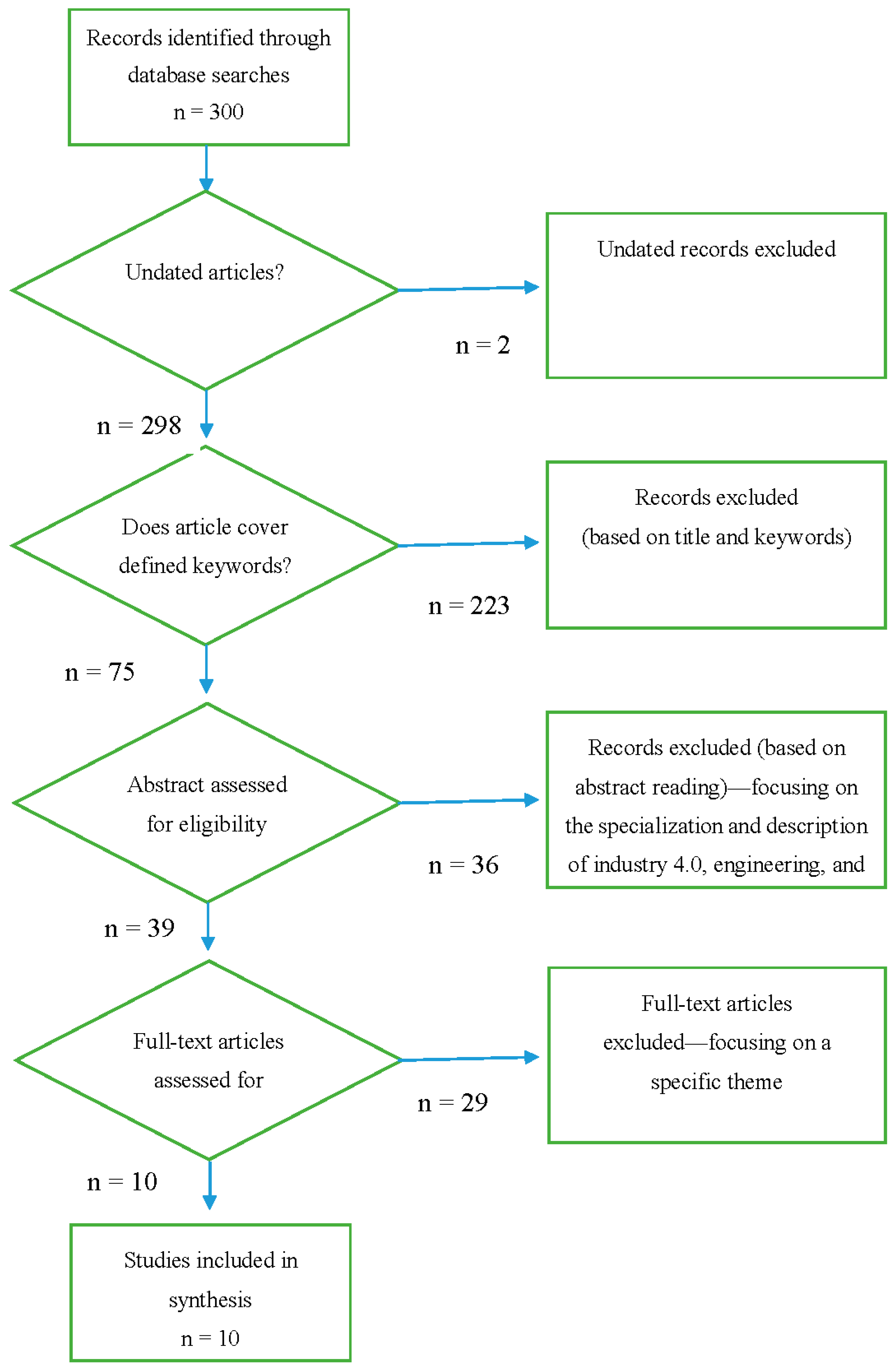

The methodological framework by Arksey and O’Malley (2005) was used for the scoping review, which involved five stages: (1) identifying research questions; (2) identifying relevant studies; (3) selection of the study; (4) charting the data; and (5) collating, summarizing, and reporting the results (Arksey and O’Malley 2005). A flow diagram referring to Preferred Reporting Items for Systematic Reviews and Meta-Analyses (PRISMA 2009) showed the flow of articles from the search to final selection. Authors identified the following research question: What are the key activities, benefits and challenges in Industry 4.0 from a managerial perspective?

Search Strategy and Eligibility Criteria

In this paper, on December 2018, the authors conducted a scoping review to clarify the working definition for IR 4.0 in the construction industry, scoping from a paper published from 2014 to 2018 in the Web of Science and Scopus. The following keywords were used for the search: “Industry 4.0 and construction.”

A total of 298 IR 4.0-related construction studies were identified on the Scopus and Web of Science. After eliminating duplicate papers focusing only on reviews and original papers, the study distributions are illustrated in Table 1.

Table 1. Numbers of papers in Scopus and Web of Science databases from Industry 4.0 plus construction query.

|

Keywords |

Search Engine |

2014 |

2015 |

2016 |

2017 |

2018 |

Grand Total |

|

Industry 4.0 and Construction (Title search) |

Scopus |

7 |

15 |

28 |

44 |

97 |

191 |

|

WoS |

1 |

21 |

16 |

23 |

46 |

107 |

|

|

Annual total |

8 |

36 |

44 |

67 |

143 |

298 |

|

Source: Authors’ computation, 2019.

Synthesis of Search Results

The stylized facts of articles related to Industry 4.0 and construction are conducted in the form of a relative analysis by comparing annual published articles from the Scopus and Web of Science (WoS) resources search engine from 2014 to 2018. The results show 298 published articles in Scopus (191) and WoS (107), of which 7 articles on “Industry 4.0 and construction” are in the Scopus search engine, with only 1 from WoS in 2014. The number of related published 2015 articles on “Industry 4.0 and construction” in Scopus increased to 15 and, likewise, the number of published articles on “Industry 4.0 and construction” in WoS increased to 21 in 2015. The search for “Industry 4.0 and construction” articles published in 2016 resulted in only 16 articles in WoS, but the number further increased in Scopus to 44 in 2016. For published articles on “Industry 4.0 and construction,” both search engines indicated increased figures in 2017 and 2018, at 44 and 97 for Scopus and 23 and 46 for WoS, respectively (Figure 2).

Figure 2. Trend of published articles on “Industry 4.0 and construction”. Source: Authors’ design, 2019.

The findings revealed that more published articles on “Industry 4.0 and construction” were found in Scopus from 2014 to 2018. Scopus contributed more than 60 percent of the publications on “Industry 4.0 and construction” in 2014, 2016, 2017, and 2018; in 2015, less than 60 percent of publications came from Scopus. In total, 298 published articles were found in Scopus and WoS on “Industry 4.0 and construction” from 2014 to 2018. This study concludes that 64 percent of the found published articles on “Industry 4.0 and construction” were in the Scopus search engine and 34 percent were found in the WoS search engine. The annual trend of published “Industry 4.0 and construction articles” depicts an increasing transformation, with the number at its lowest in 2014 and highest in 2018. This result indicates that the number of published articles on “Industry 4.0 and construction” in the Scopus and WoS search engines was 8 in 2014, which increased to 36 in 2015. This figure further increased to 44 and 67 in 2016 and 2017, respectively. In 2018, the number of found published articles on “Industry 4.0 and construction” in Scopus and WoS were double the 2017 figures, at 143. The search for “Industry 4.0 and construction” revealed 300 published articles, in which two were undated articles and were excluded in the review process because they would have been difficult to properly cite. Thus, 298 articles remained for an initial desktop review, but 223 were excluded at this stage because of the partial exclusion of the keywords for this study, leaving 75 articles. After thoroughly reading the abstract, 36 were excluded because of specialization description issues, and 39 articles remained. This study comprehensively reviewed these 39 articles and found that only 10 were most relevant to this study for a systematic review synthesis (Figure 3).

Results

The scoping review for this study relies on the synthesis of the literature gathered from the empirical studies conducted to dissect the connection between the fields of IR 4.0, construction, and engineering. In this study, 10 articles fall into these categories and were conducted primarily in developed countries in Europe, with a few from developing countries in Asia. These studies shared the common attribute of the important role that digitization plays in ascertaining efficiency in management and production (Table 2).

Figure 3. Preferred Reporting Items for Systematic Reviews and Meta-Analyses (PRISMA) flow diagram of search process.

Table 2. Characteristics of studies (journals).

|

Study/Author(s) |

Title |

Objective |

Method |

Main Finding |

Limit of the Study |

|

Maresova et al. (2018) |

“Consequences of Industry 4.0 in Business and Economics” |

To contribute to the body of knowledge on Industry 4.0 as it relates to business and economics. |

Scoping review |

A clear description of human capital development, smart technology adoption, intelligent manufacturing, and digitalization. |

Lacks methodological steps |

|

Woodhead et al. (2018) |

“Digital construction: From point solutions to IoT ecosystem” |

To identify the way Internet of Things (IoT) solutions are conceived. |

Longitudinal review of the literature |

Understanding the transformational process in the construction industry. |

Lacks uniformity |

|

Bock (2015) |

“The future of construction automation: Technological disruption and the upcoming ubiquity of robotics” |

To describe opportunities for potential construction automation. |

Scoping review and overlay of S-curves |

i. Robot systems are more developed and work independently. ii. General-purpose robots are disrupting the construction industry space. |

Lacks methodological steps and case study |

|

Oesterreich and Teuteberg (2016) |

“Understanding the implications of digitization and automation in the context of Industry 4.0: A triangulation approach and elements of a research agenda for the construction industry” |

To explore the designing and application of technologies to the construction industry. |

Triangulation methods—systematic literature review and case study research |

The state-of-the-art instances of these technologies are at different levels of maturity. |

i. Low response ii. Lacks empirical analysis |

|

Dallasega et al. (2018) |

“Industry 4.0 as an enabler of proximity for construction supply chains: A systematic literature review” |

To develop a model for Industry 4.0 and construction proximity. |

Systematic review |

Industry 4.0 mainly influences technological, organizational, geographical and cognitive proximity dimensions. |

i. Limitations of scope ii. Lacks empirical analysis |

|

Niu et al. (2016) |

“Smart Construction Objects” |

To describe smart construction objects (SCOs). |

Smart prefabricated façade model/simulation |

Industry 4.0 equipped smart properties and promoted the automation of construction production lines. |

Depends on excess simulations |

Table 3. Characteristics of studies (other publications).

|

Study/Author(s) |

Title |

Objective |

Method |

Main Finding |

Limit of the Study |

|

Alaloul et al. (2018) |

“Industry Revolution IR 4.0: Future Opportunities and Challenges in Construction Industry” |

i. To define research areas related to Industry 4.0 and the construction industry. ii. To depicts existing studies on Industry 4.0 and the construction industry. |

Systematic review |

The use of a digitization process in managerial operations is rare in the construction industry. |

Lacks empirical analysis |

|

Eroshkin et al. (2017) |

“The paradigm of the integration of different types of management information systems in investment and construction company implementing the project approach” |

To examine trends and developments in construction project management systems. |

Report |

Technologies boost optimal production lines in the construction industry. |

Scant literature review |

|

Hampson (2014) |

“R&D Investment and Impact in the Global Construction Industry” |

To bring together contributions from leading industry researchers in a diverse group of countries to investigate the role of research and development (R&D) in the construction industry. |

Case study |

Industry 4.0 maximizes the impact of R&D in the construction industry. |

Not applicable |

Source: Authors’ design, 2019.

Construction project management represents the adequate coordination of construction resources (labor, materials, financing, and machinery) to achieve the highest quality, minimum duration and minimum cost to achieve optimal project targets. Management faces concurrent interdependent decisions during construction projects, and, with the aid of IR 4.0, efficient and effective management decisions are made (Niu et al. 2016). Most synthesized studies do not directly discuss management’s perspective on IR 4.0 and the construction industry; however, this study determined the applicability of the research problem.

The synthesis for this study relied on the assessment of the residual 10 articles, among which 1 is a conference paper, 1 is a paper, 1 is a book publication, and 7 are journal papers. From a broader perspective, IR 4.0 is a comprehensive term that researchers have described from different angles, but a connection is always made at some point in the description. Liu et al. (2018) asserted that IR 4.0 in most studies is linked to IoT, cyber CPS, ICT, enterprise architecture (EA), and enterprise integration (EI). These areas of technology (automation) have spillover effects into managerial operations/decisions and efficiency in the construction industry.

The development and deployment of other technologies supporting the success of this approach to date are pushing toward IR 4.0. Several studies have provided clear evidence that the construction industry is doing more and is generating and championing the use of these digital methodologies (Table 3). At the same time, IR 4.0 introduces some implications for the construction industry. In particular, over the last three years, the use of digital techniques in design and construction has started to mature and has even become the norm for many companies. Dallasega et al. (2018) and Alaloul et al. (2018) concluded that IoT’s speedy management of real-time information sharing and coordination of communication improves flow and the supply chain of construction materials, thus enhancing the efficiency of the production line. Therefore, production costs will be at a minimum and profit margins will be improved because investments are adequately applied.

Eroshkin et al. (2017) opined that an automated control system assists the performance of long-term projects and, thereby, allows management decisions to be less taxing and cumbersome because investment monitoring and implementation are handled through an automated system. Niu et al. (2016) asserted that the global construction industry before the advent of IR 4.0 faced problems such as delayed deliveries, unsatisfactory quality, and poor budgeting techniques; however, with the adoption of information technology, the narrative has changed, leading to a satisfactory result and, thereby, ensuring management’s productivity (Maresova et al. 2018; Oesterreich and Teuteberg 2016; Alaloul et al. 2018).

In summary, all of the assertions regarding IR 4.0 and the construction industry from the management perspective are captured in the benefits from IR 4.0 to the construction industry: cost savings, time savings, on-time and on-budget deliveries, improved quality, improved collaboration and communication, improved customer relationships, enhanced safety, an improved image for the industry, and improved sustainability in E&C (Oesterreich and Teuteberg 2016).

Discussion

Science, technology, and innovations (STIs) are engines to drive growth, as witnessed in the fourth industrial revolution (IR 4.0). IR 4.0 is viewed as an impetus to technological improvements in an organization and increases the remote coordination of human, material, and financial resources in the construction industry. Given these IR 4.0 qualities, operations with geographical and cognitive proximity dimensions are efficiently managed (Dallasega et al. 2018).

These mechanisms transform most developed countries from traditional societies towards high-mass consumption driven by mass production, as aided by “smart production” (Rostow 1960). One of the traditional factors of production is land, which is directly associated with the E&C industry and is not excluded from the benefits that IR 4.0 brings to the economy. The key relevance of IR 4.0 for construction is categorized by 3D value chain models: smart factory, simulation and modeling, and digitization and visualization. The smart factory value chain consists of automation, modularization (prefabrication), and product-lifecycles (PLM). The simulation and modeling value chains involve simulation tools, building information modeling (BIM), augmented reality (AR), virtual reality (VR), and mixed reality (MR). Lastly, digitization and visualization entail cloud computing, mobile computing, and social media, and these are utilized for the effective management of construction tasks (Maresova et al. 2018; Oesterreich and Teuteberg 2016; Alaloul et al. 2018). These dimensional value chains are key to successful managerial operations in the construction industry that will facilitate organization growth. In specific terms, the benefits and challenges of IR 4.0 for the construction industry are highlighted in Figure 1 and we have rephrased them as follows.

The benefits are as follows:

- Cost/time savings: on-time/on-budget delivery;

- Quality control: improving quality;

- Effective communication and collaboration;

- Building customer relationships;

- Efficient safety measures;

- Industry branding and image-boosting;

- Sustainability assurance: blue/green economy.

The challenges are as follows:

- Poor speed of technology adoption;

- High cost of implementation;

- Technology comes with operational change: organizational and process changes;

- Enhanced skills required;

- Battle for acceptance by personnel;

- Exposure to data theft;

- Risk of legal and contractual modification.

The aforementioned factors indicate that the merits of IR 4.0 to construction clearly outweigh the demerits, from continual gains to decision making and managerial efficiency that are obtained as a result of “smart production” (Liu et al. 2018). The complexity of construction will further enhance massive investments in R&D that will further transform the industry to the next level of revolution.

Within the above findings, the authors are aware of the possible limits caused by our research method. Some of the activities, benefits, and challenges in the management view of Industry 4.0 may have been neglected due to the search method. Attention was focused on keywords from management tied directly to construction and Industry 4.0. However, there may be benefits found in management areas that are widely used in the construction industry, such as in project management. On the other hand, the results of the study also point out that this sector is not yet sufficiently researched in the context of current management trends. The benefit of this study is a summary of the current state of knowledge and the challenges in management of construction industry.

- Conclusions

This study found that the majority of the articles used for synthesis employed systematic and scoping review techniques to display the importance of IR 4.0 to the construction industry. The technique used assisted these articles in showing the opportunities that innovations, R&D, and cloud computing afford to management decision making, investment management, project preparation, and project assessment in the construction industry.

Despite the enormous efficiency impetus that technologies, innovations, and IoT give in terms of the smartness of the managerial functions in the construction industry, their adoption is still in its infancy; particularly in low-income countries, in which per capita income is minimal and unevenly distributed among members of society. Thus, traditional (manual) production lines and management operations are still largely employed given the high cost of technology adoption in low-income countries, but these are relatively well adopted in high-income countries. In most underdeveloped countries, construction activities were engaged more with manual labor given the availability of cheap labor and the high unemployment rate.

Therefore, stakeholders in the construction industry are advised to engage more in terms of investment in STIs with innovators to enhance cheap technologies that will promote the adoption of inclusive “smart production and management” in the construction industry.

For the best performance of managers, the adoption of technologies is key to the optimal operation of the construction industry. Adequate skills for utilizing the technologies are required, thus necessitating technological transfers in the form of labor development, skills transfer, training, and retraining to fully explore the capacity of new technologies for improved management performance.

Industry 4.0 is a brand-new philosophy bringing social change and affecting areas from security, education, science, the labor market to the social system. In the construction industry, the managerial perspective is addressed from several aspects, such as management decision making, investment management, and project assessment. However, management optimization models at the company level remain a challenge for future research. Modern enterprise solves not only the question of self-production but also an attendance system and energy. The interoperability of the individual parts of the process should be addressed at the optimization plan level. Service can also be remotely addressed. The construction market in developed countries suffers from a lack of labor force. This problem may be solved by an up-to-date method “age management”. This managerial approach searches for potential workers among older people. Another point for follow-up research could be open communication and a knowledge of cultures. At the 2015 “The Fourth Industrial Revolution” meeting (World Economic Forum Annual Meeting 2015), it was said that, thanks to modern technology, communication at a global level and in the digital environment is commonplace, and openness and respect for other cultures needing to communicate with each other has become one of the preparations for technological progress.

References

(Alaloul et al. 2018) Alaloul, Wesam S., Mohd Shahir Liew, Noor Amila Wan Abdullah Zawawi, and Bashar S. Mohammed. 2018. Industry Revolution IR 4.0: Future Opportunities and Challenges in Construction Industry. MATEC Web of Conferences 203: 02010.

(Arksey and O’Malley 2005) Arksey, Hilary, and Lisa O'Malley. 2005. Scoping studies: Towards a methodological framework. International Journal of Social Research Methodology 8: 19–32.

(Autodesk BIM 360 API 2019) Autodesk BIM 360 API. 2019. Available online: https://forge.autodesk.com/en/docs/bim360/v1/overview/introduction/ (accessed on 1 May 2019).

(Bahrin 2016) Bahrin, Mohd Aiman Kamarul, Mohd Fauzi Othman, NH Nor Azli, and Muhamad Farihin Talib. 2016. Industry 4.0: A review on industrial automation and robotic. Jurnal Teknologi 78: 137–43.

(Bennett 2014) Bennett, F. Lawrence. 2014. The Management of Construction: A Project Lifecycle Approach. London: Routledge.

(Bilal et al. 2015) Bilal, Muhammad, Lukumon O. Oyedele, Junaid Qadir, Kamran Munir, Olugbenga O. Akinade, Saheed O. Ajayi, Hafiz A. Alaka, and Hakeem A. Owolabi. 2015. Analysis of critical features and evaluation of BIM software: Towards a plug-in for construction waste minimization using big data. International Journal of Sustainable Building Technology and Urban Development 6: 211–28.

(Bock 2015) Bock, Thomas. 2015. The future of construction automation: Technological disruption and the upcoming ubiquity of robotics. Automation in Construction 59: 113–21.

(Crawford 2006) Crawford, J. Kent. 2006. The Project Management Maturity Model. Information Systems Management 23: 50–58.

(Dallasega et al. 2018) Dallasega, Patrick, Erwin Rauch, and Christian Linder. 2018. Industry 4.0 as an enabler of proximity for construction supply chains: A systematic literature review. Computers in Industry 99: 205–25.

(Drucker 2007) Drucker, Peter F. 2007. Management Challenges for the 21st Century. London and New York: Routledge. ISBN 9780750685092.

(Eroshkin et al. 2017) Eroshkin, S. Yu., N. D. Koryagin, D. V. Kovkov, D. V. Panov, and A. I. Sukhorukov. 2017. The Paradigm of the Integration of Different Types of Management Information Systems in Investment and Construction Company Implementing the Project Approach. Procedia Computer Science 103: 605–8.

(Essay UK Evolution of Management Theory 2018) Essay UK Evolution of Management Theory. 2018. Available online: https://www.ukessays.com/essays/management/management-theory-and-evolution-management-essay.php#citethis (accessed on 30 April 2019).

(Fengque et al. 2017) Fengque, Pei, Tong Yifei, He Fei, and Li Dongbo. 2017. Research on Design of the Smart Factory for Forging Enterprise in the Industry 4.0 Environment. Mechanics 23: 146–52.

(Gálvez-Martos et al. 2018) Gálvez-Martos, José-Luis, David Styles, Harald Schoenberger, and Barbara Zeschmar-Lahl. 2018. Construction and demolition waste best management practice in Europe. Resources, Conservation and Recycling 136: 166–78.

(Greve and Argote 2015) Greve, Henrich R., and Linda Argote. 2015. Behavioral Theories of Organization. In International Encyclopedia of the Social & Behavioral Sciences, 2nd ed. Amsterdam: Elsevier, pp. 481–86.

(Gulzar 2015) Gulzar, Ayesha. 2015. Impact of Industrial Revolution on Management Thought. Sukkur IBA Journal of Management and Business 2: 1–6.

(Hampson 2014) Hampson, Keith. 2014. R&D Investment and Impact in the Global Construction Industry, 1st ed. London: Routledge. Available online: https://www.routledge.com/RD-Investment-and-Impact-in-the-Global-Construction-Industry-1st-Edition/Hampson-Kraatz-Sanchez/p/book/9780415859134 (accessed on 4 May 2019).

(Hendrickson 2012) Hendrickson, Chris. 2012. Project Management for Construction. Pittsburgh: Prentice Hall. ISBN 0137312660.

(Hermann et al. 2016) Hermann, Mario, Tobias Pentek, and Boris Otto. 2016. Design principles for Industrie 4.0 scenarios. Paper presented at the Annual Hawaii International Conference on System Sciences, Kohala Coast, HI, USA, January 5–8, pp. 3928–37.

(Khorasani and Almasifard 2017) Khorasani, Sasan Torabzadeh, and Maryam Almasifard. 2017. Evolution of Management Theory within 20 Century: A Systemic Overview of Paradigm Shifts in Management. International Review of Management and Marketing 7: 134–37.

(Kwok 2018) Kwok, Angus C. F. 2018. The Evolution of Management Theories: A Literature Review. Nang Yan Business Journal 3: 28–40.

(Lasi et al. 2014) Lasi, Heiner, Peter Fettke, Hans-Georg Kemper, Thomas Feld, and Michael Hoffmann. 2014. Industry 4.0. Business & Information Systems Engineering 6: 239–42.

(Lee and Lee 2015) Lee, In, and Kyoochun Lee. 2015. The Internet of Things (IoT): Applications, investments, and challenges for enterprises. Business Horizons 58: 431–40.

(Liu et al. 2018) Liu, Xiulong, Jiannong Cao, Yanni Yang, and Shan Jiang. 2018. CPS-Based Smart Warehouse for Industry 4.0: A Survey of the Underlying Technologies. Computers 7: 13.

(Machiavelli, 1532) Machiavelli Niccolo. 1532. The Prince.Rome: Antonio Blado d'Asola.

(Maresova et al. 2018) Maresova, Petra, Ivan Soukal, Libuse Svobodova, Martina Hedvicakova, Ehsan Javanmardi, Ali Selamat, and Ondrej Krejcar.. 2018. Consequences of Industry 4.0 in Business and Economics. Economies 6: 46.

(Niu et al. 2016) Niu, Yuhan, Weisheng Lu, Ke Chen, George G. Huang, and Chimay Anumba. 2016. Smart Construction Objects. Journal of Computing in Civil Engineering 30: 04015070.

(Oesterreich and Teuteberg 2016) Oesterreich, Thuy Duong, and Frank Teuteberg. 2016. Understanding the implications of digitisation and automation in the context of Industry 4.0: A triangulation approach and elements of a research agenda for the construction industry. Computers in Industry 83: 121–39.

(Olum 2004) Olum, Yasin. 2004. Modern Management Theoeries and Practices. East African Central Banking Course 1: 5–6.

(Pindur and Rogers 1995) Pindur, Wolfgang, Sandra E. Rogers. 1995. The history of management: A global perspective. Journal of Management History 1: 59–77.

(PMI Congress Denver 10′08 Archives 2008) PMI Congress Denver 10′08 Archives. 2008. Available online: http://motivate2b.com/category/keynotes/pmi-congress-denver-1008/ (accessed on 27 June 2019).

(RIBA 2013) RIBA. 2013. RIBA Plan of Work 2013: Overview. London: Royal Institute of British Architects. ISBN 978-1-85946-519-6.

(PRISMA, 2009) PRISMA. 2009. Available online: http://prisma-statement.org/PRISMAStatement/PRISMAStatement (accessed on 27 June 2019)

(Rostow, 1960) Rostow, Walt W. 1960. The stages of economic growth: A non-communist manifesto. Cambridge: Cambridge University Press.

(Sarker and Khan 2013) Sarker, Sadrul Islam, and M. R. Khan. 2013. Classical and Neoclassical Approaches of Management: An Overview. IOSR Journal of Business and Management 14: 1–5.

(Schmidt et al. 2014) Schmidt, Gavin A., Max Kelley, Larissa Nazarenko, Reto Ruedy, Gary L. Russell, Igor Aleinov, Mike Bauer, Susanne E. Bauer, Maharaj K. Bhat, Rainer Bleck, and et al. 2014. Configuration and assessment of the GISS ModelE2 contributions to the CMIP5 archive: GISS MODEL-E2 CMIP5 SIMULATIONS. Journal of Advances in Modeling Earth Systems 6: 141–84.

(Schumpeter 1942) Schumpeter, Joseph. 1942. Capitalism, Socialism and Democracy. Available online: https://eh.net/book_reviews/capitalism-socialism-and-democracy/ (accessed on 4 May 2019).

(Shamim et al. 2016) Shamim, Saqib, Shuang Cang, Hongnian Yu, and Yun Li. 2016. Management Approaches for Industry 4.0. Paper presented at the 2016 IEEE Congress Evolutionary Computation (CEC), Vancouver, BC, Canada, July 24–29, pp. 5309–16.

(Tzu 1910) Tzu, S. 1910. The Art of War. London: Routledge. ISBN 1903328039.

(Using Cross Project Learning to Improve Project Management 2010) Using Cross Project Learning to Improve Project Management. 2010. Available online: https://www.pmi.org/learning/library/cross-project-learning-establish-environments-6547 (accessed on 27 June 2019).

(Wang et al. 2015) Wang, Yan, Xinzhe Li, and Xirui Li. 2015. Eco-Topia: Design 4.0 and the Construction of E-Image City. Paper presented at the 2015 International Conference on Arts, Design and Contemporary Education, Moscow, Russia, April 22–24, vol. 23, pp. 414–17.

(Jackson, 2013) William J. Jackson. 2013. A history of management thought. Accounting History Review 23: 325–328.

(Woodhead et al. 2018) Woodhead, Roy, Paul Stephenson, and Denise Morrey. 2018. Digital construction: From point solutions to IoT ecosystem. Automation in Construction 93: 35–46.

(World Economic Forum Annual Meeting 2015) World Economic Forum Annual Meeting. 2015. Available online: https://www.weforum.org/events/world-economic-forum-annual-meeting-2015/ (accessed on 27 June 2019).

|

© 2019 by the authors. Submitted for possible open access publication under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/). |

Encyclopedia

Encyclopedia