1000/1000

Hot

Most Recent

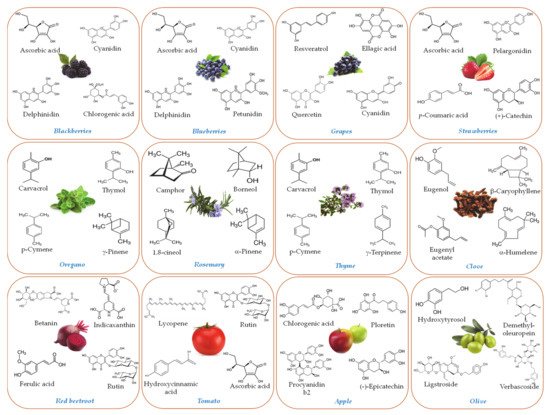

Many consumers are switching to a plant-based diet because of their concerns about animal-derived foods on the environment, human health, and animal welfare. There has therefore been great interest in identifying, isolating, and characterizing functional ingredients from botanical sources, especially waste streams from food and agricultural production.

A diverse range of encapsulation technologies have been developed to encapsulate bioactive agents, which vary in the ingredients and processing methods used to assemble them. In this section, we review a number of the most important ones that can be used to encapsulate botanical bioactive substances[1].

In general, micelles and microemulsions are colloidal particles comprised of surfactant molecules assembled into spheroid structures with the non-polar tails facing inwards (away from water) and the polar heads facing outwards (toward water). Typically, micelles are only formulated using surfactants, whereas microemulsions may also contain co-surfactants and oils. Micelles typically have diameters around 5 to 20 nm, whereas microemulsions have diameters around 20 to 100 nm. Hydrophobic bioactives are typically solubilized within the non-polar domains within the interior of these colloidal particles, i.e., between the surfactant tails or within a central lipid core. Amphiphilic bioactives may also be solubilized between the surfactant tails. Micelles and microemulsions are thermodynamically stable because they have a lower free energy than the separated components (oil, water, and surfactant). It should be noted, however, that they are only thermodynamically stable over a certain compositional and environmental (pH, ionic strength, and temperature) range, and tend to breakdown if they move out of this range. In principle, micelles and microemulsions should form spontaneously when the different components are brought into contact because of the negative free energy associated with their assembly. In practice, it is often necessary to apply some form of external energy (such as mixing or shearing) to overcome activation energies associated with self-assembly of the surfactants in water.

Traditionally, micelles and microemulsions are formed from small molecule synthetic surfactants, such as Tweens and Spans. Nevertheless, they may also be formed from some plant-derived surfactants, such as the saponins derived from quillaja or tea trees. These surfactants have a hydrophilic part and a hydrophobic part, which allows them to self-assemble into micelles or microemulsions in aqueous solutions.

In general, liposomal systems consist of colloidal particles that are made up of one or more concentric phospholipid bilayers. Nanoliposomes (d < 100 nm) can be distinguished from liposomes (d > 100 nm) due to their smaller diameters. Nevertheless, both types of system are only metastable, i.e.,they tend to breakdown over time because the separated state has a lower free energy than the liposomal system. Even so, the formation of the phospholipid bilayers does occur spontaneously because of the hydrophobic effect. Liposomal systems can be used to encapsulate amphiphilic, hydrophilic, or lipophilic bioactive substances because they have regions with different polarities. Hydrophilic bioactives can be incorporated into the aqueous interior of liposomal systems or between the polar head groups of the phospholipids, whereas lipophilic and amphiphilic bioactives can be incorporated within the hydrophobic domains formed by the phospholipid tails. Liposomal systems can be further characterized by their tendency to form single (unilamellar) or multiple (multilamellar) phospholipid bilayers. The formation of these different structures is governed by the ingredient formulation and processing methods utilized in their assembly

Liposomal systems can be formulated entirely from plant-derived ingredients, such as soybean or sunflower lecithin, which means that they are suitable for application in plant-based foods and other functional materials. This kind of colloidal dispersion can be fabricated using a variety of approaches, which vary in their efficacy and suitable for large scale production. Some of the most commonly employed methods for producing liposomal systems are solvent evaporation/rehydration, solvent injection, and microfluidization methods. The main disadvantages of liposomal systems are that it is often challenging to incorporate high amounts of bioactive components, the encapsulation efficiency is relatively low, and they have a tendency to breakdown over time, particularly when exposed to extreme conditions, such as high salt concentrations, acidic conditions, and elevated temperatures.

Nanoemulsions and emulsions both consist of small droplets of one fluid (the “dispersed phase”) distributed throughout another immiscible fluid (the “continuous phase”). In the food industry, these two fluids are usually oil and water. An oil-in-water (O/W) system is formed when the oil phase forms the droplets, whereas a water-in-oil (W/O) system is formed when the water phases forms the droplets. Typically, the droplets are coated by a layer of emulsifier molecules to prevent them from aggregating with each other. The free energy of nanoemulsions and emulsions is higher than that of the separated phases, and so they are thermodynamically unfavorable. These systems must therefore be designed to ensure that they are metastable, i.e., have a sufficiently long shelf life for the intended application. This usually involves controlling the droplet composition, concentration, and size, as well as by using suitable additives such as emulsifiers, thickeners, gelling agents, weighting agents, and ripening inhibitors. Conventionally, the mean diameter of the droplets in nanoemulsions is below 100 nm, whereas it is above this value for emulsions. The smaller dimensions of the droplets within nanoemulsions has some important consequences for their functional attributes, typically leading to greater optical transparency, improved resistance to aggregation and gravitational separation, and a higher bioavailability of any substances encapsulated within them.

Nanoemulsions and emulsions can be created using a broad spectrum of methods, which can be classified as high-energy or low-energy approaches. High-energy methods employ specially designed mechanical devices, such as high-shear mixers, colloid mills, microfluidizers, sonicators, or high pressure valve homogenizers, to generate intense disruptive forces that break up the oil and water phases. In contrast, low-energy methods rely on the spontaneous formation of small droplets when certain oil, water, and surfactant mixtures are treated in a specific manner, e.g., their composition or temperature is changed. These latter methods include phase inversion temperature, spontaneous emulsification, and emulsion inversion point methods.

Solid lipid nanoparticles (SLNs) and nanostructured lipid carriers (NLCs) have structures that are fairly similar to those found in O/W nanoemulsions, but the oil droplets are fully or partially crystallized, respectively. Indeed, these systems are often formed by creating an O/W nanoemulsion at a temperature above the melting point of the oil phase and then cooling it to crystallize the droplets. Like nanoemulsions, the lipid particles in SLNs and NLCs are stabilized by coating them with a suitable emulsifier. One of the advantages of SLNs and NLCs over nanoemulsions is that crystallizing the oil phase retards the diffusion of molecules inside the lipid particles, which can improve the retention of encapsulated substances, as well as protecting them from chemical degradation. It should be noted, however, that the oil phase must be carefully designed to achieve this. If the oil phase forms a crystalline structure that is too regular, then any encapsulated bioactive agents may be expelled because they cannot be accommodated within the crystals. In addition, the formation of a highly regular crystalline phase can cause lipid particles to undergo a transition from a spherical to an irregular shape, thereby increasing their oil-water surface area. Consequently, there may not be enough emulsifier molecules present to saturate the lipid particle surfaces, thereby promoting particle aggregation. SLNs are particularly prone to these problems because they contain fully crystalline nanoparticles. Conversely, NLCs are less prone because the lipid phase is selected to be only partially crystalline after it solidifies, thereby preventing the expulsion of encapsulated bioactive substances and inhibiting particle morphology changes.

Plant-based proteins and polysaccharides can be used to assemble biopolymer nanoparticle and micro-gels. Biopolymer nanoparticles mainly consist of tightly packed proteins and/or polysaccharide molecules, with only a little water. Conversely, biopolymer hydrogels consist of a protein and/or biopolymer network that traps large amounts of water. The biopolymer molecules in these particles are typically held together by physical or chemical bonds, including hydrogen bonding, hydrophobic attraction, electrostatic interactions, and disulfide bonds. The dimensions of these particles ranges from around 100 nm to 1000 mm depending on the ingredients and fabrication method used. There are a wide range of different fabrication methods available to produce biopolymer nanoparticles and microgels, including antisolvent precipitation, injection-gelation, phase separation-gelation, emulsion templating, and molding methods. The composition, porosity, shape, and dimensions of biopolymer nanoparticles and microgels can be manipulated to provide desirable loading, retention, and release properties.

|

Plant Extracts |

Concentration |

Meat/Meat Product |

Main Effects |

Ref. |

||

|---|---|---|---|---|---|---|

|

Antioxidant Effects |

Antimicrobial Effects |

Other Effects |

||||

|

Rosemary extract |

800–1600 ppm |

Beef meat |

Reduce primary (peroxide values) and secondary (TBARs values) lipid oxidation |

Inhibit the growth of microorganisms (total viable counts) during refrigerated storage |

Minimum changes in color parameters |

[65] |

|

Orange essential oil and cactus acid fruit extract |

0–5% |

Emulsified meat system |

Increase antioxidant activity (DPPH; ABTS) and reduce lipid oxidation during storage (TBARs) |

NR |

Increase fat content (with bioactive compounds from orange essential oil) and increase the total phenol content |

[66] |

|

Radish, hibiscus and beetroot extracts |

0.4–7.29 g/kg |

Cooked ham |

NR |

NR |

Cooked ham with hibiscus presented the best color (instrumental and visual aspect parameters). From beetroot, the unencapsulated extract showed the best results |

[67] |

|

Lupulon–xanthohumol nanoliposome |

50–200 ppm |

Cooked beef sausage |

Addition of liposome + nitrite successfully prevented lipid oxidation (TBARs) |

Inhibit the growth of microorganisms (total viable counts and molds/yeast) (nitrite + nanoliposome combination presented the best results) during refrigerated storage. Nitrate + nanoliposome effectively inhibit the growth of Clostridium perfringers and coliforms |

Liposome + nitrite successfully maintain the redness and did not produce changes in sensory properties of beef sausage (Customer acceptance) |

[68] |

|

Allium sativum essential oil |

0.10% |

Minced meat |

NR |

The essential oil microcapsules showed inhibitory effect (in essential oil concentration-dependent manner) against microorganisms growth (total aerobic mesophilic flora, sulfite-reducing anaerobes and E. coli) |

NR |

[69] |

|

Thyme essential oil |

1% |

Hamburger-like meat products |

NR |

Inhibit the growth of thermotolerant coliforms and E. coli |

NR |

[70] |

|

Prickly pear fruit extract |

5% |

Beef burger patties |

NR |

Samples treated with encapsulated prickly pear fruit extract showed lower values of mesophilic bacteria, Enterobacteriaceae and Pseudomonas spp. |

Samples treated with encapsulated prickly pear fruit extract showed the smallest variations of color (redness) and texture. Maintain the pH values during storage, in contrast to control samples in which pH values increase progressively |

[71] |

|

Olive leaves extract |

100 mg oleuropein / kg |

Meat systems (with healthy oil mixture) |

Higher oxidative stability (peroxide and TBARs values) than meat systems without extract (5 days under accelerated oxidative conditions). High antioxidant activity (FRAP and DPPH) |

NR |

Improvement of binding properties and texture |

[72] |

|

Laurus nobilis leaf extract |

1000–1500 ppm |

Minced beef |

Inhibit oxidative degradation (peroxide and TBARs values) |

Samples with extract presented the lowest values of total viable count and psychotropic count. Also inhibit the growth of Staphylococcus aureus and E. coli |

Nanoencapsulated extracts reducing spoilage processes (lipolysis and non-protein volatile nitrogen). The score of sensory properties (general acceptance) decreased with the inclusion of extract, although all treatments had sensory ratings approved by the evaluators |

[73] |

|

Quinoa peptide-loaded nanoliposomes |

3–5 mg/mL |

Burger |

Reduce primary (peroxide values) and secondary (TBARs values) lipid oxidation |

Reduce the total bacterial count and growth of S. aureus, mold, and yeast |

Reduce proteolytic activity derived from enzyme and/or microbial spoilage |

[74] |

NR: Effects not reported or studied.