1000/1000

Hot

Most Recent

Agriculture generates 11.4 billion tons of biomass worldwide, including residues from crop production and industrial processing. Improper disposal of agricultural residues results in environmental pollution and the waste of valuable biomass resources. Management of agricultural waste is particularly suboptimal in developing countries where low added-value traditional practices to manage the residues are commonplace.

Agriculture generates 11.4 billion tons of biomass every year. Agricultural biomass is made up of the resources containing non-fossil, organic carbon recently (<100 years) derived from living plants, animals, algae, microorganisms, or organic waste streams [1]. The consequence of this intense farming is the generation of large amounts of agricultural residues. Agricultural residues are derived from crop production processes but are not used as food for humans or raw materials for the industry (e.g., cotton). These include both primary residues (in the form of stalks, leaves, roots, peels, husks, cobs, shells, nuts) and secondary residues (derived from processing activities like straw, sawdust, and waste woods). Similar features characterize the agricultural residues, and basic composition generally is referred as lignocellulosic [2]. However, the chemical composition of these residues may vary depending on their sources. Accordingly, the systematic identification, quantification, and characterization of such biomass chemical composition are the initial and most important steps during the research and application of biorefinery products.

Consequently, with the increase in food production, agricultural residues are also expected to increase considerably [3]. Usually, the amount of agricultural residues exceeds food production (in terms of edible parts of the crops). More than half of all absolute dry matter in the global harvest are agricultural residues like cereal and legume straws; in tops, stalks, leaves, and shoots of tuber, oil, sugar, and vegetable crops; and in the pruning and litter of fruit and nut trees [1][4]. Large amounts of agricultural residues are widespread in large food producers of developing countries. Extensive cultivation areas characterize these countries accompanied by traditional practices to manage the residues (e.g., covering soil, composting agricultural residues, open burning in landfills, outdoor degradation). Open burning and outdoor degradation practices harbor a low added-value as they do not represent further increases in profitability or environmental benefits. Countries like Colombia produce 71 Mt tons of agricultural residues/year from eight crops compared to 14 Mt/year of edible production obtained from the same eight crops [5]. In contrast, Germany produces 40 Mt of agricultural residues annually, mainly from cereals and oilseeds [6]. Although many factors contribute to waste volume differences (geographical context and arable land), it is essential to highlight that the countries localized on the equatorial belt are more sensitive to the effects of climate change, such as crop damage due to diseases, droughts, and flooding, which in turn increases the volume of residues due to crop spoilage [7].

The enormous amounts of agricultural waste generated by crop production represent a hazard to the environment and human health when they are not properly managed [8]. Practices to reduce or eliminate agricultural residues include on-farm burning, which has become very common, particularly in developing countries [9]. Waste burning results in soil moisture loss leading to less available moisture to sow the next crop, negatively affecting germination. Burning also affects soil fauna, particularly the population of earthworms and beneficial insects [10]. Furthermore, this practice generates greenhouse gases (CO2, CO, CH4, N2O, SO2), aerosols, particulate matter, smoke, volatile organic compound, and radioactive gases; thereby, exacerbating global and regional atmosphere chemistry [10]. In addition, the smoky emissions may lead to health threats like lung infection, chronic bronchitis, and asthma [11]. Another common practice used by farmers is to leave their agricultural waste in the field. Although this practice seems harmless, the accumulated waste could contain infested plant material, leading to pest and disease dissemination favoring the harvest lost [10]. Several factors, such as the lack of highly skilled farm labor, the lack of waste management policies in some areas, and the weak implementation of waste management policies in other locations, further intensifies the environmental burden of unmanaged agricultural waste [12].

A strategy to deal with agricultural waste lies in implementing bioeconomy initiatives based on the better management of plant biomass. Bioeconomy strategies are considered a new paradigm to address the depletion of natural resources and the valorization of residues due to global demands, consumption patterns, and other environmental, social, and economic challenges. Thus, a desirable bioeconomy approach for waste management is exploring the hidden potential of biomass through the development of bio-based value chains (BBVC) [1]. Adding value to the waste makes it possible to identify potential uses and develop circular economy models to balance the demand and supply of goods/food and environmental sustainability. Some of the benefits of using BBVC to manage agricultural residues are: (1) Agro-waste is not a threat to food security because edible food sources are not used; (2) findings from previous studies suggest that the lignocellulose byproducts, including corn stover, rice, and wheat straw, and pineapple and banana leaves, can be used to extract natural cellulose fibers with properties suitable for textile, bioplastics, and other industrial applications; (3) a large diversity of goods and new materials with high economic value can be used as energy sources; (4) the addition of value for agricultural residues can contribute to the development of BBVC and job generation; (5) contribution to minimizing on-farm burning to reduce the negative impacts on environmental and human health; (6) as raw materials, agricultural residues are attractive to large-scale industries as well as small scale processing in rural areas; and finally (7) agricultural residues as input for BBVC offer a possibility to implement circular models, closing material and energy flows and transforming linear production processes into circular or closed ones, and accordingly reducing the generation of waste [1].

Colombia is a country rich in natural resources whose main primary economic activity is agriculture. As a result, large amounts of agricultural residues are produced and left unmanaged annually. A particular crop to explore from a BBVC perspective is cacao. In Colombia, cacao cultivation accounts for more than 140,000 ha and generates considerable amounts of waste. The highest volume of residues from cacao is derived from the shells known as cacao pod husk (CPH), representing 52 to 70% of the fruit’s wet weight. Thus, it is expected that CPH residues may reach roughly 2,100,000 t in 2021 in Colombia [13]. Although CPH represents a large proportion of cacao waste, minimal added-value management practices are implemented for this crop in Colombia. Some of the most common methods to manage CPH are either leaving the residue in the field without any treatment or cutting CPH into smaller pieces on the ground without any protection or treatment.

To develop a successful BBVC strategy to manage cacao residues, it is essential to have information on the characterization and potential uses of the CPH waste. This information provides insights into possible products to be developed and prioritized in a target region, thus reducing the knowledge gap about the potential uses of CPH and what could be done. Additionally, local information on the crop and how farmers currently manage their agricultural waste are requirements for the successful development of any BBVC strategy.

Cacao world production in 2018/2019 was 4834 million tons of beans, of which 77% came from Africa, the first world producer, 17% from the Americas, and 6% from Oceania [14]. Cacao production is predominantly a cash crop, where more than 90% of the world’s cacao production originates from small farms with 2 to 5 hectares [15]. Colombia occupies the fourth place in Latin America with 59,740 tons for 2018/2019 [14].

Cacao production in Colombia has comparative advantages derived from its geography and location in the tropics. Colombia’s climate and soil and cacao trees’ ability to grow under agroforestry systems (co-cultivation with other non-cacao crops) help conserve natural diversity by letting different biological systems cooperate and flourish [16][17][18][19]. Recently, the economic importance of cacao production, and its vast potential for the internal and external market, has been recognized by the Colombian government. Therefore, in 2020 the Ministry of Agriculture and Rural Development (MADR) promoted the increase of cacao cultivation areas. The cultivation extension also led to a rise in CPH, which could be translated into severe environmental problems if appropriate management is not implemented [20][21]. For example, due to the concave shape of the cacao pod, in rainy seasons, they work as a reservoir of water that facilitates the multiplication of insects, and disease propagation like Moniliophthora roreri and Phytophthora spp., which are the leading cause of economic losses from cacao activity [13][21][22].

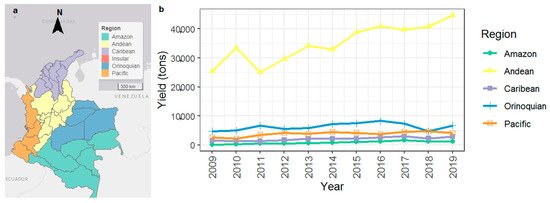

Cacao is cultivated in 30 states out of 32 from the total national territory with about 147,000 ha (Figure 1a). The highest production is concentrated in (1) Inter-Andean dry valleys including the departments of Huila, Tolima with 79,663 tons, (2) the Santander mountains, covering the districts of Santander and Norte de Santander with 26,670 tons, (3) the tropical humid forest including Arauca and Meta with 6680 tons, and (4) the low marginal coffee zone: Caldas, Quindío, Risaralda, southwest of Antioquia, with 6607 tons [23] (Figure 1b).

Figure 1. Cacao production according to (a) geographical region, (b) variation from 2009 to 2019. Source [24].

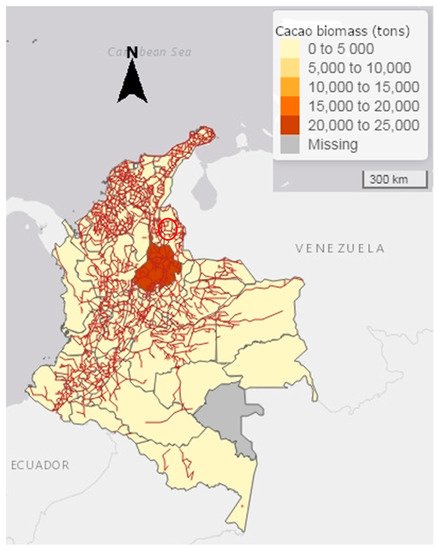

The CPH residual biomass can be roughly calculated based on the national bean production (Figure 2). Variables like bean index (dry bean weight), pod index (number of seeds per pod), and proportion of the CPH weight in relation to the total pod weight must be considered. To estimate the CPH biomass produced in Colombia for 2019, we considered the above variables weighted for 26 Colombian cacao cultivars [25]. The production for 2019 in the country was 59,740 tons which, divided by the bean index (1.2 g), generates 49,783 million seeds. This value divided by the pod index (40 seeds/pod) gives 1244 million pods. This number multiplied by the average pod weight (181.5 g wet weight) gives 225,891 tons. Finally, this value is multiplied by the proportion of CPH in the fruit (70% dry weight), giving as a result 189,748 tons in residual biomass only for the year 2019 in Colombia. This results in 3.17 tons of residues per ton of cacao bean produced. Furthermore, considering that from 2009 until 2019, there was an annual increase of about 2.06% in production for all states in Colombia, we could say that annually 3248 tons of waste are being added to the cacao chain in the country. It could represent a worrying scenario considering that waste management practices are few or non-existent in Colombia.

Figure 2. Colombia map representing cacao waste biomass (CPH) in tons based on 2019 beans production and the transport network (red lines). The red circle highlights the Caldas region.

The CPH waste value calculated above is underestimated when it is compared to other Colombian reports. Some reports indicate that each ton of dry seed generates about 10 tons of cacao pod husk (fresh weight); meanwhile, other authors report that 79 to 90% corresponds to the cacao pod’s shell [26][27][28][29]. Other authors suggest a volume of 2,100,000 tons for 2021 [13]. The authors do not report how those numbers were estimated. Furthermore, differences in the data can relay in humidity percentage, water status (wet or dry cocoa beans, weight per clone, surface and volume per pod, and maturity states). Altogether, it is clear that CPH waste represents a critical residue because of its large volume and can be used as an important input to valorize.

The increment in cacao production in Colombia is due to the increase in national demand and increased exports. The internal market, which is not entirely supplied, forces the national companies to import cacao [14]. The country’s cacao has also been recognized as fine and aroma cacao, thus increasing the exports. For example, in 2019, about 4948 tons were exported to Mexico (54% of share), followed by Malaysia with 20%, Belgium with 10%, the United States with 5%, and countries such as Argentina, Holland, and Indonesia representing 3% of exports [30]. Both the internal and external demand favor an increase in the waste biomass produced, providing an opportunity to develop a robust bio-based economy and add value to this large cacao waste volume.

It is essential to valorize the cacao waste to understand when and how the CPH biomass is formed and its basic chemical composition. CPH starts to develop at the fruiting stage. Cacao pods are open-pollinated. A cacao pod’s growth cycle can usually be divided into three sub-phases: An early accelerating/cell division phase, a linear/cell enlargement phase, and a saturation phase for ripening/maturation, where the growth patterns often follow sigmoid curves [30]. Regarding the pod length, width, surface, and volume, studies have been usually done in African, Malaysian, and Brazilian cultivars [30][31]. On average, a cacao pod has 16.2 cm in length and 7.88 cm in width. It takes about 157 days to reach maturity, but it can vary between different genotypes up to 163 days or more.

Furthermore, the time to reach the maximum pod length or width is between 71.9 and 87 days on average. The estimated pod surface areas showed a range from ±100 to 610 cm2, with a mean of approximately 330 cm2. Actual pod volumes vary from 100 to 1040 milliliters (mL), and the average is over 500 mL. The authors agree that significant differences are observed between clones [30]. All the above features make CPH a large volume of waste crop compared to the coffee husk (another considerable residue in Colombia) as CPH occupies more than double of waste per fruit [32].

CPH makes up 79% of the fruit weight, and the remaining 21% of the weight is allocated for beans in the slime and the placenta [26][27]. The ear has a rough crust almost 4 cm thick where it is filled with a thick, sweet, and edible pink pulp [33]. This cacao pod husk comprises three tissues named exocarp, mesocarp, and endocarp [34]. Table 1 presents the ranges and averages calculated for various physicochemical parameters of the CPH. In general, CPH has a low moisture percentage of about 10%. It contains a good content of fiber (43%) and sugars (45%) but a low fat content (0.48%). It also has a high polyphenol content (21%) and low alkaloids (theobromine and caffeine) with less than 0.4 mg/100 g. Regarding the lignocellulosic components, CPH contains 37, 33, 23, and 3% of hemicellulose, cellulose, lignin, and pectin. In relation with the physical parameters (pH, acidity, calorific value) it is to highlight the calorific value of CPH (331%), which is 12-fold less compared for example to coffee husk [35].

Table 1. Reports of physicochemical characterization of CPH.

| Parameter | Minimum | Maximum | Average | References |

|---|---|---|---|---|

| % Moisture | 6.67 | 16.1 | 10.19 | [28][36][37][38][39][40][41] |

| % Volatile material | 49.9 | 68.49 | 59.39 | [28][36][37][38] |

| % Ash | 6.7 | 13.5 | 10.92 | [28][36][37][38][39][40][41][42][43][44] |

| % Fixed carbon | 10.43 | 20.5 | 16.42 | [28][36][37][38] |

| Crude protein | 4.21 | 14.63 | 8.55 | [39][41][44][45][46] |

| % Fat | 0.12 | 1.5 | 0.48 | [39][40][41][44] |

| % Fiber | 3.1 | 136.6 | 43.65 | [39][40][41][45][46][47] |

| Starch mg/100 g | 2.2 | 2.2 | 2.2 | [45] |

| % Carbohydrates | 74.93 | 74.93 | 74.93 | [39][44] |

| Glucose mg/100 g | 1.16 | 1.16 | 1.16 | [46] |

| Sucrose mg/100 g | 0.18 | 0.18 | 0.18 | [46] |

| Total sugars | 45.42 | 45.42 | 45.42 | [41] |

| Total polyphenols (g/Kg sample) | 21.41 | 21.41 | 21.41 | [41] |

| Caffeine mg/100 g | 0.03 | 0.03 | 0.03 | [47] |

| Tannins mg/100 g | 0.12 | 5.20 | 0.12 | [44][47] |

| Theobromine mg/100 g | 0.2 | 0.679 | 0.41 | [36][40][44][47] |

| Hemicellulose mg/100 g | 37 | 37 | 37 | [43] |

| Cellulose mg/100 g | 26.1 | 35.4 | 33.02 | [43][45][48] |

| Lignin mg/100 g | 14.7 | 21.6 | 23.75 | [43][45][48] |

| Pectin mg/100 g | 3.71 | 3.71 | 3.71 | [46] |

| pH | 6.25 | 6.25 | 6.25 | [41] |

| Titratable acidity | 0.38 | 0.38 | 0.38 | [41] |

| % Calorific value | 331.31 | 331.31 | 331.31 | [39] |

Recent studies have shown that pods’ developmental age can influence their sensitivity to infection and the severity of the symptoms produced. As cacao pod development and disease sensitivity are closely linked, fungicide applications’ timing has also been linked to pod development [30]. Better knowledge of the fruit’s development and the chemical composition of CPH can better inform pest and disease management strategies and define potential bio-products derived from CPH to be manufactured. Adding value to the cacao waste can bring economic benefits by selling products derived from CPH or use the products in their farms, reducing the production costs, i.e., mixing the rich-nutrient biomass with chemical fertilizers. Moreover, environmental benefits can be obtained as farmers contribute to close the production process under a circular economy frame.