Green technologies can enhance nutraceutical content and/or availability, even after their incorporation into foods and beverages.

1. Introduction

More than two millennia ago, the father of modern medicine related the use of appropriate foods for therapeutic benefits (Hippocrates, 460–377 BC). In this sense, the origin of the term ‘nutraceutical’, first coined by Stephen DeFelice in 1989, comes from the combination of nutrients and pharmaceuticals, because these compounds have been shown to provide medical or health benefits, including the prevention and the treatment of disease

[1]. Nevertheless, a regulatory definition has not been reached yet. As synonyms of this terminology, EFSA has defined a ‘bioactive compound’ as a type of chemical found in small amounts in plants and certain foods (such as fruits, vegetables, nuts, oils, and whole grains) and which have actions in the body that may promote good health

[2]. In this sense, the term ‘phytochemical’ also refers to nutritive or non-nutritive, biologically active compounds present in edible natural foods, including fruit, vegetables, grains, nuts, seeds, and tea, which also prevent or delay chronic diseases in humans and animals

[3]. Nevertheless, an EFSA or USDA positive opinion regarding a bioactive compound implies the need to corroborate a clear relationship based on clinical studies in healthy consumers. Therefore, the use and development of these substances and their incorporation into foods and beverages depends on their safety, adverse effects, and toxicity studies

[4].

2. Preservation of Fruit and Vegetable Beverages Using Green Technologies

Despite the high nutritional value of fruit and vegetable beverages, their shelf life is limited due to processing steps in which the blending process breaks most of the cells and leaves them unprotected against microbial and enzymatic spoilage, which contribute to impairment of sensory, nutritional, and safety parameters

[5]. The main strategy to preserve quality and safety is refrigeration; however, even under low storage temperatures the deterioration rate is very high.

In this sense, heat treatments such as pasteurization and sterilization have been widely used to ensure safety and prevent spoilage

[6]. The main aim of these procedures is to destroy pathogenic microorganisms (

Escherichia coli,

Staphylococcus,

Listeria,

Salmonella,

Bacillus, and

Clostridium, among other species) and decrease spoilage organisms that grow during their shelf life. Moreover, these thermal treatments are used to inactivate enzymes such as pectin methylesterase, polyphenoloxidase, and peroxidase, which are responsible for detrimental effects on product quality.

However, the application of high temperatures over long periods usually affects the nutritional and sensory quality of smoothies and juices

[7]. In addition, the continuous use of thermal treatment in the Food Industry has a high economic cost and a high impact on carbon footprint. In the last few decades, alternative treatments, referred to as ‘Green Technologies’, have been developed to reduce costs and make possible more sustainable production processes. A summary of these emerging technologies, which support energy efficiency, recycling, health and safety concerns, and renewable resources, is shown in

Figure 1.

Figure 1. Green technologies to improve the healthiness of fruit and vegetable beverages. MW: microwave; US: ultrasounds; UV: ultraviolet; LED: Light Emitting Diode; HPP: High-Pressure Processing; PEF: Pulsed Electric Field; RFQ: Radiofrequency.

2.1. Microwaves

Microwave (MW) processing is a thermal treatment used for the pasteurization of liquid products that can reach high temperatures in seconds, which considerably reduces application time without altering sensory and nutritional quality

[7]. For instance, continuous MW heating, combining high power and short time (3.6 kW for 93 s) reaching 90 °C, inactivated up to 96% of peroxidase activity compared to conventional heating of untreated smoothies. Furthermore, this treatment increased the viscosity of a tomato smoothie

[8]. In this sense, Markowski et al.

[9] related this increase in viscosity as an indicator of severe heat treatment, and the highest degradation of ascorbic acid.

2.2. Ultrasounds

Ultrasound (US) is an emerging technology characterized by its high efficiency, low and economical instrumental requirements; it has been used in juices to increase their shelf life while maintaining their nutritional and physicochemical attributes

[10]. However, it decreases the viscosity of juice due to cavitation phenomena. The Ultrasound acts on cellular structures, breaking them due to extreme conditions, mainly pressure. From an industrial point of view, a less viscous liquid should behave better under this process. For instance, 147 W US treatment for 2 min affected the viscosity of a fruit smoothie and even achieved the maximum retention of anthocyanin (99%)

[11]. In addition, other authors

[12] have reported that ultrasound treatment was able to retain ascorbic acid (84–91%) content even more than using pulsed electric fields (PEF) (80–83%).

2.3. Ultraviolet

Ultraviolet (UV) light, especially UV-C (280–100 nm), has been widely reported on for its germicidal effects against a wide range of pathogenic and food spoilage microorganisms, although recent findings have shown that low doses of UV-C are also able to enhance the nutraceutical content in acerola fruits

[13]. Furthermore, UV-B (320–280 nm) and UV-A (400–320 nm) have demonstrated properties that improve the content of the bioactive compounds in broccoli sprouts

[14][15], kale sprouts

[16], bell peppers

[17], carrots

[18], and broccoli

[19], among others. UV light is an environmentally friendly technology with low costs in terms of equipment, energy and maintenance. However, due to the low penetration power and transmission of UV light, the application of this technology in beverages is limited

[20].

2.4. Light Emitting Diodes (LEDs)

A Light Emitting Diode (LED) emits different light colours depending on the energy of the photons. The technological advancements in LED technology have resulted in widespread application in horticultural production systems due to its limited thermal dissipation, low energy requirements and the possibility of finely customizing the light intensity and spectral properties

[21]. For instance, past research has shown that different regions of the visible spectrum are able to affect the biosynthesis of nutraceuticals, since fruit, plants, and vegetables have photoreceptors in these wavelengths that trigger the accumulation of glucosinolates, carotenoids, phenolic acids, and flavonoids, among others.

2.5. High Hydrostatic Pressure Treatment

High pressure processing (HPP) is based on Le Chatelier’s principle. Low molecular weight compounds such as vitamins, minerals, and volatile compounds are rarely affected by HPP due to the low compressibility of covalent bonds. In contrast, macromolecules like proteins, lipids, or starches can similarly change their native structure under heat treatments

[22]. The application of HPP in beverages ranges from 50 to 1000 MPa for several minutes and cycles, in combination with controlled temperature (<0 °C up to 100 °C). In such conditions, HPP can produce important antimicrobial effects with no consequences in the physicochemical and nutritional profile

[22][23]. Furthermore, in combination with high temperatures (60–90 °C), HPP technology (300–700 MPa) can be used for food sterilisation, although this can lead to colour losses

[23].

2.6. Pulsed Electric Fields

Pulsed electric field (PEF) treatment involves the application of direct current voltage pulses for very short periods (µs-ms), which results in an electric field the intensity of which depends on the gap between the electrodes. The microbial inactivation fundament is based on the electroporation of bacterial membranes producing pores in cellular tissues, leading to leakage of intracellular contents. As bacterial spores are resistant to PEF treatments, its application should be focused on pasteurization

[24].

2.7. Radiofrequency

Radiofrequency (RFQ) refers to electromagnetic waves in the range of 10–300 MHz, however, the range of permitted frequencies in industrial applications is 10–50 MHz

[25]. When foods with several factors affecting the electric field (food composition, salt, fat content, moisture, temperature, etc.) are exposed to an alternating electric field, dielectric heating occurs. Such heating is directly related to microbial reduction at a relatively low temperatures (60–65 °C), even able to inactivate pathogenic microorganisms such as

Listeria monocytogenes and

E. coli [26]. In this sense, the controlled application of this technology provides fast heating with the purpose of sterilization, pasteurization, thawing, and drying. However, lengthy exposure to high temperatures can produce loss of nutraceuticals, colour, and aroma, altering the quality of fruit and vegetable beverages.

2.8. Cold Plasma Treatment

Cold plasma (CP) technology provides a wide range of antimicrobial action while requiring low temperature changes and short times for application, which make it preferable for use with the thermolabile compounds responsible for the nutritional and sensory quality in fruit and vegetable beverages

[27]. Plasma is the fourth state of matter, an ionized gas composed of ions, radicals (reactive oxygen and nitrogen species, ROS and RNS, respectively), atoms, and electrons in both excited and ground states

[28]. These excited atoms and molecules emit excess energy in broad-spectrum electromagnetic radiation, including UV, when they return to a more stable state. The main parameters for plasma generation are pressure, voltage, treatment time, and type of gas

[29]. Its application in juices is based on its ability to inactivate microorganisms located on food surfaces, food packaging materials, and process equipment under atmospheric pressure conditions

[29][30].

3. Phytochemical Elicitors in Fruit and Vegetables Used in Beverages

Although the term ‘elicitor’ was originally applied to molecules able to induce the production of phytoalexins

[31], nowadays it is used for compounds that stimulate any type of plant defence. Therefore, plant elicitors could be defined as external agents (biotic or abiotic) which act as indirect sources of enrichment and fortification due to plant response by synthetization of secondary metabolites because of the stress-induced stimulation.

In this sense, the first plant elicitors were described by Keen

[32] as biotic stresses produced by pathogens. Nowadays, the exact molecules (polysaccharides, oligosaccharides, proteins, glycoproteins, or fatty acids) are independently added to produce such elicitation. However, the application of controlled postharvest abiotic stresses was proposed in 2003 by Cisneros-Zevallos

[33] as an innovative tool to increase the biosynthesis of health-promoting compounds. In this review, we will focus on some of the abiotic stresses applied in raw plant materials used for beverages.

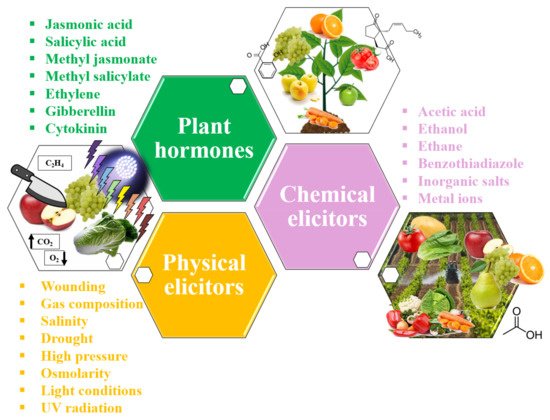

In this sense, abiotic stress can be classified according to its nature into three main groups: physical elicitors, chemical elicitors, and plant hormones (Figure 2).

Figure 2. Summary of abiotic stresses applied as plant elicitors.

Physical elicitation, such as wounding, temperature, gas composition, salinity, drought, high pressure, osmolarity, light conditions, and UV radiation, refers to controlled physical damage applied to the plant to trigger the activation of the plant’s secondary metabolism as a defence mechanism. To confirm this behaviour, many authors have studied the correlation between these abiotic stresses and the accumulation of nutraceuticals. For instance, Jacobo-Velázquez and Cisneros-Zevallos have shown a direct relation between wounding carrot tissues and the accumulation of chlorogenic acid and its derivatives, which highly increased in combination with high temperatures (>15 °C), UV-C light, and the application of plant hormones

[34][35]. Low doses of UV-A, UV-B, and UV-C in combination with wounding in fresh-cut carrot was also effective

[36][37]. In addition, these authors have shown this behaviour in red prickly pears after a combination of wounding and UV-B light

[38]. Furthermore, our own findings have demonstrated that the combination of UV-B and UV-C radiation separately applied can enhance glucosinolate biosynthesis in broccoli by-products

[19] and phenolics in carrots

[18]; furthermore, the simultaneous application of UV-B and UV-C at low doses can increase sulforaphane in broccoli and radish sprouts

[39]. Moreover, hyperoxic conditions have shown to be interesting tools for improving phenolic biosynthesis in carrots

[40] and tatsoi baby leaves

[41], alone or combined with UV-C radiation.

In a similar trend, acetic acid, ethanol, ethane, benzothiadiazole, inorganic salts, and metal ions have been applied to crops as chemical elicitors of major bioactive compounds to improve the quality of plants and fruits. For instance, some heavy metal salts such as AgNO

3 and CdCl

2 are able to trigger the production of phytoalexin and alkaloids; synthetic chemicals can also produce these signals

[31].

Lastly, plant hormones such as jasmonic acid, salicylic acid, methyl jasmonate, methyl salicylate, ethylene, gibberellin, and cytokinin, among others, have also been studied as abiotic elicitors in plant cultivars. Thus, jasmonic acid, salicylic acid, and methyl jasmonate have been studied in combination with physical elicitors to increase the accumulation of glucosinolates in broccoli sprouts

[15][42].

In this sense, most of the “Green technologies” previously detailed could act as inductors of the elicitation of phytochemicals in fruit and vegetables, which can be an enriched source of functional juices and beverages. In fact, these new technologies (HPP, US, UVC, PEF, RFQ, and CP) can extend the shelf-life of such products without the need to apply high temperatures, which helps to preserve their sensory and nutritional quality with no reduction in the phytochemical content.