In recent years, advancements in micromachining techniques and nanomaterials have enabled the fabrication of highly sensitive devices for the detection of odorous species. Recent efforts done in the miniaturization of gas sensors have contributed to obtain increasingly compact and portable devices. Besides, the implementation of new nanomaterials in the active layer of these devices is helping to optimize their performance and increase their sensitivity close to humans' olfactory system. Nonetheless, a common concern of general-purpose gas sensors is their lack of selectivity towards multiple analytes. In recent years, advancements in microfabrication techniques and microfluidics have contributed to create new microanalytical tools, which represent a very good alternative to conventional analytical devices and sensor-array systems for the selective detection of odors.

- Microfabricaton, Gas Sensors

1. Introduction

In the last decades, monitoring of odors has been a relevant topic in applications such as air quality, environmental science, health care analysis, or forensic applications [1]. Moreover, humans' olfaction has long played a significant role in industries such as wine-tasting, cuisine, perfumery, or product packaging [2]. In recent years, the unconscious perception of aromas has also shown to drive customers' behavior and experience throughout many different applications [3]. Thus, the value of good smell has recently become a competitive factor for many industries to launch new products and services. In this context, new sensing devices and platforms that enable a fast, in-situ and real-time monitoring of odors are on the demand for current and future industrial applications [4]. Odorous species consist of volatile organic compounds (VOCs), which generally evaporate from solid or liquid sources at relatively low temperatures (i.e., ambient temperature). There exist hundreds of different VOCs that can originate unpleasant odors, and most of them can be detected by human's olfactory system at concentrations that range from a few ppm (i.e., parts per million) to ppt (i.e., parts per trillion) trace levels [5]. Today, multiple gas sensors are commercially available for the monitoring of VOCs, and the selection of the most optimal device basically depends on each application [6]. Even though most of gas sensors today are still far to provide sensitivities closed to biological systems, recent studies show that the level of miniaturization of these devices can play a significant role to increase their sensitivity and overall performance [7][8]. In recent years, advancements in micromachining techniques have enabled the introduction of microelectric and mechanical systems (MEMS) for gas sensing applications as well [9][10]. Miniaturized gas sensors not only contribute to have more compact, portable, and low-cost devices but also enable the in-situ and real-time monitoring of compounds, which is a key advantage for odor monitoring applications [11]. Moreover, reported cases show that sensors incorporating micro- or nanomaterials in their structure (i.e., 0-D, 1-D, or 2-D composites) achieve significant improvements in their sensing performance as well. These structures own a high surface-to-volume ratio, which enable a better interaction with odorous species and target VOCs, in order to obtain higher sensitivities [12][13][14].

Nonetheless, a major concern of general-purpose gas sensors is their lack of selectivity towards odors and compounds of different nature [15]. Several strategies exist to improve the selectivity of single-based gas sensors, such as specially functionalized surfaces, doping of nanomaterials, temperature cycling, or the use of multicomposite materials [16]. However, these strategies tend to foster devices tailored to a very specific application, which compromise their modularity and flexibility of implementation. In order to tackle these problems, two well-known strategies exist to enhance the selectivity of gas sensors: (i) the use of cross-reactive sensor arrays with pattern recognition intelligence (e-noses) [17][18][19] or (ii) the use of chemical analytical devices, which force the separation of each individual compound in a mixture, employing long chromatographic columns or strong magnetic fields [20][21][22]. First of all, electronic noses have been on the spotlight of research for many years, due to their similarities to humans' olfactory system and their good performance in the identification of complex odors and gas mixtures. Nonetheless, e-noses often present some limitations that hinder their wide-spread implementation, such as short lifetime, sensitivity to masking species, considerable dimensions, tedious operations, and high implementation costs, due to the nature and number of sensors employed by these systems, which can range from 2 to 40 units in some applications [23][24]. On the other hand, conventional analytical methods (i.e., gas chromatography/mass spectrometry) have been traditionally deployed in laboratory facilities, with bulky devices and trained professionals to run them. Thus, despite of the high selectivity offered by these systems, they are costly, lack portability, and provide poor flexibility. In this context, microanalytical tools represent a very good alternative to both, array-based systems and conventional analytical methods, for the correct discretization of multiple odors. These systems normally employ a single gas sensor for detection and have a very compact and portable size, which fosters the in-situ and real-time monitoring of VOCs. In the last decades, many efforts have been devoted to the miniaturization of conventional devices, such as gas-chromatography systems. Microgas chromatographs (µGC) try to incorporate all the key components employed in large-scale systems in a small and compact device, exploiting the use of new micromachining techniques. However, despite of the high performance showcased by these devices in some applications, they still present some concerns, such as complicated and tedious configurations, short lifetime, high-power consumptions, and high costs of implementation [25][26]. The price of current commercially available µGC devices range from 10 to 100 k€, which still limits their practical implementation in many applications [27]. For this reason, recent advancements in microfluidics have enabled to obtain new analytical tools for the discretization of individual VOCs in a mixture. These systems integrate a general-purpose gas sensor coupled with a functionalized microfluidic channel, in order to force the separation of analytes prior to detection [28][29][30]. Compared to other analytical tools, microfluidic-based devices avoid the use of long separation columns and complex electronics in their structure, offer a much simpler configuration, and can operate at room temperatures [31]. Hence, these new microanalytical devices have emerged as a very promising solution for the creation of practical, low-cost, and compact tools for odor discretization. This review intends to outline the potential of microfabricated gas sensors and new microanalytical tools in the creation of sensitive, selective, and easy-to-deploy platforms for the purpose of odor monitoring. In the first place, this work focuses on recent efforts done in the miniaturization of gas sensors for the detection of VOCs, as well as in the implementation of new nanomaterials to increase the sensitivity and overall performance of these devices.

2. Gas Sensors for VOCs Detection

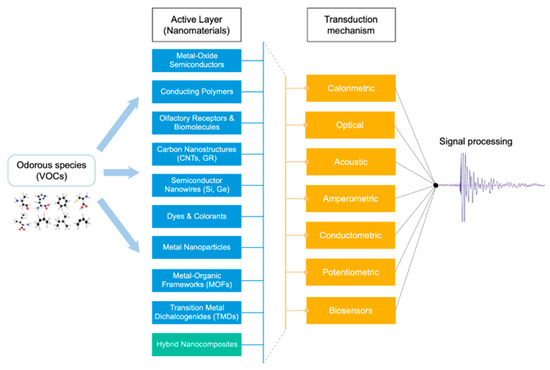

Recent advancements in microfabrication techniques and nanomaterials have enabled to obtain increasingly sensitive and compact devices for the purpose of odor monitoring. This section intends to outline the different families of microfabricated gas sensors that exist for the sensitive detection of odorous species. It is generally accepted that VOCs are the main components in odors and aromas of different nature [32][33]. Thus, for the purpose of odor monitoring, there is the need of devices that can detect different VOCs at pretty low concentrations, ranging from a few ppm (i.e., parts per million) to ppt (i.e., parts per trillion) trace levels depending on the application. In general terms, gas sensors are devices that experience a change in one or several physical properties when they are exposed to vapor analytes [34]. They normally comprise a transducer and an active layer. The active layer converts a desired chemical interaction with VOCs into a change of its intrinsic properties (e.g., optical, acoustic, electrical, etc.), volume, or mass. The transducer is then responsible to trace these changes and convert them into a measurable electric signal, which relates to the analyte's nature and concentration [34]. Hence, gas sensors can be grouped according to two basic principles of association: (i) the transducing mechanism being employed or (ii) the active layer used to interact with vapor analytes. Based on the transduction mechanism, gas sensors can fall into four general families: optical, electrochemical, gravimetric and thermal, or calorimetric devices. On the other hand, gas sensors can be classified based on the nature of the active layer they employ for sensing. Metal oxide semiconductors (MOS), polymers, carbon nanostructures, biomaterials, hybrid composites, and other nanomaterials are the six main categories of functional materials identified in the literature to interact with VOCs (see Figure 1).

Figure 1. General framework with the different families of gas sensors that exist for the monitoring of VOCs. Gas sensors can be classified according to two basic principles: (i) the functional materials used to interact with the different compounds or (ii) the transduction mechanism employed for sensing.

3. Microanalytical Tools for VOCs Discrimination

Chemical analytical methods have been widely employed in large-scale facilities for the discrimination of multiple VOCs in complex odors and gas mixtures. These strategies rely on the different structure and chemical composition of compounds, with the objective to force their individual separation and achieve their qualitative and quantitative recognition [35]. Common laboratory techniques used for this purpose are: gas chromatography (GC), mass spectrometry (MS), infrared spectroscopy (IR), or ion-mobility spectroscopy (IM). Among all these methods, GC and coupled systems (e.g., GC-MS) are probably the most implemented large-scale techniques in analytical chemistry for the discrimination of VOCs [36][37][38]. The segregation power of conventional GC-systems is determined by the interaction of VOCs between a mobile and a stationary phase. The mobile phase is generally injected in the form of a carrier gas (e.g., H, He, or N2), which is responsible to carry target analytes through a capillary column until they reach a final detector [39]. The capillary column is then coated with a stationary phase, strategically selected to foster the physical and chemical interaction with vapor compounds and force their separation [40]. Thus, the working principle of GC-systems rely on the different “retention times” that analytes spend inside the separation column, which depend on factors such as the nature of VOCs and the stationary phase or the operating temperature [41]. Even though conventional GC systems are highly precise and selective towards hundreds of different VOCs, they need to operate in big laboratory facilities, and normally require of sampling processes to collect, store, and transport gas samples directly from the source [42][43]. In addition, preconcentration activities are generally required to ensure the good performance and selectivity of these systems [44]. Apart from their lack of portability and bulky size, other disadvantages of conventional analytical systems are the high temperatures needed during operation, as well as their long operating times, which can be up to several hours [45]. In this context, many efforts have been devoted in the last decades to the miniaturization of conventional analytical devices. A wide range of portable and microgas analyzers are commercially available today for the selective detection of VOCs, such as the measurement device X-PID Series 9000/9500 from bentekk [46] or the 490 Micro-GC from Agilent [47]. Despite the portability and high selectivity provided by these devices, they are still quite difficult and expensive to deploy, which limits their applicability. Other commercial devices, such as FROG-5000 from Defiant Technologies are easier to handle and deploy, but they still come with high costs of implementation [48]. However, recent advancements in micromachining techniques and microfluidics have contributed to obtain increasingly compact, and miniaturized analytical tools, which foster the in-situ and selective monitoring of VOCs in a much cost-effective manner [49]. Moreover, these devices offer faster response and operating times, enhance the analysis of smaller volumes, and eliminate the risk of contamination, degradation, or loss of samples being analyzed.

4. Conclusions

In conclusion, this work has successfully showcased the potential of microfabricated gas sensors and new microanalytical devices, in the creation of sensitive and selective tools for odor monitoring. These tools represent a promising alternative to conventional analytical devices as well as array-based systems (e-noses) and open up a full window of opportunity for the practical and cost-effective monitoring of odors in multiple applications. In the first place, this review has presented the principal groups of microfabricated gas sensors that exist for the sensitive detection of VOCs. Based on their transduction mechanism, gas sensors can fall into four big families: optical, gravimetric, electrochemical, and calorimetric gas sensors. The principal advantages and drawbacks of each transducer have been reviewed in this work. Besides, the working principal and different typologies of these devices have been identified. In conclusion, advancements in micromachining techniques can contribute to obtain increasingly compact, light, flexible, and portable transducers for the monitoring of VOCs, which are key for the widespread implementation of gas sensors in odor-sensing applications. Second, this work has highlighted the different groups of nanomaterials that can be employed to interact with VOCs. These can fall into six main categories: metal-oxide semiconductors (MOS), polymers, carbon nanostructures, biocomposites, hybrid structures, and other nanomaterials. Advancements in micromachining techniques have enabled to come up with 0-D, 1-D, or 2-D structures, which can provide high levels of sensitivity. Owing to the high surface-to-volume ratios, nanomaterials provide a better interaction with target analytes, which results in a greater overall performance and optimum operation. In the past, these materials could not reach the performance of other high-power composites, such as conventional MOS. However, with the conformation of new micro- and nanostructures, MOS and other functional materials (i.e., polymers or carbon nanocomposites) are able to reach high sensitivities (i.e., < ppb levels), while still ensuring a low-cost operation. In addition, hybrid composites, combining two or more functional materials in their structure, have enabled to increase the sensitivity, stability, and overall performance of single nanocomposites in the detection of VOCs. Finally, bio-materials also showcase great potential in the sensitive detection of VOCs and odorous species. Despite the good performance and high sensitivity of bioelectronic devices, they require complex fabrication processes and need of very specific conditions to operate, which still hinder their scalability and easy implementation.

On the other hand, this work has reviewed recent efforts done in the conformation of microanalytical tools for the selective detection of VOCs. These tools could represent a good alternative to both, conventional analytical methods and electronic noses for the purpose of odor discrimination. In the area of microanalytical tools, microgas chromatographs (µGC) have been widely investigated in the last decades, due to their good selectivity provision and small and portable size. µGC force the diffusion of gas molecules along µ-columns, which are strategically coated and designed to foster their segregation. In order to optimize the separation efficiency of µ-columns, long channels with high aspect ratios (depth vs. width) are generally recommended. In general terms, those columns that foster a higher sample capacity and promote a better interaction between analytes and the stationary phase show greater performances. In addition, multiple-dimensions µGC systems, with two or more separation columns in parallel, have demonstrated to improve the selectivity and efficiency of single µGC significantly. Nonetheless, µGC systems need high temperatures to operate and require a carrier gas tank and complex electronics to control all the µ-fabricated elements in their structure (e.g., injectors, valves, preconcentrators, etc.). All these factors not only compromise the miniaturization and lifetime of these systems but also contribute to tedious and time-consuming configurations, difficult operations, and high-power consumptions.

For this reason, microfluidic-based devices have recently emerged as a very promising alternative to those systems, for the fast, versatile, and cost-effective discrimination of multiple VOCs in a mixture. Even though microfluidic devices are still far to provide the segregation of other analytical tool, these devices have recently proven good selectivity in samples with more than eight different analytes. Microfluidic-based devices count on an optimized microfluidic channel, which is attached to a general-purpose gas sensor for detection purposes. Compared to µGC and other analytical methods, these devices can operate at room temperature without employing a carrier gas, which results in a more compact and portable design, low-cost fabrication, and simple and easy implementation. The segregation power of these devices relies on the free-diffusion of gas molecules along the channel, which tends to be rather small. Hence, in microfluidic channels, the physisorption of gas molecules with the channel walls is normally more relevant than diffusion to foster their good separation. For this reason, microfluidic channels are generally of a few centimeters' length, straight, and designed to achieve high surface-to-volume ratios (width vs. depth). Moreover, recent studies show that the nature and properties of channel's material coating has an important effect on the performance of these devices, especially with nonpolar analytes. Hence, the optimization of channels' geometry, coating material, as well as a good control of environmental factors (i.e., temperature and relative humidity) are extremely important for the separation efficiency and performance of microfluidic-based devices. Finally, even though microfluidic devices are still far to reach the market and need of advanced technical development, the combination of these systems with new microfabricated gas sensors showcases great potential for the practical and low-cost monitoring of odors in future industry applications.

References

- Sichu, L. Overview of Odor Detection Instrumentation and the Potential for Human Odor Detection in Air Matrices; 2009; pp. 5–43. Available online: https://www.mitre.org/sites/default/files/pdf/09_4536.pdf (accessed on 7 of January 2020).

- Wilson, A.D.; Baietto, M. Applications and advances in electronic-nose technologies. Sensors 2009, 9, 5099–5148, doi:10.3390/s90705099.

- De Luca, R.; Botelho, D. The unconscious perception of smells as a driver of consumer responses: A framework integrating the emotion-cognition approach to scent marketing. AMS Rev. 2019, 1–17, doi:10.1007/s13162-019-00154-8.

- Litman, T. Autonomous Vehicle Implementation Predictions: Implications for Transport Planning; Victoria Transport Policy Institute: Victoria, BC, Canada, 2014.

- Son, M.; Lee, J.Y.; Ko, H.J.; Park, T.H. Bioelectronic Nose: An Emerging Tool for Odor Standardization. Trends Biotechnol. 2017, 35, 301–307, doi:10.1016/j.tibtech.2016.12.007.

- Szulczyński, B.; Gębicki, J. Currently Commercially Available Chemical Sensors Employed for Detection of Volatile Organic Compounds in Outdoor and Indoor Air. Environments 2017, 4, 21, doi:10.3390/environments4010021.

- Nazemi, H.; Joseph, A.; Park, J.; Emadi, A. Advanced micro-and nano-gas sensor technology: A review. Sensors 2019, 19, 1285, doi:10.3390/s19061285.

- Donarelli, M.; Ottaviano, L. 2D Materials for Gas Sensing Applications: A Review on Graphene Oxide, MoS2, WS2 and Phosphorene. Sensors 2018, 18, 3638, doi:10.3390/s18113638.

- Mohamed, E.F. Nanotechnology: Future of Environmental Air Pollution Control. Environ. Manag. Sustain. Dev. 2017, 6, 429, doi:10.5296/emsd.v6i2.12047.

- Kaushik, A.; Kumar, R.; Arya, S.K.; Nair, M.; Malhotra, B.D.; Bhansali, S. Organic-Inorganic Hybrid Nanocomposite-Based Gas Sensors for Environmental Monitoring. Chem. Rev. 2015, 115, 4571–4606, doi:10.1021/cr400659h.

- Jalal, A.H.; Alam, F.; Roychoudhury, S.; Umasankar, Y.; Pala, N.; Bhansali, S. Prospects and Challenges of Volatile Organic Compound Sensors in Human Healthcare. ACS Sens. 2018, 3, 1246–1263, doi:10.1021/acssensors.8b00400.

- Mirzaei, A.; Leonardi, S.G.; Neri, G. Detection of hazardous volatile organic compounds (VOCs) by metal oxide nanostructures-based gas sensors: A review. Ceram. Int. 2016, 42, 15119–15141, doi:10.1016/j.ceramint.2016.06.145.

- Choi, K.J.; Jang, H.W. One-dimensional oxide nanostructures as gas-sensing materials: Review and issues. Sensors 2010, 10, 4083–4099, doi:10.3390/s100404083.

- Joshi, N.; Hayasaka, T.; Liu, Y.; Liu, H.; Oliveira, O.N.; Lin, L. A review on chemiresistive room temperature gas sensors based on metal oxide nanostructures, graphene and 2D transition metal dichalcogenides. Microchim. Acta 2018, 185, doi:10.1007/s00604-018-2750-5.

- Pavelko, R.G.; Vasiliev, A.A.; Llobet, E.; Vilanova, X.; Sevastyanov, V.G.; Kuznetsov, N.T. Selectivity problem of metal oxide based sensors in the presence of water vapors. Procedia Eng. 2010, 5, 111–114, doi:10.1016/j.proeng.2010.09.060.

- Bindra, P.; Hazra, A. Selective detection of organic vapors using TiO2 nanotubes based single sensor at room temperature. Sens. Actuators B Chem. 2019, 290, 684–690, doi:10.1016/j.snb.2019.03.115.

- He, J.; Xu, L.; Wang, P.; Wang, Q. A high precise E-nose for daily indoor air quality monitoring in living environment. Integration 2017, 58, 286–294, doi:10.1016/j.vlsi.2016.12.010.

- Fitzgerald, J.E.; Bui, E.T.H.; Simon, N.M.; Fenniri, H. Artificial Nose Technology: Status and Prospects in Diagnostics. Trends Biotechnol. 2017, 35, 33–42, doi:10.1016/j.tibtech.2016.08.005.

- Schroeder, V.; Evans, E.D.; Wu, Y.C.M.; Voll, C.C.A.; McDonald, B.R.; Savagatrup, S.; Swager, T.M. Chemiresistive Sensor Array and Machine Learning Classification of Food. ACS Sens. 2019, 4, 2101–2108, doi:10.1021/acssensors.9b00825.

- Biniecka, M.; Caroli, S. Analytical methods for the quantification of volatile aromatic compounds. TrAC Trends Anal. Chem. 2011, 30, 1756–1770, doi:10.1016/j.trac.2011.06.015.

- Huikko, K.; Kostiainen, R.; Kotiaho, T. Introduction to micro-analytical systems: Bioanalytical and pharmaceutical applications. Eur. J. Pharm. Sci. 2003, 20, 149–171.

- Giungato, P.; Di Gilio, A.; Palmisani, J.; Marzocca, A.; Mazzone, A.; Brattoli, M.; Giua, R.; de Gennaro, G. Synergistic approaches for odor active compounds monitoring and identification: State of the art, integration, limits and potentialities of analytical and sensorial techniques. TrAC Trends Anal. Chem. 2018, 107, 116–129, doi:10.1016/j.trac.2018.07.019.

- Loutfi, A.; Coradeschi, S.; Mani, G.K.; Shankar, P.; Rayappan, J.B.B. Electronic noses for food quality: A review. J. Food Eng. 2015, 144, 103–111, doi:10.1016/j.jfoodeng.2014.07.019.

- Hu, W.; Wan, L.; Jian, Y.; Ren, C.; Jin, K.; Su, X.; Bai, X.; Haick, H.; Yao, M.; Wu, W. Electronic Noses: From Advanced Materials to Sensors Aided with Data Processing. Adv. Mater. Technol. 2019, 4, 1–38, doi:10.1002/admt.201800488.

- Lussac, E.; Barattin, R.; Cardinael, P.; Agasse, V. Review on Micro-Gas Analyzer Systems: Feasibility, Separations and Applications. Crit. Rev. Anal. Chem. 2016, 46, 455–468, doi:10.1080/10408347.2016.1150153.

- Zampolli, S.; Elmi, I.; Mancarella, F.; Betti, P.; Dalcanale, E.; Cardinali, G.C.; Severi, M. Real-time monitoring of sub-ppb concentrations of aromatic volatiles with a MEMS-enabled miniaturized gas-chromatograph. Sens. Actuators B Chem. 2009, 141, 322–328, doi:10.1016/j.snb.2009.06.021.

- Spinelle, L.; Gerboles, M.; Kok, G.; Persijn, S.; Sauerwald, T. Review of portable and low-cost sensors for the ambient air monitoring of benzene and other volatile organic compounds. Sensors 2017, 17, 1520, doi:10.3390/s17071520.

- Paknahad, M.; Ahmadi, A.; Rousseau, J.; Nejad, H.R.; Hoorfar, M. On-Chip Electronic Nose for Wine Tasting: A Digital Microfluidic Approach. IEEE Sens. J. 2017, 17, 4322–4329, doi:10.1109/JSEN.2017.2707525.

- Mehrabi, P.; Hui, J.; Montazeri, M.M.; Nguyen, K.T.; Logel, A.; O’Brian, A.; Hoorfar, M. Smelling through Microfluidic Olfaction Technology. 2018. Available online: https://yorkspace.library.yorku.ca/xmlui/handle/10315/35359 (accessed on 11 of March 2020).

- Paknahad, M.; Ghafarinia, V.; Hossein-Babaei, F. A microfluidic gas analyzer for selective detection of biomarker gases. In Proceedings of the 2012 IEEE Sensors Applications Symposium (SAS), Brescia, Italy, 7–9 February 2012; pp. 10–14, doi:10.1109/SAS.2012.6166309.

- Paknahad, M. Development of Highly Selective Single Sensor Microfluidic-Based Gas Detector. Ph.D. Thesis, University of British Columbia, Vancouver, BC, Canada, 2017; doi:10.14288/1.0357368.

- Schiavon, M.; Martini, L.M.; Corrà, C.; Scapinello, M.; Coller, G.; Tosi, P.; Ragazzi, M. Characterisation of volatile organic compounds (VOCs) released by the composting of different waste matrices. Environ. Pollut. 2017, 231, 845–853, doi:10.1016/j.envpol.2017.08.096.

- Jha, S.K. Characterization of human body odor and identification of aldehydes using chemical sensor. Rev. Anal. Chem. 2017, 36, doi:10.1515/revac-2016-0028.

- James, D.; Scott, S.M.; Ali, Z.; O’Hare, W.T. Chemical sensors for electronic nose systems. Microchim. Acta 2005, 149, 1–17, doi:10.1007/s00604-004-0291-6.

- Jha, S.K.; Yadava, R.D.S.; Hayashi, K.; Patel, N. Recognition and sensing of organic compounds using analytical methods, chemical sensors, and pattern recognition approaches. Chemom. Intell. Lab. Syst. 2019, 185, 18–31, doi:10.1016/j.chemolab.2018.12.008.

- Yu, H.; Xie, T.; Xie, J.; Ai, L.; Tian, H. Characterization of key aroma compounds in Chinese rice wine using gas chromatography-mass spectrometry and gas chromatography-olfactometry. Food Chem. 2019, 293, 8–14, doi:10.1016/j.foodchem.2019.03.071.

- Dong, W.; Guo, R.; Liu, M.; Shen, C.; Sun, X.; Zhao, M.; Sun, J.; Li, H.; Zheng, F.; Huang, M.; et al. Characterization of key odorants causing the roasted and mud-like aromas in strong-aroma types of base Baijiu. Food Res. Int. 2019, 125, 108546, doi:10.1016/j.foodres.2019.108546.

- Zhang, K.; Yang, J.; Qiao, Z.; Cao, X.; Luo, Q.; Zhao, J.; Wang, F.; Zhang, W. Assessment of β-glucans, phenols, flavor and volatile profiles of hulless barley wine originating from highland areas of China. Food Chem. 2019, 293, 32–40, doi:10.1016/j.foodchem.2019.04.053.

- Muñoz, R.; Sivret, E.C.; Parcsi, G.; Lebrero, R.; Wang, X.; Suffet, I.H.; Stuetz, R.M. Monitoring techniques for odour abatement assessment. Water Res. 2010, 44, 5129–5149, doi:10.1016/j.watres.2010.06.013.

- Jha, S.K.; Hayashi, K. Body odor classification by selecting optimal peaks of chemical compounds in GC–MS spectra using filtering approaches. Int. J. Mass Spectrom. 2017, 415, 92–102, doi:10.1016/j.ijms.2017.03.003.

- Karasek, F.W.; Clement, R.E. Chromatography-Mass Spectrometry Principles and Techniques; Elsevier Science B.V: Amsterdam, AE, The Netherlands, 1988; pp 5-8.

- Grabowska-Polanowska, B.; Miarka, P.; Skowron, M.; Sułowicz, J.; Wojtyna, K.; Moskal, K.; Śliwka, I. Development of sampling method and chromatographic analysis of volatile organic compounds emitted from human skin. Bioanalysis 2017, 9, 1465–1475, doi:10.4155/bio-2017-0128.

- Li, S. Recent Developments in Human Odor Detection Technologies. J. Forensic Sci. Criminol. 2014, 1, 1–12, doi:10.15744/2348-9804.1.s104.

- Papageorgiou, M.; Lambropoulou, D.; Morrison, C.; Namieśnik, J.; Płotka-Wasylka, J. Direct solid phase microextraction combined with gas chromatography—Mass spectrometry for the determination of biogenic amines in wine. Talanta 2018, 183, 276–282, doi:10.1016/j.talanta.2018.02.006.

- Wang, D.K.W.; Austin, C.C. Determination of complex mixtures of volatile organic compounds in ambient air: An overview. Anal. Bioanal. Chem. 2006, 386, 1089–1098, doi:10.1007/s00216-006-0475-5.

- Dräger Ltd. X-PID 9000/9500. 2019. Available online: https://www.draeger.com/Products/Content/x-pid-9000-9500-pi-9104798-en-master.pdf. (accessed on 14 of September 2020) Integrated, L.T.E. Multi-Gas Detection.

- Micro GC. Go Mobile with a Complete, Portable Gc. Available online: https://www.agilent.com/cs/library/brochures/5991-6041EN.pdf (accessed on 14 of September 2020).

- Defiant Technologies. FROG-5000. Available online: https://www.defiant-tech.com/frog-portable-gas-chromatograph-gc (accessed on 14 of September 2020).

- Cheung, K.; Velásquez-García, L.F.; Akinwande, A.I. Chip-scale quadrupole mass filters for portable mass spectrometry. J. Microelectromech. Syst. 2010, 19, 469–483, doi:10.1109/JMEMS.2010.2046396.

Encyclopedia

Encyclopedia