Circular economy (CE) is known as a “closed loop” economy, in which the industrial and social evolutionary concepts aim to achieve holistic sustainability goals in relation to a no waste philosophy. It aims for a regenerative system in which waste and input energy are minimized. This can be achieved through the (re)design of maintenance, repair, reuse, remanufacturing, refurbishing, and recycling. CE has attracted increasing research interest, with an almost exponential growth in publications. This reflects the increased interest from companies and policymakers in Europe, China and other regions

[1].

The managerial conceptualization of CE is considered in the works of McDonough and Braungart, Stahel, and Lovins

[2]. Under the principles of CE, products and materials approaching their end-of-life stage can be regenerated or restored or replaced.

The CE also refers to industries shifting in favor of renewable energy, causing toxic chemicals and waste elimination, while its advantages are driven by the superior design of materials, products, systems, and business models

[2]. Other CE benefits are determined by the entrepreneurial sector, where businesses can benefit through material savings, supply risk reduction, customer loyalty improvements, and new revenue streams opening

[2].

Product-service systems (PSS) are a specific type of value proposition that a business (network) offers to (or co-produces with) its clients. They are one of the most effective instruments for moving society towards a resource-efficient CE. The advantage of PSS thinking is that it moves away from existing product concepts, and focuses on the final need, demand, or function that needs to be fulfilled. Product-service systems (PSS) have been developed for more than fifteen years. However, they have still not been widely implemented, due to various reasons (for example, consumer culture;

[3][4]).

Special implementation practices for CE transforms the ways in which manufacturing industries do business. However, challenging preconditions towards a successful CE necessitate production and consumption systems, as well as the standard approach for creation, fabrication, and commerce of products. In this framework, four principles of CE, pointing towards resource depletion and materials valuation at the industrial sector, have been proposed by the Ellen MacArthur Foundation

[2]: (1) Optimization of resources and energy uses throughout life cycling, (2) Products and components maintenance and use for longer periods, (3) Systematic cycling of materials as many times as possible through cascaded uses, and (4) Pure materials use to improve the quality of post-life use. Therefore, the paradigm shift of the CE topic has gained recognition as the way forward to harmonize economic growth with environmental issues and resources scarcity

[5].

Indicatively, there are loops where companies conserve their assets during their lifecycle, being not disposed in landfills for the longest possible period. Other loops are referred to as resource adoption, reintegration into nature, or feedstock into subsequent supply chains. Such conceptualization of CE is driven by organizational changes of modeling production and consumption, while advancing developmental changes in the ways that industries profit and overall economic activities are transacted

[2].

De los Rios and Charnley

[2] signaled a challenge to reduce the dependence of new products’ resources. Other challenges reveal the influential role of designing consumer behavior against both the careless depletion of resources and the superficial changes in products

[2][6].

Based on the literature production, evolutionary definitions, and designing features of CE, Gregorio et al. (2018) analyzed publications that have been grouped at the concepts of circular economy (CE), green economy (GE), and bioeconomy (BE), all of which are linked by the common objective to promote sustainable development. These CE, GE, and BE concepts were developed in the 1970s and the 1990s. However, it was not until the beginning of 2004 that they became popular in the economic context. Specifically, regarding CE, the number of publications and their geographical dispersion have increased considerably since 2009, while in China it was reported the majority of published studies abided to the 2008 passing of a National Circular Economy Law. Following the approval of the EU Action Plan on CE in 2015, a publication increase is expected to continue in these countries

[7].

GE is considered a tool to “

improve human well-being and social equity, while significantly reducing environmental risks and ecological scarcities”

[7]. GE is designed to implement economic models and to generate profit while avoiding environmental degradation, enhancing eco-innovation, improving resources and waste management, as well as reusing of raw materials and supporting the transition towards sustainable consumption and production

[7].

BE is considered a tool which was introduced in 1971 by the economist Georgescu-Roegen, stating that “

the economy must be a branch of biology…….we are one of the biological species of this planet and as such we are subject to all the laws that govern the existence of terrestrial life”

[7]. These authors denoted that the European Commission defines BE as “an economy that covers the production and use of renewable biological resources (land and sea) and the conversion of these resources and waste into value-added products, such as food, feed, biological products, and bioenergy”

[7]. BE has been structured on the more efficient use of resources, reduced dependence on non-renewable resources, mitigation of climate change, ensuring feedstock and security, thanks to the use of renewable resources for industrial purposes, the feasible competitiveness, and employment developed among companies. At a global level, the increased trend of BE adoption and strategies in recent years is noteworthy

[7].

In the scientometric study of

[7], it was shown that the existing literature is rich in analyzing implemented policies and issues related to more sustainable modelling paths and research in China and the EU. Specifically, the general analysis upon definition related to the CE framework was accompanied by the evolution of environmental policies to mitigate climate change and develop CE. Existing practices on eco-design unveiled that there is little research in this field. Besides, eco-design directives should include more environmental aspects and focus on resource efficiency, recommending that efficiency indicators should be established. Moreover, within the EU, policy design and analysis were mainly focused on recycling and fostering its relationship with ecological design (

[7][8]).

2. Functionality of Circular Economy at the Context of Wastewater Management

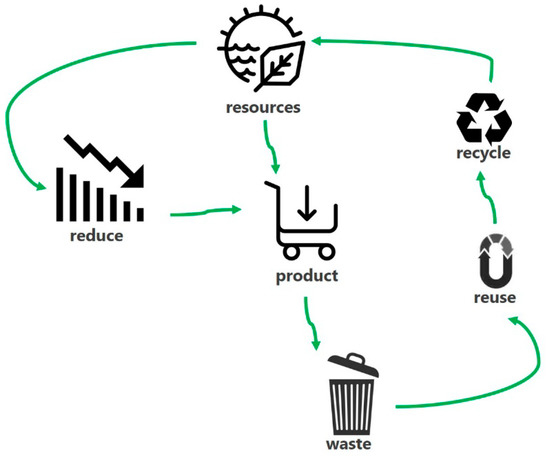

CE was conceptualized in 1990 and it was a response to the desire to substitute the prevailing traditional linear economic model with a circular one whose principal aim is to keep the value of products, materials, and resources in the economy for as long as possible. This model minimizes waste and the consumption of resources and foresees that goods generate value through their use at the end of their useful life. CE is based on four principles, the so-called 3Rs—reduce, reuse, and recycle—and a fourth principle, sustainable design strategies to achieve greater durability in the designed products, incorporated by the Ellen MacArthur Foundation

[7]. CE is an aspiration without borders. To get a real CE model from the current linear economy model, the following steps must be taken: reuse, recycling, recovery, and prevention. Reuse is the first step to start the transition to the CE, but prevention is the most important step in this new paradigm. Waste management is currently carried out in the following order: production, presentation, collection, transport, and treatment. According to Argudo-García et al.

[9], all waste should be reused, and for that, CE aims to minimize the elimination

[9].

Among the aforementioned change strategies, the principle of the 3Rs—reduce, reuse, and recycle—unveils that waste hierarchy lists different options for managing waste from an environmental perspective, from best (waste prevention) to worst (disposal). In this context, Directive 2008/98/EC established two main objectives for EU waste legislation: waste prevention and development of a “recycling society”

[9].

Waste prevention has been and continues to be the first and most important objective of EU waste management policy. Developing a recycling society implies reducing the environmental impact of resource use and improving the resource efficiency of such use. This approach not only avoids producing waste, but also uses it as a resource

[9].

Based on the processes of resource input, enterprise production, product consumption and abandonment, CE is a cycle economy of closing materials which is continuously improving the efficient use of resources, transforming traditional economic development (being reliant on the linear increase of the net consumption of resources) towards circular economic development (being reliant on ecological resource circulation), as shown in .

Figure 1. Basic mode of CE deployment. Source: adapted and modified from Wang

[10] p. 1424.

Although the strategy to improve the commitment of all actors of supply chains is still a challenging issue, yet, little is known about consumer behavior drivers that are to be engaged in closed loops within natural ecosystems

[11][12]. It is exemplary noted that while supporting the CE in urban areas and converting organic waste into organic fertilizers, there is great potential to close the biodegradable waste loop

[9].

For example, in the food sector, an interesting feature of CE is gaining maximum value from food waste while re-circulating within food supply chains

[11]. Circularity can also be perceived in various ways in lesser-utilized remanufacturing

[13]. The corresponding research may contribute in novel perspectives of sustainable energy and material flows through ecosystems and close the broken cycles, taking into account the risks associated in the inter and intra organizational interactions and the underlined risks

[14][15].

CE is composed of three levels: inter-enterprise circulation; regional circulation (mainly referring to industrial park circulation); and social circulation (mainly referring to the circulation between enterprises and society)

[16]. The generally considered evaluation methods for judging circulation at each level is shown in :

Table 1. CE conceptualization and evaluation methods. Source: adapted and modified from Wang

[10] p. 1424.

|

Evaluation Method

|

Conceptualization

|

|

Life cycle

|

Valuation of the environmental impact at each one step of the product life cycle.

|

|

Clean production; Auditing

|

Standardization of procedures; investigation and diagnosis of production process; finding of high pollution reasoning, increased consumption, low efficiency; planning and promoting strategies of cleaner production and technologies of improved production.

|

|

Material flow analysis

|

Determination of material flow, diffusion, and utilization at urban contexts, in quantitative terms.

|

3. Evaluation of Resources at the Context of Circular Economy

With the plan to make European businesses cleaner and more competitive, the EU adopted an ambitious new Circular Economy Package, in which ambitious measures were delivered to cut resource use, reduce waste, and boost sustainable production and consumption

[17]. In this respect, assessment methods can be focused on resource recovery from waste within a CE context, with a need to consider aggregated values such as environmental, economic, social and technical domains towards an integrated approach

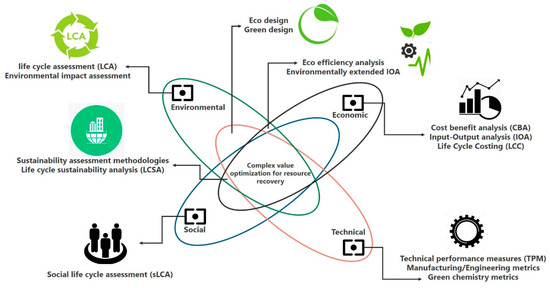

[18]. In , suitable metrics can evaluate the “complex value” of materials, components, and products by holistically summing up their environmental, economic, social, and technical benefits and impacts across the system

[19].

Figure 2. Framework of methods, tools, and domains, in appreciation of research value. Source: adapted and modified from Iacovidou

[19], p. 931.

In solid waste management, there are several types of decision-making processes; among them the most widely used are that of life-cycle assessment (LCA), cost-benefit analysis (CBA), multi-criteria decision making (MCDM)

[20], as well as the energy–water–food nexus towards a cleaner future by improving CE

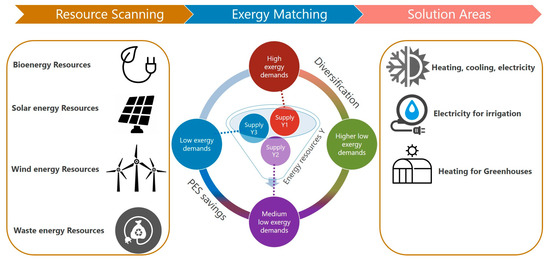

[21]. LCA is an analytical assessment of the environmental performance of products or services over their whole life cycle, including resource consumption, production, utilization, and disposal. The key technical metrics of “recyclability” are of great importance in resource recovery from waste (RRfW) systems. Based on , it is noteworthy that with solid waste management the aforementioned decision support frameworks—LCA, CBA, MCDM—are linked to each other. Specifically, LCA only considers potential environmental aspects when evaluating waste management systems and ignores other decision-making options such as the economic and social effects. CBA is a monetary valuation method, the main goal of which is to maximize economic efficiency. CBA analyzes costs and benefits, including economic aspects, natural resources, and environmental impacts due to waste minimization—which can be especially introduced in emerging countries where open dumping and open burning are the main waste treatments implemented

[9], waste recycling, and the by-products of waste treatment

[20].

Figure 3. Mind map of developing CE based on the operation of a dairy farm. Source: adapted and modified from Kilkis and Kilkis

[21] p. 1088.

Holistic methodologies are able to systematically and practically measure and assess the circularity degree of a given system and take in account all the heterogeneous resources involved in its lifecycle. Hence developmental opportunities can be paved on the framework conceived based on a set of key performance indicators (KPI) suitable to the assessment of the circularity performance. These KPIs can deal with the circularity degree of the resources within the product life cycle and can also support the quantification of those that are the economic and environmental benefits of the CE. From a company’s portfolio circular innovation perspective (both for completely new products and incremental improvement of existing products), these circular KPIs can support not only the decision making process along the design of new products but also the comparison of different versions of the same product based on their degree of circularity and the benefits they can bring. Companies would be able to compare different products based on their circularity and on benefits they can achieve

[22]. Besides the aforementioned performance indicators, environmental indicators have also been introduced in the urban areas, serving as routes of sustainable development in waste management and supporting the following features

[9]:

-

Indicators are considered as basic tools in the provision of information about the state of the environment, thus contributing to awareness among public authorities and the population in general.

-

Indicators can be used in the preparation and the evaluation of environmental policies.

Therefore, CE indicators can be defined and calculated in order to reintroduce urban solid waste from urban areas into the CE context. Thanks to these indicators, a clear framework of the environmental situation can be determined in the urban areas where it is applied—a standardized collection of generated waste data, the ease of adaptation to the management of environmental policies, as well as the performance of regular comparative analyses about waste generation

[9].

Encyclopedia

Encyclopedia