Please note this is a comparison between Version 1 by Khaled O. Sebakhy and Version 2 by Dean Liu.

Solid-state NMR is a nondestructive and noninvasive technique used to study the chemical structure and dynamics of starch-based materials and to bridge the gap between structure–function relationships and industrial applications.

- solid-state NMR spectroscopy

- starch

- food science

1. Introduction

The world population is expected to increase to 10 billion by 2050 [1], resulting in growing concerns over global food security. Food production is one of the largest industries globally [2]. Estimates by the United Nations Food and Agriculture Organization (FAO) suggest that a 50% production increase may be needed to meet future demands [1]. A key concern is whether the high demand for food may lead to instability in value-chains, and furthermore, if production targets can be met considering increased water and land scarcity. The future of sustainable food systems may include a shift towards a plant-based diet, as well as significant reductions in food waste [1]. To achieve this, the efficiency of production for existing plant-based foods may need to be improved. Thus, it is critical to understand the connection between the form, function, and properties of the our food constituents [3].

Starch is a highly abundant, biodegradable, and hydrophilic carbohydrate typically found in staple crops such as corn, potatoes, wheat, rice, and green fruits [4][5][6][7][4,5,6,7]. It is an important raw material within a wide range of industries from packaging (e.g., coatings, films adhesives) to biomedical and pharmaceuticals (e.g., tissue and drug carriers) [8]. It is used most frequently in the food industry, where it is estimated that up to 60% [3] of the starch produced is used either as a food product, or a food-based additive for preservative, thickening, texturizing, emulsion stabilization, aroma and flavor encapsulation, or quality enhancement [8][9][8,9]. Starch can be used to produce biodegradable packaging films, used to extend the shelf life of foods [10][11][10,11], or for encapsulation of food compounds which can improve food quality via protecting bioactive food ingredients from oxidation, or degradation due to UV or acidic conditions [12].

2. Study of Dynamics in Starch in the Presence of Plasticizers and Structural Modifications

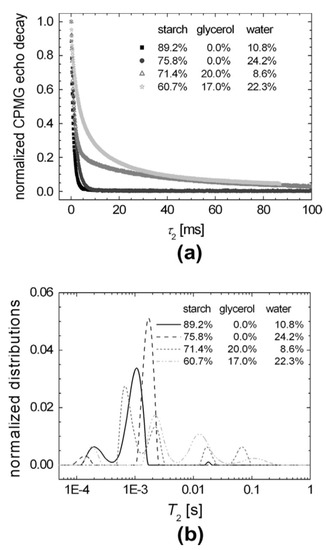

Many industrial and food applications of starch are directly related to its physical-chemical properties, such as gelatinization, crystallinity, adhesion, solubility, and viscosity. Starch plasticization, via the addition of water and glycerol in different proportions, can tune the thermoplastic properties and change the phase transition of starch. This, in turn, produces a physically modified starch in a homogeneous polymeric state [13][14][15][16][17][100,101,102,103,104]. Carr–Purcell–Meiboom–Gill (CPMG) echo decay train [18][19][105,106] is an essential component in NMR pulse sequences used for measuring the dynamic properties of starch [20][107]. Train pulses refocus the inhomogeneous broadening of the nuclear spins. This makes it possible to obtain spin–spin T2 relaxation decays that possess crucial information regarding the dynamics and composition of native and plasticized starch. The CPMG decay curves presented in Figure 16a show a slight difference for native starch (10.8% water) and starch with addition of water (24.2% water). However, upon the addition of glycerol, a significant difference was revealed. Three separated peaks appeared for native and water mixed starch, as represented in Figure 16b. In contrast, four peaks were observed in the case of glycerol addition (with and without water).

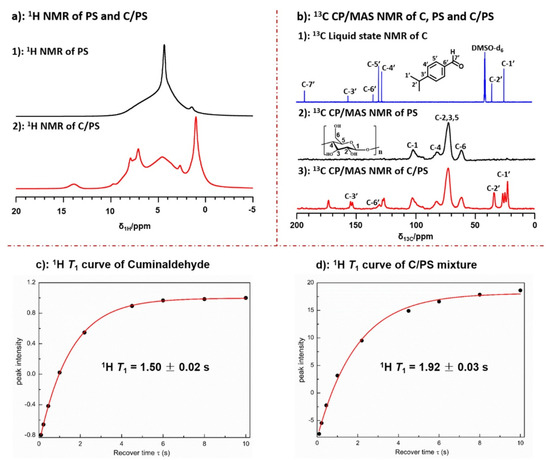

Figure 27. ssNMR techniques for measuring the structure and relaxation properties of PS (black) and C/PS (red): (a) single pulse 1H MAS NMR spectra for PS and C/PS; (b) 13C CP MAS NMR spectra for PS and C/PS compared to solution state spectrum of cuminaldehyde; and (c) 1H T1 relaxation curve for cuminaldehyde; and (d) 1H T1 relaxation curve for C/PS. Adapted with permission from Ref. [30][117]. Copyright 2022, Elsevier.

Encyclopedia

Encyclopedia