1000/1000

Hot

Most Recent

During the last years, great progress was made in material science in terms of concept, design and fabrication of new composite materials with conferred properties and desired functionalities. The scientific community paid particular interest to active soft materials, such as soft actuators, for their potential as transducers responding to various stimuli aiming to produce mechanical work. Inspired by this, materials engineers today are developing multidisciplinary approaches to produce new active matters, focusing on the kinematics allowed by the material itself more than on the possibilities offered by its design. Traditionally, more complex motions beyond pure elongation and bending are addressed by the robotics community. From basic kinematics (bending, twisting, shear, and compression/elongation) and towards the generation of complex motions (when building the actuator into the rest of the robot body), several mechanical programming strategies are described in the literature. A wide set of complex motions can be obtained, strongly related to the targeted application. We define complex motions as deformations beyond pure elongation, shear, twist or bending.

Nowadays, soft matter has gained increased interest as source material for the fabrication of robotic devices with a large range of applications. Conventionally, classic robotics systems are made of rigid connections and actuators, allowing high forces to be applied and accuracy in motion. However, the main limitations are the restricted degrees of freedom and the potential danger during the process of human–machine interaction. In this aspect, soft actuators are proposed as a suitable alternative to solve these problems, ensuring a safe and flexible actuation solution[1][2]. Their main advantage is that they are made of flexible materials and are based on deformation for actuation. Currently, a vast set of soft materials and kinematics are described, and new solutions are still evolving to overcome the challenges of the field[3]. On the other side, it is actually the generation of such numerous solutions that is presenting a difficulty, from a materials point of view, to properly select the most suitable solution for a given device functionality and application ranging from flexible medical devices to industrial grippers[4][5]. An additional complexity is the technological transfer from fundamental research to industrial application. The main question to be answered, “What is the next step?”, is often faced by material scientists once a new transducer is fully developed and optimized, where the choice of the device’s proper use remains unclear. On the other side, mechanical engineers require new materials indispensable for alternative and innovative solutions.

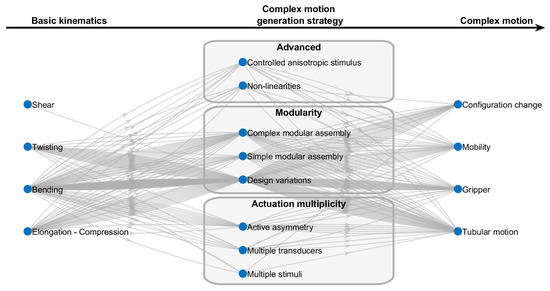

From the basic kinematics (bending, twisting, shear, and compression/elongation) and their combinations, soft robots capable of complex motions and of achieving complex tasks can be designed. Here, we define complex motions as deformations beyond pure elongation, shear, twist or bending. This deliberately broad term gathers a variety of motions enabled by the infinite number of degrees of freedom of continuous robots. Similarly, we define the complex motion generation strategy as the way used to create a complex motion from basic kinematics when building the actuator into the rest of the robot body. While the strategies to generate simple kinematics have been largely studied, the methods to generate or program complex motions remain mostly exploratory and lack of methodology. Here, we propose a classification of the strategies (Section 3.1) and of the complex motions (Section 3.2). These complex motions are strongly related to the targeted applications and will be discussed together. Figure 1 presents an overview of the different strategies to achieve complex motions based on simple kinematics. This representation aims to give an overview of the different strategies possible. It highlights that various motions can be obtained with most of the strategies. However, several strategies have been more investigated, and other less studied promising solutions could open new opportunities.

Figure 1. Roadmap towards complex motion generation: one soft robot is represented by a set of arrows. Complex motions can be generated using several strategies in parallel.

Towards many soft robotics applications, the ability of complex motion generation to achieve sophisticated tasks is a key point to unleash their potential. Various strategies have been recently proposed but are generally very exploratory and lack a real design methodology. Here, we proposed a classification based on three types of complex motions generation strategies: actuation multiplicity, modularity and advanced strategies (Table 1). As previously, these methods can be combined, and the choice of the strategy will be strongly dependent on the transducer and stimulus. It is important to notice that the generation of complex motions is not always explored, in particular when the application requires a simple kinematics or when the work focuses on the transducer capabilities. The versatility or reprogrammability of a given actuator, i.e., the eventual multiplicity of shapes and motions achieved, is an important comparison criteria here. This versatility can be embedded in the stimuli-responsiveness of the transducer itself, in the asymmetry (active asymmetry) or with other strategies developed in this section. Focusing on reconfigurable and shape changing robots,[6] [188] proposes an overview of recent advances and further challenges of the field [6].

| Classification | Description | Examples | |

|---|---|---|---|

| None | Simple kinematics only | [6,14,18,24,95,152] | |

| Actuation multiplicity | Multiple stimuli | Several stimuli per transducers | [86,176,189] |

| Multiple transducers | Several transducers per actuator | [42,44,46,49,85] | |

| Active asymmetry | Stiffness variation | [12,32,68,74,75,159,190] | |

| Modularity | Design variations | Modified actuator design to achieve a given task | [8,15,37,39,48,51,58,71,77,81] |

| Simple modular assembly | Reproduction of a given module, controlling the assembly with a single stimulus |

Hinges [41,57,80] Tubular segments [9,40,178,179] Metamaterials [59,71,81] Other [91] |

|

| Complex modular assembly | Reproduction of a given module, controlling the assembly with one stimulus per module |

Tubular segments [7,12,22,75,90] Voxels [13,17,32,94] Hinges [70] Rigid base [28,30,79] Other [92] |

|

| Advanced | Non linearities | Exploitation of a nonlinear transducer response | [9,10,16,21,41,67] |

| Controlled anisotropic stimulus | Variable or structured controlled stimulus | Light [82] Magnetic field [59,72,75,123] |

|

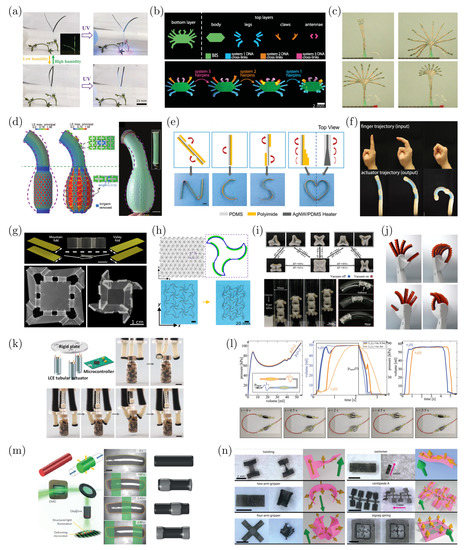

Several strategies can be classified as actuation multiplicity: some transducers show different actuation modes in response to multiple stimuli. Different kinematics will be obtained depending on the stimulus, and using these transducers properties allows for large versatility in the actuator capabilities. First, a given transducer can react to multiple stimuli. This solution depends on the stimuli-responsive behaviour of the transducer and remains widely unexplored. As shown in Figure 2a, Zhao et al. [7] used a supramolecular polymer in a bilayer configuration, responding both to UV light and humdity changes through incorporation of multiple stimuli-responsive groups[7]. Ryabchun et al.[8] integrated hydrazone photoswitches into LC, allowing stable reversible actuation using different light wavelengths[8]. Odent et al.[9] described a bilayer composed of two layers with different pH- and thermal-responsive swelling, allowing bidirectionality and fine control of the bending behaviour of the system[9].

Figure 2. Examples of strategies towards the generation of complex motions. (a) Multiple stimuli[7]. Copyright 2019, John Wiley and Sons. (b) Multiple transducers[10]. Copyright 2017, American Association for the Advancement of Science. (c) Active asymmetry[11]. Copyright 2019, John Wiley and Sons. (d) Design variations (kirigami)[12]. Copyright 2018, John Wiley and Sons. (e) Design variations[13]. Copyright 2017, Royal Society of Chemistry. (f) Tubular segments simple modular assembly [14]. Copyright 2017, National Academy of Sciences. (g) Hinges simple modular assembly[15]. Copyright 2019, American Association for the Advancement of Science. (h) Metamaterial simple modular assembly[16]. Copyright 2018, American Association for the Advancement of Science. (i) Voxel complex modular assembly[17]. Copyright 2020, John Wiley and Sons. (j) Rigid base complex modular assembly [18]. Copyright 2020, MDPI. (k) Rigid base complex modular assembly[19]. Copyright 2019, American Association for the Advancement of Science. (l) Nonlinearities [20]. Copyright 2018, John Wiley and Sons. (m) Controlled anisotropic stimulus [21]. Copyright 2016, Springer Nature. (n) Design variation and controlled anisotropic stimulus[22]. Copyright 2018, American Association for the Advancement of Science.

Similarly, several works have proposed to combine multiple transducers. These transducers can even react to different stimuli or at different levels of a single stimulus. This approach is similar to the multiple stimuli strategy but is more versatile since every transducer can be customized to react to a given stimulus. This strategy opens many possibilities in terms of actuation versatility; each transducer stimulation can lead to a given motion. Cangialosi et al.[23] demonstrated this principle with DNA-induced swelling (Figure 2b)[23], with different domains of the actuator responding selectively to different DNA sequences. Alternatively, bilayer mechanisms with two stimuli-responsive layers have been demonstrated, for example, with an hygroscopic expansive paper layer and a thermally expansive elastomer layer[24]. This configuration allows for bidirectional bending when heated or placed in a humid environment. Here, each layer acts passive when the other is stimulated. Similarly, Sachyani Keneth et al. [25] developed a bilayer-like actuator composed of a passive kapton layer and an SMP layer, additional to the heating layer[26]. This configuration combines the shape memory capacities and the thermal expansion of SMP, allowing to program unique shapes and motions. Lahikainen et al. [27] used multiple segments of LC[27], one segment actuated by photothermal effect with a first wavelength and one segment using photochemical actuation mode with two other wavelength having antagonist effects. This allows for a fine control of the motion using different stimulation patterns. Furthermore, the possibility to realize complex nonreciprocal motions while simplifying the actuation signal complexity has been demonstrated.

Finally, as discussed in Section 2.4.4, a particular class of transducer multiplicity consists in using active asymmetry, i.e., stiffness variation, to generate complex motions. The difference here is that the active asymmetry does not generate mechanical work but a change in the mechanical properties. Chautems et al.[11] demonstrated a magnetically actuated catheter with different variable stiffness segments that can be stimulated separately (Figure 2c). The same principle has been demonstrated with fluidic actuation[28]. As stated before, this principle has also been widely used to demonstrate shape locking[29][30]. The possibility to generate kinematics to change continuously a structure or voxel using local stiffness variation has also been demonstrated[17][31][32]. This particular solution seems especially promising to generate extremely versatile soft robots.

A second class of strategies is based on actuation modularity. The most common consists in design variations. The basic actuator is modified to achieve the targeted task. Variable bilayer configuration or magnetization profiles are classical examples. Note that almost all actuators use combinations of design variation with other strategies to generate complex motions. The motions achieved using this strategy can be extremely complex but cannot be modified, since they are programmed in the kinematics. As a typical example, Sun et al. [33] modified the reinforcement pattern of tubular pneumatic actuators to generate various motions[33]. Similarly, Jin et al.[12] showed that complex and finely programmed biomimetic motions can be generated using a pneumatic actuator with a variable kirigami pattern (Figure 2d)[12]. Alternatively, as shown in Figure 2e, by varying a bilayer configuration along the length of a sample, for example by changing the passive layer position and thickness, it is possible to control the curvature locally[34]. Similarly, using an anisotropic passive layer in a bilayer configuration allows for the generation of bending in various directions or helixing[35]. With IPMC, Chang et al. demonstrated that designing actuators with only one electrode side allows complex patterning and the generation of new kinematics.

Instead of varying the design, a simple module capable of simple kinematics can be repeated. These repeated modules can be stimulated together (simple modular assembly), as illustrated in Figure 2f, where all the modules are actuated by a unique pressure source , or in Figure 2g, where all active modules are actuated using the same heat source [15]. Alternatively, the different modules can be stimulated independently (complex modular assembly), as illustrated in Figure 2c and Figure 2i [17]. Actuating the modules independently increases strongly the versatility of the actuator and the design and control complexity. For both strategies, various subclasses of modular assemblies can be defined. Table 1 redirects the reader to relevant works for each modular strategy. A widely studied type of module consists in tubular segments. Connolly et al. [14] studied the influence of fibre reinforcement on a segment kinematic and demonstrated the possibility to achieve complex motions with a single pressure source, such as finger biomimetism, by combining elongating and bending segments (Figure 2f)[14]. Alternatively, hinges mechanisms, consisting in small bending segments (hinges) in between larger rigid segments, allow for active origami-like shaping, usually with non-reconfigurable kinematics. As illustrated in Figure 2g with a simple modular assembly, [15] showed origami folding of rigid segments driven by thermally actuated LCE hinges[15]. Metamaterials can be seen as another class of modular assembly when made of active repeated cells. Passive auxetic structures and metamaterials have been widely studied and reviewed[36][37][38]. However, few works on active materials have been reported. Among them, Zhang et al. [16] proposed a swelling active metamateiral capable of isotropic and anisotropic contraction and tunable stress–strain curves, fixed by the unit cell design (Figure 2h). A promising type of modular assembly consists in the use of voxels. One voxel can be a given kinematics or reprogrammable. Each voxel is generally controlled by one or more stimulus, leading to complex leads management in the case of tethered transducers. Lin et al. [17] designed pneumatic voxels with active asymmetry that can be assembled in several ways and stimulated separately to achieve complex tasks (Figure 2i)[17]. What we call here rigid base modular assembly is illustrated in Figure 2j,k [18]. Several soft modules are assembled in a rigid structure, typically to form grippers or walkers. Other complex modular assemblies can be proposed. As an example, Sun et al.[39] developed a TCP-actuated arm composed of three independent modules[39].

The complex designs and modular assemblies presented above, relying on several stimuli, present the advantages of leading to high versatility but the disadvantage of increasing the actuation complexity, since multiple stimuli are required. To overcome this limitation, several advanced strategies have been proposed. The use of the transducer nonlinearities has been studied to propose elegant strategies to achieve complex motions with limited stimulus complexity. Gorissen et al. [20] demonstrated sequential actuation of McKibben muscles with a single pressure source using the nonlinear pressure–volume curves of the muscles and the pressure drop of the leads. (Figure 2l) [20]. Even if not implemented, Han et al. [40] proposed several strategies to obtain a stepped temperature response of a fluidic chamber filled with phase change fluid[40]. Pal et al. [41] used the release of elastic energy stored in a passive membrane when deformed pneumatically to program rapid deformation of soft structures [41].

Finally, using a complex controlled anisotropic stimulus proved efficient to achieve sequential motions or high versatility with a single stimulus, typically light or magnetic field. Palagi et al. [21] reported an LCE microactuator simulated by structured light (Figure 2m)[21]. This structured light actuates extremely locally and with a cyclic pattern on the LCE, generating swimming or other locomotion modes. Xu et al. [22] developed magnetic robots capable of complex tasks by using both design variation and a controlled anisotropic stimulus (Figure 2n)[22]. When placed in a variable and controlled magnetic field, the flexible robots will develop various motions depending on both their magnetization profile and the magnetic stimulation. These solutions present an advantage to allow fabrication of small-scale untethered robots.

Using the presented strategies, a large class of complex motions can be achieved. Due to the large variety of motions achieved by soft robots, it is difficult to propose an exhaustive classification. Nam and Pei[42] proposed a complete taxonomy of 4D printing SMP behaviors that could be extended for other soft transducers and fabrication methods [42]. The complex motions are generally related to the task to achieve and hence to the target application. Using materials with stiffness similar to soft biological tissues, soft robotics has been developed as a bioinspired field[43][44] [45]. Several applications have been identified pushing the development of complex soft robots: biomedical applications[46][47] (surgical tools [48][49], microrobots [50], rehabilitation and cell culture), human–machine interaction (haptic devices and wearables), locomotion, manipulation [51], microfluidic and structure self-assembly [52]. Towards those applications, the complex motions are classified here into several classes: soft arms, transportation, configuration changes and grippers. This is further detailed and illustrated in Table 2. Biomimetic motions can be identified transversely in this classification. This classification is not exhaustive but aims at providing an overview of the typical motions achieved in soft robotics and the corresponding target applications. Note that many papers provide impressive demonstrators but without targeting specific applications.

Table 2. Complex motions classification and their typical applications: black indicates a rigid material, and grey indicates the transducer.

A large variety of motions can be achieved by soft arm structures, from simple bending to complex trunk or octopus arm-like robots (Figure 2f,k), including simple helixing and multiple curvature systems (Figure 2c). This class gathers soft structure that precisely position an end effector relative to a fixed base. Such actuators often present a tubular shape. An important driving application for such actuators is the development of minimally invasive surgery devices. The STIFF-FLOP project strongly contributed to advances in this field[53][54], and the developed surgical module was validated on cadaver tests [55]. Similarly, Yeung et al. [56] reviewed soft pneumatic-based devices in colonoscopy that obtained Food and Drug Administration (FDA) approvals[56]. Alternatively, the development of versatile manipulators able to manipulate fragile objects has also be widely demonstrated, as illustrated in Figure 2k[19]. Other applications of such robots have been proposed, such as a soft arm for agroforestery [57].

This class of motions gathers various types of mobile robots, often bioinspired. Among them, many robots capable of locomotion to reach space through tortuous paths or on unequal grounds have been demonstrated. In addition, the development of untethered microrobots for surgical procedures and drug delivery is the second driving application for this type of motions. Various strategies can be used to achieve transportation, as detailed in Table 2. Walking or inching robots are described here as robots standing on the ground via legs or segments and are able to produce a displacement, even by actuating them alternatively or by relying on an asymmetric actuation. An example is given in Figure 2n (untethered centipede robot). Similarly, inchworm or crawling robots lay directly on the ground and are generally tubular. They rely on sequential actuation of several segments or on an asymmetrical coefficient of friction with the ground. Jumping or rolling robots rely on quick shape configuration or on external dragging forces to move. They are often untethered. Finally, swimming robots are able to move in fluids thanks to oscillating motions. An example is shown in Figure 2m.

Gripper-like motions have been widely studied and act as an important driving force for the development of soft robots. Shintake et al.[5] and Hughes et al. [51] reviewed soft gripper designs and capabilities [5][58]. The developed structures allow the manipulation of fragile or complex shape objects. Other potential applications usually mentioned are micromanipulation and drug delivery. In their classical configuration, bending soft segments are placed on a rigid structure. This class of soft robotics solution is one of the few to have reached the market today[5]. A common alternative design consists in what we call star gripping, consisting of monolithic grippers shaped as folding star, generally used on a smaller scale (Figure 2n). Additionally, various designs have been proposed in the literature.

Finally, developing structures able to change their configuration and to morph into complex shapes is another ability enabled by soft stimuli-responsive transducers. This is strongly related to the concept of 4D printing, detailed in Section 4. Impressive demonstrators able to mimic biological and other complex shapes have been demonstrated, as illustrated in Figure 2d. Self folding structures, based typically on origami structures, allow to build complex and sometimes reconfigurable structures (Figure 2g). Rus and Tolley[59] reviewed active origami structures design, fabrication and control[59]. Muscle-like actuators, composed of rigid segments actuator by soft contractile muscles, is another typical bioinspired class of motion [24][58]. Complex shapes changes have also been demonstrated with active metamaterials structures[16][60], and self-tightening knots[61]. These solutions could find, among others, biomedical applications in deployable stents or for surgical sutures. Note that planar actuators able to develop Gaussian curvature are an important class but are not detailed in this review. For complete reviews on such actuators capabilities and principles, the authors redirect the reader to van Manen et al. [62]. As developed in Table 2, a variety of applications is proposed for such configuration change robots, but they generally remain at the stage of the demonstration.