1000/1000

Hot

Most Recent

Carbon nanotubes are a quasi-one-dimensional nanomaterial having excellent compatibility with cementitious material. Recently several research carried out utilising different types of Carbon nanotubes (Single wall carbon nanotube, multiwall carbon nanotube, -COOH and -OH functionalised carbon nanotube etc.) to investigate its influences in terms of flowability, microstructure, mechanical, and durability properties. CNT is chemically inert material but addition of small doses of CNTs can significantly improve the mechanical and microstructural properties of concrete/cementitious composites. CNT act as nucleating agents and promote the higher growth of C-S-H. However, improvement of mechanical, microstructural and durability properties depends on CNTs concentration, physical properties and type of CNTs.

Concrete is one of the most frequently used materials in the construction industry worldwide. However, the formation of cracks and nanoscale pores are significant drawbacks that reduce the mechanical performance and durability of concrete. Recently, the concept of utilizing well-dispersed nanomaterials within the concrete structure has developed to make concrete more durable and crack-free[1][2][3]. Excellent performance characteristics of carbon nanotubes (CNTs) make them an attractive material[4][5], able to increase the mechanical performance of cement-based composites. According to Van Der Waals’ attraction theory, it is very difficult to disperse this nanomaterial uniformly within the cement-based composite due to its extremely small size. The nanoscale size materials have a strong agglomeration tendency that can effectively influence the mechanical and microstructural performance of cementitious composites[6][7]. Several investigations were carried out utilizing sonication, surfactants to disperse CNTs within composite structures[8][9][10][11]. Without a proper fabrication technique or the direct addition of raw CNTs into a fresh concrete mixture, the conventional concrete mixing process cannot ensure the homogeneous dispersion of CNTs and mechanical performance. Carbon nanotubes are categorized into single-walled and multi-walled. Due to expansive synthesis and production costs, multi-walled carbon nanotubes are commonly used. Recently, CNTs functionalized with -COOH (carboxyl) and -OH (hydroxyl) were introduced. They can affect the physical properties of cement and might result in chemical reactions[12] that influence the mechanical and microstructural performance[13] of concrete. In addition to improved mechanical and structural performance, the properties of fresh cement-based composites, such as flowability, are also influenced by the incorporation of CNTs. Literature studies show that CNTs caused the flowability of cement paste and mortar to decrease[7][14][15]. Some authors report a slight increase in the flowability of modified concrete where a proper CNT dispersion technique and mixing process was used[10][16][17][18]. Some studies were carried out to investigate the effects of CNTs on the hydration of cement composites[19][20][21][22][23][24]and research results show that CNTs effectively influence the hydration of cementitious composites. CNTs most often accelerate the hydration process and add to the development of higher heat during hydration. Even though several investigations have reported the relevant properties of CNTs incorporated in cement-based composites, this paper aims to provide valuable information about CNTs incorporated in cement-based composites for further studies.

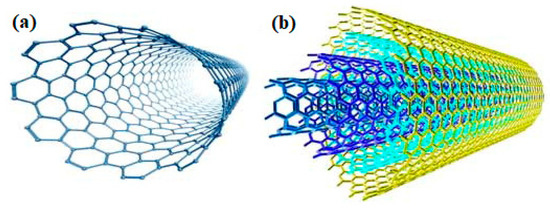

Carbon nanotubes are a quasi-one-dimensional nanomaterial, classified into single-wall carbon nanotubes (SWCNTs) and multi-wall carbon nanotubes (MWCNTs) according to their crystallization organization. Generally, SWCNT and MWCNT have different Young’s modulus, thermoelectric, electrical conductivity and optical properties[25]. In the CNT each carbon atom in the atomic scale is aligned at 120° in the XY plane and part of a hexagonal structure. Figure 1 shows the structure of single and multi-wall carbon nanotubes.

Figure 1. (a) Single-wall and (b) multi-wall carbon nanotube[26].

Chemical Vapor Deposition (CVD) technique is mostly used to synthesize CNTs in sizeable amounts, while the arc-evaporation method is well known for producing the best quality CNTs. A carbon nanotube is expected to exhibit exceptionally high stiffness and axial strength, attributed to its C-C bonding. According to computer simulation calculations by Overney G, Zhong W et al.[27], the Young’s modulus of SWCNT is expected to be 1.5 TPa. The mechanically calculated Young’s modulus of MWCNT was about 1–1.8 TPa[28]. Due to the excellent properties of CNTs, they have been widely used in cementitious composites by various researchers to improve the properties of concrete. Because of lower cost and higher availability, MWCNTs are preferred over SWCNTs in CNT-cement-based composites. A small amount of CNT can effectively influence the fresh and mechanical properties of cementitious composites. The basic properties of CNT are shown in Table 1.

Table 1. Characteristics of different types of CNTs[10].

| Notation | CNTSS | CNTSL | CNTPL | CNTCOOH | CNTOH |

|---|---|---|---|---|---|

| Commercial Name | TNIM8 | TNIM6 | TNIM6 | TNIMC6 | TNIMH4 |

| Form as Supplied | Suspension | Suspension | Powder | Powder | Powder |

| Purity (%) | >90 | >90 | >90 | >90 | >90 |

| Outer diameter (nm) | >50 | 20–40 | 20–40 | 20–40 | 10–30 |

| Inner diameter (nm) | 5–15 | 5–10 | 5–10 | 5–10 | 5–10 |

| Length (μm) | 10–20 | 10–30 | 10–30 | 10–30 | 10–30 |

| Aspect ratio | ~300 | ~667 | ~667 | ~667 | ~1000 |

| True density (g/cm3) | ~2.1 | ~2.1 | ~2.1 | ~2.1 | ~2.1 |

| COOH (%) | 1.36–1.5 |

Carbon nanotubes have a remarkable chemical stability and mechanical performance and can be used, due to their structural characteristics, in concrete, to improve its performance. To get a better mechanical and microstructural performance, a proper dispersion of CNTs should be ensured. Different physical and mechanical dispersion techniques are used with certain advantages and disadvantages. Study results suggest that sonication and a polycarboxylate-based superplasticizer are the most common methods, and that both the sonication energy and duration time influence the degree of CNT dispersion.

Flowability is one of the most critical factors of fresh concrete influenced by the addition of CNTs. The influences of CNTs summarized in this paper reveal that the flowability of cement-based composites incorporating CNTs decrease with increased CNT concentration.

A CNT is a chemically inert material that does not participate in the hydration process but accelerates the hydration process by nucleation effects. Several studies show both that CNTs accelerate the hydration process and that cement composites incorporating CNTs also achieve the maximum level of generated heat during the hydration process.

CNTs embedding cement-based composites demonstrate an excellent mechanical performance due to CNTs’ nucleation effects, crack bridging effects and better adhesion to hydration products. The studies also suggest that CNTs provide sites for the formation of C-S-H in higher quantity, leading to a higher mechanical strength of cement-based composites. The mechanical performance of cement-based composites can be influenced by several parameters, such as the degree of CNT dispersion, the techniques used for CNT dispersion, water/cement ratio, type and properties of CNTs, the surfactants used and the geometry of CNTs.

Long CNTs improve the microstructure of cement-based composites by crack bridging and interacting with the surrounding hydrates but reduce the degree of dispersion of CNTs within the composite structure.

Compared to plain cement paste, the flexural strength of CNTs incorporated in cement pastes was observed to increase with the inclusion of CNTs. In the case of CNTs with a higher aspect ratio, the flexural strength of cement-based composites was observed to increase with higher concentrations of CNTs.

The microstructure of CNTs incorporated in cementitious composites shows that the compatibility between cementitious materials and CNTs is excellent. The improvement of the microstructure was noticed by the addition of carbon nanotubes. Denser structure and a pore, void and crack filling ability were observed by the addition of CNTs. Besides, a better bonding between CNTs and hydration products was also noticed. The agglomerated CNTs were also observed by SEM, which can be attributed to improper CNT dispersion techniques.

CNT incorporating cementitious composites with a low water-cement ratio have better durability performance. In the same way, the chemically treated CNTs have a high resistance to chloride ion permeation. Moreover, CNTs have a greater effect on the long time-dependent creep and shrinkage.

The enhanced durability properties are attained by the pore filling and nucleation effect of CNTs, which, in turn, reduce the number of micropores and nanopores. Thus, the incorporation of CNTs not only improves the shrinkage and water loss characteristics of cementitious materials but also improves their freeze-thaw resistance.